Types of produced white cast iron

Depending on the crystalline structure, as well as the presence and ratio of the constituent elements, white cast iron is divided into:

- ordinary;

- alloy;

- heat resistant;

- stainless.

A separate type is cast iron alloys with high electrical resistivity.

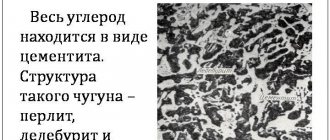

The internal structure of ordinary white cast iron contains carbon in the form of cementite grains. The amount of carbon affects the melting point and, depending on this, cast iron is divided into:

- hypoeutectic with a lower melting point, carbon not more than 4.3%;

- eutectic with a carbon content of 4.3%;

- hypereutectic - more than 4.35% and can reach - 6.3%.

The effect of cast iron bleaching is achieved by rapidly cooling the casting, which as a result is heterogeneous in composition. The top layer, up to 30 mm thick, becomes white, and the rest of the core is ordinary gray cast iron.

Educational materials

Cast iron is an alloy of iron and carbon, in which the carbon content is more than 2.14%.

In addition to carbon and iron, the alloy contains impurities: silicon, manganese, phosphorus, sulfur, etc. These impurities have a significant impact on the formation of the alloy structure, and consequently on the mechanical, physical and other properties of cast iron.

Depending on the form in which carbon is present in the alloys, white, gray, malleable and high-strength cast irons are distinguished. According to the chemical composition, cast iron is divided into carbon and alloy.

White

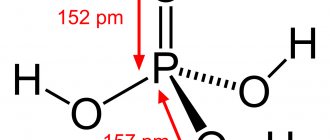

are called cast irons in which carbon is predominantly in a bound state in the form of cementite Fe3C (a very small amount of carbon is in the solid solution). These cast irons, whose phase transformations occur according to the Fe-C diagram, are divided into hypoeutectic, eutectic and hypereutectic. Due to the large amount of cementite, white cast iron has a high hardness of 450...550 HB, is brittle and practically cannot be machined by cutting, therefore it is practically not used as structural materials. They can be used for parts that require high surface wear resistance. For example, ball mill balls are made for grinding ores and minerals.

White cast irons are pigmentable and are used to produce steel and malleable cast iron.

Gray

are called cast irons in which carbon is predominantly in a free state in the form of graphite plates. Graphite is formed at a very low cooling rate, when the degree of supercooling of the liquid phase is low. It grows from one center and, branching in different directions, takes the form of highly curved petals. In the plane of the section, graphite has the form of straight or swirling plates, which are cross sections of graphite petals. When fractured, these cast irons are gray in color. The mechanical properties of cast iron are determined by its structure, mainly the graphite component, its quantity, shape and size of inclusions.

Graphite has low strength and can be considered as internal cuts, breaks in the continuity of the metal base. With increasing carbon content, more graphite precipitates and less mechanical strength of cast iron. Gray cast iron has poor tensile strength, is brittle, but has good fluidity, low shrinkage during crystallization, is easy to cut, has good anti-friction properties (graphite acts as a lubricant), absorbs vibration, and is insensitive to stress concentrators (notches, undercuts).

The specific gravity of gray cast iron ranges from 6.6...7.4 g/cm3 and depends on the amount of carbon, the degree of graphitization and the quantitative ratio of structural components.

The heat capacity of gray cast iron also depends on the above factors and in the temperature range 0...700 0C is equal to 16 cal/(g∙0C). Thermal conductivity is 0.16 cal/(cm∙s∙0C). The average coefficient of linear thermal expansion in the temperature range 0…100 0С can be taken as (10…11)∙106 cm/(cm∙0С), and in the temperature range 100…700 0С it is equal to 14∙106 cm/(cm∙0С).

The main elements in cast iron are Fe-C-Si and permanent impurities - Mn, P, S. Silicon has a strong graphitizing effect, manganese makes graphitization difficult. Sulfur is a harmful impurity that worsens the casting and mechanical properties of cast iron.

Phosphorus is a useful admixture in cast iron, as it improves fluidity. Phosphide eutectic areas increase the hardness and wear resistance of cast iron. Most often, the phosphorus content is in the range of 0.2...0.5%. For castings that require high wear resistance, the phosphorus content is allowed 0.7%, and for art casting - up to 1%.

A visual representation of the influence of carbon and silicon on the degree of graphitization of cast iron and its structure is given by the structural diagram (casting wall thickness 50 mm) shown in Figure 37.

I - white cast iron; II - half cast iron; III - gray cast iron on a perlite basis; IV - gray cast iron on a ferrite-pearlite basis; V- gray cast iron with ferritic base

Figure 37 — Structural diagram

Gray cast iron is marked with the letters SCH, followed by a number indicating the guaranteed tensile strength in kgf/mm2

(10-1 MPa).

Ferritic cast irons

grades SCh10, SCh15, SCh18 are used for minor parts that experience light loads. For example, foundation plates, covers, flanges, engine frames, compressors, furnace gates and dampers, filter and oiler housings, flywheels, gearbox housings, pumps, brake drums, clutch discs, etc. The structure of gray cast iron is shown in Figure 38.

Ferrite-pearlitic cast irons

grades SCh20, SCh21, SCh25 are used for parts operating under increased static and dynamic loads. Examples include cylinder heads, pistons, steam cylinder piston ring bushings, centrifugal pump wheels, machine tool frames, gears, diaphragms, low pressure cylinders and turbine exhaust pipes.

a- on a ferritic basis; b- on a ferrite-pearlite basis;

c- perlite based

Figure 38 — Structure of gray cast iron

Pearlitic cast irons

grades SCh30, SCh35, SCh40, SCh45 are used for parts operating under high loads or in severe wear conditions: gears, cylinder liners, camshafts, etc. Small isolated graphite inclusions reduce the strength of cast iron less. Grinding of graphite inclusions is achieved by modifying liquid cast iron with ferrosilicon, aluminum or ferrocalcium (0.3...0.6% by weight of the charge). Castings made of gray cast iron are subjected to heat treatment: to relieve internal stresses - type I annealing (560 0C), normalization or hardening with tempering to increase mechanical properties and wear resistance. To increase the wear resistance of cylinder liners, camshafts and other products, pearlitic cast iron is subjected to nitriding.

Forged

are called cast irons in which carbon is in a free state in the form of flakes. This form of graphite is the main reason for the high strength and plastic characteristics of malleable cast iron. The term “malleable cast iron” is conditional, since products made from it, like any other cast iron, are made not by forging, but by casting, and indicates increased ductility compared to gray cast iron. The composition of malleable cast iron is maintained within fairly narrow limits: 2.4…2.9% C; 1.0…1.6% Si; 0.2…1.0% Mn; up to 0.18% P and up to 0.2% S.

The low carbon content of ductile iron is necessary for two reasons. Firstly, to obtain high strength characteristics, the number of graphite inclusions should be reduced. Secondly, it is necessary to avoid the release of lamellar graphite when cooling castings in the mold (for the same purpose, the thickness of the casting wall should not exceed 50 mm).

Malleable cast iron is obtained from white cast iron by annealing, which sometimes lasts up to 5 days. According to the structure of the metal base (Figure 39), which is determined by the annealing mode, malleable cast irons are ferritic and pearlitic.

Annealing for ferritic cast iron is carried out according to mode 1 (Figure 40), which ensures graphitization of all types of white cast iron cement.

a – ferritic; b – pearlite

Figure 39 – Microstructure of malleable cast irons

Figure 40 – Scheme of annealing white cast iron for malleable

White cast iron castings are loaded into metal boxes and covered with sand or steel filings to protect them from oxidation and slowly heated to a temperature of 950...1000 0C. During a long (10...15 hours) exposure at this temperature, the first stage of graphitization occurs. It consists of the decomposition of eutectic and excess secondary cementite.

By the end of the first stage, the cast iron consists of austenite and annealed carbon inclusions (A + D). Then the temperature is slowly reduced to 720...740 0C. In this case, the second stage of graphitization occurs.

During the exposure process (25...30 hours), perlite cementite disintegrates:

P(F + C) -> F + G

and malleable cast iron on a ferritic base is formed.

Pearlitic cast iron is produced by annealing, which is carried out in an oxidizing environment according to mode 2 (see Fig. 40). In this case, the duration of the first stage of graphitization is increased, after which the castings are continuously cooled to 20 0C. Austenite turns into pearlite (A -> P), and graphite remains in the structure. The result is malleable cast iron based on pearlite.

Malleable cast irons are marked with the letters KCH, followed by numbers indicating the guaranteed tensile strength in kgf/mm2

(10-1 MPa) and elongation in percent. Ductile iron grades:

- KCh-30-6; CC 35-10; KCh 37-12 - ferritic;

- CC 45-7; CC 60-3; KCh 80-1.5 - pearlite.

These cast irons are used to make high-strength parts that operate under severe wear conditions and are capable of withstanding shock and alternating loads. The high density of malleable cast iron castings makes it possible to produce parts for water and gas installations, valve bodies, faucets, and gate valves.

Highly durable

are called cast irons in which carbon is in a free state in the form of nodular graphite. They are obtained by modification with magnesium, which is introduced into liquid cast iron in an amount of 0.02...0.08%. Due to the fact that modification with pure magnesium is accompanied by a significant pyroelectric effect, an alloy of magnesium with nickel is used.

Cast iron after modification has the following chemical composition: 3.0...3.6% C; 1.1…1.9% Si;. 0.3...0.7% Mn;. up to 0.02% S and up to 0.1% P. According to the structure of the metal base, cast iron can be ferritic or pearlitic (Figure 41).

a-ferritic; b- pearlite

Figure 41 — Microstructure of high-strength cast irons

Nodular graphite is a less potent stress raiser than flake or flake graphite and therefore reduces less the mechanical properties of the metal base. Cast irons have high strength and some ductility, retaining their strength up to 500 0C (ordinary cast iron up to 400 0C). They are marked with the letters HF, followed by a number indicating the guaranteed tensile strength in kgf/mm2 (10-1 MPa). Ductile iron grades:

- HF 38; HF 42; HF 50 - ferritic;

- HF 60, HF 80; HF 120 - pearlite.

High-strength cast irons are used in various branches of technology, effectively replacing steel in many products and structures. For example, housings of steam turbines, pumps, valves, guide vanes, crankshafts, pistons and other critical parts operating under high cyclic loads and wear conditions.

In some cases, heat treatment of castings is used to improve the mechanical properties; to increase strength - hardening and tempering at 500...600 0C; to increase ductility - annealing.

The disadvantage of high-strength cast iron is significant volumetric shrinkage, which leads to the appearance of shrinkage porosity and gas pockets in castings.

Alloy cast iron > Continue >

Advantages and disadvantages

Like all cast iron alloys, white ones are distinguished by great strength combined with brittleness under strong mechanical shocks. Among the main positive qualities of white cast iron are:

- high hardness;

- high resistivity;

- wear resistance;

- increased corrosion resistance.

An important quality of white cast iron is considered to be very good resistance to high temperatures, which is used to reduce the number of cracks in initial castings.

The main disadvantages include such qualities as:

- fragility and the possibility of destruction under mechanical stress;

- low casting qualities and poor mold filling;

- the likelihood of internal cracks forming during casting;

- complex and low-quality mechanical processing.

Formation of defects during welding due to the rapid burnout of carbon and the formation of pores.

Application area

Ordinary white cast iron is used very limitedly, since it is poorly applicable to mechanical and heat treatment. For the production of products it is often used in the form of unprocessed or partially processed castings.

The alloy is most widely used in the manufacture of large parts of simple configuration. These are housings and parts of machine tools and rolling mills, balls for mills, drive and support wheels. In addition, white cast iron is used for the manufacture of assembly units that are constantly exposed to abrasive materials.

An important point is the use of ordinary cast iron as a raw material for the manufacture of malleable grades of iron-carbon cast iron and steel alloys.

Alloying of white cast iron

The presence of alloying additives in the alloy greatly changes its physical properties, which significantly expand its scope of application. Very common substances are used as alloying elements in metallurgy.

To increase hardness, the following can be added to an iron-carbon cast iron alloy: nickel, phosphorus, manganese, chromium, vanadium, silicon, copper, titanium and sulfur.

In the event that the amount of alloying additives is approximately equal to the carbon content, cast iron acquires the maximum possible hardness.

Wear resistance, as a physical characteristic of white cast iron, is considered regardless of its hardness. Its increase is achieved by changing the structure of the metal by adding carbides and phosphides in the form of evenly distributed inclusions. The quality of casting parts directly depends on the chemical composition of the alloys and the amount of alloying elements.

Depending on the percentage of alloying impurities, white cast iron is divided into:

- low alloyed up to 2.5%;

- medium alloyed up to 10%;

- highly alloyed.

Already finished cast iron castings are subjected to additional temperature treatment (annealing), as a result of which the internal stresses of the metal are relieved and the external dimensions are stabilized. The annealing temperature of white alloy cast iron is about 850°C.

The heating and cooling process occurs slowly to prevent the formation of internal cracks and other defects.

Alloy cast iron alloys are widely used in production:

- parts of industrial equipment and machine tools;

- components and parts of cars, tractors and agricultural machinery;

- rolling stock; pipes, pumps, boilers;

- household and household products.

This is due to the improved qualities of the metals compared to ordinary white cast iron.

Features of receiving

When producing white cast iron, it is important to exclude the graphitization process during crystallization of the melt, which is done:

- optimal selection of starting substances;

- technology for cooling the alloy in molds.

The degree of wear resistance of castings is largely determined by the nature and composition of carbides. Alloying the metal with nickel, manganese and chromium gives a martensitic carbide structure. When their total concentration is equal to the carbon content, the hardest structure is formed.

Most often, chromium is used as the main alloying additive. It gives the alloy high corrosion resistance, which is maintained even in aggressive environments. After normalization, these blanks are resistant to acids at temperatures up to 1000 degrees. Additional alloying with nickel (0.1%), titanium (0.5%) and copper (0.5-2.0%) gives the parts the ability to maintain their geometric shape and original dimensions under prolonged heating conditions.

Stainless alloys

To increase the resistance of white cast iron to corrosion, large amounts of chromium are added to it. This leads to the formation of an oxide film on the surface and further cessation of oxygen access. In addition, high-chromium white cast iron becomes resistant to alkaline solutions, sulfuric and nitric acid.

Additionally, the process of alloying with chromium prevents the possibility of coagulation of carbides when the alloy is heated strongly. This allows you to obtain high-quality welded joints of parts made of white cast iron. If nickel and molybdenum are added along with chromium during the alloying process, the resulting stainless alloy can be compared in strength to the best heat-resistant steels, which are much more expensive.

Chromium-containing white cast iron is used in cases of severe operating conditions, the presence of alkalis and oxidizing agents, and the need for high electrical resistance.

Marking

In industry, types of cast iron are labeled as follows:

- pig iron

– P1, P2; - pig iron for castings

– PL1, PL2, - pig iron

- PF1, PF2, PF3, - conversion high-quality cast iron

– PVK1, PVK2, PVK3; - cast iron with lamellar graphite (gray cast iron

- SCh (numbers after the letters “SCh” indicate the value of tensile strength in kgf/mm2, 1 kgf/mm2 = 10 MPa); - malleable cast iron

- KCh (the numbers after the letters “KCh” indicate the value of tensile strength in kgf/mm2 and relative elongation in%); - cast iron with nodular graphite for castings (high-strength cast iron)

– HF (the numbers after the letters “HF” indicate the value of tensile strength in kgf/mm2 and relative elongation in %); - anti-friction cast iron

(gray - AChS, high-strength - AChV, malleable - AChK); - alloyed cast iron with special properties

- Ch (the letters after the letter “Ch” indicate alloying elements: X - chromium, C - silicon, G - manganese, N - nickel, D - copper, M - molybdenum, T - titanium, P - phosphorus, Yu - aluminum).