Updated: 04/23/2021 12:51:21

Expert: Konstantin Borisovich Polyakov

Cast iron is one of the most famous materials for the production of castings. It is characterized by strength, good wear resistance, thermal conductivity and other attractive performance properties. But it itself is not metal. This is an alloy.

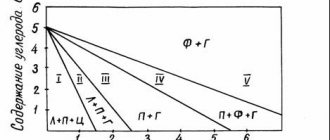

According to standards, this material is an alloy of iron and carbon. The metal part in it is at least 90%, non-metallic - up to 6.67%. In addition to carbon itself, the alloy may include other impurities - manganese, phosphorus, silicon, and so on. Not only the brand, but also the physical and chemical properties depend on the percentage of these inclusions.

Thus, the most widely used are white and gray cast iron. They just differ in the percentage of carbon content in the composition. And because of this, performance properties also vary.

In this article we will figure out what the difference is between gray and white cast iron - and what is better to use for certain purposes.

What is gray cast iron?

The corresponding type of cast iron is one of the most common in the field of mechanical engineering. This metal is characterized by the presence of plate-shaped graphite in the thin section. Its content in gray cast iron may vary. The larger it is, the darker the metal becomes at the fracture, and also the softer the cast iron. Castings from the type of metal in question can be produced in any thickness.

Main features of gray cast iron:

- minimum relative elongation - as a rule, not exceeding 0.5%;

- low impact strength;

- low plasticity.

Gray cast iron contains a small percentage of fixed carbon - no more than 0.5%. The remaining part of the carbon is presented in the form of graphite - that is, in a free state. Gray cast iron can be produced on a pearlitic, ferritic, or mixed ferrite-pearlite base. The metal in question usually contains a significant percentage of silicon.

Gray cast iron is quite easy to process using cutting tools. This metal is used for casting products that are optimal in terms of compression resistance. For example, various supporting elements, batteries, water pipes. The use of gray cast iron is also widespread in mechanical engineering - most often in the manufacture of parts that are not characterized by shock loads. For example, housings for machine tools.

Tool carbon steels

Designation and marking of tool carbon steels

Tool carbon steels are marked in accordance with GOST 1435-90.

Tool carbon steels are produced in the following grades: U7.U8GA.U8G, U9, U 10, U 11, U 12 and U 13. The numbers indicate the carbon content in tenths of a percent. The letter G after the number means that the steel has a high manganese content. The grade of high quality tool carbon steel has the letter A.

Examples of designation and decoding

- U12 - tool steel, high-carbon, containing 1.2% carbon, high-quality.

- U8GA - tool steel, high-carbon, containing 0.8% carbon, 1% manganese, high quality

- U9A - tool steel, high-carbon, containing 0.9% carbon, high quality.

Designation and marking of alloy steels

Alloy steels are marked with a combination of numbers and capital letters of the alphabet. The designation does not contain the word “steel” or the symbol “St”. For example, 40Х, 38ХМ10А, 20Х13. The first two digits indicate the carbon content in hundredths of a percent. The following letters are abbreviations for the element. The numbers after the letters indicate the content of this element in whole percentages. If there is no number behind the letter, then the content of this element is up to 1%.

Table 4. — Designation of elements brand

| Yu-Al Aluminum | C-Si Silicon | A-N Nitrogen |

| R-V Bor | G - Mn Manganese | D-Cu Copper |

| F-V Vanadium | M-Mo Molybdenum | E-Se Selenium |

| B-tungsten | N-Ni Nickel | C-Zr Zirconium |

| F-Fe Iron | T-Ti Titan | B-Nb Niobium |

| K-Co Cobalt | Ta - Tantalum | X-chrome |

For the manufacture of measuring instruments, X, HVG are used. Steels for dies: 9Х, Х12М, 3Х2Н8Ф.

Steels for impact tools: 4ХС, 5ХВ2С.

Designation of high-speed high-alloy steels

All high speed steels are high alloy. These are steels for equipping the working part of cutters, cutters, drills, etc.

The marking of high-speed steels always begins with the letter P and a number indicating the tungsten content as a percentage. The most common brands are P9, P18, P12.

- Corrosion-resistant steels.

Corrosion-resistant (or stainless steel) is steel that has high chemical resistance in aggressive environments. Corrosion-resistant steels are obtained by alloying low- and medium-carbon steels with chromium, nickel, titanium, aluminum, and manganese. Anti-corrosion properties are imparted to steels by introducing a large amount of chromium or chromium and nickel into them. The most widely used are chromium and chromium-nickel steels. For example, chromium steels 95Х18, 30Х13, 08Х17Т. Chromium-nickel stainless steels have greater corrosion resistance than chromium steels, have increased strength and good processability with regard to pressure treatment. For example, 12Х18Н10Т, 08Х10Н20Т2. - Heat- and

resistant to chemical destruction in gas environments, operating in a lightly loaded state - Heat-resistant steels

are steels that can withstand mechanical loads without significant deformation at high temperatures. Heat-resistant steels include steels containing chromium, silicon, molybdenum, nickel, etc. - For example, 40Х10С2М, 11Х11Н2В2МФ.

- Wear-resistant steels

with increased wear resistance: ball bearing, graphitized and high-manganese. Features of the designation of bearing steels. The marking begins with the letter Ш, the number after the letter X indicates the chromium content in tenths of a percent. For example, ШХ9, ШХ15ГС.

What is white cast iron?

This type of cast iron is characterized by the presence of carbon, which is almost completely represented in the metal structure in a bound state. The metal in question is hard and at the same time quite fragile. It is resistant to corrosion, wear, and temperature effects. White cast iron is quite difficult to work with hand tools. When broken, this metal has a light tint and a radiant structure.

The main area of application of white cast iron is subsequent processing. As a rule, it is converted into steel, and in many cases into gray cast iron. In industry, its use is not very common due to its fragility and difficulty in processing.

The percentage of silicon in white cast iron is significantly less than in gray cast iron. The metal in question may also have a higher concentration of manganese and phosphorus (note that their presence is largely determined by the chemical composition of the ore from which the cast iron is smelted). Actually, an increase in the amount of silicon in a metal is accompanied by a decrease in the volume of bound carbon in its structure.

Production technology

Cast iron has been smelted for several decades, which is due to its unique performance qualities. The large number of varieties of alloys determines the application of special marking rules. Marking of cast iron is carried out as follows:

- Foundries are designated by the letter L.

- Gray has become widespread; the combination of letters “SCH” is used to designate it.

- Malleable is designated KCH.

- Extreme or white is designated by the letter P.

- Anti-friction or gray indicate ASF.

- Alloy cast irons can have a wide variety of chemical compositions and are designated by the letter “C”.

The technology of cast iron production involves several stages that make it possible to obtain the required structure. Considering the process of producing cast iron, we note the following points:

- Production is carried out in special blast furnaces.

- Alloyed and heat-resistant cast iron can be obtained by using iron ore as a raw material.

- The technology is presented in the reduction of iron oxides ore. As a result of the restructuring of the crystal lattice and changes in the structure, the output is a material called cast iron.

- Considering production methods, we note that the features of the technology also lie in the materials used - cokes. Coke refers to natural gas or thermoanthracite, which acts as fuel.

- The production of cast iron involves tempering iron in solid form using a special furnace. At this stage, liquid cast iron is obtained.

Equipment for the production of cast iron can vary significantly. In addition, the production technology used largely determines what kind of material will be obtained. An example is the production of ductile iron, which involves giving the structure an unusual shape.

Comparison

The main difference between gray cast iron and white is that the former contains a small percentage of fixed carbon, while the latter, on the contrary, contains mainly fixed carbon. This feature determines the difference between the metals under consideration in terms of:

- hardness;

- colors on the break;

- wear resistance;

- fragility;

- machinability with hand tools;

- scope of application;

- percentage of fixed and free carbon;

- percentage of silicon, manganese, phosphorus.

To more clearly study the difference between gray and white cast iron in these aspects, a small table will help us.

Physical properties

Cast iron has become widespread due to its attractive physical properties:

- The price of the material is significantly lower than the price of other alloys. That is why it is used to create all kinds of products.

- Looking at the density of cast iron, let us recall that this figure is significantly less than that of steel, making the material much lighter.

- The melting point of cast iron can vary slightly depending on its structure, in many cases it is 1,200 degrees Celsius. Due to the inclusion of various additives in the composition, the melting point of cast iron can significantly increase or decrease.

- When selecting a material, many pay attention to the fact that the color of cast iron may vary slightly depending on the structure and chemical composition.

The boiling point of cast iron also in most cases depends on the chemical composition. In order to consider the physical characteristics of a material, it is necessary to pay attention to each of its varieties.

A different structure and composition become the basis for imparting other physical and mechanical qualities.

Table

| Gray cast iron | White cast iron |

| Less hard | More solid |

| Darker at the break | Lighter on the break |

| Less resistant to wear | More resistant to wear |

| Less fragile | More fragile |

| Easy to process with hand tools | Not very easy to work with hand tools |

| Actively used in various industries | Mainly used for the purpose of making steel, gray cast iron |

| Has a large percentage of free carbon - in the form of graphite | Includes mostly fixed carbon |

| Characterized by a large percentage of silicon, a smaller percentage of manganese and phosphorus | Characterized by a lower percentage of silicon, a higher percentage of manganese and phosphorus |

Common metal markings

In accordance with the recommendations of GOST 1215–79, the marking of malleable cast iron includes the first letters of its name - KCH. The written number, consisting of two digits, displays the indicator of tensile strength or the limit of resistance to deformation and fracture, measured in 10 MPa - CN 70. The number written with a hyphen reflects the amount of plastic deformation during stretching with the unit of measurement “%” (relative elongation ) – KCH70-2.

In addition to this, grades of ductile alloys are classified based on their structures. The ferritic and ferrite-pearlite class includes CNs with relatively low fracture resistance limits and higher percentages of relative elongation. Alloys with a pearlite structure are presented with high tensile strength values and relatively low elongation values.

According to GOST 26358, it is possible to determine the following properties of ductile cast iron grades:

- temporary tensile strength;

- Brinell hardness (HB);

- relative extension.

Book table of contents open close

Materials used in mechanical engineering Carbon steels Ordinary quality carbon steels High-quality carbon steels Tool carbon steels Cast irons: classification and properties Ductile cast iron High-strength cast iron Anti-friction cast irons Alloy steels: properties and classification Structural alloy steels Tool alloy steels Steels and alloys with special properties: stainless steel, ball bearing , spring, automatic Electrical steels and alloys Powder materials Alloys of non-ferrous metals Copper and its alloys Aluminum and its alloys Anti-friction alloys Composite materials Composite materials with a metal matrix Materials with a non-metallic matrix Structural materials on an organic basis Plastics: composition, properties and classification Rubbers: composition, properties and types Structural materials on an inorganic basis Inorganic glass: properties and classification Thermal and sound insulating fiberglass materials Sitalls: preparation and properties Ceramic materials: properties and types Graphite and its properties Protective materials and their types

Usage

Due to its special physical and mechanical properties, the use of cast iron has become possible in various fields:

- For the production of various parts in the field of mechanical engineering. For a long time, this particular alloy has been used in the manufacturing of many different parts for internal combustion engines. At the same time, machine manufacturers change the main parameters of the material by alloying it, which is necessary to achieve unique qualities. Among other things, brake pads made from this alloy have become extremely popular.

- Cast iron products can withstand the effects of low temperatures. Thanks to this, the material is used during the manufacture of equipment and tools that are used in harsh climate conditions.

- Cast iron is valued in the metallurgical field. This is due to the low price, which in most cases depends on the carbon concentration and the properties of the resulting structure. High casting qualities also make the material much more beautiful. The resulting products are highly durable and resistant to wear.

- Over the last half century, the alloy in question has been actively used in the manufacturing of plumbing equipment. This is due to high anti-corrosion abilities, as well as the possibility of obtaining products of very different shapes. Examples include cast iron bathtubs and heating appliances, various pipes, radiators and sinks. Despite the emergence of materials that could replace cast iron, such products are quite popular. This is due to the fact that they preserve their original appearance over a long period of operation.

- The alloy is also used for the production of various decorative elements, which is associated with high casting qualities. Examples include fencing bars, various figures, and much more.

Among other things, the scope of use depends on the following parameters of the material in question:

- Some grades have great strength, which is specific to steel. This is actually why the material is used even after the emergence of modern alloys.

- Products made of cast iron are able to retain heat for a long period. In this case, thermal energy can be equally distributed throughout the material. These qualities began to be used in the manufacturing process of heating radiators or other such products.

- In most cases, it is believed that cast iron is an environmentally safe material. This is actually why it is often used in the process of making various dishes, for example, cauldrons.

- High resistance to acid-base conditions.

- Excellent hygiene as all contaminants can be easily removed from the surface.

- The material under consideration has a fairly long service life provided that the operating instructions are followed.

- The chemicals contained in it cannot cause harm to health.

To summarize, we recall that the long-discovered production technology of the material in question remained virtually unchanged for a long time. This is due to the fact that at relatively low costs it was possible to obtain a significant volume of molten alloy.

At the moment, material is often manufactured from scrap, which makes it possible to further reduce the selling price of the resulting product to a high degree.