Every car owner needs a battery charger, but it costs a lot, and regular preventive trips to a car service center are not an option. Battery service at a service station takes time and money. In addition, with a discharged battery, you still need to drive to the service station. Anyone who knows how to use a soldering iron can assemble a working charger for a car battery with their own hands.

The nuances of battery operation

The most common type is the lead-acid battery. The service life of the device is calculated on average for 5 years. Recharging such batteries requires using at least 10% of the current from the total capacity of the device.

For example, with an indicator of 75Ahh, a minimum current value of 7.5A is required for charging. If the current is higher, the battery will not fail, but the car may lose its brains.

Repairing the control unit for air conditioning, gearbox, alarm system, and so on is not a cheap pleasure.

A device with a voltage of 11.9-12.1 Volts is discharged; in working condition, the charge level should be 12.5-12.7 Volts.

A little theory about batteries

Any battery is a storage device for electrical energy. When voltage is applied to it, energy is stored due to chemical changes inside the battery. When a consumer is connected, the opposite process occurs: a reverse chemical change creates voltage at the terminals of the device, and current flows through the load. Thus, in order to get voltage from the battery, you first need to “put it down,” that is, charge the battery.

Almost any car has its own generator, which, when the engine is running, provides power to the on-board equipment and charges the battery, replenishing the energy spent on starting the engine. But in some cases (frequent or difficult engine starts, short trips, etc.) the battery energy does not have time to be restored, and the battery is gradually discharged. There is only one way out of this situation - charging with an external charger.

How to find out the battery status

To decide whether charging is necessary, you need to determine the state of the battery. The simplest option - “turns/does not turn” - is at the same time unsuccessful. If the battery “doesn’t turn”, for example, in the garage in the morning, then you won’t go anywhere at all. The “does not turn” condition is critical, and the consequences for the battery can be dire.

The optimal and reliable method for checking the condition of a battery is to measure the voltage on it with a conventional tester. At an air temperature of about 20 degrees, the dependence of the degree of charge on the voltage at the terminals of a battery disconnected from the load (!) is as follows:

- 12.6…12.7 V - fully charged;

- 12.3…12.4 V - 75%;

- 12.0…12.1 V - 50%;

- 11.8…11.9 V - 25%;

- 11.6…11.7 V - discharged;

- below 11.6 V - deep discharge.

It should be noted that the voltage of 10.6 volts is critical. If it drops below, the “car battery” (especially a maintenance-free one) will fail.

Correct charging

There are two methods of charging a car battery - constant voltage and constant current. Each has its own characteristics and disadvantages:

- Constant voltage charging - suitable for restoring the charge of not completely discharged batteries, the voltage at the terminals of which is not lower than 12.3 V. The process is as follows: a direct current source with a voltage of 14.2–14.7 V is connected to the battery terminals. The end of the process is monitored by the current consumption: when it drops to zero, charging is considered complete. The disadvantage of this method is that the initial charging current may be high; The more the battery is discharged, the higher the current. The advantages of the method are obvious - you do not need to constantly adjust the charging current, and the battery is not in danger of being overcharged if you forget about it.

- DC charging is the most common and reliable method. In this mode, the charger produces a constant current equal to 1/10 of the battery capacity. The end of the charging process is determined by the voltage on the battery - when it reaches 14.7 V, the battery stops charging. The disadvantage of this method is that the battery can be damaged if you do not remove it from charging in time.

Conditions for homemade battery charging

To charge the device, the following requirements must be met:

- Constant voltage setting – 14.4V;

- Possibility of charging for a long time;

- Automatic shutdown when maximum current values are exceeded;

- Protection against pole connection error. When connecting minus to plus, the charging process must be stopped.

Any violation of the above requirements may irreversibly damage your device.

Precautionary measures

When using self-assembled devices, the following safety precautions should be observed:

- All devices, including the battery, must be on a fire-resistant surface.

- When using the manufactured device for the first time, it is necessary to ensure full control of all charging parameters. It is imperative to control the heating temperature of all charging elements and the battery; the electrolyte should not be allowed to boil. The voltage and current parameters are controlled by a tester. Primary monitoring will help determine the time it takes to fully charge the battery, which will be useful in the future.

Assembling a battery charger is easy even for a beginner. The main thing is to do everything carefully and follow safety measures, because you will have to deal with an open voltage of 220 volts.

Models of homemade battery chargers

Any homemade charger does not provide any guarantee of long-term operation. The main thing here is simplicity and efficiency. Next, let's look at examples of how you can charge a car battery yourself.

Microwave oven charger

Some car enthusiasts use a transformer from a broken microwave oven. But this transformer will need to be redone, since it is a step-up transformer, not a step-down transformer.

It is not necessary that the transformer be in good working order, since the secondary winding in it often burns out, which will still have to be removed during the creation of the device.

Remaking the transformer comes down to completely removing the secondary winding and winding a new one.

An insulated wire with a cross-section of at least 2.0 mm is used as a new winding. sq.

When winding, you need to decide on the number of turns. You can do this experimentally - wind 10 turns of a new wire around the core, then connect a voltmeter to its ends and power the transformer.

According to the voltmeter readings, it is determined what output voltage these 10 turns provide.

For example, measurements showed that there is 2.0 V at the output. This means that 12V at the output will provide 60 turns, and 13V will provide 65 turns. As you understand, 5 turns adds 1 volt.

Scheme.

Well, then everything is done as described above - the diode bridge is made, all the components are connected and the functionality is checked.

It is worth pointing out that it is better to assemble such a charger with high quality, then place all the components in a case that can be made from scrap materials. Or mount it on a base.

Be sure to mark where the “positive” wire is and where the “negative” wire is, so as not to “over-plus” and damage the device.

Using a lamp and a semiconductor diode

This method of recharging a battery device is relevant at home. To implement this, you must have a 220V outlet.

- The circuit elements include a standard 100-150 Watt incandescent lamp, a semiconductor diode, a socket plug and a cable with crocodile clips.

- In this connection, the diode serves as a voltage converter from AC to DC.

- To prevent a short circuit, it is enough to use a 10-15 A fuse. The lamp and diode must be connected to the “+” of the battery.

With a lamp power of 100 watts, the incoming current will be 0.17A. To achieve a value of 2A, you will need to charge the battery for at least 10 hours.

Most likely, it will not be possible to completely restore the charge of a dead battery, but it will be enough to start the car.

Causes and signs of battery discharge

During the operation of the battery, when the engine is running, the battery is constantly recharged from the vehicle's generator. You can check the charging process by connecting a multimeter to the battery terminals with the engine running, measuring the charging voltage of the car battery. The charge is considered normal if the voltage at the terminals is from 13.5 to 14.5 Volts.

Battery charge level table.

Question to the expert

What should be the minimum battery voltage?

The voltage of a normally charged battery during parking should be at least 12.5 Volts. If the voltage is less than 11.5 Volts, the car engine may not start during the start.

To fully charge, you need to drive the car for at least 30 kilometers, or about half an hour in city traffic. Reasons for battery discharge:

- The battery has significant wear (more than 5 years of operation);

- improper operation of the battery, leading to sulfation of the plates;

- long-term parking of the vehicle, especially in the cold season;

- urban rhythm of car driving with frequent stops when the battery does not have time to charge sufficiently;

- leaving the car's electrical appliances on while parked;

- damage to the electrical wiring and equipment of the vehicle;

- leaks in electrical circuits.

Additional material: What is a multimeter and how to choose one.

Many car owners do not have the means to measure battery voltage (voltmeter, multimeter, probe, scanner) in their on-board tool kit. In this case, you can be guided by indirect signs of battery discharge:

- dim lights on the dashboard when the ignition is turned on;

- lack of starter rotation when starting the engine;

- loud clicks in the starter area, lights on the dashboard going out when starting;

- complete lack of reaction from the car when the ignition is turned on.

If the listed symptoms appear, first of all you need to check the battery terminals, if necessary, clean and tighten them. In the cold season, you can try to bring the battery into a warm room for a while and warm it up.

Do-it-yourself charger.

Charging model assembled from a PC power supply

The standard power supply for a personal computer is rated at 12 Volts. To charge the battery, we remind you that you will need at least 14.4 Volts.

First, all unnecessary wires are unsoldered; for charging you will only need green wires. The end of this cable is soldered to the negative contacts where the black wires exit.

- This circuit allows you to start the charger directly. The wires coming from the battery terminals are connected to the minus and plus on the power supply. The plus is soldered where the yellow cable exits, and the minus is soldered to the end of the black wire.

- Next, you need to regulate the power; a TL494 or TA7500 microcontroller is assigned to this characteristic in the power supply. We turn the board over and look for the leftmost leg of the microcircuit.

- 3 resistors are connected to the lower output of the microcontroller. You need to find a resistor connected to the terminal of the 12V block, unsolder it, and then measure the effective resistance.

To determine the required number of kOhms, a variable resistance resistor is soldered in place of the soldered resistor. We connect the power supply board to the network by hooking up a multimeter to it.

Using a variable resistor, we obtain the minimum required voltage value of 14.4 Volts. Once this voltage is reached, we solder the variable resistor and measure the resistance.

Next, install a constant resistor designed for the obtained value. Such a homemade charger will produce a current of about 5-6A, which is quite enough to charge batteries with a capacity of 50-60Ah.

If the transformer is not suitable

Not always in a garage or at home you will find just such a transformer that will be powered by 220V and output 13 - 15V at the output terminals. Most models used in everyday life do have a 220V primary coil, but the output can be of any value. To fix this you will need to make a new secondary.

First, recalculate the transformation ratio using the formula: U1/U2 = N1/N2,

where U1 and U2 are the voltage on the primary and secondary windings, respectively;

N1 and N2 are the number of turns in the primary and secondary, respectively.

For example, an electric machine is used as a 42V power supply, but you want to get 14V for the charger. Therefore, you need to make 31 turns on the charger secondary with 480 turns in the primary. This can be achieved either by reducing the number of turns, removing unnecessary ones, or by winding a new one. But the first option is not always suitable, since the cross-section of the transformer winding may not withstand the current with a smaller number of turns.

U1*I1 = U2*I2 ,

Where U1 and U2 are the voltage on the primary and secondary windings, I 1 and I 2 are the current flowing in the primary and secondary.

As you can see, with a decrease in the number of turns and voltage on the secondary winding, the current strength in it will increase proportionally. As a rule, the cross-sectional margin is not enough, so after determining the current strength, a new conductor is selected for it from the data in the table:

Table: selection of cross section, depending on the flowing current

| Copper conductor | Aluminum conductor | ||

| Section of veins. mm2 | Current, A | Section of veins. mm2 | Current, A |

| 0,5 | 11 | — | — |

| 0,75 | 15 | — | — |

| 1 | 17 | — | — |

| 1.5 | 19 | 2,5 | 22 |

| 2.5 | 27 | 4 | 28 |

| 4 | 38 | 6 | 36 |

| 6 | 46 | 10 | 50 |

| 10 | 70 | 16 | 60 |

| 16 | 80 | 25 | 85 |

If the calculated current value at the output of the charger exceeds the required 10% of the battery capacity, a current-limiting resistor must be included in the circuit, the value of which is selected in proportion to the excess current.

How to properly use a homemade charger

Any homemade device requires special care to use. Here are some tips when using them:

- Carefully observe polarity when connecting. Check manual charging with a multimeter.

- Do not close the contacts to check the operating voltage level. Although it is recommended to short-circuit for 1-3 seconds in order to establish which can the discharge is coming from, such a short-circuit can have a negative impact later when charging the device.

- Connect the battery to the network only after the terminals have been correctly connected and securely fixed. Switch off in reverse order.

- Many people, when working with a battery, forget about the acid inside the device. After removing it, do not keep it in an area exposed to sunlight and allow it to overheat.

- After charging the battery, do not leave it for a long time. A homemade charging device can fail at any time. And as a consequence, you will have to purchase a new battery.

Homemade chargers are ideal for cases when the battery has already passed more than 3-4 years of use and is close to exhausting its service life.

If you don’t have the financial means, then such models will really help you start your car, especially in winter. For relatively new batteries, it is better to purchase certified factory starting devices.

What you need to know when charging a battery

When charging a car battery, it is important to follow a number of rules. This will help you extend your battery life and maintain your health:

- All lead batteries are charged with a current no higher than one tenth of the battery capacity. If you have a battery with a capacity of 60 A/h in your car, then the calculation of the charging current looks like this: 60/10 = 6 A.

- Explosive gases may be released during charging. This is especially true for serviceable batteries. One spark is enough for hydrogen accumulated in a garage or other room to explode. Therefore, you need to charge batteries in a well-ventilated area or on a balcony.

- Charging the battery is accompanied by the release of heat, so constantly monitor the temperature of the battery case by touch. If the battery becomes noticeably hot, immediately reduce the charging current or stop charging altogether.

- If the battery is serviceable, constantly monitor the electrolyte level in the banks and its density. During the charging process, the electrolyte “boils away” and the density increases. If the plates in the jar are exposed or the density rises above 1.29, and charging is not yet complete, add distilled water to the electrolyte.

- Do not overcharge the battery. The maximum voltage on it with the charger connected is 14.7 V.

- Do not allow the battery to be deeply discharged; recharge it periodically. If the voltage on the battery drops below 10.7 when the load is off, the battery will have to be thrown away.

The question of creating a simple battery charger with your own hands has been clarified. Everything is quite simple, all you have to do is stock up on the necessary tools and you can safely get to work.

Originally posted 2018-07-04 08:34:51.

Photo of a homemade charger for a car battery

Composition and terms

Autocharging consists of a primary power source for the charger itself, which provides a specified charging mode for the battery, and circuits to protect it from various types of emergency situations. Circuit design, these nodes can be combined to one degree or another. Below, for brevity, the following is used. abbreviations:

- AKB – rechargeable battery.

- PI is the primary power source.

- IP – any other power source.

- Ultrasound – protection device.

- TZ – current protection.

- ZN – overvoltage protection.

No need!

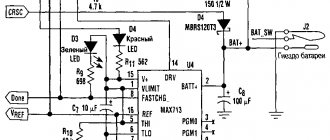

Let's first talk about typical mistakes in designing homemade chargers for lead batteries. The first is illustrated by pos. up. Connecting directly to the household electrical network (left) is not worth discussing. This is not a mistake, this is a gross and dangerous violation of safety regulations. The error is in limiting the charging current by capacitive ballast. Expensive, by the way, this is a method by today's standards: the battery of oil-paper capacitors alone at 32 uF 350 V (lower voltage is not possible) costs more than a good branded charger.

Incorrectly and irrationally constructed charger circuits for car batteries

But the main thing is that a reactive load appears in the network. If your electric meter has a reactivity indicator (LED “Return”), then when these charges are plugged into the network it will flash. Managing modern electrical equipment is impossible without computers, and the “return” confuses the electronics even to the point of shutting down due to a false alarm. That's why today's electricians are merciless when it comes to reactive power. Well, what if it turns out that its source is illiterate or an overly cunning consumer, then... let’s not look into the night.

The circuit below, if we take into account the same capacitive ballast, was developed skillfully, this charger will protect the battery, figuratively speaking, from the Tunguska meteorite; (a detailed description of it can be found here: https://ydoma.info/avtomobil-zaryadnoe-ustrojstvo-dlya-avtomobilnogo-akkumulyatora.html). But, with all due respect to the author, who certainly knows his business, building such a difficult (and expensive) charger for lead batteries is like assigning a nanny from a kindergarten to command a platoon of experienced, seasoned soldiers. A lead battery needs little to live well. What will we do next?

Charging Requirements

Based on the operating conditions of individual vehicles and the specified conditions of the battery charging mode, the requirements for a charger for a car battery are as follows:

- A homemade charger for a car battery must be autonomous, not requiring supervision and control of the charge current/voltage, because The battery will be charged mainly overnight;

- The PI memory must provide a stable voltage of 14.4 V, acceptable in the case where there is a voltage drop across the US, 15.6 V;

- The ultrasonic switch must ensure irreversible disconnection of the battery from the charger both when the charging current is exceeded and when the voltage on the battery increases above 15.6 V. Irreversible means that the ultrasonic switch must be self-locking, i.e. to reset it to its original state, you will need to turn off and turn on the IP again;

- Also, the ultrasound must provide protection against polarity reversal, i.e. Incorrect, reverse polarity, battery connection. If the conditions in clause 3 are met, protection against polarity reversal is provided automatically.

About polarity reversal

In case of battery polarity reversal, 2 cases are possible: the battery is serviceable, undercharged or deeply discharged and/or “profitable”, depleted, and has largely exhausted its resource, or a fully charged battery is incorrectly connected to the charge. In the first case (properly undercharged), the charge current increases above the nominal one. In the second, before this, the battery voltage will “jump” for a short time above the specified IP, and then the extra current will immediately “jump” and the battery will boil. In the latter situation, in order to save the battery from irreparable damage, it must be turned off due to overvoltage.

About thyristor rectification

The scope of application of controlled thyristor rectifiers is limited due to the large switching noise they create on the rectified voltage. But in the charger these interferences are not a hindrance; the battery will extinguish them. But in terms of other properties, thyristor rectifiers for charging batteries are not only suitable, but ideal.

The fact is that after thyristor rectification without smoothing, the charging current is supplied to the battery in short pulses with a cut-off edge of increased (but not excessive) amplitude. As a result, charging a car battery with a thyristor rectifier gives a desulfating effect without any additional tricks. And, what is also important, the probability of the battery going into self-heating when charging from a thyristor charger is an order of magnitude less: unnecessary electrochemistry has time to dissolve in the intervals between pulses. Another plus is the same as for Schottky diodes: a radiator for a pair of thyristors needs the same area as for the Schottky assembly.

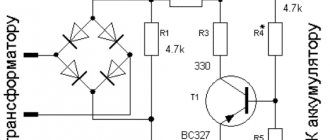

For the sake of simplicity, thyristor chargers are often built using a half-wave rectification circuit, see figure:

Thyristor chargers for car batteries with half-wave rectification

The bottom scheme is the cheapest, because To control a power thyristor, instead of a low-power thyristor, its transistor analogue is used; it is two to three times cheaper. The circuit on the top right is the most expensive due to the very expensive industrial thyristor T122-25, which also requires an anti-noise filter C1T1C2. Otherwise, these memory devices are equivalent.

Half-wave thyristor memory devices have one, but fatal, drawback - that same half-wave rectification. Half of the primary half-waves of current are lost. In order not to double the charge, you have to resp. increase the amplitude of the charging pulse. It goes beyond the permissible limits, and the advantages of thyristor rectification are negated. On the contrary, a half-wave thyristor charger is more dangerous for the battery than a diode charger.

Charger circuits for car batteries with full-wave thyristor rectification retain all its advantages and are free from the above disadvantage. But an appropriate approach to constructing a thyristor rectifier is needed. For example, the diagram on the left in Fig. – typically amateur. The rectifier is made similarly to a diode bridge, which doubles the voltage drop across it and requires a couple of completely unnecessary, rather expensive components. The switching interference from such a charger is strong, and you need to wind an atypical transformer.

Schemes of thyristor chargers for car batteries with full-wave rectification

The well-known Amperus auto-charging circuit is close to the optimal one for thyristors, on the right in Fig. Its authors also took care of good anti-noise isolation of control circuits, which allows Amperus to be used in an apartment. The only small drawback is that the charge current and voltage are interdependent, because are set together with a 1 kOhm resistor. Therefore, it is advisable to use Amperus with ultrasound (see above).