Brass is an alloy of copper and zinc. The golden hue gives it a similarity to gold, but this compound is much cheaper. Pure copper is more expensive than brass. This is due to the lower cost of zinc, which is part of brass. The resulting alloy has characteristics that copper does not have at a lower price.

The alloy is resistant to environmental influences. However, it requires varnish to be applied to the surface, as it turns black over time. Due to its ductility and hardness, it is used both in industrial production and for the manufacture of costume jewelry as decorations.

Brass fittings

Classification of brasses

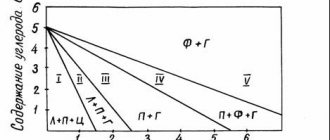

Depending on the chemical composition there are:

- Simple (two-component) brass. They contain only copper and zinc. Simple brass is marked with the letter “L” and a number that indicates the percentage of copper. For example: L85 contains 85% copper and 15% zinc.

- Special (multi-component) brass. They contain copper, zinc, lead, aluminum, iron and other elements that improve the basic properties of the material. Such elements are called alloying elements. Special brass is marked with the letter “L”, as well as letters and numbers indicating additional alloying elements and their percentage. For example: LA77-2 contains 77% copper, 2% aluminum and 21% zinc.

Special brasses are divided into classes named after the main alloying element (manganese, aluminum, silicon, tin, nickel, lead).

According to the degree of processing of brass there are:

• deformable (brass tape, wire, pipe, brass sheet); • foundry (fittings, bearings, instrument parts).

Read more about brass alloys

Brass L63, Brass LS59-1

There is also a classification based on the amount of zinc in the alloy:

• 5-20% zinc – red brass (tompak); • 20-36% zinc – yellow brass.

What is

This is one of the most recognizable materials on the planet. Like bronze, brass is not a metal, but an alloy.

It can be two- or multi-component. The base component of the alloy is the main non-ferrous metal of the planet, copper:

- In the first case, it is supplemented with zinc (up to 44%). This pair accounts for the bulk of the mass in the alloy.

- In multicomponent compositions, tin, lead, nickel, iron, manganese, and other alloys are added to zinc.

Zinc improves consumer properties, simultaneously reducing the price of the final product.

Brass is not a metal. Like bronze, it is a conglomerate of several components.

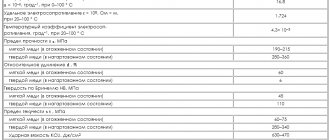

Basic properties of brass

Brass lends itself well to pressure processing. Mechanical properties are relatively high, corrosion resistance is satisfactory. If we compare brass with bronze, then their strength, corrosion resistance and anti-friction properties are less. They are not very stable in air, in salt sea water, carbon dioxide solutions and solutions of many organic acids.

Brass has a beautiful color and, compared to copper, has better corrosion resistance. However, as the temperature increases, the corrosion rate also increases. This process is most noticeable in thin-walled products. Corrosion can be provoked by: humidity, traces of ammonia and sulfur dioxide in the air. To prevent this phenomenon, brass products are subjected to low-temperature firing after processing.

Almost all brasses, when the temperature drops (to helium temperatures), remain ductile and do not become brittle, which makes it possible to use them as a good structural material. Due to the higher recrystallization temperature (300-370°C) than copper, the creep of brasses at high temperatures will be less. At average temperatures (200-600°C), the phenomenon of brittleness occurs, since impurities insoluble at low temperatures (for example: lead, bismuth) form brittle intercrystalline layers. As the temperature increases, the impact strength of brass decreases. Compared to copper, the electrical conductivity and thermal conductivity of brass is lower.

Is steel a ferrous or non-ferrous metal?

The question of whether steel belongs to ferrous or non-ferrous metals should be considered based on the classification of carbon alloys, which is provided for by many GOSTs.

According to various regulatory documents, steel is divided into the following types of ferrous metals:

- low-carbon, carbon and high-carbon alloys with a carbon content of up to 0.25; 0.25–0.6 and over 0.6%, respectively;

- low-alloy, medium-alloy and high-alloy grades of alloys with a controlled content of alloying additives up to 2.5; from 2.5 to 10 and over 10%, respectively;

- structural, tool, high-speed, corrosion-resistant, heat-resistant and other types of steel for various applications.

Of the entire extensive range of steel grades, only seven items form the group of non-magnetic alloys. We remind you that the absence of magnetic properties is the main characteristic of non-ferrous metals. At the same time, non-magnetic steel grades contain iron, which is one of the defining characteristics of ferrous metals.

Taking into account the small number of non-magnetic steels, they can be considered an exception to the general rule with an unclear status. From an ordinary point of view, it is generally accepted that ferrous metals are alloys that are susceptible to corrosion from atmospheric influences. Although high-alloy alloys can also rust.

Let's look at how alloying elements affect the properties of brass.

- Tin significantly increases the anti-corrosion properties in sea water and increases the strength of the alloy. Brass with tin is often called marine brass.

- Manganese increases strength and corrosion resistance. Manganese brasses are often combined with tin, iron and aluminum.

- Nickel improves corrosion properties and strength in various environments.

- Silicon reduces strength and hardness and also improves weldability. Brasses containing silicon and lead have good anti-friction properties. Such alloys can replace more expensive ones, such as tin bronze.

- Lead significantly improves machinability, but at the same time degrades mechanical properties. Lead brass is called automatic, since it is processed on automatic machines. This alloy is the most common.

- Aluminum reduces the volatility of zinc due to the formation of a protective film (aluminum oxide) on the surface of molten brass.

Is cast iron a ferrous or non-ferrous metal?

We remind you that the main difference between ferrous and non-ferrous metals is the presence or absence of magnetic properties. There are several grades of non-magnetic cast iron, for which nickel, manganese, silicon and chromium are used for alloying. The entire range of cast irons is divided into white, gray, malleable, high-strength and pig alloys. The absolute majority of them are cast irons with magnetic properties.

Cast iron is used in foundries, and only pig iron is used for subsequent steel smelting. Basically, cast iron is a ferrous metal, but non-magnetic alloys have a dual nature, which allows them to be classified as both groups of metals. By the way, some brands of alloy cast iron are also susceptible to corrosion under atmospheric influences.

Methods of obtaining

The technology for producing brass involves the processes of the copper and zinc industries, as well as the processing of recyclable materials. The raw materials for the production of alloys are blanks of copper, zinc and other metals for the production of multicomponent alloys. We also use our own production waste and secondary raw materials. All blanks are manufactured in accordance with GOST.

For smelting brass, various types of smelting furnaces are used, which are used for smelting copper alloys. The most effective are electric induction low-frequency furnaces with a magnetic core. Melting is carried out under exhaust ventilation, since some elements of the alloy evaporate intensely and can harm human health. It is undesirable to overheat the alloy, due to the likelihood of some components igniting in air. Pure and recycled metals are used as charges for smelting brass.

The raw materials are first prepared and the ovens are cleaned. Copper heated to red heat is placed in a furnace, and then lumps of zinc are added. When melting copper-zinc alloys, the significant oxidation of zinc is taken into account. To reduce oxidation, a number of measures are carried out. To make multi-component alloys, copper is added first, followed by the remaining components carefully.

The homogeneous mass is poured into molds to produce foundry brass. The result is flat and round ingots. After casting, wrought alloys undergo a deformation procedure. The resulting products differ in the degree of hardening and aging, as well as the hardness of the material. Preliminary heat treatment of workpieces significantly increases the strength and corrosion resistance of brass.

How to properly care

Under the influence of the external environment, brass becomes dull, losing its decorative qualities and brightness. To maintain the beauty and shine of the material, you need to properly and regularly care for it. Let's look at the main cleaning methods.

What is forbidden to wash

During production, copper alloy products are protected with a special coating. It is easy to damage a thin layer with sandpaper. Even the finest grain of abrasive material can scratch or completely remove the upper protective tier.

Prohibited means Source market.yandex.ru

To clean brass products, it is prohibited to use vinegar and acid-based products. The aggressive substance destroys the zinc in the alloy. As a result of dezincification, the metal acquires a poisonous red color.

Application

Cooling systems for motors, various bushings, and adapters are made from brass. The alloy is used in the construction industry. For example, for the manufacture of plumbing equipment and design elements. Fastening elements such as bolts and nuts are also made from brass. This alloy is used in shipbuilding and in the manufacture of ammunition.

There are several types of rolled brass:

- A brass rod

is a long metal product that is a blank for various parts. The rod has different cross-sectional shapes: round, oval, rectangular, square, hexagonal, trapezoidal. - A brass plate

is a flat semi-finished product with a rectangular cross-section more than 25 mm thick, which is produced by rolling or casting. The slabs are soft, hard, semi-hard and extra hard. Brass plates are used in industry for decorative finishing of buildings. - Brass wire

is an elongated profile of small diameter. Wire is used in the production of electrical equipment and decorative elements, as well as in mechanical engineering, aircraft manufacturing, welding and the footwear industry. - Brass pipe

– has high ductility, resistance to corrosion and wear. Pipes are used in housing and communal services, mechanical engineering, instrument making, and electric power. - A brass circle

is a solid round profile. The product is used in the automotive industry, instrument making, and in the manufacture of machine tools and mechanisms. - Brass sheet

is indispensable in printing, automotive, electrical power, instrument making, electrical, construction and chemical industries.

Story

The documented history of brass begins one hundred years BC:

- At this time, the production of the alloy was mastered by the ancient Romans.

- 900 years later, residents of the Near and Middle East met him. The source of raw materials (copper, lead) were deposits in northern Persia (present-day Iran).

- During the same period, it was brought to the Caucasus along the Silk Road.

- The British were the first Europeans to acquire alloying at the end of the 18th century. It was a copper-zinc material.

The material's popularity over thousands of years has been bolstered by its resemblance to gold.