- Preparation of orthophosphoric acid Method based on the use of high temperatures

- Production of a mixture under the influence of inorganic acids

- Purification and concentration

- Application in medicine

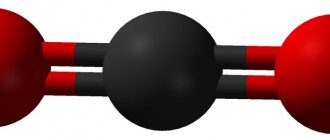

Orthophosphoric acid belongs to the category of medium strength inorganic type, the combination formula is H3PO4.

At standard temperature and pressure conditions, the reagent appears as very small, colorless, odorless crystals. At average air temperatures, the dehydrate appears as micro-sized diamond-shaped crystals. The second name of the product is phosphoric acid, which looks like an 85% transparent, odorless liquid. The crystals completely decompose when mixed with solvents. Dissociation equation H3PO4 = 3H(+) + PO4(3-). The dehydrate consists of three atoms, so decomposition takes three stages. The molar mass of the chemical combination is 98 grams per 1 mole. The molecular weight is equal to the value of 98.

Phosphoric acid has the following main characteristics:

- when mixed with chemical indicators, the color of the product changes to red;

- at high temperatures forms a pyrophosphorus combination;

- Crystals disintegrate in water in three standard stages;

- when combined with strong derivatives, it forms polyhedral salts;

- when combined with silver, the substance produces a slight yellow precipitate.

Preparation of orthophosphoric acid

Science first learned about orthophosphoric acid from the scientist Boyle, who discovered the formula during chemical experiments. The basis for squeezing the substance is phosphorus oxide. Robert took special laboratory instruments, phosphorus and nitrogen reagents for his work. The separation of matter consists of the oxidation of the base. There are several methods for isolating phosphoric acid in production:

Method based on the use of high temperatures

The technique is based on heat treatment until the released oxide reacts with an aqueous solution.

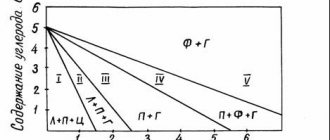

Technological generation is different, but the result is one matter. The first type is based on the joint interaction of both reagents in one container. Phosphorus is fed into the vessel under high pressure, which decomposes under the influence of high temperatures. The substance is multifunctional: it oxidizes the oxide, protects the surface of the container from fire, and removes some of the heat from the reaction. The column used is made of steel that can withstand the negative effects of phosphoric acid at temperatures up to 100 degrees. The mixture obtained in this way contains practically no phosphorus, but does contain a small amount of arsenic. The liquid is purified with special chemicals, followed by filtration.

The second technique is based on the separate processing of reagent components. For the decomposition procedure, the first chamber is used, and the second vessel is used to saturate the mass. The containers used are highly protected from the negative effects of dehydration, which allows you to maintain the integrity of the walls and increase the service life of the item.

Production of a mixture under the influence of inorganic acids

Since the 80s, scientists have been extracting phosphorus compounds based on sulfur, which reacts with phosphites.

The method has gained great popularity in agriculture due to the demand for fertilizers to saturate the soil with nutrients. The described method is the main type of chemical release due to minimal energy consumption. Scientists use two methods of isolating the formula separately or combining techniques for an effective result. The standard method of producing the chemical is based on the principle of pressing the substance at low temperatures, which eliminates the risk of corrosion. The described method is suitable for processing raw materials in large volumes. The preliminary stage is crushing the mass into small particles. Then phosphate and separately sulfuric acid enter the reactor. The temperature is maintained at an optimal value of 80 degrees. Due to the preliminary crushing of the raw materials and concentration of the resulting mixture, the time of dehydrate release increases. The advantage of the second stage used to isolate the combination is that there is no concentration step involved. The processing process is carried out at an optimal temperature of 100 degrees. The degree of concentration reaches 48%.

The combination of the two processes was invented by Japanese scientists. The technique makes it possible to extract gypsum, which is in short supply in the country due to the lack of natural deposits of raw materials.

Purification and concentration

This technology allows you to concentrate the resulting mass and purify it from additional impurities harmful to health. Concentration is carried out by vacuum type evaporation. Some plants use the technique of 2 or more evaporators, used in a certain sequence. At the legislative level of the Russian Federation, an official ban on the release of fluorine into the air has been approved, so the remainder from the technological process is recycled.

Structure

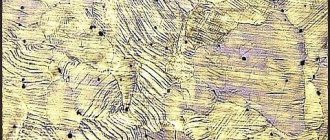

The compound H3PO4 has a total of 32 valence electrons. Since phosphorus is the least electronegative, it is placed in the center. Hydrogen atoms attach to the outside of oxygen atoms, forming he-groups.

In this structure, each atom has a full outer shell: phosphorus and oxygen atoms have eight valence electrons, and hydrogen atoms have two valence electrons around them.

Phosphorus may have an extended octet (more than eight valence electrons), so it receives a +1 formal charge, while oxygen (the one not attached to a hydrogen atom) receives a -1 formal charge. By forming a double bond, phosphorus and oxygen lose their charges.

There are still 32 valence electrons in the structure, and each atom has a formal charge of zero. So this is the most likely or probable Lewis structure for H3PO4.

The compound contains 3 OH single bonds, 3 PO single bonds and 1 P=O double bond. Each single bond is a sigma bond and the double bond consists of a sigma bond and a pi bond.

Phosphoric acid: spherical model and dimensions of the structural formula

The molecular geometry of PO(OH)3 is tetrahedral and the crystal structure is monoclinic. And since the distribution of charges on the central atoms is asymmetrical, the molecule is considered polar.

Recent advances in nanotechnology, including near-edge X-ray absorption techniques and high-angle X-ray scattering techniques, have allowed scientists to accurately determine the structure of phosphoric acid. The P=O bond distance in the structure is close to 152 picometers, and the P=OO distances were refined to 309 picometers, with a bond angle close to tetrahedral.

Safety rules when working with phosphoric acid

When interacting with orthophosphoric acid, you should follow the recommendations of specialists in order to ensure safety for human health and the environment.

It is important to exclude direct interaction with the respiratory system, vision, and skin. Rules for using phosphoric acid:

- when processing liquid indoors, there must be a good level of ventilation;

- to protect the skin, respiratory organs, and vision, it is necessary to use: rubber gloves, respiratory masks (respirators) and safety glasses;

- open areas of the skin must be covered, which will avoid burns if the product comes into contact with a person;

- If the product comes into contact with the skin, rinse the burned area with clean water, apply a loose gauze bandage and seek medical advice from a hospital.

Removing rust

It is better to start treating metal with orthophosphoric acid with mechanical intervention. It is recommended to clean large objects with a metal brush or grinder. Small parts can be sanded with sandpaper. After cleaning the item to be restored, degrease the surface. What other recommendations are there:

- after treatment with the product, be sure to wash off the acid;

- do not use the chemical on food products: this is only allowed if you completely remove any remaining acid;

- At the end of etching, make sure the item is processed and dried.

We offer you for review several methods of acid cleaning: the immersion method and the application method.

Method of total processing of metal parts

This option is suitable for parts that can be easily loaded into a tank. For example: metal tools, small parts, coins, antiques and all kinds of fasteners. Let's move on to the work in detail:

- take your item and wash it with soapy water, dry it and degrease it;

- find a deep reservoir and pour phosphoric acid into it - 150 grams of 85% product per liter of water;

- put the part in the solution for about a couple of hours;

- remove the item and rinse thoroughly with running water;

- make a solution with 50% water, 48% regular and 2% ammonia;

- Rinse the parts with the solution and dry completely.

This method will help you save your favorite things and protect them from further corrosion.

Local rust removal

This etching method will be appropriate for items that cannot be immersed in a tank. For example: overall car parts, bicycle frames or permanent metal parts of the structure. Let's move on to step-by-step instructions:

- mechanically clean the part using a metal brush, emery cloth or grinder;

- wash the area with a sponge to remove dirt and dust;

- degrease the products with the following means: anti-silicone, purified gasoline, solvent 647 or 646;

- apply acid to the object using a brush;

- wait about 1.5 hours and wash everything off with the solution as in the method above:

- Dry the item dry otherwise hydroxide will form on the area.

In this way, you can restore parts without immersion, but keep in mind that you need to apply the acid carefully.

Interesting information: if you want to treat rust on objects in hard-to-reach places, take acid and pour it into a water sprayer. This method allows you to apply the product from a distance. Just remember to use safety glasses, a respirator and rubber gloves.

Using our tips, you can restore many metal parts from rust with phosphoric acid or give a new look to your earthenware and enameled items.

Rules for storing and transporting orthophosphoric acid

To store orthophosphoric acid, it is recommended to use vessels made of glass, polymer or steel that are resistant to rust.

The place where the bottle will be placed should be protected from direct sunlight. The room must be dry to prevent condensation. It is recommended to maintain room temperature storage, avoiding sudden changes in values. The shelf life of the contents of the bottle, provided all recommendations are followed, is 12 months. Phosphoric acid is transported in vehicles equipped with metal containers. The properties of the tank do not change when exposed to chemical components. Phosphoric acid can be transported by water transport, taking into account compliance with safety recommendations, in tightly closed barrels. Hydroxide is classified as a hazardous substance, therefore, when transporting cargo over long distances, it is necessary to prepare accompanying documentation.

Why do you need a rust converter?

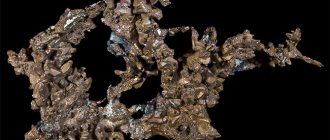

When iron is exposed to moisture, the process of its oxidation begins, which contributes to the formation of corrosive areas on the metal surface. At the same time, in the future, areas of rust begin to attract moisture available in the atmospheric environment.

The chemical and physical effects of soil have a destructive effect on metal material. The main enemy of metal is atmospheric rust. A thin layer of moisture forms on the surface of metal structures; the presence of chemical elements in the air aggravates the process and accelerates the destruction of the product. Therefore, if it is operated near an industrial zone, the service life is significantly reduced compared to a forest zone.

In addition, if a metal object is left in the ground for a long time, then the chemical elements present in it will also adversely affect its integrity. Therefore, such structures must be additionally protected so that they last much longer.

The most effective option for combating the formation of corrosive areas is a rust reducer. This is a chemical reagent that helps neutralize iron oxide, thereby reducing its harmful effects. A protective film is also formed on the surface, preventing the spread of rust. These positive properties have made the use of the converter popular when laying pipelines, in the industrial sector, and during the construction of various structures using metal.

The most effective option for combating the formation of corrosive areas is a rust reducer.

Operating principle of converters and their composition

To understand the operation of the rust converter, you should consider the process in more detail. The constituent components are responsible for obtaining a positive result after treating the affected areas with the product. Contains:

- Phosphoric acid is used to create most rust-fighting substances. It serves as a base and forms a phosphate film, which has the function of improving the degree of adhesion to paints. If the film collapses, then localization of corrosion will occur in this area;

- Tannin transforms iron oxide into tannate zones, where rust particles are reliably connected to each other and to an undamaged area of metal, and also serves as a corrosion-inhibiting component;

- Zinc Monophosphate, a zinc layer helps protect the metal surface due to a better level of positive electrode potential compared to iron. Thanks to this, it can better combat the oxide reaction;

- Adsorption and passivating rust inhibitors serve as a retardant of the destruction process;

- Various film-forming substances (epoxy, alkyd resins and others) can also be used.

When the product is applied to a rusty area, the phosphoric acid contained in the composition triggers a chemical reaction, after which a layer is formed that helps transform the corroded areas.

When a rust converter with zinc is used, the process is different. A combination of zinc particles with air occurs, leading to the appearance of a film on the surface. It will serve as a barrier. Other elements are also necessary; they act during protection from new exposure.

The constituent components are responsible for obtaining a positive result after treating the affected areas with the product.

Harm to the body

Officially, phosphoric acid is recognized as completely safe for human health and is approved for use in different countries around the world, but scientific practical data indicate the presence of harmful consequences for the body of living beings. The product is non-toxic and does not lead to negative consequences when consumed in small quantities. It can cause the development of caries, which arises from a violation of the integrity of the top layer of enamel when it comes into contact with sugar crystals. The resulting environment is favorable for the life of bacteria in the oral cavity. Phosphoric acid is in demand in the production of carbonated drinks, baked goods, sausages and processed cheeses, the use of which leads to a violation of the acidity level. The body's protective functions begin to restore the alkaline balance using calcium taken from bones and teeth. A lack of calcium compounds leads to pain in the joints and destruction of the integrity of the teeth. A solution of orthophosphoric acid with a concentration of more than 50%, if the technology and process control are not followed, causes:

- burns of mucous membranes and skin;

- the occurrence of bloody discharge from the nose;

- dental problems;

- abnormalities in the blood count;

- vomiting;

- diarrhea caused by a malfunction of the digestive tract.

With prolonged action of a food additive on the body, a person loses the sense of appetite, which leads to sudden weight loss and health problems. If you have diseases of the intestinal tract, the use of products with the food additive E338 should be completely excluded from the diet.

How does it work

The process is simple. You buy a converter; it usually comes in spray cans. Next, it is sprayed onto the site of the outbreak, then it is advisable for us to leave this place for about half an hour - an hour.

The product does not remove rust at all, if I may put it roughly, it freezes it and prevents it from spreading further. An iron phosphate film forms on the affected surface, which is a protective element. The work period is approximately one to two years, then it is advisable to repeat the procedure.

I would like to note from personal experience that my uncle is a minibus taxi driver and works on his minibus almost every season before winter. And you know, it really rots less when compared with untreated neighboring cars along the route.

But we are wondering whether it is possible to produce it with our own hands, what is the approximate composition. I’ll say right away that there are two compositions, the one that is used in production, and the one that is made at home.

Area of use of H3PO4

In the modern world, one chemical formula is often used to solve problems in various fields of science, everyday life and medicine.

Phosphorus hydroxide is in demand in various applications. Phosphoric acid is used when it is necessary to create calcium and aluminum salts using an organic synthesis recipe. In industry, dehydrate is indispensable when processing parts to protect the top layer from the destructive effects of rust. Phosphoric acid not only removes the resulting defect, but also protects the structure from the reappearance of corrosion. Household chemicals used to care for the home contain a phosphorus base. Phosphorus crystals are also in demand in other areas:

- oil production;

- production of match products;

- production of film necessary for recording video format;

- for the manufacture of items with optimal resistance to high temperatures;

- as a component of surface cleaning products;

- in the automotive industry. The use of the substance allows you to remove a machine defect without compromising the integrity of the surface.

In agriculture, phosphoric acid is needed to nourish plants, which leads to rapid crop growth. Thanks to phosphorus, agricultural crops are highly resistant to low temperatures and negative natural conditions. The soil is saturated with useful particles, which has a positive effect on its fertility. Some animal species require the presence of phosphorus compounds to ensure the normal development of the body's metabolism. The properties of the product help in the formation of the shell of a turtle and growths in some representatives of the animal world. Phosphoric acid in the food industry is used under the letter code E in combination with the numeric code 338. The additive can be found in the following food products: sausage, carbonated drinks.

Application in medicine

The chemical element is in demand among dentists during a tooth filling session. The composition is used to etch the base of the tooth enamel before starting treatment of a flaw in the tooth cavity. The disadvantages of the technology include the lack of control over the level of penetration of the chemical into the dental surface. The difficulty of the technique is also the impossibility of obtaining data on complete leaching of the composition before starting treatment. If the applied product is not completely washed off, the protective properties of the bonding decrease with the formation of a “mini acid type”. This acid can be found in toothpastes used to whiten tooth enamel.

Rust removal

The element is used both in everyday life for one-time rust removal, and on a massive industrial scale.

It is recommended to follow recommended safety rules when working with this type of acid. The main advantage of the combination is its double action on the base:

- removal of masses that have changed their properties under the influence of rust;

- creating a film that protects the part from further development and the formation of a new defect.

The outer coating is formed due to the decomposition of the oxide of the metal layer, with the dissociation of the product being replaced by a phosphorus compound. Reviews from people who have personally tried this method of eliminating flaws indicate the formation of a gray film after exposure to dehydrate on the metal. The resulting plaque has an oily texture to the touch. Metal surfaces are cleaned using the following effective methods:

- immersing a whole metal object in a vessel with a solution;

- applying liquid only to the defect area using a spray bottle or a wide brush;

- Application to metal is carried out after manual cleaning of the surface necessary to eliminate destroyed particles.

In the process of choosing a method for applying granules prepared for use, it is necessary to take into account the individual characteristics of the object being processed and the conditions of the place where the process is carried out.

Mechanism of metal processing with phosphorus reagent

To clean a metal product, several methods based on the use of dehydrate are combined. The choice of method for cleaning a part depends on the volume of the structure affected by the defect and the individual characteristics of the structure. There are two options for processing the product:

Complete immersion of the selected position in phosphoric acid

Using the chosen cleaning method is advisable if it is necessary to clean a small structure from greasy deposits of various origins. First, you should thoroughly wash the metal object with clean water and a surface cleaner. To prepare the solution you will need a basin and 150 ml of phosphoric acid; when mixing liquids, it is important to use personal protection. The part should be completely immersed in the prepared base for 60 minutes. To improve the reaction of the substance to the structure, you should regularly stir the solution using a disposable tool. After completing the process of dissolving fats, you should wash the product from the remnants of the applied layer using an artificial mixture. To prepare the liquid, you need alcohol, water and ammonia, mixed in a ratio of 2:50:48, respectively. The completion of cleansing will be rinsing the structure with clean water and drying it in a dry, warm place.

Applying liquid using a brush or spray bottle

The method is relevant when it is not possible to completely immerse the part in a container, due to its large parameters. The preliminary stage is mechanical cleaning of the base from rust. After removing the affected layer manually, the solution should be applied to the selected area of the structure. After the solution reacts with the area, you must wait 1 hour, then wash off the residue with a neutralizer. The completion of the procedure is drying the product in a well-ventilated area. If necessary, the time of exposure of the product to the surface of the part can be increased.

Rust converter

In order to modify the flaw in the form of rust, the structure is treated with a solution with the addition of special chemical components. All converters are divided according to the principle of the presence of various additional impurities in their composition:

- primer. A representative of this group is the base used to prepare steel parts for painting. The composition includes base and H3PO4;

- stabilizing modifiers;

- a converter that reacts with rust. The mixture contains manganese salts, which form a protective film on the treated base. It is necessary to strictly adhere to the manufacturer's recommendations for using the product indicated on the packaging.

Use of phosphoric acid in everyday life

In everyday life, the solution is used as part of chemicals used to clean surfaces.

Phosphoric acid cleans toilets and bathrooms well and removes rust. It is not recommended to use these products to clean the surfaces of bathtubs and toilets made of acrylic. Phosphoric acid is recommended for washing surfaces made of earthenware and enamel. To remove rust from the base of bathtubs and washbasins, you must first degrease the base. After removing fat from the surface, apply the liquid to the base defect. To prepare the mixture, you need to take 1 liter of water and the main product in a volume of 200 g. Depending on the degree of contamination of the structure, the exposure time to phosphoric acid ranges from 60 minutes to 12 hours. At the end of the procedure, you need to thoroughly rinse the composition with a solution of soda and running water. The bathroom is treated with a mixture of soda, which neutralizes the remainder of the product, then the remaining chemical layer is removed with clean water. The advantage of the technology is the preservation of the integrity of the surface of the object, since mechanical cleaning is not required.

Application in food production

The H3PO4 formula is used in the food industry as an antioxidant to preserve the properties of crystals. The product protects against discoloration of supplies, the appearance of sour taste and the proliferation of pathogenic bacteria. Granules are often used for the purpose of flavoring acidification of various edible products and carbonated drinks. This product differs from natural lemon juice in its short squeezing stage and low cost. The mixture is used to prepare the following food products: sugar, baking powder, cola drinks, Sprite. The use of this supplement is officially permitted, but doctors, based on the results of the study, recommend limiting the content of the substance in the body. A high concentration of the drug in the body leads to deterioration of health.

Expert advice

You need to clean areas of rust very carefully so that no holes appear and the metal does not become too thin. It is not recommended to use discs with very large abrasive particles during work, as instead of removing rust, they can cause more harm than good.

Before starting all repair work to remove rust, you must remember that this product is very powerful and strong. After all, it can remove not only the rust itself, but also the decorative coating: chrome, zinc. Therefore, it is necessary to process car parts very carefully and carefully so that you do not have to spend money on new spare parts in the future.

If all work to remove rust using phosphoric acid was carried out in accordance with all standards, then the resulting surface will be durable and reliable. And although the use of converters is considered the most popular method for body work, we should not forget about other options known to craftsmen.

A little converter is applied to a surface cleaned of a thick layer of rust and left for a couple of minutes or hours, depending on the concentration of the solution, and then further repair work begins.

Previous MaterialsUsing camouflage vinyl film for a car Next MaterialsThe best anti-corrosion agent for a car today: rating of anti-corrosion body treatment products

Rules for diluting orthophosphoric acid

The dehydrate is available in crystalline powder form, which requires prior dissolution to prepare the solution. To obtain a liquid formula, it is necessary to dilute the crystals in clean water in a ratio of 1/6. Following the manufacturer's recommendations, the result of dilution is a solution that is colorless and odorless. To remove rust, companies produce ready-made solutions containing a certain amount of phosphoric acid. The composition of the product is hidden from buyers. At the same time, the price of finished phosphoric acid is higher compared to the product in powder form. To clean metal parts, use a diluted concentrate of orthophosphoric acid, observing individual safety rules when working with phosphoric acid. In our store you can buy phosphoric acid, as well as hydrochloric, nitric, and other acids.

Types of rust modifiers

There is a qualification of converters according to the form of release. Products are available in cans, liquid, paste and gel. Aerosols can be equipped with a flexible nozzle; it helps to easily apply the substance to any hard-to-reach places. If you need to treat a large area, then it is more rational to give preference to liquid or thick types; they can be applied with a brush or spray.

There is also a division of funds according to the principle of action and constituent components.

If you need to treat a large area, then it is more rational to give preference to liquid or thick types.

Acid converters

This group of corrosion converters has the largest size. Most of the solutions included in the group for removing corrosive areas are made on the basis of phosphoric acid. It promotes the transformation of iron oxide into iron phosphate, which no longer has a detrimental effect on the metal surface and is easily washed off.

There are several advantages of acid products:

- Possibility of use at any stage of metal damage;

- Suitable for use on thin and thick metal, used on car bodies, metal structures, household appliances;

- The ability to cope with the task even at low temperatures; their effectiveness does not decrease from low-temperature exposure.

Possibility of use at any stage of metal rust damage.

Neutral converters

These are acid-free products based on tannin. They also convert iron oxide into inactive elements, while helping to improve the quality of adhesion of the metal material to various paints and varnishes.

To improve the penetration of the product into the structure of the material, specialized additives are added to them. It is acceptable to use them when working with ferrous and non-ferrous metals, alloys, and delicate objects; they are used for car bodies; they are also used to prepare iron for the process of concreting and processing with mastic.

The advantages are the following:

- Lack of acids, which eliminates the need to rinse off the product before using the item;

- Stronger effect due to the presence of special attachments;

- Obtaining deep impregnation, which helps fight a thick corrosive layer;

- Can be applied as a primer for metal;

- You can choose any type of tool;

- No harmful elements in the composition;

- Explosion and fire safety.

It is permissible to use them when working with ferrous and non-ferrous metals, alloys, delicate objects, and are used for car bodies.

Rust to soil converter

You can also find them called primers. The constituent components are tannic acid, organic polymers (ethylene glycol, butoxyethanol and others). They transfer iron oxide into the primer layer. Most often they are used when it is necessary to treat multi-layer corrosion, due to their powerful effect.

When the loose mass is washed off from a metal object, a protective coating is formed that prevents moisture, steam, and chemical elements from entering its structure. The surface gains better strength and resistance to mechanical loads, thereby increasing the service life of the structure.

Most often they are used when it is necessary to treat multi-layer corrosion, due to their powerful effect.

Rust converters with zinc

From the name it is clear that the basis of the product is zinc oxide. Zinc particles coat the surface of the metal, removing rust and creating an anti-corrosion layer. The surface must first be treated with sandpaper. Without this, the effect will be worse.

Zinc particles coat the surface of the metal, removing rust and creating an anti-corrosion layer.

Price

Phosphoric acid can be purchased in pharmacies, hardware stores, and ordered through Internet sites. For industrial purposes, they are purchased in bulk at discounts. The average cost for Moscow in rubles is:

| Quantity, liter | Average price, rub. | |

| Food thermal | 1 | 400 |

| Technical 85% | 0,8 | 380 |

| 1600 | 13500 | |

| Soldering flux | 0,01 | 180 |

| 0,003 | 40 | |

| Food additive E388 | 1 | 85 |

Production process

In laboratory conditions it is obtained:

- Dissolving phosphorus (V) oxide in water when heated.

- Hydrolysis of phosphorus pentachloride in hot water.

- When concentrated nitric acid reacts with white phosphorus.

The industry uses thermal and extraction (sulfuric acid) methods. The thermal method, which allows to achieve the greatest purity of the product, includes the following stages:

- Oxidation of elemental phosphorus by combustion in excess air to produce tetraphosphorus decaoxide (phosphoric anhydride).

- Hydration and absorption of its vapors in special towers.

- Condensation of the resulting acid with the capture of mist from the gas phase.

The extraction method uses the reaction of sulfuric acid decomposition of natural salts with a yield of up to 95%. Process stages:

A mixture of sulfuric acid and natural phosphate, the so-called. The pulp is fed from the hopper into the extractor - a steel lined vat with a stirrer.- In 4 hours, the pulp heated to 90 °C successively passes through several such reactors. As a result, phosphoric acid is formed and calcium sulfate crystallizes.

- To separate, the pulp enters a perforated belt with a filter cloth, and through its holes the finished product is collected into a vacuum chamber.

Chemical properties

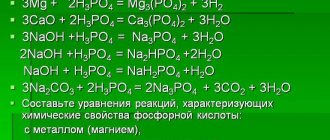

The inorganic compound is considered tribasic and of medium strength. The following chemical properties of orthophosphoric acid are characteristic:

- reacts to indicators by changing color to red;

- when heated, it is converted to pyrophosphoric acid;

- in aqueous solutions undergoes three-stage dissociation;

- when reacting with strong acids, it forms phosphoryls - complex salts;

- forms a yellow precipitate when interacting with silver nitrate;

- thermally decomposes to diphosphoric acid;

- upon contact with bases, amorphous hydroxides, it forms water and salt.

Packaging requirements and rules for handling the substance

The container in which the acid is packaged must be marked “Dangerous” or “Corrosive Liquid”.

The additive can be stored and transported in the following packaging:

- polyethylene canisters;

- glass bottles;

- containers and tankers made of stainless steel, which has undergone special treatment;

- plastic cubes.

For convenience, the containers themselves are placed in polyethylene drums or wooden boxes, inside of which there should be soft filler to avoid damage to the packaging.

Contact of the substance on the skin or mucous membranes, in the eyes or in the respiratory tract can cause burns, nausea, vomiting, dizziness and tissue damage. In this case, you must immediately seek medical help.

Acid is dangerous to handle, so you can only work with it away from open sources of fire, in a well-ventilated area.

It is mandatory to have protective clothing: gloves, a respirator, goggles, boots and a suit for working with hazardous substances.