Geometric dimensions

The performance characteristics depend on the parameters listed above. All three diameters determine which hole needs to be made with a drill when working with a tap. From the pitch and stroke - how firmly the screwing will occur, the more turns, and the more often they are, the better. This kind of work is more delicate, so it is virtually impossible to do it at home, only with special equipment.

The strength of the connection depends on how deep the grooves are. There are limitations here too. If the bolt is made in miniature, then there should not be too much of a difference between the recesses and ridges, as this increases fragility.

The profile angle determines how well the front of the tap will penetrate the material. It’s not so easy to start rotations, and besides, to do it quite smoothly, without distortions. The softer the material (for example, copper or aluminum), the better the screwing. The proportionality of the two elements that come into interaction is very important.

Scope of application

They are used everywhere - in the automotive industry, machine tool industry, in the manufacture of household appliances and in everyday life. The peculiarity of the technology is that it has firmly entered our lives because of its convenience, and has also captured all areas of production, since structures can be produced both large and miniature. The simplest examples are a nut and a bolt. In the first case, an internal thread was made using a tap, and in the second, an external thread was made using a die.

Nuts and screws of different materials are used everywhere. From the smallest fastenings, for example, when screwing the lid of a mobile phone, to the huge nuts that hold the wheels of heavy-duty vehicles.

Geographically, the method is used all over the world. In Russia there are GOSTs, our markings are measured in mm. Abroad, inch measurements are used. We offer a table showing how millimeters and inches relate:

Diameter in inches

External section in mm

Internal section in mm

Main settings

It is difficult to match a bolt and nut to each other if they had different sizes and designs. But they mirror each other, so we can talk about characteristics that are suitable for both parts:

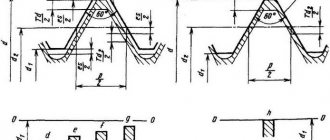

- Outside diameter. Most procedures are determined by it, including when it is necessary to drill a hole for a tap. In diagrams it is written as d or D for a bolt and nut, respectively.

- Medium – d2 and D2. If you take the basic unit of coil, you need to divide it in half to find these points.

- Internal – d1 and D1. Determined by the upper edges. If you draw an imaginary line along them, you can see a cylinder that will display this size.

- Step (P) - if we take a thread, then each rotation of it leads to the formation of a line on one of the sides. The distance between two points (ridges, blades) is the parameter. You can find it by marking 10 mm on the surface with a ruler (measurements can also be made in centimeters), then count how many turns are within these limits and divide the resulting number by 10.

- Stroke – (t) it is equal to the previous value, if we consider single-thread bolts, with one thread. But since two-start ones are more common, then t = 2P. Or 3P, if there is a three-lead element. That is, this is a full turn to the starting point of one turn.

Read also: Adjustable wrench sizes by numbers

- Profile angle – it is very important to calculate it. It is individual for different workpieces depending on the thickness and density of the material. Cannot exceed 140 degrees.

- The screwing length or nut height is the distance over which there are turns that interact with the mirror internal thread.

Thread diameter

The conditional parameter used to designate threads in drawings and reference tables is called the nominal diameter.

If we describe an imaginary cylinder around the protrusions of the external thread and the cavities of the internal thread, then its diameter will be called external. And the designation on the drawings: D – for internal; d – for external.

The internal diameter is the size of the inscribed cylinder in the recesses of the external thread and at the points of the vertices of the internal thread, denoted by: D1 and d1 for internal and external, respectively.

The average diameter is a parameter of an imaginary cylinder whose segments are equal to ½ thread pitch. Designated: D2 and d2.

The internal diameter of the bolt is used to calculate the stress in the fastener. Its value can be taken from the table with diameters, or calculated independently based on the nominal value.

Designation rules

The marking contains several parameters. Each of them finds a letter or number display. If there is no such set at the end of the product (die and tap, ready-made metal fasteners), then it is probably a fake. What is indicated:

- The tolerance level, that is, the accuracy of compliance with the declared dimensions.

- Type. For metric - the letter M. For other options, other markings, for example for cylindrical - G.

- Inner diameter. The step is not indicated, since according to the standards, all structures have a similar move if they have the same cross-section.

There is also a designation for the make-up length. She may be:

All of the above is indicated both on the drawing during the design and manufacture of products, and already at the time of production - the engraving method is usually used. It is the most durable, and when trying to save money, paint is used.

Application

Metric threads are widespread in the countries of the former Soviet Union. Used for application to both internal and external planes of fasteners. Typically used for fastening metal structures of various types. For these purposes, a variety of bolts (anchor and conventional) and other types of fasteners are manufactured. She found a particular purpose in mechanical engineering, construction of engineering communications, especially in the plumbing sector. Most pipe and container fittings are manufactured with this type of thread.

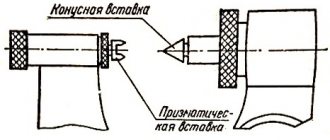

Most often, this type of carving is applied to cylindrical objects. But in some cases, when it is necessary to achieve tightness, a conical shape is used. This form, with a metric thread applied, allows you to achieve maximum tightness, even without the use of additional sealing agents. Most often used for installation of pipelines.

Tolerance fields

For a number of production cycles, maximum compliance of the parts being connected is important. Such values are called exact. It leads to:

- increased tightness - no extra gaps;

- strength;

- no vibration.

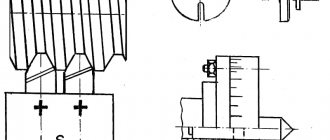

Manufacturing takes place exclusively on metalworking machines, which are based on a remote control. Here the operator is not responsible for the process, but only enters the design developed using a computer-aided design program into the computer. Tools grind teeth with high precision up to 0.001 mm.

The second standard accuracy size for metric threads is medium. It is the norm and is used most often. It is this category that includes the fasteners that are supplied to the shelves of hardware stores. Manufacturing is machine-made, but with the use of manual installation and fastening of the part, drill direction, etc.

Third class is rough. This includes cuts that are made by craftsmen at home. Often do not have three-layer processing, in many cases the ends of the turns are broken or ready to crumble.

Types of metric threads

Metric threads also mean all types with different profiles, measured in millimeters. These include:

- triangular thread;

- trapezoidal;

- rectangular;

- round.

In addition to the metric system for measuring parameters, the following are used:

- inch;

- modular, where the module is the ratio of the length, expressed in millimeters, to the number π;

- pitch, basic unit - pitch - the ratio of the number π to the length, expressed in inches.

Modular threads are used for worm gears in mechanical engineering, just like pitch threads. Inch and metric are fastening thread types, but can be used for transmission.

By location they are distinguished:

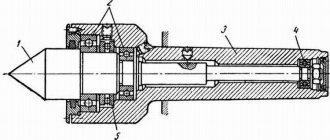

The internal thread is located in the hole, it is obtained with a tap, a specialized tool that is a rod with cutting edges.

Internal metric thread

External threads are made with a cutter or die on a rod. They can also be obtained by coasting on appropriate equipment.

External metric thread

The shape of the surface can be cylindrical or conical.

Metric conical thread is used for installation of pipelines. It is performed on surfaces where the larger diameter exceeds the small one by 16 times. Diameters vary from 6 to 60 mm.

They are also divided according to the direction of the turns into right and left. To determine the direction of the thread, it is necessary to position the part so that its axis is located away from the observer. Then, the right-hand thread is formed by a circle rotating from left to right with translational motion along the axis, and the left-hand thread, accordingly, counterclockwise.

There are different types of step sizes:

- large (with a main, large step);

- small (with small);

- special.

A large pitch is considered normal and is suitable for any materials, including fragile ones. Small allows you to withstand heavy loads, but the materials must have certain strength characteristics. Small and special ones are rarely used.

Large and fine thread pitch

The place of transition from a smooth surface to a helical one is called the approach. Based on their number, they are divided into: single- and multi-pass. The latter are also subdivided by the number of passes: two-, three- and multi-pass.

Another classification is by application. They are:

- fastening and thrust-fastening;

- kinematic or chassis;

- special purpose.

Below are the main types of metric threads and their letter designations:

- the capital letter "M" symbolizes the metric type,

- if it is made on the surface in the form of a cone, then “MK”;

- for conditions where heat resistance and strength are required, use the metric cylindrical “MJ”;

- according to ISO – “EG-M”;

- trapezoidal – “Tr”;

- persistent with an angle of inclination of one side of 30º – “S”;

- persistent reinforced - “S45”, where the number is the angle of inclination of one of the sides.