Spotter is the common name for a single-sided spot welding machine designed for repairing car body parts. Its design is quite simple, so any home craftsman with experience working with electrical devices can make a spotter with his own hands.

The only thing that cannot be mistaken is the choice of power, calculation of the current strength and the number of windings. Craftsmen use various devices as power sources, but not all of them are capable of providing optimal operating conditions.

For example, a homemade microwave spotter, even when using several transformers from this household appliance, is generally suitable for warming up. If there is no sufficiently powerful electrical network at the repair site, devices with an autonomous source are used, consisting of a battery and a voltage interruption circuit.

Such devices have one significant drawback - limited operating time. When assembling a homemade spotter, you can use various control systems: from a simple button with a relay to an inverter source. In the latter case, the current supplied from the inverter to the welding site is regulated with high accuracy both in duration and in pulse amplitude.

Is it possible to make a spotter with factory specifications?

If you correctly calculate the parameters, select the appropriate components and make high-quality not only the power supply, but also the tool accessories, then a homemade spotter in its functionality will be no different from its factory counterpart.

If you have some amateur radio skills, it is easy to make the power supply and the necessary wires yourself. As a welding gun, you can use any product of a suitable shape, the design of which would allow you to strengthen the threaded contacts at its ends and would be convenient to use.

The gun and reverse hammer will require several parts, which are best turned on a lathe. Some electrode tips can be made with your own hands using ordinary plumbing tools, but some are still better to order or purchase ready-made.

In order to operate a home-made device, additional devices may be required (pullers, combs, rods), which can also be made independently. Consumables for a spotter (welding washers, studs, corrugated wire, carbon electrodes, etc.) are inexpensive and are freely sold in specialized stores.

VIEW Spoter on AliExpress →

Homemade reverse hammer

If the previous points have been completed, then difficulties should not arise in the future. Making a reverse hammer yourself is an economically profitable enterprise, since factory hammers are quite expensive.

The part of the polyurethane foam manipulator in which the container with the contents is located is best suited for this purpose. 3 rods are welded to the vacated area, which will become uprights.

Main components for assembly

To assemble and test a homemade spotter, you need the following components and consumables:

- Frame. Sheet metal box structure with front and back panels. Ventilation holes and a ground terminal are required.

- Power supply. In its simplest form, it is a do-it-yourself transformer with a circuit breaker in the primary circuit.

- Power cables. The welding cable must have a terminal for connection to power and a threaded contact for connection to the gun, and the ground cable must have a terminal and contact pad for welding connection to the body part.

- Control circuit. The minimum version includes a switch button on the gun, an input voltage cut-off relay, control wires and a control circuit power supply.

- Welding gun. At one end there is a contact threaded connection for connecting electrodes and adapters, and at the other there is a socket for connecting a welding cable.

- Equipment. The basic version includes electrodes for washers and pins, a return hammer and an adapter for connecting a carbon electrode.

Provided that all components are made without deviations and nothing has to be adjusted or altered, for DIY assembly you will need ordinary plumbing and power tools. Measuring instruments you may need are a tape measure, a caliper and a multimeter.

VIEW Spoter on AliExpress →

Assembling a reverse hammer (inopuller) with your own hands

In order to assemble a reverse hammer with your own hands, you need the following parts:

- steel rod 60 cm long, 17 mm in diameter, with threads on both ends;

- steel bushing with a through hole with a diameter of 15 mm, a length of 15 cm and a diameter of 40 mm;

- return spring;

- travel stop nuts and washers;

- adapters for attaching electrodes.

First, a washer is put on the end of the rod intended for fastening into the gun and the nut is tightened tightly. The rod is then passed through the bushing and return spring. The final step is to attach a washer and nut to the bottom threads, and then screw on the electrode adapter.

During operation, the massive bushing will be repelled by the spring and perform reciprocating movements between the two washers.

Making a working pistol

Branded spotter pistols are usually produced in the form of devices with a pistol grip.

Much of what folk craftsmen make with their own hands can only conditionally be called a “pistol.” Often it is just a cylinder with a button and a terminal for connecting a cable at the end. This is because the spotter gun consists of only three parts: the body, the contact rod and the switch. The contact rod is usually made of brass. At one end there is a thread for attaching a reverse hammer, and at the other there is a clamp for connecting power.

For those who make such devices with their own hands, whether to place it in a pistol case or use it as is is a matter of personal preference. At the same time, despite the low welding voltage, it must be insulated: these are the requirements of safety regulations.

VIEW Spoter on AliExpress →

Transformer for spotter

Any transformer is suitable for making a power source for a spotter.

Videos of the manufacture of spot welding machines based on transformers for microwaves and other household appliances are distributed on the Internet. At the same time, the authors of these crafts do not report what current their devices are designed for, and this is very important, since the penetration of the metal surface during the operation of the spotter should occur in a fraction of seconds, without appearing in any way on the back side of the part. Factory devices have a power of 3÷5 kW with an open circuit voltage of 7÷8 V (welding voltage - 1.5÷2 V).

For a spotter assembled by yourself and intended only for body repairs, a power of 1.5÷2 kW is sufficient. It is not difficult to calculate how many turns there should be in the secondary winding of a transformer.

To do this, the number of turns of the primary winding (new) must be divided by the quotient of 220 divided by 7 ÷ 8. Usually it turns out just a few turns.

If the number of turns in the network winding is unknown, then the secondary voltage can be selected experimentally by unwinding or adding turns. It should be noted that for the ground and the gun, cables with the same cross-section should be used, corresponding to the maximum current of the secondary winding.

Control unit diagram

There are quite a lot of electronic circuits on the Internet that are labeled as spotter control units.

Some of them refer to industrial designs of spot welding installations (including old ones), others are replete with electronic components and have redundant parameters, and a number of circuits are not at all related to our topic. Many of the proposed devices implement adjustments to the open circuit current and voltage, as well as control of the duration of the welding pulse. Their manufacture requires a certain skill, and the parts used are not that cheap.

Choosing one of these schemes is advisable if you plan to make a spotter for commercial use in a small auto repair shop. And for devices that are made by hand and used at home, there are simpler solutions.

Electronics for a spotter from what is at hand

In general, while the tea was boiling and brewing, I listened to a short lecture about how you shouldn’t do what you shouldn’t do, that you need to be closer to the people and then people will be drawn to me, and also briefly plunged into the history of car repair shops, illustrated with delicious tales from the life of “chiropper” and “tinsmith”.

Then I realized that a spotter is a small “welder” that works on the principle of a spot welding machine. It is used to “grab” metal washers and other small fasteners to a dented car body, with the help of which the deformed sheet is then straightened. True, they also need a “reverse hammer”, but they say that this is no longer my concern - only the electronic part of the circuit is required from me. Having looked at spotter circuits online, it became clear that we needed a one-shot device that would “open” the triac for a short time and supply mains voltage to the power transformer. The secondary winding of the transformer should produce a voltage of 5-7 V with a current sufficient to “grab” the washers.

To generate a triac control pulse, different methods are used - from simple capacitor discharge to the use of microcontrollers with synchronization to the phases of the mains voltage. We are interested in the simpler circuit - let it be “with a capacitor”.

Also, while searching for parts, we found several power supplies with DC output voltages from 5 to 15 V - we chose an industrial one from “Soviet” times called BP-A1 9V/0.2A ( Fig. 2 ). When loaded with a 100 Ohm resistor, the power supply produces a voltage of about 12 V (it turned out that it had already been converted).

We select triacs TS132-40-10, a 12-volt relay from the available electronic “garbage”, take several KT315 transistors, resistors, capacitors and begin to prototype and test the circuit (in Fig. 3 one of the setup stages).

The result is shown in Figure 4 . Everything is quite simple - when you press the S1 button, capacitor C1 begins to charge and a positive voltage equal to the supply voltage appears at its right terminal. This voltage, having passed through the current-limiting resistor R2, is supplied to the base of the transistor VT1, it opens and voltage is supplied to the winding of relay K1, and as a result, the contacts of relay K1.1 close, opening triac T1.

As capacitor C1 charges, the voltage at its right terminal gradually decreases and when it reaches a level less than the opening voltage of the transistor, the transistor will close, the relay winding will be de-energized, the open contact K1.1 will stop supplying voltage to the control electrode of the triac and it will close at the end of the current half-wave of the mains voltage . Diodes VD1 and VD2 are installed to limit the pulses that occur when the S1 button is released and when the relay winding K1 is de-energized.

In principle, everything works like this, but when monitoring the time of the open state of the triac, it turned out that it “walks” quite a lot. It would seem that even taking into account possible changes in all on-off delays in electronic and mechanical circuits, it should be no more than 20 ms, but in fact it turned out to be many times more and plus this, the pulse lasts 20-40 ms longer, and then for all 100 ms.

After a little experimentation, it turned out that this change in pulse width is mainly due to a change in the supply voltage level of the circuit and the operation of transistor VT1. The first was “cured” by mounting a simple parametric stabilizer inside the power supply unit, consisting of a resistor, a zener diode and a power transistor ( Fig. 5 ). And the cascade on transistor VT1 was replaced by a Schmitt trigger on 2 transistors and the installation of an additional emitter follower. The scheme took the form shown in Figure 6 .

The principle of operation remains the same, the ability to discretely change the pulse duration using switches S3 and S4 has been added. The Schmitt trigger is assembled on VT1 and VT2 [1], its “threshold” can be changed within small limits by changing the resistance of resistors R11 or R12.

When prototyping and testing the operation of the electronic part of the spotter, several diagrams were taken, from which time intervals and the resulting delays of edges can be assessed. At that time, the circuit had a timing capacitor with a capacity of 1 μF and resistors R7 and R8 had a resistance of 120 kOhm and 180 kOhm, respectively. Figure 7 above shows the state on the relay winding, below - the voltage at the contacts when switching a resistor connected to +14.5 V (the file for viewing by the SpectraPLUS program is in the archived appendix to the text, the voltages were taken through resistor dividers with random division coefficients, therefore "Volts" scale is not true). The duration of all relay power pulses was approximately 253...254 ms, the contact switching time was 267...268 ms. The “extension” is associated with an increase in the shutdown time - this can be seen in Figures 8 and 9 when comparing the difference that occurs when the contacts are closed and opened (5.3 ms vs. 20 ms).

Diagram of a spotter based on a welding machine

For a craftsman who has minimal skills in electrical engineering and uses a self-assembled device to repair his own vehicles and the cars of friends, a device based on an old medium-power welding transformer with a simple control unit is quite sufficient.

In this case, the best option is a spotter control system made from simple and accessible parts, the diagram of which was published in the “Modeler-Constructor” magazine (see below).

Spotter circuit

The author uses a serial welding transformer with a power of 1 kW with a primary winding of 200 turns (any other one with similar characteristics can be used). He replaced the secondary with two parallel windings of 3 turns with a total cross-section of 100 mm².

The calculated open circuit voltage according to this circuit is approximately 6.5 V. S1 is the input circuit breaker of the device. S2 is a shutdown button, when closed, voltage is supplied to contactor K1 and its contacts K1.1 and K1.2 open. Control over the duration of the welding process is visual.

In principle, it is easy to supplement this scheme for controlling a spotter from a welding machine with a time relay (including electronic) and a current control system.

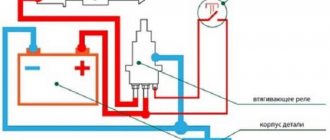

In the video (see below), the author of the homemade device used exactly this circuit, only instead of a contactor he uses a low-voltage relay powered from a rectifier. For a spotter, this is the only correct solution, because in this case, a safe voltage is supplied to the button located on the working gun.

Working pistol

If you plan to use a spotter regularly, then the best solution would be to purchase a factory pistol. This is due to the fact that the gun is the main working element and will be constantly exposed to high currents, and if it malfunctions, it can cause harm to the person using it. But if the application is limited to special cases, it is quite possible to make it yourself.

For the base, you can take a standard glue gun or a manipulator from an old welding machine. You need to make an insulated handle for the manipulator; PCB is perfect for this purpose, from which you need to cut two symmetrical rectangular parts.

It is necessary to install a bracket in the handle to secure the electrode from the working cable. Also, if desired, you can equip the handle with lights that will signal the presence of voltage.

A copper rod is ideal for creating a bracket. An electrode from the working cable will be connected to it; it is better that this electrode can be removed from the device without disassembling the handle.

Spotter housing and final assembly

In general, the assembly of a homemade spotter is completed by placing its main elements in the housing and bringing the terminals and controls to the front panel.

The housing can be ordered according to a drawing or simply a sketch, or (if possible) manufactured locally. Sometimes craftsmen begin to operate a spotter, the parts and wires of which are simply laid out on a workbench or even on the floor. This option is only suitable for debugging and selecting parameters; such an electrical installation cannot be used in constant mode.

Since there are various options for making spotters with your own hands, their body layouts can also be different. For example, if a welding transformer is intended for use outdoors, then in this case the device may take the form of a stable base with a transformer, a terminal block and a separate control system housing.

In other cases, housing options may be different, but the control system elements must always be reliably protected from external influences.

VIEW Spoter on AliExpress →

Battery based

A battery powered spotter is suitable for applications where mains power is insufficient, unstable or non-existent and where body work is limited.

Typically, this situation arises during body repair of a personal car in a garage cooperative or at a summer cottage. The body of such a homemade spotter may consist of a small support frame for installing the battery, to which a terminal block and a relay that controls shutdown are attached. If this is a one-time job, then you can do without a housing at all by attaching the relay to the battery with a clamp.

Based on a household microwave

To make a spotter with your own hands, a transformer from a microwave is also suitable. In this case, the only limitation is its power, since most microwave ovens are designed to consume less than 1 kW.

To solve this problem, you can use two or three transformers connected in parallel. The advantage of such a power source is the small size of the transformers used, which can be placed in a row inside a small-sized housing.

The result is a fairly compact and mobile spotter. The only thing you have to worry about is cooling the internal space of such a device.

Exhaust devices

As we wrote earlier, the spotter welds a fastening element to the damaged area of the body, and then either a reverse hammer or a pulling device is attached to this element.

A traction device is used for smooth, shock-free pulling of the damaged area. Typically, such devices consist of a durable frame that is mounted on four legs. This design provides good support. The frame is durable and can withstand pulling force with a large margin. The hook of the exhaust device engages with the welded fasteners, and smooth extraction is performed.

We have two types of such devices in stock. One type uses one hook to engage the fastener, while another device can use six hooks at once (this is convenient if the area of the damaged area is large and several fasteners are welded onto it at once.

More detailed information can be obtained from our experienced specialists. They will be happy to advise you on all types of consumables for the spotter.

How to make an electrode for a spotter

Spotter electrodes and adapters are small cylindrical attachments made of brass, each of which is used to work with certain types of welding fasteners: washers, nails, studs, crimped wire rivets. In stores, each of these elements can cost from 500 to 1000 rubles or more, and for ordinary body work you need at least five or six types of electrodes:

- for rings;

- for spot welding;

- for corrugated wire;

- for welding with carbon electrode;

- for triangular washers;

- for pins and nails.

Making them yourself is not so difficult, but it requires certain skills and the availability of appropriate equipment. Alternatively, you can make only the simplest attachments with your own hands, and order more complex ones in a workshop with turning and drilling equipment.

In battery spotters, batteries with a capacity of 40÷60 Ah are usually used as a power source. If anyone has had to work with such devices, please write in the comments: how quickly the battery discharges and how the quality of welding changes as it discharges.

Types of fasteners

In our warehouse you can purchase the following types of fasteners:

- – Insulation nails, used to secure insulation. The nail is welded to the body, and then the insulation is pinned onto it. The sharp part of the nail is covered with a special cap.

- – Washers for spotters are one of the most popular types of fasteners. We have such oval-shaped washers in stock, with an additional tip. It is this tip that is welded to the damaged area of the metal. There are two modifications of such washers, with a straight and curved tip. To correct dents, a special reverse hammer attachment is connected to the spotter washers, which can also be purchased from us.

- – The three-beam star is itself an electrode that is welded to the damaged part of the body for subsequent repairs.

Nutrition

The current source for welding guns is special step-down transformers. The high voltage side is connected to a 380 Volt industrial electrical network, the low voltage winding usually consists of one turn made of a solid copper disk. The secondary winding is designed in such a way that the open circuit voltage is from 2 to 5 Volts.

The current flowing in the secondary winding of the pliers during spot resistance welding can reach values from 2 – 3 kA to 15 kA and higher for different models.

Such transformers are voluminous and quite heavy devices. Despite this, designs in which the transformer is built into a common housing with welding tongs currently predominate.

This is due to the fact that in the case of a separate location of the transformer, it is necessary to ensure its connection with the electrodes through a large cross-section cable.

Such a connection, in addition to being heavy and rigid, causes a noticeable voltage drop in the welding circuit. The weight of the unit can be easily handled by using a suspended structure.

Making welding pliers for spot welding with your own hands and their correct use

Reading time: 2 min

In order to connect metal elements, welding is most often used. There are a lot of approaches and methods for it, and each is used depending on the situation and has its own pros and cons.

But the main criteria for choosing a technology have always been the speed of work, the properties of the seam and, of course, the characteristics of the metal used.

One of the methods - spot welding (also called contact welding) - combines most of the advantages: fast soldering, high accuracy, as well as connection quality, simple execution.

This technology can be used in production workshops and for home repairs. It works best when joining thin sheets of metal, which is why it is often used in automobile factories.

Exhaust devices

As we wrote earlier, the spotter welds a fastening element to the damaged area of the body, and then either a reverse hammer or a pulling device is attached to this element.

A traction device is used for smooth, shock-free pulling of the damaged area. Typically, such devices consist of a durable frame that is mounted on four legs. This design provides good support. The frame is durable and can withstand pulling force with a large margin. The hook of the exhaust device engages with the welded fasteners, and smooth extraction is performed.

We have two types of such devices in stock. One type uses one hook to engage the fastener, while another device can use six hooks at once (this is convenient if the area of the damaged area is large and several fasteners are welded onto it at once.

More detailed information can be obtained from our experienced specialists. They will be happy to advise you on all types of consumables for the spotter.

Important selection options

When choosing a device, you need to take into account its main characteristics:

- Operating current . It determines the thickness of the workpieces to be joined. At a maximum current of 3500A, the thickness of the connected parts is up to 1 mm. A current of 6000A will allow you to deal with workpieces up to 4 mm.

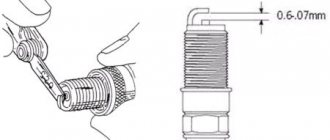

- Electrode protrusion . Determines the dimensions of the workpiece from the seam side and the distance of the seam line from the edge.

- Electrode material . Copper alloys with additives are used: Be, Cd, Cr and others. They help extend the life of the electrode, increasing its strength and reducing the need for frequent sharpening.

- Device weight . Welding pliers for spot welding are designed for frequent use, so a unit that is too massive will lead to rapid fatigue of the worker and reduce his productivity.

It is also important to take into account the type of drive for pressing the electrodes, the possibility of cooling them, no-load current, the range of adjustment of the pulse duration and some other parameters.

Equipment advantages

Spot welding pliers offer the following benefits:

- high speed;

- no need for consumables: consumable electrodes, filler rods, shielding gases;

- high seam strength;

- low weight and dimensions of the welding machine;

- the ability to create a hermetic connection by placing overlapping weld spots along the seam line.

Resistance welding is widely used for joining thin-sheet workpieces, creating housings, meshes of reinforcement, air ducts, containers for bulk products and low-pressure vessels. This technology is also used in the assembly and repair of automobile bodies. The smallest welding pliers are used when assembling casings in instrument making.

Types of fasteners

In our warehouse you can purchase the following types of fasteners:

- – Insulation nails, used to secure insulation. The nail is welded to the body, and then the insulation is pinned onto it. The sharp part of the nail is covered with a special cap.

- – Washers for spotters are one of the most popular types of fasteners. We have such oval-shaped washers in stock, with an additional tip. It is this tip that is welded to the damaged area of the metal. There are two modifications of such washers, with a straight and curved tip. To correct dents, a special reverse hammer attachment is connected to the spotter washers, which can also be purchased from us.

- – The three-beam star is itself an electrode that is welded to the damaged part of the body for subsequent repairs.