Spotter is the common name for a single-sided spot welding machine designed for repairing car body parts. Its design is quite simple, so any home craftsman with experience working with electrical devices can make a spotter with his own hands.

The only thing that cannot be mistaken is the choice of power, calculation of the current strength and the number of windings. Craftsmen use various devices as power sources, but not all of them are capable of providing optimal operating conditions.

For example, a homemade microwave spotter, even when using several transformers from this household appliance, is generally suitable for warming up. If there is no sufficiently powerful electrical network at the repair site, devices with an autonomous source are used, consisting of a battery and a voltage interruption circuit.

Such devices have one significant drawback - limited operating time. When assembling a homemade spotter, you can use various control systems: from a simple button with a relay to an inverter source. In the latter case, the current supplied from the inverter to the welding site is regulated with high accuracy both in duration and in pulse amplitude.

Is it possible to make a spotter with factory specifications?

If you correctly calculate the parameters, select the appropriate components and make high-quality not only the power supply, but also the tool accessories, then a homemade spotter in its functionality will be no different from its factory counterpart.

If you have some amateur radio skills, it is easy to make the power supply and the necessary wires yourself. As a welding gun, you can use any product of a suitable shape, the design of which would allow you to strengthen the threaded contacts at its ends and would be convenient to use.

The gun and reverse hammer will require several parts, which are best turned on a lathe. Some electrode tips can be made with your own hands using ordinary plumbing tools, but some are still better to order or purchase ready-made.

In order to operate a home-made device, additional devices may be required (pullers, combs, rods), which can also be made independently. Consumables for a spotter (welding washers, studs, corrugated wire, carbon electrodes, etc.) are inexpensive and are freely sold in specialized stores.

VIEW Spoter on AliExpress →

Main components for assembly

To assemble and test a homemade spotter, you need the following components and consumables:

- Frame. Sheet metal box structure with front and back panels. Ventilation holes and a ground terminal are required.

- Power supply. In its simplest form, it is a do-it-yourself transformer with a circuit breaker in the primary circuit.

- Power cables. The welding cable must have a terminal for connection to power and a threaded contact for connection to the gun, and the ground cable must have a terminal and contact pad for welding connection to the body part.

- Control circuit. The minimum version includes a switch button on the gun, an input voltage cut-off relay, control wires and a control circuit power supply.

- Welding gun. At one end there is a contact threaded connection for connecting electrodes and adapters, and at the other there is a socket for connecting a welding cable.

- Equipment. The basic version includes electrodes for washers and pins, a return hammer and an adapter for connecting a carbon electrode.

Provided that all components are made without deviations and nothing has to be adjusted or altered, for DIY assembly you will need ordinary plumbing and power tools. Measuring instruments you may need are a tape measure, a caliper and a multimeter.

VIEW Spoter on AliExpress →

Assembling a reverse hammer (inopuller) with your own hands

In order to assemble a reverse hammer with your own hands, you need the following parts:

- steel rod 60 cm long, 17 mm in diameter, with threads on both ends;

- steel bushing with a through hole with a diameter of 15 mm, a length of 15 cm and a diameter of 40 mm;

- return spring;

- travel stop nuts and washers;

- adapters for attaching electrodes.

First, a washer is put on the end of the rod intended for fastening into the gun and the nut is tightened tightly. The rod is then passed through the bushing and return spring. The final step is to attach a washer and nut to the bottom threads, and then screw on the electrode adapter.

During operation, the massive bushing will be repelled by the spring and perform reciprocating movements between the two washers.

Making a working pistol

Branded spotter pistols are usually produced in the form of devices with a pistol grip.

Much of what folk craftsmen make with their own hands can only conditionally be called a “pistol.” Often it is just a cylinder with a button and a terminal for connecting a cable at the end. This is because the spotter gun consists of only three parts: the body, the contact rod and the switch. The contact rod is usually made of brass. At one end there is a thread for attaching a reverse hammer, and at the other there is a clamp for connecting power.

For those who make such devices with their own hands, whether to place it in a pistol case or use it as is is a matter of personal preference. At the same time, despite the low welding voltage, it must be insulated: these are the requirements of safety regulations.

VIEW Spoter on AliExpress →

Transformer for spotter

Any transformer is suitable for making a power source for a spotter.

Videos of the manufacture of spot welding machines based on transformers for microwaves and other household appliances are distributed on the Internet. At the same time, the authors of these crafts do not report what current their devices are designed for, and this is very important, since the penetration of the metal surface during the operation of the spotter should occur in a fraction of seconds, without appearing in any way on the back side of the part. Factory devices have a power of 3÷5 kW with an open circuit voltage of 7÷8 V (welding voltage - 1.5÷2 V).

For a spotter assembled by yourself and intended only for body repairs, a power of 1.5÷2 kW is sufficient. It is not difficult to calculate how many turns there should be in the secondary winding of a transformer.

To do this, the number of turns of the primary winding (new) must be divided by the quotient of 220 divided by 7 ÷ 8. Usually it turns out just a few turns.

If the number of turns in the network winding is unknown, then the secondary voltage can be selected experimentally by unwinding or adding turns. It should be noted that for the ground and the gun, cables with the same cross-section should be used, corresponding to the maximum current of the secondary winding.

Control unit diagram

There are quite a lot of electronic circuits on the Internet that are labeled as spotter control units.

Some of them refer to industrial designs of spot welding installations (including old ones), others are replete with electronic components and have redundant parameters, and a number of circuits are not at all related to our topic. Many of the proposed devices implement adjustments to the open circuit current and voltage, as well as control of the duration of the welding pulse. Their manufacture requires a certain skill, and the parts used are not that cheap.

Choosing one of these schemes is advisable if you plan to make a spotter for commercial use in a small auto repair shop. And for devices that are made by hand and used at home, there are simpler solutions.

DIY spotter: detailed assembly instructions

The spotter belongs to the category of equipment for performing contact welding. During operation, the unit produces a current discharge, which melts the metal in a split second and allows spot welding without the usual pliers.

For correct operation, a replaceable attachment is used - a reverse hammer, which simultaneously with the spotter straightens out dents, thereby imparting lost rigidity to the metal and returning its original shape. If you want to use the unit for small amounts of work, then it is easier to assemble the device from improvised means. In this review from the editors of Seti.

guru we will answer the question of how to make a spotter with your own hands, we will consider the sequence of assembling such a unit from various household appliances and unnecessary equipment.

Industrial spot welding device

A do-it-yourself spotter is most often used for straightening a car and leveling out dents on metal.

This type of equipment is very popular among workshop technicians, since during the process of straightening the body there is no need to dismantle the fender or door of the car. All work can be carried out directly on the outer part of the casing.

It is especially convenient to work with the device in those places that are difficult to get to.

During operation, the device produces a discharge, the metal heats up, and welding occurs at the point of contact.

Welding with a spotter does not leave deep marks and, after leveling, can be easily removed with a grinder.

The fact is that heating and cooling at the point of contact occur so quickly that the metal does not have time to oxidize and react. Moreover, homemade models can be adjusted in such a way that the current strength and exposure time can be changed depending on the thickness of the metal that needs to be processed.

The spotter consists of the following elements: 1 – reverse hammer, 2 – housing where the power supply and control unit are located, 3 – hook, 4 – electrodes, 5 – gun. Two cables come from the body of the device: ground and the working wire with the gun. The gun is what the welder operates in his hands.

The operating technology is as follows: The mass is fixed to the body of the car from which the battery has previously been removed. The gun starts the current flow. When the trigger is pulled, a discharge occurs that melts the metal.

At the same time, or before this stage, the master knocks out small “mounds” with a reverse hammer, onto which a discharge is applied by a spotter.

They are subsequently cleaned, thereby thickening the metal and obtaining the necessary shape and strength.

For your information! The action of the spotter is based on such a physical phenomenon as current resistance. In this case, the use of conventional welding materials (consumable electrodes, welding wires and others) is not required.

Working diagram of the spotter

To correctly assemble the tool, you need to understand the basic operating diagram of the spotter.

Power supply diagram.

This scheme works according to the following principle: when the spotter is turned on, voltage is supplied to transformer T1. Next, it is converted and supplied from its secondary winding to the diode bridge.

Then it passes through the closed contacts of the “Impulse” switch to capacitor C1, which begins to charge. Since the thyristor is closed at this time, no electric current is supplied to the welding transformer.

Schematic diagram of the spotter operation

To start this transformer and receive welding current on its secondary winding, it is necessary to change the position of the “Impulse” switch, which will disconnect capacitor C1 from charging and connect it to the thyristor control circuit. The current generated as a result of the discharge of the capacitor first passes through the resistance (R1), which is responsible for the operating modes of the device, and enters the control electrode of the thyristor, which leads to its opening.

DIY spotter for body repair

The tip of the spotter is similar to a pistol; in manual mode, you can use it to adjust the time required to straighten the part; to do this, simply press the button and do not release it.

There are several options for making a spotter for body repair with your own hands from used devices. Let's look at each assembly option in detail.

We select components

and the most difficult part of the job is choosing the right transformer. To create the necessary current pulse, you need a 1500 A transformer. If you don’t have one at hand, a little later we’ll tell you how to make it yourself.

In addition to this most important part, to assemble the spotter you will need: a reverse hammer, a control unit (it contains a 200 V thyristor), a diode bridge, a contractor (220 V), and a 30 A relay.

How to properly convert a transformer for a spotter

Rewinding the transformer is the most labor-intensive step. Typically, copper or aluminum wire is chosen for these purposes. Let's look at the order of work in more detail.

| Illustration | Description of action |

| For work we use 2 empty coil blanks, our task is to combine them into one | |

| We cut off the protruding side parts from two coils, glue them with second glue, wrap them with cloth and fill them with varnish. We glue the corners with cardboard. This is done so that the wire does not bend when winding. We got one big blank. | |

| We begin winding the wire in several layers, diameter 1.1 mm. In our case, we got about 112 turns per row. We lay each layer with insulating paper. This will minimize the risks of interturn short circuits. | |

| Let's make a branch. There will be three of them. You can change the voltage on the secondary without winding it. This will slightly increase the load on the primary, but for short-term work, for example, switching the current from 3 Volts to 5 Volts, it is quite suitable. | |

| We take the wires out of the coil |

Important! The length of the outgoing ends of the secondary winding of the transformer must provide for the possibility of its connection to the output terminals, and the primary - for connection to the electrical circuit of the device. It is advisable to impregnate the transformer you have made with shellac.

If you want more knowledge on how to properly wind a spotter transformer, watch this video

Manufacturing of the control unit

The task when assembling the control unit is to correctly connect the jumpers to break the contacts of the primary network. We provided the basic diagrams earlier. In addition, the control unit contains wires, contacts for the start button, as well as other switches necessary for operation.

Selecting a spotter body and power cable

Even though you are making a homemade instrument, you need to take care of aesthetics. Therefore, it is important to make the body of the unit (what those who turn to you for help will pay attention to) functional and convenient. Think in advance about which control elements you want to place and where.

An example of the location of controls on the body of a homemade spotter: 1 – button to turn the device on and off, 2 – current regulator, 3 – pulse regulator, 4 – lever for switching from manual to automatic mode, 5 and 6 – welding cables.

The body for the spotter can be made of different materials: metal, plastic and even wood. Some craftsmen use a PC system unit. This is quite convenient, since it already has the ability to install microcircuits and coolers. Sometimes a wooden box with a hinged lid is used as protection.

Some models have a retractable telescopic carrying handle.

The task is to ensure the possibility of opening the box and access to all controls at any time. The dimensions of the housing are selected individually; it is better to treat the structure with a dielectric material.

On the reverse side of the cable for ground, you can install a quick-clamping element (crocodile) or equip it with a terminal for threaded fastening.

Particular attention should be paid to the quality of the welding cable.

The length is calculated according to this principle. For every 10 A of the maximum permissible current that the spotter produces, there should be 1 mm² of cable cross-section.

For the mass, use a cable whose length does not exceed 1.5 m, for a worker - no more than 2.5 m.

Making a working welding gun - detailed photos and video instructions

The welding gun is one of the most important elements of the spotter. If you plan to use the device quite actively, it is better to buy a ready-made sample. But for small-scale work, a homemade unit is quite suitable.

The peculiarity of the gun is that it can combine one or more functions: used as a welding machine, as a reverse hammer.

Some craftsmen simplify and speed up their work as best they can. Let's look at how one of these devices works, the most interesting in our opinion is a gun for welding washers using a spotter.

| Illustration | Description of action |

| The design involves the use of a pneumatic gun, which provides hooks for effective fastening with a spotter. The cylinder and piston of a pneumatic drive are essentially an ordinary metal tube and a metal round rod. | |

| The body was made of stainless steel 1 mm thick. The central moving mechanism, the shutter, was made of a millimeter-thick copper pipe. | |

| The pipe was cut, straightened and 2 pieces of copper plate were made. A cutout was made in one plate for the washer to be welded, then the 2 plates were connected to each other. Thus, we managed to avoid milling work. | |

| The gun is a pneumatic drive for the shutter; it helps to distort it and thereby push out the next washer for welding. |

In most cases, the assembly glue gun serves as the basis for the welding gun. The task is to develop a design that would allow the electrode to be changed without disassembly.

Sometimes another attachment is used for work - a puller for a spotter. It performs two functions at once: welding and surface leveling.

| Illustration | Description of action |

| As we can see, the nozzle allows not only to carry out resistance spot welding, but also to slightly level the surface at the same time. | |

| During the work process, do not forget to check the level |

Making a reverse hammer for a spotter with your own hands

A reverse hammer (the top one in the photo) is needed to straighten the body surface.

Usually it is assembled from metal rods, welding them and shaping the tip with nuts.

The blank on the pin must move freely to create reverse thrust during operation.

A sharp tip must be welded to the end of the electrode, which makes contact with the surface of the body when straightening the car.

We offer you a short video instruction on how to make a reverse hammer.

What can spotters be made from?

To make a spotter, old welding machines, batteries and even used microwave ovens are used.

DIY spotter from an inverter welding machine

However, most often an inverter welding machine is used as the main unit for converting a spotter.

The welding machine contains everything necessary for the operation of the device.

The main thing is to prepare a transformer to create the required current and make a gun.

If you have a backup welding machine, then we will help you decide to convert it into a spotter. How to make a spotter with your own hands from an inverter welding machine, watch this video.

Microwave spotter

Converting a spotter from a microwave with your own hands has its own characteristics. In general, the scheme and sequence of work does not differ from the process of assembling an inverter unit, however, we need to configure the device so as to achieve a pulsed operating mode. To do this, you will need a large capacitor with a control system. Let's briefly consider the stages of work.

| Illustration | Description of action |

| Let's prepare microwave transformers for work. | |

| We release the primary winding we need. | |

| We need to later lay the secondary winding cable in the vacated housing. | |

| This is what our assembled transformer looks like. | |

| And this is what the entire transformer network looks like. All that remains is to bring the necessary elements to the case and connect the power supply. |

DIY spotter from an old battery

A battery-powered spotter is an excellent option for a hiking tool. You don't need a network connection to use it.

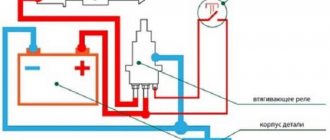

Spotter made from battery and retractor relay

The connection diagram is as follows: the relay body and welding wire are connected to the negative terminal. A contact is welded at the end of the wire, intended for attachment to the welding part that needs to be straightened.

Electrical circuit of a battery spotter

The positive terminal is connected to the relay using a bolt. The second bolt from the relay attaches a wire to it that goes to the recoil hammer or gun. In addition, a wire goes from the positive terminal to the control contact.

How to properly operate a homemade device

The work process involves a certain sequence of actions. Let's tell you more about them.

| Illustration | Description of action |

| The main condition for high-quality work of the spotter is the cleanliness of the surface being welded. Usually the surface is cleaned with a grinder with a rigid petal attachment. | |

| The next stage is to weld the mass. | |

| Using an attachment - a reverse hammer, we begin to straighten the metal: from the edges of the dent to the center. We carry out work at minimum current. | |

| Using a spotter, special fasteners are welded. These can be hooks, or, as in our case, ordinary chain links. | |

| This fastening is necessary in order to straighten deep longitudinal potholes in metal using a spotter comb or with your own hands. And then the maters clean the surface and there is no trace left of the deformation. |

At the end of the article, a little about safety precautions when working with equipment:

- It is very important to regularly inspect and clean all parts of the device.

- Pay attention to the correct connection and insulation of the wires. And also for grounding the device.

- If you plan to process a large surface, do not forget to wear special safety glasses.

We hope that the recommendations of the Seti.guru editors were useful to our readers

Diagram of a spotter based on a welding machine

For a craftsman who has minimal skills in electrical engineering and uses a self-assembled device to repair his own vehicles and the cars of friends, a device based on an old medium-power welding transformer with a simple control unit is quite sufficient.

In this case, the best option is a spotter control system made from simple and accessible parts, the diagram of which was published in the “Modeler-Constructor” magazine (see below).

Spotter circuit

The author uses a serial welding transformer with a power of 1 kW with a primary winding of 200 turns (any other one with similar characteristics can be used). He replaced the secondary with two parallel windings of 3 turns with a total cross-section of 100 mm².

The calculated open circuit voltage according to this circuit is approximately 6.5 V. S1 is the input circuit breaker of the device. S2 is a shutdown button, when closed, voltage is supplied to contactor K1 and its contacts K1.1 and K1.2 open. Control over the duration of the welding process is visual.

In principle, it is easy to supplement this scheme for controlling a spotter from a welding machine with a time relay (including electronic) and a current control system.

In the video (see below), the author of the homemade device used exactly this circuit, only instead of a contactor he uses a low-voltage relay powered from a rectifier. For a spotter, this is the only correct solution, because in this case, a safe voltage is supplied to the button located on the working gun.

Do-it-yourself spotter attachments - Metalist's Guide

Among the many accessories for a spotter there is a hook or, as it is more often called, a comb.

If anyone doesn’t know, I’ll briefly tell you about the cases in which body repair specialists use a comb when working with a spotter.

You can read about how I assembled a spotter from a welding machine, or rather from a welder’s transformer, in this article - “How to make a spotter from a welding machine”

DIY spotter from a welding machine

Straightening work may require not only filigree mastery of the simplest and necessary tools, but also precise knowledge of geometry and an understanding of the intricacies of the geometry of car body panels. But high-quality straightening is rarely possible without special devices. One of these auxiliary tools was a spotter, the construction of which we will talk about.

Spotter, what is it?

A spotter for straightening a car is an excellent opportunity to avoid the complete dismantling of body panels when straightening them. The device allows you to remove surfaces even in the most difficult to reach places. In addition, the spotter helps restore the geometry of complex power elements without resorting to disassembling them.

The ease of use of the device made it indispensable for straightening work, and with a certain power, the spotter can be used as a spot welding machine. From the photograph it is quite clear how the device works, and we will look at the principle of its operation, as well as how to make a spotter with your own hands from a welding machine right now.

Spotter, reverse hammer and attachments

We’ll look at the spotter’s electrical circuit later, especially since there are several fundamentally different ones.

The main thing is to understand how the device works, and you can basically assemble it from what you have in the garage, from an old transformer to a barely breathing battery. Spotter, from English spot, spot, point projection.

It was not for nothing that the device was named this way, since it operates on the principle of a hammer, pointwise, but in the opposite direction.

That is, the reverse hammer is fixed using a guide to the damaged area on the body, and the hammer itself can move along this guide in the form of a heavy washer, which applies an impact force to the point of fixation of the guide.

The branded spotter can operate in two modes - in a short-term mode, when it is necessary to quickly and reliably secure the spotter guide at the desired point using ring attachments, and also in the carbon electrode welding mode at minimum power.

DIY spotter from an inverter

The inverter spotter is most often found among homemade products, although there are some other schemes. Do-it-yourself spotters are made without inverters, but they are less powerful, although still quite functional.

Since the spotter is one of the branches of resistance welding, but differs from it in that there are no pliers in the design, it is more common to consider the spotter as an analogue of electric arc welding.

That is, the voltage is passed through the car body - one contact is attached to the body, and the second contact is the rod itself with the nozzle.

Below we have given a simple diagram of a spotter, which, however, can be modified at your discretion.

Operating principle of an inverter-based spotter circuit

The inverter spotter, which we assemble with our own hands, consists of two main elements - an inverter for welding and a thyristor relay, which is indicated in the diagram V9, and to assemble the device you will need:

- two-hundred-volt thyristor;

- a 12-volt step-down transformer to control the relay from a button;

- 30 amp relay;

- diode bridge;

- 220 volt contact group and control button.

The transformer is connected to the network through a diode bridge, to which an electronic relay thyristor is connected. Transformer T1 powers the control branch of the thyristor circuit.

Spotter housing and final assembly

In general, the assembly of a homemade spotter is completed by placing its main elements in the housing and bringing the terminals and controls to the front panel.

The housing can be ordered according to a drawing or simply a sketch, or (if possible) manufactured locally. Sometimes craftsmen begin to operate a spotter, the parts and wires of which are simply laid out on a workbench or even on the floor. This option is only suitable for debugging and selecting parameters; such an electrical installation cannot be used in constant mode.

Since there are various options for making spotters with your own hands, their body layouts can also be different. For example, if a welding transformer is intended for use outdoors, then in this case the device may take the form of a stable base with a transformer, a terminal block and a separate control system housing.

In other cases, housing options may be different, but the control system elements must always be reliably protected from external influences.

VIEW Spoter on AliExpress →

Battery based

A battery powered spotter is suitable for applications where mains power is insufficient, unstable or non-existent and where body work is limited.

Typically, this situation arises during body repair of a personal car in a garage cooperative or at a summer cottage. The body of such a homemade spotter may consist of a small support frame for installing the battery, to which a terminal block and a relay that controls shutdown are attached. If this is a one-time job, then you can do without a housing at all by attaching the relay to the battery with a clamp.

Based on a household microwave

To make a spotter with your own hands, a transformer from a microwave is also suitable. In this case, the only limitation is its power, since most microwave ovens are designed to consume less than 1 kW.

To solve this problem, you can use two or three transformers connected in parallel. The advantage of such a power source is the small size of the transformers used, which can be placed in a row inside a small-sized housing.

The result is a fairly compact and mobile spotter. The only thing you have to worry about is cooling the internal space of such a device.

Do-it-yourself spotter: description and operating principle of the device (100 photos)

Almost anyone can assemble a homemade welding spotter; you do not need to be an expert in electrical engineering or mechanics. Spot welding with a spotter is most actively used when repairing dents on car bodies.

Schematic diagram

The only thing that will make you scratch your head is the circuit diagram that you need to understand. This is a diagram of the simplest of the different types of spotters.

The main unit of the spotter will be a welding transformer, and the voltage transmitted to its winding is supplied through a diode bridge, which contains a transistor. This resistance is controlled by changing the voltage transmitted by a low-power transformer.

Required materials for assembly

- Welding transformer;

- Supply transformer;

- Diode bridge capable of operating at a voltage of at least 5-8 V;

- Set of diodes (12V);

- Thyristor (hammer);

- Variable resistance, the nominal value of which is 100 ohms.

The most inaccessible element in this circuit is the welding transformer.

If desired, you can make it yourself. To do this, you need to purchase or manufacture a magnetic circuit whose working cross-sectional area will be more than 350 square meters. millimeters.

To protect yourself from a painful electric shock and prevent damage, you must first follow the instructions for working with the spotter and well insulate the windings of your homemade transformer.

Suitable for this purpose:

- Cardboard or paper;

- Varnished fabric;

- Paraffin-soaked rags.

The ends of the winding must be of sufficient length so that they can be connected to the terminals and to the electrical circuit of the installation.

Case manufacturing

The first thing you should tackle is making the base for attaching the homemade spotter. For it, it is better to choose a material based on a dielectric. To manufacture an unsuitable housing, it is better to draw up a detailed drawing and indicate the location of the main structural components.

An old microwave or welding machine can be a good option for the housing. It is necessary to remove excess equipment and place new one so that the load is evenly distributed throughout the volume of the box. If you plan to move the spotter frequently, you can install wheels on the bottom of the body.

Accessories

The manufactured spotter needs to be equipped with the following key elements:

- Manipulator gun;

- Welding cables;

- Reverse hammer (inopuller).

In order to choose the right welding cables, you need to know that for every 10 amperes of the maximum possible current value, you need to use 1 sq. mm section. The length of the working cable should not exceed three meters, and the cable weight should not exceed two. Otherwise, there will be large voltage losses.

The ends of the cables must be equipped with connecting elements to connect them to the gun and spotter. To connect to a spotter, it is better to use quick-release terminals, and for connection to a gun, a threaded section would be the best option. Before assembling, familiarize yourself with the photo of the spotter and the main components of the device.

Working pistol

If you plan to use a spotter regularly, then the best solution would be to purchase a factory pistol.

This is due to the fact that the gun is the main working element and will be constantly exposed to high currents, and if it malfunctions, it can cause harm to the person using it.

But if the application is limited to special cases, it is quite possible to make it yourself.

For the base, you can take a standard glue gun or a manipulator from an old welding machine. You need to make an insulated handle for the manipulator; PCB is perfect for this purpose, from which you need to cut two symmetrical rectangular parts.

It is necessary to install a bracket in the handle to secure the electrode from the working cable. Also, if desired, you can equip the handle with lights that will signal the presence of voltage.

A copper rod is ideal for creating a bracket. An electrode from the working cable will be connected to it; it is better that this electrode can be removed from the device without disassembling the handle.

Homemade reverse hammer

If the previous points have been completed, then difficulties should not arise in the future. Making a reverse hammer yourself is an economically profitable enterprise, since factory hammers are quite expensive.

The part of the polyurethane foam manipulator in which the container with the contents is located is best suited for this purpose. 3 rods are welded to the vacated area, which will become uprights.

In the rod of the device, you need to remove the stop and the curved part, and in its place a bracket is installed to connect the cable from the spotter.

DIY spotter photo

How to make an electrode for a spotter

Spotter electrodes and adapters are small cylindrical attachments made of brass, each of which is used to work with certain types of welding fasteners: washers, nails, studs, crimped wire rivets. In stores, each of these elements can cost from 500 to 1000 rubles or more, and for ordinary body work you need at least five or six types of electrodes:

- for rings;

- for spot welding;

- for corrugated wire;

- for welding with carbon electrode;

- for triangular washers;

- for pins and nails.

Making them yourself is not so difficult, but it requires certain skills and the availability of appropriate equipment. Alternatively, you can make only the simplest attachments with your own hands, and order more complex ones in a workshop with turning and drilling equipment.

In battery spotters, batteries with a capacity of 40÷60 Ah are usually used as a power source. If anyone has had to work with such devices, please write in the comments: how quickly the battery discharges and how the quality of welding changes as it discharges.