Processing the harvest of berries and fruits is one of the most important tasks that not only farmers, but also owners of personal plots have to solve. Technical devices that greatly facilitate this process include a juice press, which allows you to quickly and without significant physical effort turn fruits and berries into tasty juice rich in vitamins. There is a wide variety of such devices on the modern market, but those home craftsmen who want to save money on purchasing them can easily make such a press with their own hands.

Extracting juice using a garden press

Design options

All juice press models have some common elements:

- Frame. The barrel, drives and all other parts are attached to it. It is usually made of thick, strong metal, since it must support the weight of the entire structure (plus the fruit). Additional beams can be welded at the bottom of the frame to create a cross. This will make the frame more stable.

- Drum-shaped mesh. A lattice just on the bottom will not work, as the fruit will diverge in all directions under pressure. The mesh is installed over the entire internal surface of the structure. At the same time, it must be very durable. Therefore, a drum from a washing machine is often used, and the grate is also made from wooden blocks.

- Barrel with a tap at the bottom. Actually, the juicer body itself, where the mesh should be installed. The barrel must be strong (made of metal). There should be a tap at the bottom, preferably with a handle that can be used to close and open it.

- Pressure mechanism and cover. The drum grid is placed in a barrel, fruits are poured inside (preferably in a bag), and everything is covered with a lid on top, which plays the role of a piston. A mechanism is mounted on the lid that will push it down. In a screw device, this function is performed by a screw.

Devices that create pressure in the tank can be different:

- Mechanical. A hole is made in the top crossbar of the frame with a screw thread inside. A screw piston is inserted into this hole. It is attached to the lid at the bottom, and a handle-bar is mounted on top. A person needs to screw in the piston himself using a handle. The design is extremely simple, but requires physical effort.

- Hydraulic. A system where a device is placed between the cover and the upper frame beam that uses the force of a fluid to create pressure. Such a device in homemade juice presses is often a jack. The latter can have a manual or electric drive.

- Pneumatic. In this case, energy is transferred using air rather than liquid. However, often the same jack, but of a pneumatic design, acts as a mechanism. The drive can also be electrical or mechanical.

You can also distinguish types of presses based on the type of device that transfers pressure from the power plant to the fruit:

- A press with a piston that moves down and up in a cylinder. The fruits are placed in a container, and the piston presses from above. This type of device is the most common and popular due to the simplicity of the design and the low cost of all its components.

- Auger. In this case, the press is more like a meat grinder. Usually this type is not used by summer residents, since it is almost impossible to create it with your own hands. Firstly, you will need a large auger, which is difficult to find. Secondly, such devices require an electric drive, which also complicates and increases the cost of the design.

Worm gear or hydraulic jack: what to choose?

The screw (worm) mechanism in the press is implemented in the form of a large screw (threaded axis) with a nut or a mechanical jack. The latter option is much simpler - you can buy it at a spare parts store or take it out of the trunk of a car; you don’t need to look for, adjust, grind or weld anything.

Designs based on a hydraulic jack are much more productive

(force from 1t) than mechanical ones, and require a minimum of human labor. Hydraulic bottle jacks make it possible to squeeze juice quickly and in large volumes. They fit comfortably into any design.

You can design a press with a removable mechanism, then you don’t have to buy a special jack, but you can use the one on duty in the trunk. After all, the apple harvest is not good every year.

Necessary tools and materials to make a juice press

To work you will need the following tools:

- circular saw for metal;

- a regular saw (if the grate is made of wood);

- planks, wooden planks, stainless steel sheets;

- corners;

- hammer;

- bolts;

- nuts;

- spanners;

- welding machine;

- pliers;

- wire cutters;

- polypropylene sugar bag.

You will need the following materials for the press:

- metal beams for the frame;

- wooden blocks or strong steel tubes;

- screws, bolts, nuts;

- metal tank, preferably stainless steel, but iron can also be used;

- faucet with opening handle;

- jack or threaded screw.

Manufacturing of main parts

Let's look at the basic elements of the press and how they can be made.

Frame

You need to take metal beams and weld them into a frame in the form of a rectangle. But at the same time, it is necessary to make sure that the tank fits freely inside, and there is also free space between it and the upper beam. At the bottom, small blocks can be welded perpendicular to the frame to make a cross, thanks to which the structure will become stable.

An approximate drawing is shown above, but the actual dimensions must be taken based on the dimensions of the tank and those beams that are available.

It is recommended to make everything from iron to make the structure as durable as possible, but wood can also be used.

Tank

A desirable but optional design element. It is made from stainless steel. If ordinary steel or cast iron is used, then the inside must be coated with an anti-corrosion coating. The tank needs to be round, so the load will be distributed evenly.

Approximate dimensions: half a meter in height and 30-40 cm in diameter. But in general, the tank that is available is taken. Of course, it should not have any chips, holes, rust, or mold. A hole is made at the bottom for the tap.

Pallet

If there is no tank, then you can make an open juice press, without walls. But this will require a tray that will collect the juice. It is usually taken from a simple large flower pot. This choice, although cheap, is not practical, since this material is easily chipped and difficult to process. It is better to make a metal tray from a basin. Or weld it from stainless steel sheets. You need to make a hole at the bottom for the tap.

Tap

It's better to find a tank with a tap at the bottom. But if there is no such container, then it must be welded. First you need to buy the faucet itself. Then find a tube that fits its diameter and make a cut on it, and then weld it to the tank.

The cut screw part is wrapped with double-sided thin adhesive tape. This way the faucet will hold tighter, and the tightness will also be higher.

Then the tap itself is installed. It must have a closing valve so that you can stop the flow of juice so that it does not spill when not needed.

Lattice

The inner drum from a washing machine is best suited as a grille. But if it is not there, then you can make a lattice from wooden blocks. They must be at least 2 cm thick, as they will have to withstand heavy loads.

You cannot use chipboard, as it produces sawdust, resins and other harmful elements.

To create the wall, take two flexible stainless steel strips of the same length as the circumference of the tank. You will also need bars half a meter high, 2 cm thick and wide, as well as self-tapping screws coated against corrosion. The boards are placed in a row so that there is a gap of 1 cm between them. The bars are fastened into a single flexible sheet using two strips of stainless steel and self-tapping screws.

A “raft” is hammered together to create the lid and bottom. Between the bars located on the same plane, the distance should be half a centimeter. First, they knock together a lattice, and then cut out a circle of the required diameter from it.

Filters

It is best to use a polypropylene sugar bag as a filter. You can use linen, lavsan or polyester. But the latter often tear quickly, and the canvas will experience heavy loads.

Power element of the structure

There are several types of juice presses, each of which uses a different power element.

Press with jack

The easiest way to use a press is to use a jack. However, it does not have to be installed there forever. In addition, a device designed for 3-5 tons is sufficient. Hydraulic and pneumatic devices are suitable.

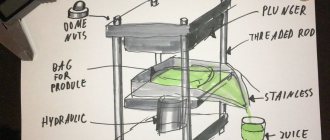

The figure above shows a design using a jack. There are wooden gratings inside the frame. In this case, a scheme is used without using a tank, but with a tray below. The jack is placed on the board and rests against the top beam of the frame. The photo below shows a similar design in real life.

Press with screw

If a person was unable to get a jack, then he can make a screw juice press with his own hands. The screw will require a long iron beam. In addition, it needs to be threaded and a corresponding nut made, which will then need to be welded to the frame. So the service of a turner will be required, so mechanisms with a jack are preferable.

The nut is welded to a hole in the top of the frame. The screw is pushed through it. In its upper part you need to make two identical handles lying in the same plane, opposite each other. This is required so that they balance each other during rotation and do not create vibrations on the screw.

Of course, the screw does not have to be firmly attached to the lid. But you can make a hollow in it, in which the lower end of the screw will stand securely.

Screw press

The difficulty in making a screw juicer lies in the screw itself. This part must have axial symmetry; its blades must also have the same height. In this case, it is desirable that the knives have the same angle of inclination along the entire length of the screw. At the same time, since the auger will have a decent mass, it is difficult to turn it manually. Therefore, an electric motor will also be required.

Above is an example of a screw press for juice. There is an electric motor at the back that drives the propeller. There is a cylinder in the center where the auger is located, and a loading hopper is attached to it on top. There are a lot of holes in the front of the cylinder through which the juice comes out. It falls on a tray, along which it flows into a container. The implementation of the press according to this scheme is shown in the photo below.

When to buy

Tabletop manual mechanical mini press

But when you under no circumstances need to make a press yourself, it is when you are engaged in precision mechanics, optics, or jewelry work. All homemade presses are not particularly accurate: you can’t make them better at home and/or homemade conditions. And an inaccurate mini-press can break or irreparably damage a tiny irreplaceable part, crack a lens, a gemstone, etc. In these cases, it is still better to purchase a desktop mini-press; Of these, manual mechanical rack and pinion (see figure on the right) are widely available and their prices are reasonable.

How to make a juice press

Let's consider two design options: mechanical screw and hydraulic with a piston.

Mechanical screw press

First of all, you need to make a lattice. To do this, take a stainless steel sheet 1.2-1.5 meters long, half a meter high and a couple of millimeters thick. Holes with a diameter of 5 mm are made in it in a checkerboard pattern. The distance between holes is 2 cm.

Next, you need to roll the sheet into a short, mundane cylinder. It is necessary to bring one side behind the other, as shown in the photo below, and then weld them together.

Next, using the same scheme, you need to make a tank (without holes), which will be slightly larger in diameter than the grille. The tank does not have to have a bottom. An ordinary metal pallet can perform its task. Then an iron frame is made to fit the dimensions of the tank.

A hole is made in the top of the frame. A suitable nut is welded to it, into which the screw is inserted.

Next, the entire structure is assembled.

At the end you can apply anti-corrosion paint.

Hydraulic juice press

Let's consider a more complex design of a manual juice press with a built-in grinding device. It is useful for processing large and hard fruits (for example, apples).

First you need to find a tank or make a cylinder with a tray.

You need to make a lid and a bottom for it. They are made of wooden beams, about 2 cm thick. They are laid in two planes in a lattice with a gap between the planks of 0.5-1 cm.

Next, the bars are attached to each other using self-tapping screws.

Then a circle of the required diameter is cut out from this blank. The bottom is made flush with the tank so that the drainage wall can be placed on it. But the lid, on the contrary, should fit into the grill freely, so its radius is made smaller by 2.2-2.5 cm. You need to make several of them (2-3 pieces). One covers the entire structure from above, the others must be placed between the bags (they will become intermediate).

A circle is cut out with a circular saw.

The drainage grate is also made from timber. A gap of 0.5-1 cm is needed between the planks. The bars themselves must be thick enough (2 cm), since they will be subject to load. All planks are connected by two stainless steel metal strips.

A wooden grate is placed at the bottom.

Wooden grate at the bottom.

Next, a drainage wall is installed.

The entire structure must be covered with a lid on top.

Next, the metal frame is welded according to the above recommendations.

A cross is welded to the bottom, which will make the structure more stable.

To attach the crusher with the motor, an additional pair of plates is attached to the main frame (perpendicular to each other).

It is better to make the shaft with knives from stainless steel. They are fixed at the bottom of the crusher.

The system is assembled so that both shafts are at the bottom. It's safer and prettier.

An old steering rod is fitted under the belt tensioner. The finished crusher consists of a 220 V motor, a transmission shaft, a working container and blades inside.

The tank is placed inside the frame, and the hole in the crusher is made so that it goes directly into the tank. The photo below shows a fully completed juice press.

We put the bag of fruit inside, cover it with a lid, put a jack on it and gradually increase the pressure. However, wooden blocks will also be required, since the level of the lid will drop significantly.

Wooden juice press

The press will require the following materials:

- for the frame - 3 boards measuring 40*100 mm and 3 meters long;

- to fasten these bars you will need a threaded rod 14 mm wide and 1 meter long;

- also to create the frame you need 8 nuts 14 mm wide;

- for pallets you will need 5 slats with a cross section of 20*40 mm and a length of 3 meters;

- for the table you need a piece of plywood with an area of 30*30 cm;

- You can use a baking tray as a tray, in which you can make a hole for juice;

- To create pressure you need a jack. A weak model for 1-2 tons is enough;

- To extract juice, you will need dense, durable fabric: calico, linen, polypropylene.

To begin with, you can cut all the workpieces to the desired size.

Large boards for the frame should be cut into the following blocks:

- two of them: 950, 650, 650, 650 mm;

- one: 950, 950, 300, 300, 300 and 200 mm.

The pallet will consist of 12 slats, which are stacked crosswise. Therefore, 5 narrow boards are divided into sections 30 cm long. In total, you get 50 slats (12 per pallet, of which there are 4 pieces).

The threaded rod is divided into 4 sections of 25 cm each.

To assemble the frame, you need to carefully drive the slats onto the sections of the threaded rod. To ensure that no traces of blows remain on the boards, you must either use a mallet or place a piece of wood under an ordinary hammer.

In this case, it is extremely important to make all angles of the frame 90° so that the structure does not become loose. Finally, you need to tighten the studs with nuts.

A table on which the pallet will be located is screwed to the bottom of the frame.

We attach a short block to the top of the frame, against which the jack will rest. You can make a round metal heel stop in the center to prevent the jack from leaving marks on the wood.

Next, you need to make an element on which the jack is placed.

The pallets are assembled using stainless steel screws, as they will be constantly in the juice.

Additionally, you can make a frame where apples wrapped in filter cloth will go.

Wooden parts that will be in direct contact with the juice must be made of a material that does not give off odor. Therefore, any coniferous trees are not suitable.

Metal parts must be coated with an anti-corrosion coating. It is better to cover it with silver dust.

Preparation of raw materials

The principle of squeezing apple juice

simple - the finer the raw materials are chopped, the more product will be obtained at the exit. It is best to use a special chopper (crusher), since finely chopping several buckets of apples by hand is theoretically possible, but in fact difficult to implement. An electric meat grinder for large volumes is also not an option: it roars, howls, gets hot, and may eventually burn out. You can also make a suitable crusher yourself.

The simplest design of a homemade crusher

A deep hopper is mounted lightly on the cone from moisture-resistant plywood or stainless steel sheet. For stability, two bars are attached to it from below. A wooden roller (preferably made of beech) with self-tapping screws wound in a spiral is cut into the lower part of the container. You can use a regular kitchen rolling pin as a drum.

. The axis of rotation of the roller comes out, a drill is inserted into it and the process begins.

Some people simply crush apples in a bucket using a construction mixer.

How to use the press

Before work, all fruits are washed and cleaned of rotten parts. Before pressing, they are poured into polypropylene or other durable bags. Make sure there are no holes in it first. This filter is needed to retain the pulp so that only the juice is released. The bag itself with fruits or berries is thrown into the tank.

Before work, the inner surface of the tank, tray, grille, lid and other elements are cleaned and washed. It is advisable to treat them with an antiseptic (chlorhexidine, alcohol, something else). The latter is necessary to prevent pathogenic bacteria from getting into the juice.

During the process, you need to monitor the condition of the bag to see if there is a risk of rupture. Watch for a gradual increase in pressure, do not increase it too quickly. At the end there should be dry cake left.