Category: Wickets

Published 09/03/2021 · Comments: · Reading time: 5 min · Views: Post Views: 841

Gates are usually made of metal. The design turns out to be heavy, so all components are selected to be durable. Before purchasing and welding hinges for a gate, people check whether this part can withstand the load. Components come in different shapes and types; if a person wants to install them on the gate with his own hands, then he first needs to understand the features of these fasteners and the intricacies of working with them.

Application of internal loops

Despite some controversy among users regarding hidden garage fittings, internal hinges offer the following advantages:

- A higher level of security and burglary resistance, which is especially important if you store very expensive and valuable property in your garage.

- Long service life, which in practice is estimated at many decades.

- High resistance to loads, thanks to which doors weighing up to 400-500 kg each can be hung on hidden hinges without any significant consequences for the overall design.

If you value the security of your property, hidden hinges are a great investment and will give you peace of mind over your property.

Internal hinges for garage

Features of hinges

All types of hinges for gates are divided into the following three groups:

- Classic type, looking like regular doors, with the same mechanism. But some have the benefit of anti-corrosion treatment. They are also characterized by increased reliability and resistance to loads, which is ensured by bearings with increased strength. There is a type of hinges without ears that you need to weld yourself - this is a universal type.

- Hidden ones have increased resistance to hacking. Such a wicket structure is difficult to remove because the suspensions are mounted in a hidden manner.

- Decorative, performing the same function, but endowed with aesthetics. Models match the exterior and can be selected according to style. Sometimes they are made individually, to order.

A photo of a beautiful gate is presented below.

Appearance of the assembled fence

Each of the listed groups has advantages and disadvantages, but functionality is inherent in all varieties, of which there are quite a few. GOST provides for classification into groups.

If you consider this in relation to your needs, it will be easier to make a choice.

Welded hinges

Iron gates, and every other one, in an iron frame are attached to the supports with special welded hinge hinges.

Kinds

Welded door hinges for gates differ from each other primarily in size and material of manufacture. In addition, there are differences in shape, design and ability to carry a certain load.

They are in form:

- Cylindrical;

- Hexagonal;

- Drop-shaped.

By design:

- Simple - with a removable or non-removable “finger”;

- Ball-type - with an iron ball, which ensures easy opening of the gate by reducing the friction force in the hinges;

- Bearing - with a bearing between the two halves of the product.

By load:

- Uncomplicated;

- Reinforced - with welded plates, allowing the load on the loop to be distributed more evenly. This increases the reliability of fastening the gate and increases the service life of the canopies.

Required number of loops

The overall dimensions of the welded hinges, as well as their number, are selected in accordance with the weight of the gate. The heavier it is, the more there should be. Or they themselves should be more wonderful.

The recommended quantity is shown in the table:

| Loop brand and height, mm | 610-4 (100) | 610-5 (125) | 613-4 (100) | 613-5 (125) | 500-4 (100) | 500-5 (125) | 401-4 (100) | 700-4 (100) | 700-5 (125) |

| Web weight, kg | |||||||||

| 30 | 2 | ||||||||

| 40 | 3 | 2 | 2 | ||||||

| 50 | 3 | 3 | 2 | ||||||

| 60 | 3 | 2 | |||||||

| 70 | 3 | 2 | |||||||

| 80 | 3 | 2 | 2 | ||||||

| 90 | 3 | 3 | 2 | ||||||

| 100 | 3 |

Installation of gates on welded hinges

It’s worth emphasizing right away that it’s very difficult to do this work on your own, and it’s simply unrealistic if you don’t have experience. Welding is a complex, labor-intensive process, scary for a beginner. Based on this, it is possible to undertake installation only if this is not the first time you have seen and held a welding machine in your hands.

In addition to this, do not forget to stock up on electrodes, a mask and personal protective equipment. And the necessary tools:

- An iron brush for cleaning work surfaces from dirt, rust, and old paint;

- Grinder for cleaning welds;

- Tape measure or ruler, pencil;

- Construction level;

- Clamps or other devices for fixing parts.

Then, it is necessary to make markings on the door leaf, depending on the number of hinges. The top and bottom should be placed no further than 15-20 cm from the edge.

It is much more ergonomic to weld them while the gate and frame are in a horizontal position.

A detailed description of the process is shown in the table:

| Image | Description |

| Lay the gate or its frame and support post on a horizontal plane so that there is a gap of 3-4 mm between the pipes to which the hinges will be welded. To do this, place spacers between them made from pieces of metal or used circles from an angle grinder, and clamp them with clamps. | |

| Along the welding line, draw a line parallel to the edge on the support pipe and fix an even block or piece of pipe along it. It is possible to clamp it with clamps, or to grab it with spot welding. Having placed the loop touching the block, place matches or pieces of wire under it to provide a gap. | |

| While holding the cylinder pressed against the block, tack its upper half in two places to the frame pipe. | |

| After this, grab the bottom part and remove/cut off the temporary block. | |

| Remove the clamps holding the gate and the box together and make sure that the leaf moves securely. If everything is fine, replace the spacers and clamps again in order to thoroughly weld the hinges. | |

| Full weld both seams. | |

| Clean the seams with a grinder so that no sagging remains. | |

| Open the gate and weld the seams on the back side. Clear them out. | |

| To give the structure a finished aesthetic look, prime and paint it. |

If the gate posts are already in place, installation is carried out using a different technology. The instructions recommend that you first accurately mark and weld the upper parts of the hinges to the gate leaf.

After this, as in the case of overhead awnings and a wooden gate, the sash is installed in the opening and fixed in it using pads and wedges. The verticality of the installation, and being in the same plane with the box, is checked by the building level.

After this, the lower part is inserted into the upper part of the loop, and its position is marked on the support post with chalk or a construction pencil. Or it is immediately tacked in two places by spot welding.

Having grabbed all the hinges, you need to remove the wedges and pads and check the movement of the gate. Only then is it possible to make vertical continuous seams.

And then everything is the same: the internal seams are boiled, they are cleaned, after which the entire structure is painted in the chosen color.

Hinges for gates: how to properly weld awnings onto round and square posts

Massive metal doors are suspended from door frames on hinges that are welded to the posts and door leaf. Poor-quality installation affects the performance of the door: it does not fit tightly, warps, jams, and stops closing completely. Therefore, before taking up the tool, the master must understand how to properly weld canopies on gates.

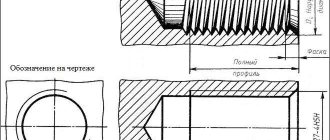

Before welding the hinges onto the gate, their type is determined. They are hinged, semi-hinged and hinged. For heavy gates, it is recommended to use large hinge hinges: the bearing they contain reduces friction inside the canopy, increasing its service life and making it easier to open the door. It is most convenient to work with parts with a round and hexagonal cross-section; it is more difficult to work with canopies with a square cross-section.

The larger the mount, the higher its load-bearing capacity. Therefore, a part with a safety margin is first selected: weak canopies will deform and collapse under load. But also the requirements for the strength of the hinges are higher for those gates that are used more often - it is correct to weld massive hinges even on a small gate if it is constantly being opened and closed. Only high-strength alloys are chosen as the material for canopies.

To weld the hinges in place, plates are used - metal plates attached to the top and bottom of the canopies to ensure a reliable connection. The height of one plate should be equal to the height of the loop, the width is selected based on the installation conditions.

For example, for a garage door 2.5 x 2.5 m, elements of 80 x 80 mm are used.

Hinges are sold in hardware stores. Factory assembled products are supplied with plates already welded. However, it is possible to manufacture an element according to a drawing in a private workshop.

Having decided on future nodes, you can begin preparing for work. To do this you will need the following tools:

- level;

- roulette;

- hammer;

- mounting pads (boards, bricks, nuts and bolts);

- grinding machine (“grinder”);

- metal brush;

- lubricant (solidol or lithol);

- welding machine;

- dry electrodes with a diameter of at least three mm;

- individual protection means.

When carrying out welding work, the contractor is obliged to comply with safety requirements. Forbidden:

- Carry out work on a faulty welding machine.

- Connect the equipment to an ungrounded power source or to a power source of improper power.

- Weld near flammable materials and explosive substances.

- Work without personal protective equipment, wearing flammable clothing. Personal protective equipment includes: mask, mittens (or leggings), shoes. It is recommended to wear a welding suit while working.

Preparatory work

They start by welding the plates to the hinges. This step can be skipped if you are using ready-made canopies with mounting plates or when mounting them on round poles of small cross-section. The plates are cut from sheet steel using a grinder, choosing sheets with a thickness of at least 5 mm.

Before assembling the hinge, its internal part (the place where the bearing is located) is carefully treated with lubricant, and the area allocated for welding is cleaned of dust and rust. Cook on a horizontal surface. Two plates are laid side by side along the long side with a gap of 2–3 mm. Half of the canopy is placed on top, welded to one of the plates with a continuous seam. A similar operation is performed with the second half. The resulting seams are carefully cleaned.

Important: according to fire safety rules, welding work is carried out either on unpainted or fully painted, dry parts. Paint that is not completely dry can ignite from a spark.

The hinges are installed on the side in which the opening will occur. Work is carried out in a horizontal position; surfaces involved in welding are degreased and treated with a brush, having previously removed the layer of paint coating in the area.

The location of future hinges is outlined - they are placed 15-20 cm from the upper and lower edges of the gate. To do this, the door is placed inside the opening on mounting pads that provide a gap between the bottom edge of the gate and the ground. Level by changing the height of the linings. It is recommended that at least two people perform this operation. Having leveled and fixed the canvas, apply the awnings, mark their location on the gate and on the door frame.

After applying the markings, the swing element is removed from the stands, removed from the opening, and returned to the horizontal plane. The hinges are welded in disassembled form: the upper half is allocated for the door leaf, the part with the pin is for supporting structures. The part is laid along the marks and secured by preliminary spot welding. Check the level to see if there is any misalignment. If the axis of the canopy is parallel to the plane of the swing element, major welding is performed along the entire contact line. The finished continuous seam is cleaned with a grinding machine.

The lower part of the loop is welded to the loot. If it is not possible to lay the support horizontally, then they work in a vertical position. Tack spot welding is performed according to the following algorithm:

- Above.

- From below.

- In the center.

- In the center of the upper half of the future seam.

- In the center of the lower half of the future seam.

This is followed by leveling and checking installation of the sash. If there are no defects in the connection, it can withstand the load, the door opens smoothly and fits tightly to the frame, then weld it with a permanent continuous seam. When welding, the oil used to lubricate the hinges may burn out or leak, causing the door to creak and jam. To prevent this from happening, the sash is lifted and the insides of the canopies are generously lubricated again.

The door is returned to its operational position, and the weld seams are cleaned with a grinder. Surfaces are degreased and painted, and attachments (locks, bolts, mailboxes) are installed. A small hole is made in the hinges, through which the mechanism will be lubricated during operation.

Installation recommendations

For square-section posts, it is recommended to always use plates, maintaining a gap of 3–5 mm between the edge of the gate and the support. There are several ways to weld hinges to round posts:

- without the use of mounting plates;

- with a plate only on the sash;

- with a narrow spacer on the side of the post and a full plate on the gate.

Several distinctive features of welding hinges to corrugated sheets

Quite often, profiled sheets are used as a material for creating gates or fences. If a person needs to weld hinges to this material, then some factors should be taken into account. It is required to make lintels that must be parallel to the vertical part of the sash.

An important step in working on swing iron gates is welding the hinges

It is necessary to secure the jumpers in those places where the hinges are welded. They must divide the sash into 3 identical elements. Hinges must be welded to the jumpers. To cover the welding area and jumper, small pieces of corrugated sheeting can be screwed on top. It is better to give preference to thicker loops with a length of more than 1 m.

Basic truths

The process of installing hinges can be considered using the example of a metal gate. In order for it to properly perform its main functions, a number of conditions must be met when welding hinges:

- Provide a gap between the support post and the gate frame, which should be 3-5 mm.

- Provide a gap of several millimeters between the hinge and the gate frame by welding plates - metal plates of the required thickness - to the hinge. In total, for each loop you need two strips, the length of each of them is 2 mm less than the length of half.

- The optimal distance from the edge of the gate to the loop is 15-20 cm. If you need a middle loop, then it is located exactly in the middle between the outer loops.

First, the lower part of the fastener (with the pin) is welded to the post, then the upper part (with the groove) is welded to the sash.

A properly assembled structure should have the following parts:

- a loop;

- plate; wicket frame;

- support pillar;

- lower part (with pin);

- upper part (with groove).

This design consists of several elements.

All loops must be coaxial, that is, their centers must be on the same straight line. The alignment requirement is extremely important. It is on its compliance that it depends on how evenly the weight of the gate will be distributed on the fastenings and, accordingly, how long they will last.

To work, the master will need:

- welding machine;

- metal plate for making plates;

- Bulgarian;

- hammer;

- plumb line;

- oil for lubricating hinges;

- protective equipment - mask, gloves, overalls.

At the preparatory stage, you should mark the gate frame and sash, determining the places where the hinges will be welded. Clean them from dust, dirt, and rust. To do this, you can use a wire brush and solvents. Next, a similar treatment is performed on the surface of the hinges, and lubricant is applied to their inner part.

The traditional welding method involves the installation of plates at this stage, for which it is recommended:

- Take 2 identical plates of the required thickness and length. Place them so that there is a gap of 2-3 mm between them.

- Place the bottom part of the loop on them.

- Weld the loop to one of the plates (in this case, to the right one).

- Do the same for the top of the hinge and weld it to the left plate.

- Then you need to install the shutters in the working position and fix them.

- The plates with the lower part of each hinge are spot welded to the post, then the upper hinge elements are inserted into the lower parts and spot welded to the sash. After checking the alignment of the hinges and the operation of the gate, final welding is carried out along the contour of the plates.

Purpose of the product

Hinges, or awnings, are devices with which gates are opened. The mechanism consists of several elements. They rotate around their axis and ensure the operation of the gate. The principle of free rotation underlies all types of locking mechanisms. This quality makes them an indispensable part of the gate.

After installation

To choose the right gate awnings, you need to take into account the following:

It is better to purchase loops in a specialized store. Only large retail outlets have all the necessary documents: a quality certificate, a guarantee from the manufacturer and a hinge installation diagram. This does not always guarantee the quality of the product 100%, but if you are not satisfied with the product, it can be returned or exchanged. You should buy a mechanism taking into account the weight of the swing gates. Each type of canopy is designed for a specific load that it will withstand. It is advisable to choose with a margin of safety. For example, for a sash weighing 200 kg, take a device designed for 300 kg. Take into account the location of the house for safe operation of the gate. Some types of hidden swing mechanisms prevent the gate from opening completely. This is inconvenient when leaving the yard, since open doors interfere with street traffic.

You need to use gate canopies with the correct connection method

Hinges are welded onto metal sashes, and screwed onto wooden sashes with bolts or self-tapping screws. Therefore, it is important to know what material the sashes are made of. It is worth paying attention to the material from which the canopy is made. This affects the service life. Products made of plastic or thin metal will not last long on heavy sashes

Over time, they will begin to warp and jam. If you select such loops, then this must be taken into account.

Installation option

Features when choosing loops

In order to choose the right hinges for a gate, you need to focus on the following indicators:

- system reliability;

- maximum permissible weight;

- greatest opening angle;

- fastening method;

- different design features;

- the type of material from which they are made.

When choosing fastenings according to the criteria described above, we must not forget about the individual requirements that are unique in each situation. Based on these indicators, each person will be able to choose hinges for swing gates or wickets that best satisfy all their needs. Once installed correctly, the system will work for a very long time, surprising the owner with its reliability.

Materials and tools

To do the job well, you will need professional tools

In addition to the welding machine, you will need the following tools and consumables:

- welder's protective mask;

- measuring instrument: ruler, tape measure, building level;

- lubricant for hinges - grease or a composition similar in properties to it;

- An angle grinder will be needed to clean up welding seams and dismantle an incorrectly installed hinge group.

Support pillars are best made from a profile pipe of square or rectangular cross-section. This will ensure the reliability of the structure and facilitate the installation process of the canvas.

Selection of loops and their quantity

If you decide to use welded hinges to install the gate, you can choose from several types:

- the simplest and most inexpensive option is a split cylinder with a rotating axis in one part and a cavity-cap in the other. Such hinges require periodic lubrication, without which they quickly begin to creak;

- The most popular are hinges of the same design, but improved with a ball or bearing on which the axis rests. They can be either two- or three-section;

Welded hinges with a ball Source dekoriko.ru

Another option - the same hinges with metal plates welded to each part.

However, it is not enough to know how to weld hinges to the gate - first you need to calculate the load on them and decide on the quantity. This is not difficult to do if you know the weight of the sashes.

Hinges without plates can withstand a maximum of 400 kg depending on their diameter and the length and thickness of the metal. And hinges with plates that take on part of the load are designed for a more impressive weight - they can withstand up to 600 kg.

Knowing the design load on the hinges and the weight of the structure, you can determine the required number of hinges. Of course, there will not be less than two of them per sash. And in the case of heavy gates, the number of canopies is increased to 3 or 4. An additional hinge is installed just below the top one, which bears the main load.

3 hinges are often installed on massive insulated garage doors. Source dekoriko.ru

By the way, you can strengthen ordinary hinges yourself by welding to them plates cut from thick metal of a suitable size. The weld must be continuous.

Purpose and types of loops

There are many hinge options on the market, varying in price, quality and design. It is quite possible to install a gate with your own hands, but even then there is a need to repair it. A swinging gate also requires the correct selection and installation of fittings.

Essentially, it is a mechanism consisting of 2 or more parts and a hinge, moving around an axis. There are several types of hinges based on their design and method of fastening. Wicket hinges, like those designed for garage doors, can open the door 90 or 180 degrees in one or both directions.

Installation diagram of the entrance group An important factor is the performance of the sash and its functionality. Main selection criteria:

- reliability;

- compliance with the weight they must support;

- opening angle;

- method of installation, fastening;

- material;

- other features.

Screw hinge diagram

If you follow the selection rules, you can buy a quality product that will last a long time and function well. Hinges for wickets and gates are basically no different. But the weight in the first case is less, unless the door is forged and has heavy decor.

The requirements for selection when purchasing are the same in all cases: opening without difficulty, resistance to burglary, aesthetics.

Welding on the gate

Choosing loops

The choice is made taking into account the size and weight of the valves. For example, a metal garage door will require stronger hinges with a support bearing than a gate. The stores offer a variety of types:

- Drop-shaped ones with support bearings are designed for weights up to 400 kg.

- Cylindrical, thanks to the amplifier, which works as a load distributor, and the support bearing, ensure ease of opening with a load of up to 600 kg.

- Through ones are chosen if it is impossible to weld the hinges or secure them with bolts. Fixation is carried out using a through hole in the rack. They are attached to the sash with nuts. Maximum load up to 200 kg.

- 3-section doors are difficult to break into and are used for hanging heavy sashes.

- Forged ones are functional and are used as decoration for wooden gates.

- Steel boom hinges are often installed on garage doors made of thick metal.

- Height-adjustable hinges are useful if the position of the support posts may change.

Hinge with support bearing ensures easy opening with loads up to 600 kg

Hinges for swing gates. General information

Peculiarities

If we talk about the design features of the gate, do not forget even about the little things, and especially about the hinges. The main property of all hinges is the ability to turn even with the heaviest doors, while taking the bulk of the load so that the owner does not exert much effort. The second purpose of hinges is to prevent the gate from jamming and other similar problems. For this reason, the process of selecting and welding hinges requires attention.

For this reason, we characterize loops as:

- An element of force, the task of which is to take on the weight of the doors. For this reason, the hinges must be strong.

- Collapsible element. When completely disassembling the structure, make sure that the hinges cannot be removed when the gate is closed, which will prevent a burglar from entering the territory.

Features of using adjustable hinges for swing gates

The presence of holes for lubrication, since mobility depends on this, which will significantly decrease in the cold season.- The hinges determine the opening radius of the gate, so they should be welded correctly. Before welding, you should experiment and place the hinges in different places to make a drawing and make sure that opening the valves will not be problematic.

- Pay careful attention to the position of the hinges if they will be fixed inside the sash. It is important that it is easy to open and does not jam.

Varieties

The standards prescribed in GOST divide hinges into:

- Cylindrical, with support bearing.

- Cylindrical, with reinforced structure.

- Hidden.

- Through.

- Three-section overhead.

Cylindrical, with support bearing

Cylindrical ones have a ball (bearing). This is an excellent choice for installation on standard, lightweight gates, but remember that the load on such hinges should not exceed 380 kg. This is the maximum permissible weight, but it may vary for different models, so the permissible weight should be checked when purchasing. Don't neglect these indicators. Such hinges for swing gates have a standard shape and look like a cylinder, on one part of which there is a pin. But hinges with support bearings also have a ball, which is located in the second part into which the pin is inserted.

The ball is needed for smooth operation with heavy weight. There is a plug on the other side of the cylinder, which can be removed and lubricated if necessary. Sometimes there are models with a bearing located in the middle, thanks to which we get additional sliding and smoothness. The downside is that it is difficult to lubricate, since you will need to lift the sash a little each time.

Cylindrical, with reinforced structure

Reinforced hinges can support up to 580 kg. They differ from the previous ones in appearance and in the presence of fastening plates. This makes it possible for the leaf, frame and supports to bear the weight of the gate evenly. Fastening is carried out by welding or screwing with self-tapping screws. They are made of metal that is an order of magnitude stronger, resulting in a higher weight capacity. The load-bearing capacity is also higher due to the thick walls and rod. Bearings in such hinges are always marked.

Hidden

Hinged mounts are suitable if you cannot weld or screw fasteners. To fix it, you will need to drill through the support column and use nuts and screws. But such loops have a low load-bearing capacity, the limit of which is 200 kg. Loops can be either right- or left-handed.

End-to-end

With through hinges for swing gates, the rod passes through. The simplest designs are divided into 3 main elements: a pin to connect the two halves and 2 loops. There are variations that are more complex when there may be more elements. To protect the pin from being removed, you can screw on a plug. If this is not possible, weld a special limiter.

Three-section overhead

Three-section fastenings are suitable for very heavy sashes.

Places of application

They are also suitable for fencing, and have a number of differences from previous models:

High level of wear resistance, reliability.- Eliminates the possibility of sagging of the canvas, as they take the entire load upon themselves.

- They close easily and silently.

- The most difficult type of all to crack.

Such hinges have stood the test of time, since this design was created many years ago. Now it is attractive due to its cute design, various shapes in the form of fancy figures. Look great with doors made of metal and wood.

Hidden hinges are not visible when the gate is closed, since they are located in the frame and are welded from the inside to the transverse part of the pillars. They are almost impossible to find, much less hack.

Arrow-shaped hinges can be hinged and are suitable for heavy structures. They are curly, regular and removable.

Adjustable hinges with bearings for swing gates can easily change the height of the sash. They are convenient to use if the support posts are to be displaced. The load available for such hinges is 20 kg maximum.

Distinctive features of loops in shape

- Hexagonal. They have similar features to square models, and they can be fixed between square and cylindrical, i.e. they are generalists.

- Cylindrical. They are distinguished by their high density when fixed to any gate. They have a round shape and are easy to scroll.

- Teardrop-shaped. Suitable for metal and wooden gates. Very stable and very durable, and also have an attractive design.

- Square. They have a specific shape, so during installation you will need to make a small indentation from the frame. They fit well and are attractive in appearance.

Wooden gate hinges

You can buy your favorite wooden gate inexpensively at any construction market.

An example of the design of forged hinges for a wooden gate

Many suppliers manufacture custom gates or wickets. For those who can boast of having even a little experience in construction work, it will not be difficult to make a simple structure with their own hands.

If you have a gate, all that remains is to select hinges that match it in terms of characteristics and dimensions. Correctly chosen fastening will provide the sash with an ideal “fit” and full-fledged long-term operation. For a small wooden gate, the most suitable way to fix the hinges is to install the door with self-tapping screws.

Installation of hinges with self-tapping screws

In principle, this method of attaching hinges is similar to installing interior doors. However, to install a wicket, the components must be wicket or gate components. When choosing this type of fixation, the hinges are attached to the end of the gate, providing the structure with additional stability and improving its external performance.

Stages of installing a wooden gate:

- Using wood screws, the wicket hinge should be attached to the facade of the sash in the marked places. For greater reliability, it is advisable to use at least 3 hinges for 1 gate.

Attaching hinges to the gate with self-tapping screws

The structure with attached hinges must be placed on a flat surface (on the ground) along with the posts. In this case, care must be taken to ensure that the fabric of the product is not damaged. It is best to place a lumber lining under the gate and posts, for example, a piece of plywood or chipboard. If necessary, places for hinges are prepared on the support post. For this purpose, cuts are made. It is convenient to do this work with a hammer and chisel. Piles with attachment points marked by markings are installed in holes prepared in advance for supports. The lower ends of each pillar should be treated with an antiseptic and wrapped in roofing material. The pillars must be fixed in a strict vertical line, which is verified by the building level.

An example of installed posts for a wooden gate

Using self-tapping screws, the gate is attached to reinforced piles.

For support pillars, a hole should be made at least 120 cm deep. At the bottom of the hole there must be a compacted sand cushion (15 cm in height). The pillars can be backfilled or concreted. This method of installing them will save the structure from shrinkage, which is fraught with transfer of loops.

Tips and tricks

Incorrect welding can lead to problems during further operation; to prevent this from happening, you should listen to the following recommendations:

- Before starting work, make and study a schematic drawing; if all the details are taken into account in advance, then the risk of redoing the finished structure will be much less;

- straight hinges are welded to the gate laid on a flat surface;

- You can open gates with newly welded hinges after the seams have completely cooled;

- on round posts the loop extends 5 mm outward, on rectangular posts it is welded flush;

- the welding seam should go from bottom to top.

Beginning of work

Before welding begins, you need to place the future gate leaves in the garage opening. This is done in order to achieve the correct position of the sashes and determine the scope of work. At this stage, be patient and, if possible, have an assistant. Only after you have achieved an even position of the valves can you proceed to the welding itself. The peculiarity is that it is extremely rare to carry out this type of work in a horizontal position. And making a vertical weld can be difficult even for experienced craftsmen. Taking this fact into account, welding should be carried out with special care, describing circular movements and, as it were, lifting the metal.

At first glance, this type of work seems complex and requires special skills. However, it is quite possible to perform it, following the rules and having a certain skill. The most important thing is to take your time when performing work and carry out actions in accordance with the plan.

You need to measure approximately 20-25 cm from the top and bottom of the canvas and mark it with a pencil or chalk. To prevent the hinges from baking, they need to be lubricated, for example with grease, or small pieces of wood the size of a match should be placed. This trick will help avoid jamming during operation and generally simplify the process. We weld the hinges to the gate. At the initial stage, you should not completely weld the hinges. You just need to lightly grab them by welding

It is important to remember that the lower half of the part is welded first. For those who use the welding machine for the first time, you need to remember that the loop is welded in the direction from the bottom to the top, and the movement of the electrode should be smooth and without breaks. After the first seam is completed, the gate needs to be opened and checked using a builder's level or laser level to see how well it opens and closes

You can finish the work if you are satisfied with the result. An ideally installed structure should open without effort or additional noise. Repeat all these manipulations for the remaining parts.

Places where welding was done must be carefully sanded using a grinder. The final stage is priming and painting the gate in the chosen color.

Main types of garage hinges

The building materials market offers a wide variety of hinges for swing doors. Each variety has individual parameters and advantages of use. The first thing you need to do when choosing is to select an installation option. The following installation methods are available:

- welding - the hinges are fixed on the door leaf and frame;

- installation using bolts - used when working with wood material;

- fastening with self-tapping screws - suitable for structures made from profiled sheets.

Based on placement, clamps are divided into hidden and internal. Their main differences lie in the installation method and decorative characteristics. When choosing garage hinges, the weight of the door is of great importance. Incorrect calculation of the expected load provokes skew of the canvas and difficulties with opening. For dense sheet steel with a large mass, it is recommended to purchase reinforced clamps.

With support bearing

Hinges equipped with a support bearing are the basic type of cylindrical type fasteners. The support bearing and swivel joint are reliably protected from external influences by the main body made of metal alloys.

Models with support bearings are intended for lightweight swing structures. The maximum permissible load is 100 kg. The clamps with support bearings are attached to the sashes and frame using a welding machine.

Cylindrical with additional reinforcement

Reinforced clamps are equipped with additional plates, which helps distribute the load over a large surface of the sashes or pillar. It is recommended to use cylindrical hinges with improved plates for thin profile structures. The parts are fixed to the swing gate leaves and frame by welding or screw connection.

Depending on the side of location, cylindrical reinforced hinges are divided into right and left. The diameter of the element is 50 mm. The maximum total load reaches 600 kg.

End-to-end

If it is not possible to secure the hinges by welding or screwing to the frame, a through type is used. For installation in the gate frame, mounting columns are drilled along the entire length, into which part of the retainer is threaded. For final fastening, nuts of the appropriate size are used. Thanks to a special fastening scheme, through-type fasteners can withstand loads of up to 200 kg.

Three-section invoices

For massive swing gates, it is necessary to increase the number of latches and choose a type with increased wear resistance. The best option is three-section models that can withstand the load of a heavy structure. The main advantages of overhead three-section hinges are:

- smooth sliding when opening and closing the gate;

- no creaking;

- reliable protection against burglary;

- preventing the sash from warping and sagging.

Boom loops

Garage boom hinges are suitable for attaching large swing doors, gates and thin-profile structures. The main distinguishing feature is the increased area of the clamp, due to which it provides additional strength and prevents distortions.

At the connection points, the arrow loops are able to withstand increased stress. This is facilitated by uniform distribution along the entire length of the sash. The range of dimensions of the clamps varies up to 700 mm, which makes it possible to find the optimal option for any gate design. The fastening parts are made from durable sheet steel, which ensures a long service life.

Invoices

Despite the ease of installation, overhead types of hinges are highly reliable. The fasteners are made from durable materials, including steel alloys, brass and stainless steel, which significantly increases the variability of their use. Inside the housing there are 2-4 ball bearings necessary for smooth opening of the gate.

To fix the overhead hinges on the frame, you need to mark their exact location and secure it with self-tapping screws. The clamps are included in the universal category and are not divided into left- and right-handed ones. If after installation it becomes necessary to remove the canvas from the hinges, you will need to unscrew the screws.

Advantages of Locinox hinges for gates

In the gates and fencing sector, the renowned Belgian manufacturer Locinox is a leading developer with an impeccable reputation. The company's products are highly valued all over the world.

The main advantages of Locinox hinges:

- European quality;

- innovative concepts;

- universal designs;

- current modifications;

- extreme durability;

- full opening – 180 °;

- possibility of adjustment;

- galvanized anti-corrosion steel.

Locinox hinges are the best modern solutions for fences and gates, making life easier, safer and more comfortable.

Step-by-step guide to installing corrugated sheet gates

- The first step is to mark the location for the gate.

- Next, holes for the pillars are dug at least one meter deep. Before digging in, the supports are treated with an anti-corrosion primer.

Post holes can be dug by hand or using an auger

The solution for strengthening the pillars must be compacted well.

To ensure that the gate stands level, before installation you need to position the gate and place a stone or brick under it

Locks, decorations, forged elements are installed on gates made of corrugated sheets last

The good thing about corrugated sheets is that they do not require painting. But you can purchase ready-made material, stylized as wood or stone. You can decorate the gate with forged elements or other decor - on top or along the door leaf. To decorate the gate, you can trim the top edge, but then it needs to be protected with a profile. If desired, the corrugated sheet can be painted with special paints that are resistant to external influences. You can only use the gate freely one month after installation.

What should gate hinges be like?

Metal gates are most often installed on garages and fences that protect the perimeter of the area. First of all, they perform security and protective functions, and only then decorative ones. Products in this category can weigh from 200 to 1500 kg. Therefore, in order for the structure to serve well for many years, it is necessary to select only fittings that are suitable in terms of strength.

Drawing with dimensions of gate hinges

Poor quality hinges or hinges that do not fit the gate lead to the following problems:

- cannot withstand the applied load and become deformed;

- the gate begins to sag;

- The doors no longer open easily and close tightly.

Buying high-quality hinges that best fit the gate means:

- provide the gate with all conditions for long-term service;

- forget about creaking and grinding noises when operating the sashes;

- provide the entrance to the yard or garage with maximum protection against burglary.

Modern fittings for garage structures function perfectly in any weather. Permissible temperature range:

- from – 400;

- up to +1200.

Mechanism selection

Main types of garage hinges

The rapid technological process affects many aspects of our lives, and even hinges for wooden gates (as well as metal ones) are no exception. If previously the fittings for garage doors were very simple and monotonous, today you can find many types of different hinges that differ in their features and advantages.

The table shows the main types.

| Hinges. In the middle of the product, made of steel, there is a ball, thanks to which the loop moves. This type will be discussed in more detail below. |

| Cylindrical. This fittings are also called bearing hinges. It is attached to a special support by welding metals. Due to the design features and fastening on the gate, cylindrical hinges with a support bearing are well suited only for swing gates with a small mass - the total load should not be more than 400 kilograms for each hinge. Otherwise, there is a high risk of breakdown. |

| Cylindrical reinforced. These welded hinges are improved versions of the previously discussed hinges - they have a more advanced structure and optimal load distribution. The maximum weight that one such hinge can hold without any consequences is about 600 kilograms, so reinforced cylindrical hinges can be used for installing heavy gates. |

| Through. In the event that garage door hinges for certain reasons cannot be installed by welding or screwing to a surface, through-type hinges are used. To install such fittings in the gate structure, the entire length of the mounting columns is drilled into which part of the hinge is threaded. After this, it is firmly fixed using nuts of a suitable size. Due to this fastening scheme, through garage hinges are designed for a load of no more than 200 kilograms. |

| Invoices. These are the most popular gate hinges among garage owners, which have gained such popularity due to their high reliability, strength and wear resistance. Another advantage of overhead hinges is the complete absence of squeaking when opening and closing the doors. Such fittings completely take over the load from the door leaves and do not allow them to sag. Also, overhead hinges are also burglar-resistant. |

| Forged. This is an old type of garage hinge, which was born many centuries ago and was used to hold wooden gate leaves. Despite this, forged type hinges are often used today, including for creating design solutions. Some modern models of forged hinges are in no way inferior to others. |

Which gate hinges to choose from such a variety? If you are already overwhelmed by the wide range of modern stores, read on to find out the rules of choice.

Why hinge hinges are so good

It should be noted that hinged gate hinges are highly popular. It is largely due to the numerous advantages of such loops, which are listed below:

- Ease, smoothness and noiselessness of turning, subject to regular lubrication.

- Hinges for metal gates are highly resistant to burglary.

- Ability to withstand heavy loads, especially for hinges with a large hinge.

- No chance of spontaneous closing and opening (provided the garage door is installed correctly in a vertical plane).

The positive qualities mentioned above make it possible to install hinge hinges on gates made of corrugated sheets. Thus, the hinges that are installed inside the hinges are made of durable and reliable metals with decent performance characteristics. Thanks to this, not only the possible load on the hinges from heavy door leaves increases, but also their service life.

Cylindrical garage hinges in different sizes

It is important to select the correct number and parameters of hinges based on the weight of the gate door, for example:

- For a lightweight gate made of corrugated sheets, one hinge per hinge with a diameter of 25 mm is sufficient.

- For a standard gate door you will have to choose hinges with hinges with a diameter of 35 mm or more.

- If you plan to install a massive garage door, it is necessary to increase not only the diameter of the hinge, but also the number of such balls in one hinge (up to 2-3 pieces per leaf).

How to properly weld hinges on gates and wickets: video

The goal of the gate is to lock securely, withstand force loads, and be functional. Another good gate is that it opens and closes comfortably. You not only need to know how to weld hinges on a gate or wicket, but also be able to use electric arc welding, then everything will be done efficiently and correctly. When the elements are welded correctly, the gate will open well. At the same time, there will be no gaps in the closed gate.

Variety of options

Types of loops and their properties

The gate lasts for more than one year. At the same time, it must provide reliability and a good level of protection, and the hinges that hold it must:

- turn without effort;

- do not make sounds;

- don't hang out;

- be strong.

The quality of the product, the reliability of the manufacturer and the permissible load are important.

If you hang heavy sashes on weak elements, they will quickly fail. Sometimes the number of loops increases to six instead of the standard four.

In the context

Types of loops:

- Cylinder-shaped (drop-shaped) - the design has a support bearing, is not used for light gates, load - up to 400 kg.

- In the form of a cylinder with an amplifier - the design includes a support bearing, and for reinforcement there are plates that are designed for better load distribution. For such loops the maximum load will be 600 kg. They are fastened by welding or screws and are suitable for swing gates.

- Through - this type of hinge is used when it is not possible to weld them or use screws. To fix such a hinge, you need to drill through the post, and it will be attached to the sash using nuts. Can withstand a maximum of 200 kg.

- Three-section - for very heavy large sashes. They are highly resistant to burglary. They are secured by welding.

- Forged (zhikovina) - the installation of hinges of this type has been used since ancient times. In addition to the fact that they perform their function well, these loops are very decorative. It is best to use them for wooden gates.

- Arrow hinge – made of steel, with hinges, suitable for heavy gates made of thick metal. They can be made curly. They are most widespread when used on garage doors.

- Adjustable - provide for changing the position of the sashes in height. They are usually used when the support posts can change their position. The maximum load of these loops is 200 kg.

Balls for easy and smooth opening

Weld the hinges correctly

When choosing hinges, be sure to take into account the characteristics of the gate material, its length and weight. A competent approach will help to complete the work efficiently.

We weld the hinges to the round posts

Not every welder understands how to properly weld hinges on gates and gates: round posts have their own characteristics. First, special plates must be welded to the hinge, and this is done using a continuous, even weld.

Welding is always performed at the site where the swing gates will be installed. To install the sashes vertically, you need to use a plumb line. In other words, the doors should stand exactly as they will remain later. Accurate measurements must be taken to avoid various defects.

The video explains how to properly weld hinges on gates and gates with your own hands.

The most labor-intensive part of this process is the vertical seams: they cannot be done without plates. First, the lower hinges are welded. The bayonet part is attached using gentle movements of the electrode from top to bottom.

To check whether the doors open correctly, you can use a laser level.

It will show the location of the axis; if there are no distortions, we continue. Let's consider the stages of welding work:

- the sashes should be vertical, a plumb line will help check the location;

- you need to make sure that the hinge is parallel to the edges of the sash;

- then we weld the hinges to the posts, to the fabric of the structure, after which we clean the seams well with a grinder.

Installation diagram

We weld hinges to gates made of corrugated sheets

If the gate is made of corrugated sheets, then you need:

- Make jumpers parallel to the top.

- Fix them.

- By their location, they should divide the canvas into three equal parts.

- Weld the elements.

- Cover them with corrugated sheets.

Installing hinges on a profile fence is slightly different from the classic version, which does not have any additional complications and does not require unnecessary effort. But you will have to do the following:

- make two small jumpers that are inserted parallel to the long sides and secured at the top and bottom;

- the distance should be for three such parts;

- We weld hinges to the jumpers.

After installation

The profile is screwed onto already installed elements. If you do this earlier, then during welding it will burn out and lose its aesthetic appearance. To perform such work, the best option would be to use garage door hinges. Each welded loop can withstand a fairly large load.

We weld the hinges to the stone fence

Mounting plates make the task easier: thanks to them, the load on the curtains will be reduced. Before attaching them, you need to take into account the parameters of the gate. You need to use plates whose dimensions, shape and thickness will correspond to the weight and quality of the sashes. Mounting plates can also serve decorative purposes.

Welding gate hinges involves fastening two metal objects together. And if the fence is made of stone or brick, then you need to very carefully calculate the size and weight of the gate. After this, support pillars are installed. Channels or I-beams are used as supports; they ultimately hold the sashes.

Loop welding technology

Before we talk about how to weld hinges on gates, it is worth taking a closer look at the conditions necessary for their normal operation.

Even if the load is calculated correctly, the hinges may not be able to cope with it if their position deviates even slightly from the vertical. They will quickly fail. And the second point: there should be a small gap of 1-2 mm between the hinge body and the support post so that the metal parts of the post and the mating part of the canopy do not touch or rub against each other. The same gap should be left on the side of the sash.

Video description

To understand what we are talking about, watch the video

The nuances of installation on supports of different sections

The supporting posts on which the sashes are hung can be round, square or, less commonly, rectangular in cross-section. There is a difference between how to properly weld gate hinges to round posts or supports made of profile pipes.

If the profile pipe has smooth edges without bends or distortions, then it will be easy to cope with the task of how to properly weld gate hinges to square posts. They are installed on the outer plane of the support.

Canopy with plates on a square postSource distroy.ru

In the case of a round support, you must first decide in which direction the doors will open. Then they find the most protruding line (the middle of the pillar relative to the opening) and step back from it a few millimeters outward - in the direction of plowing. 5-6 mm is enough for the wicket or gate leaf to move smoothly and without jerking around the axis of the canopy. Since it is more difficult to weld hinges on gates to round posts than to square ones, here you need to be especially careful and attentive, maintaining the same indentation size for all hinges.

Installation and welding work

Experienced welders recommend first welding the canopies to the sashes, laying them on a flat horizontal surface. A half in the form of a hollow cylinder is welded to them, and a mating part with a pin (pin up) is subsequently welded to the supports. They retreat approximately 15 cm from the top and bottom edges.

Wicket frame with welded hingesSource www.chipmaker.ru

Then the sash with welded canopies is installed in the opening on stands that provide the required distance to the ground, and is rigidly fixed with clamps, pliers and other devices. They do this so that it stands strictly vertically, and there is a gap of 5 mm or so between it and the support. To do this, use a laser level or a plumb line, and spacers of the required thickness are inserted between the elements.

Other craftsmen prefer to first install the gate, and then weld the hinges to both it and the post. There is no big difference, everyone does what is convenient for them.

Another option is to make the upper and lower ribs of the frame whole when making the sashes and cut them after hanging them on the hinges. Source sqezo.ru

Now let’s talk about how to properly weld canopies on gates. The sequence of work looks like this:

- 1.5-2.5 mm thick wire is wrapped and twisted around the loops at the top and bottom to form a gap between it and the welding plane. You can place matches or other objects of suitable thickness, but they fall out, move or break, which is very inconvenient;

- The places where the canopies are attached are marked on the supports and an even long block or profile pipe is applied to them. Fix it level, ensuring a vertical position.

Gate installation

Before welding the prepared hinges, it is necessary to install the gate in the opening. This must be done in the way they should be on a permanent basis. For installation, use a long building level or plumb line.

The gates are aligned in all planes: vertically, horizontally. Only after making sure of their correct location several times can you move on to the next stage.

Welding hinges

This process seems complicated only at first glance, but with a little practice you can do everything yourself. This is done as follows:

- The hinge is lubricated with automotive lubricant (solidol, lithol, etc.), this contributes to their smooth and easy operation after installation.

- Thin linings up to 5 mm thick are prepared; this is mainly required for turned hinges.

- Markings are made - the loops should be located at a distance of 30 cm from the top and bottom.

- The hinges are welded in several places, first to the sashes and then to the pillars. After checking for closure and opening, welding continues until a solid, even seam is formed.

- After the seams have cooled, they must be sanded and primed or painted.

This technology is used by almost all door installers.