3.2. Properties of solders

Brazing

carried out by electric contact method, graphite or copper electrodes or using arc welding. Small parts are soldered using an autogen. With the electric contact method, solder is placed in advance between the parts to be joined or introduced into the joint during the soldering process; welding is carried out without metal additives by fusing the ends of the parts being connected.

For electrical contact soldering with silver solders

Borax is usually used as a flux. Soldering with self-fluxing solders, which contain phosphorus, and welding in a protective atmosphere are carried out without the use of flux.

Solders containing phosphorus cannot be used for soldering steel and cast iron and joints subject to shock and vibration due to the brittleness of the soldered seam. The classification and chemical composition of soft and semi-hard solders are given in table. 3.1.

Table 3.1

Classification and chemical composition of soft and semi-hard solders

| Solder | Chemical composition, % | |||||||

| View | Brand | Tin | Antimony | Cadmium | Copper | Lead | Silver | Indium |

| Tin | O2 | 99,9 | – | – | – | – | – | – |

| Antimony-free | POS61 | 60–62 | – | – | – | Rest | – | – |

| POS40 | 39–41 | – | – | – | – | – | ||

| POS10 | 9–10 | – | – | – | – | – | ||

| POS61M | 60–62 | – | – | 1,5–2,0 | – | – | ||

| POSK50-18 | 49–51 | – | 17–19 | – | – | – | ||

| Low antimony | POSSu61-0.5 | 60–62 | 0,2–0,5 | – | – | Rest | – | – |

| POSSu40-0.5 | 39–41 | – | – | – | – | |||

| POSSu30-0.5 | 29–31 | – | – | – | – | |||

| POSSu18-0.5 | 17–18 | – | – | – | – | |||

| Antimony | POSSu95-5 | 94–96 | 4–5 | – | – | Rest | – | – |

| Silver | PSrO10-90 | Rest | – | – | – | – | 10±0,5 | – |

| PSrOSu8 (VPr-6) | – | – | – | – | – | 8±0,5 | – | |

| PSrMO5 (VPr-9) | – | – | – | 2±0,5 | – | 5±0,5 | – | |

| PSrOS3.5-95 | – | – | – | – | 3,5±0,4 | – | ||

| PSrOS3-58 | 57,8±1,0 | – | – | – | – | 3±0,4 | – | |

| PSr3 | – | 3±0,3 | – | |||||

| PSr3Kd | – | – | 95–97 | – | – | 3,0–4,0 | – | |

| PSrO3-97 | Rest | – | – | – | – | 3±0,3 | – | |

| PSr2.5 | 5,0–6,0 | – | – | – | 91–93 | 2,2–2,7 | – | |

| PSr2.5S | – | – | – | – | – | 2,5±0,2 | – | |

| PSr2 | 30±1 | 2±0,2 | – | |||||

| PSrOS2-58 | 58,8±1,0 | – | – | – | – | 2±0,3 | – | |

| PSr1.5 | 15±1 | – | – | – | – | 1,5±0,3 | – | |

| PSr1 | 35±1 | – | – | – | – | 1±0,2 | – | |

| Indium | POSI30 | 42 | – | – | – | 28 | – | 3 |

| PSR3I | – | – | – | – | – | 3 | 97 | |

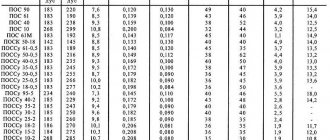

The physical and mechanical properties of soft and semi-hard solders are given in Table. 3.2.

Table 3.2

Physical and mechanical properties of soft and semi-hard solders

| Solder grade | melting point, °C | approximate soldering temperature, °C | density, kg/m³ | specific electrical resistance, μm m | limit of mechanical tensile strength, MPa | |

| solidus | liquidus | |||||

| O2 | 232 | 232 | 280 | 7310 | – | 25 |

| POS61 | 183 | 190 | 240 | 8500 | 0,139 | 43 |

| POS40 | 183 | 238 | 290 | 9300 | 0,159 | 38 |

| POS10 | 268 | 299 | 350 | 10800 | 0,200 | 32 |

| POS61M | 268 | 192 | 240 | 8500 | 0,143 | 45 |

| POSK50-18 | 142 | 145 | 185 | 8800 | 0,133 | 40 |

| POSSu61-0.5 | 183 | 189 | 240 | 8500 | 0,140 | 45 |

| POSSu50-0.5 | 183 | 216 | – | 8900 | 0,149 | – |

| POSSu40-0.5 | 183 | 235 | 285 | 9300 | 0,169 | 40 |

| POSSu35-0.5 | 183 | 245 | – | 9500 | 0,172 | – |

| POSSu30-0.5 | 183 | 265 | 306 | 9700 | 0,179 | 36 |

| POSSu25-0.5 | 183 | 266 | – | 10000 | 0,182 | – |

| POSSu18-0.5 | 183 | 277 | 325 | 10200 | 0,198 | 36 |

| POSSu95-5 | 234 | 240 | 290 | 7300 | 0,145 | 40 |

| POSSu40-2 | 185 | 229 | – | 9200 | 0,172 | – |

| POSSu33-2 | 185 | 243 | – | 9400 | 0,179 | – |

| POSSu30-2 | 185 | 250 | – | 9600 | 0,182 | – |

| POSSu25-2 | 185 | 260 | – | 9800 | 0,183 | – |

| POSSu18-2 | 188 | 270 | – | 10100 | 0,206 | – |

| POSSu15-2 | 184 | 275 | – | 10300 | 0,208 | – |

| POSSu10-2 | 268 | 285 | – | 10700 | 0,208 | – |

| POSSu8-3 | 240 | 290 | – | 10500 | 0,207 | – |

| POSSu5-1 | 275 | 308 | – | 11200 | 0,200 | – |

| POSSu4-6 | 244 | 270 | – | 10700 | 0,208 | – |

| PSrO10-90 | – | 280 | – | 7600 | 12,9 | – |

| PSrOSu8 (VPr-6) | – | 250 | – | 7400 | 19,7 | – |

| PSrMO5 (VPr-9) | – | 240 | – | 7400 | 16,3 | – |

| PSrOS3.5-95 | – | 224 | – | 7400 | 12,3 | – |

| PSrOS3-58 | – | 190 | – | 8600 | 14,5 | – |

| PSr3 | – | 315 | – | 11400 | 20,4 | – |

| PSr3Kd | 300 | 325 | 360 | 8700 | 8,0 | 54 |

| PSr2.5 | 295 | 305 | 355 | 11000 | 21,4 | – |

| PSr2.5S | – | 306 | – | 11300 | 20,7 | – |

| PSr2 | – | 238 | – | 9500 | 16,7 | – |

| PSrOS2-58 | – | 183 | – | 8500 | 14,1 | – |

| PSr1.5 | – | 280 | – | 10400 | 19,1 | – |

| PSr1 | – | 235 | – | 9400 | 26,0 | – |

| POSI30 | 117 | 200 | 250 | 8420 | – | – |

| PSR3I | 141 | 141 | 190 | 7360 | – | – |

The essence of soldering

Actually, what is soldering? This is the connection of conductors (such as wires or wires and traces on a board) using low-melting solder. It sounds simple, but in fact it is fundamentally important to ensure two things:

- reliable connection so that there is good contact all the time,

- sufficient connection area so that the soldering area does not overheat (relevant for power circuits).

- Exploitation

Why doesn't rain short-circuit high-voltage lines?

However, it is worth noting that the solder itself has a high resistivity. Therefore, it is necessary that the thickness of the coated layer be small, and the coating area, on the contrary, be larger. Also note that the thicker the conductor (such as wire), the larger the area that needs to be covered.

Preferred areas of application for soft and semi-hard solders:

O2

— tinning and soldering of collectors, armature sections and windings of electrical machines with class H insulation, tinning of critical fixed contacts, including those containing zinc;

POS90

— tinning and soldering of internal seams of food utensils and medical equipment;

POS61

- tinning and soldering of electrical and radio equipment, printed circuit boards, precision instruments with highly sealed seams where overheating is not allowed;

POS40

— tinning and soldering of electrical equipment, galvanized iron parts with sealed seams;

POS10

— tinning and soldering of contact surfaces of electrical devices, instruments, relays;

POSK50-18

— soldering of parts made of copper and its alloys that are sensitive to overheating, including soldering of copper-clad aluminum. Soldering of ceramics, glass and plastics metallized with tin, silver, nickel;

POS61M

— soldering of food utensils, medical equipment, electrical and radio equipment, printed circuit boards, parts sensitive to overheating;

POSSu61-0.5

— tinning and soldering of electrical equipment, soldering of printed circuit boards, windings of electrical machines, galvanized radio components under strict temperature requirements;

POSSu50-0.5

— tinning and soldering of aircraft radiators;

POSSu40-0.5

— tinning and soldering of sheet metal, windings of electrical machines, for soldering mounting elements of winding and cable products;

POSSu35-0.5

— tinning and soldering of lead cable sheaths;

POSSu30-0.5

– tinning and soldering of zinc sheets, carbon and stainless steels. Tinning and soldering of wires, cables, bands, radiators, various parts of equipment and devices operating at temperatures up to 160 ° C;

POSSu25-0.5

— tinning and soldering of radiators;

POSSu18-0.5

— tinning and soldering of heat exchanger tubes, electric lamps;

POSSu95-5

;

PSr3Kd

- hot tinning and soldering of collectors, armature sections, bandages and current-carrying connections of heat-resistant electric machines with high rotation speeds. Soldering of pipelines and various parts of electrical equipment.

POSSu40-2

— general-purpose solder;

POSSu30-2

— tinning and soldering in refrigeration equipment manufacturing, electric lamp production;

POSSu18-2, POSSu15-2, POSSu10-2

— soldering in the automotive industry;

POSSu8-3

— tinning and soldering in electric lamp production;

POSSu5-1

— tinning and soldering of parts operating at elevated temperatures;

POSSu4-6

— soldering of tinplate, tinning and soldering of parts with rolled and riveted seams made of brass and copper;

POSSu4

—

4

— tinning and soldering in the automotive industry;

POSK2-18

— tinning and soldering of metallized ceramic parts;

POSI30

;

PSr3I

- soldering of copper and its alloys and other metals, non-metallic materials and glass with metal coatings. Soldering of electronic equipment parts. It has high fluidity and provides good adhesion of soldered surfaces.

The parameters of soft solders with low melting points are given in table. 3.3.

Table 3.3

Soft solders (alloys) with low melting points

| alloy | chemical composition, % | melting point, °C | ||||||

| tin | lead | cadmium | bismuth | silver | indium | solidus | liquidus | |

| Wooda | 12–13 | 24,5–25,6 | 12–13 | 49–51 | – | – | 66 | 70 |

| Rose | 24,5–25,5 | 24,5–25,6 | – | 49–51 | – | – | 90 | 92 |

| D'Arce | 9,6 | 45,1 | – | 45,3 | – | – | – | 79 |

| Lipovica with indium | 11,8 | 22,2 | 8,5 | 42 | – | 15,5 | – | 48 |

Note. They are used in radio circuits with semiconductor devices and in circuits where solder is used as a temperature fuse.

The chemical composition and physical and mechanical properties of solid silver and copper-phosphorus solders are given in Table. 3.4.

Table 3.4

Chemical composition and physical and mechanical properties of solid silver and copper-phosphorus solders

| Solder grade | chemical composition, % | density, kg/m3 | crystallization temperature, °C | tensile strength, MPa | ||||

| silver | Copper | zinc | phosphorus | Start | end | |||

| PSr72 | 72±0,5 | 28±0,5 | – | – | 9900 | 779 | 779 | – |

| PSr50 | 50±0,5 | 50±0,5 | – | – | 9300 | 850 | 779 | – |

| PSr45 | 45±0,5 | 30±0,5 | 25+1 –1,5 | – | 9100 | 725 | 660 | 300 |

| PSr25 | 25±0,3 | 40±1 | 35±2,5 | – | 8700 | 775 | 745 | 280 |

| PSr71 | 71±0,5 | 28±0,7 | – | 1 ±0,2 | 9800 | 795 | 750 | – |

| PSr25f | 25±0,5 | 70±1 | – | 5±0,5 | 8500 | 710 | 650 | – |

| PSr15 | 15±0,5 | 80,2±1 | – | 4,8+0,2/–0,3 | 8300 | 810 | 635 | – |

| PMF7 (MFZ) | – | Rest | – | 7–8,5 | – | 860 | 710 | – |

The parameters of copper-zinc and copper-nickel hard solders are given in table. 3.5.

Table 3.5

Copper-zinc and copper-nickel hard solders

| Solder grade | chemical composition, % | physical properties | |||||||||

| Copper | nickel | iron | silicon | Bor | zinc | tin | crystallization temperature, °С | density, kg/m3 | tensile strength, MPa | ||

| solidus | liquidus | ||||||||||

| L63 | 62–65 | – | – | – | – | Rest | – | 900 | 905 | 8500 | 310 |

| LOK59-0.1-0.3 | 60,5– 63,5 | – | – | 0,2–0,4 | – | Rest | 0,7–1,1 | 890 | 905 | 8200 | – |

| PZHL500 | Rest | 27–30 | 41,5 | 1,5–2 | 0,2 | – | – | 1080 | 1120 | 8630 | 600 |

The parameters of silver solders with a low melting point are given in table. 3.6.

Table 3.6

Silver solders with lower melting points

| Solder grade | chemical composition, % | density, kg/m3 | crystallization temperature, °С | ||||||

| silver | Copper | zinc | cadmium | tin | nickel | Start | end | ||

| PSr50Kd | 50±0,5 | 16±1 | 16±2 | 18±1 | – | – | 9300 | 650 | 635 |

| PSr40 | 40±1 | 16,7+0,7/–0,4 | 17+0,8/–0,4 | 26+0,5/ –1 | – | 0,3±0,2 | 8400 | 605 | 595 |

| PSr62 | 62±0,5 | 28±1 | – | – | 10±1,5 | – | 9700 | 700 | 660 |

The preferred areas of application of hard solders are given in table. 3.7.

Table 3.7

Preferred applications of brazing alloys

| Solder grade | application area |

| PSr72; PSr50 | Soldering of metal-ceramic contacts and various critical current-carrying connections subject to bending and impact loads |

| PSr45 | Soldering of copper and its alloys, stainless and structural steels. Soldering of short-circuited rotor windings and damper windings of highly loaded electrical machines. Solder provides high density and strength of soldered seams |

| PSr25 | Soldering of copper and its alloys, stainless and structural steels, replaces PSr45 solder when making less critical connections |

| PSr71 | Soldering parts is similar to PSr72 solder, but where greater fluidity is required |

| PSr25f; PSr15; PMF7 | Soldering of copper and its alloys, including various current-carrying parts of machines and devices that do not experience shock and bending loads |

| L63; LOK59-0.1-0.3 | Soldering copper and cast iron. Soldered joints have high strength and perform well under shock and bending loads |

| PZHL500 | Soldering of connections operating at temperatures up to 600 °C |

The parameters of copper-phosphorus solders are given in table. 3.8.

Table 3.8

Copper-phosphorus solders

| Solder grade | chemical composition, % | melting point, °C | |

| Copper | phosphorus | ||

| PFM-1 | 90,0–91,5 | 8,5–10 | 725–850 |

| PFM-2 | 92,5 | 7,5 | 710–715 |

| PFM-3 | 91,5–93,0 | 7,0–8,5 | 725–860 |

| PMF7 (MF3) | Rest | 7,0–8,5 | 710–860 |

Note. For copper-phosphorus and silver solders, borax is used as a flux in powder form or mixed with table salt.

The parameters of solders for soldering aluminum are given in table. 3.9, 3.10.

Table 3.9

Chemical composition and physical properties of solders for aluminum soldering

| Solder grade | chemical composition, % | melting temperature, °С | limit of mechanical tensile strength, MPa | |||||

| aluminum | Copper | tin | zinc | cadmium | silicon | |||

| Cadmium | – | – | 36 | 40 | 24 | – | – | 85 |

| AVIA-1 | – | – | 55 | 25 | 20 | – | 20 | – |

| AVIA-2 | 15 | – | 40 | 25 | 20 | – | 250 | – |

| VPT-4 | 55 | – | – | 40 | – | 5 | 410 | – |

| 34-A | 66 | 28 | – | – | – | 6 | 545 | 180 |

| 35-A | 72 | 2,1 | – | – | – | 7 | 540 | 140 |

| A | – | 2,0–1,5 | 40 | 58,5 | – | – | 425 | 80 |

| IN | 12 | 8 | 80 | – | – | 410 | 185 | |

| TsO-12 | – | – | 12 | 88 | – | – | 500–550 | – |

| TsA-15 | 15 | – | – | 85 | – | – | 550–600 | – |

Table 3.10

Other solders for aluminum soldering

| Solder grade | chemical composition, % | temperature of complete melting, °С | soldering temperature, °C | density, kg/m3 | ||||

| tin o1 | zinc | cadmium | aluminum a7 | Copper M0 | ||||

| P250A | 79–81 | 19–21 | – | – | 0,15 | 250 | 300 | 7300 |

| P300A | – | 50–61 | 39–41 | – | 0,045 | 310 | 360 | 7730 |

| P300B | – | 80 | – | 8 | 0,5 | 410 | 700–750 | – |

The primary areas of application of solders for soldering aluminum P250A, P300A and P300B are given in table. 3.11.

Table 3.11

Preferred areas of application of solders for aluminum soldering

| Solder grade | application area |

| P250A | Tinning of the ends of aluminum wires, as well as dip soldering of aluminum wires with aluminum and copper tips |

| P300A | The same, soldering of connections with increased corrosion resistance |

| P300B | Fill soldering of aluminum wires with aluminum and copper parts |

For aluminum

Fontargen F 400 M powder for alloys with a small percentage of magnesium rods for argon welding. Provides tightness. Requires extensive washing - actively corrodes.

Read also: What are the levels of the Olympiads?

Castolyn FBK 192, flux cored solder. Recommended for thin-walled structures with preliminary tinning and creating a gap around the perimeter of 0.2 mm. Shell composition Zn-98%, Al-2%. Advantages of the material:

- No residual corrosion;

- Stability of wettability and fluidity at t 440;

- Acceleration of crystallization;

- Reliable fusion of aluminum with stainless steel, galvanized ferrous metal, copper.

Castolin 192 is suitable for restoring internal threads in body parts, repairing and sealing surface holes, including without applying patches. Overlapping connection.

3.3. Classification of fluxes and their designation system

Soldering fluxes

- substances and compounds used to prevent the formation of an oxide film on the surface of the solder and soldered material, as well as to remove oxidation products from the soldering zone. The melting point of fluxes is lower than the melting point of solder. Fluxes are used in solid, paste and powder form, as well as in the form of aqueous, alcohol or glycerin solutions.

Fluxes

used for soldering are classified according to: temperature range of activity;

nature of the solvent; the nature of the activator of the determining action; mechanism of action; state of aggregation. Depending on the temperature range of activity,

soldering fluxes are divided into: low-temperature (≤ 450 ° C); high temperature (> 450 °C).

By the nature of the solvent

soldering fluxes are divided into: water-based; non-aquatic

By the nature of activators

Low-temperature soldering fluxes

that determine their action are divided into: rosin; acidic; halide; hydrazine; fluoroborate; aniline; stearic.

By the nature of the activators of the determining action, high-temperature soldering fluxes

divided into: halide; fluoroborate; boride-carbon dioxide.

If the flux contains several activators, all activators must be named. For example, rosin-halide, fluoroborate-halide flux.

By mechanism of action

soldering fluxes are divided into: protective;

chemical action; electrochemical action; reactive. According to their state of aggregation,

soldering fluxes are divided into: solid; liquid; pasty.

Solder pastes

Solder paste (Tinol) is a mixture of solder and flux. This material cannot be replaced when soldering in hard-to-reach places and when installing unframed radio components. To do this, you need to apply the paste in the required amount to the soldering area and heat it with an electric soldering iron (full melting temperature 200°C). Flux residues after soldering are non-hygroscopic, non-conductive and non-corrosive.

You can make your own pasta. To do this, you need to choose a brand of solder and prepare sawdust using a file with a large notch. Then mix them with liquid flux to obtain a paste-like composition. The paste should be stored in an airtight container. The paste has a shelf life of no more than six months.

It is known that the main function of solder is good diffusion with the metal surface. In addition, it must have optimal temperature viscosity, allowing it to be evenly distributed over the surface of metals. This factor of high-quality tinning is possible only in the absence of fatty deposits and oxides on the surfaces being soldered, the removal of which is carried out by fluxes. Therefore, the final quality of the work will depend on what solders and fluxes you choose for soldering with a soldering iron.