To connect an electrical device to your home network, one surge protector or uninterruptible power supply unit is enough. These devices will protect equipment from power surges. But what to do if there is a strong voltage drop in the network, or if the power network requires the use of higher or lower voltage. For such situations, you can assemble a homemade electrical current converter from 12V to 220V. To do this, you need to understand the basic principles of operation of this device.

Converters and their types

A converter is a device that can increase or decrease the voltage of an electrical circuit. This way you can change the circuit voltage from 220V to 380V, and vice versa. Let's consider the principle of constructing a converter from 12V to 220V.

These devices can be divided into several classes/types, depending on their functional purpose:

- Rectifiers. They work on the principle of converting alternating current to direct current.

- Inverters. They work in reverse order, converting direct current into alternating current.

- Frequency converters. They change the frequency characteristics of the current in the circuit.

- Voltage converters. Change the voltage up or down. Among them are: Switching power supplies.

- Uninterruptible power supplies (UPS).

- Voltage transformers.

Also, all devices are divided into two groups - according to the control principle:

- Managed.

- Uncontrollable.

Buy or make it yourself?

Of course, purchasing a ready-made inverter is not a problem.

In any electrical goods store the selection is simply huge. And they differ in power, cost, and design options. But the price of an inverter with a power of about 0.5 kW will be at least three thousand rubles - and this is an impressive amount. Moreover, it is unlikely that you will be able to connect a lot of equipment to it. Therefore, some car owners who have a spare battery are thinking about how to make a voltage converter themselves. The article will discuss various designs of converters that have become widespread among electrical engineers.

Common Schemes

To convert voltage from one level to another, pulse converters with installed inductive energy storage devices are used. Based on this, three types of conversion schemes are distinguished:

- Inverting.

- Raising.

- Downgrades.

All of the following circuits use electrical components:

- Main switching component.

- Power supply.

- A filter capacitor that is connected in parallel with the load resistance.

- Inductive energy storage (choke, inductor).

- Diode for blocking.

Combining these elements in a certain sequence allows you to build any of the above schemes.

Simple pulse converter

The most basic converter can be assembled from unnecessary parts from an old computer system unit. A significant drawback of this circuit is that the 220V output voltage is far from ideal in its sine wave shape and has a frequency exceeding the standard 50 Hz. It is not recommended to connect sensitive electronics to such a device.

This scheme uses an interesting technical solution. To connect equipment with switching power supplies (for example, a laptop) to the converter, rectifiers with smoothing capacitors are used at the output of the device. The only negative is that the adapter will only work if the polarity of the output voltage of the socket matches the voltage of the rectifier built into the adapter.

For simple energy consumers, the connection can be made directly to the output of transformer TR1. Let's consider the main components of this scheme:

- Resistor R1 and capacitor C2 - set the operating frequency of the converter.

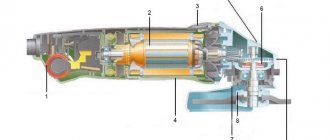

- PWM controller TL494. The basis of the whole scheme.

- Power field effect transistors Q1 and Q2 are used for greater efficiency. Placed on aluminum radiators.

- IRFZ44 transistors can be replaced with IRFZ46 or IRFZ48 with similar characteristics.

- Diodes D1 and D2 can also be replaced with FR107, FR207.

If the circuit involves the use of one common radiator, it is necessary to install transistors through insulating spacers. According to the scheme, the output choke is wound onto a ferrite ring from the choke, which is also removed from the computer power supply. The primary winding is made of 0.6 mm wire. It should have 10 turns with a tap from the middle. A secondary winding consisting of 80 turns is wound on top of it. The output transformer can also be removed from an unnecessary UPS.

The scheme is very simple. When assembled correctly, it starts working immediately and does not require fine tuning. It will be able to supply a current of up to 2.5 A to the load, but the optimal operating mode will be a current of no more than 1.5 A - and this is more than 300 W of power.

INTERESTING: In a store, a similar converter costs around 3-4 thousand rubles.

Converter circuit with AC output

This scheme is also known to radio amateurs of the USSR. However, this does not make it ineffective. On the contrary, it has proven itself very well, and its main advantage is the receipt of stable alternating current with a voltage of 220V and a frequency of 50 Hz.

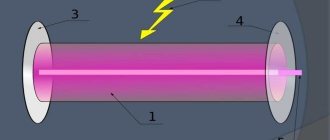

The K561TM2 microcircuit, which is a dual-type D-trigger, acts as an oscillation generator. This element can be replaced with a foreign analogue CD4013.

The converter itself has two power arms built on KT827A bipolar transistors. They have one significant drawback compared to new field-effect transistors - these components become very hot when open, which is due to high resistance values. The converter operates at low frequency, so a powerful steel core is used in the transformer.

This circuit uses an old TC-180 network transformer. It, like other inverters based on simple PWM circuits, produces a significantly different sinusoidal voltage waveform. However, this drawback is slightly mitigated by the high inductance of the transformer windings and the output capacitor C7.

IMPORTANT: Sometimes the transformer may produce a noticeable hum during operation. This indicates a problem with the circuit.

Electrician in the house

DIY 12/220 voltage converter

Currently, quite a lot of 12/220 V voltage converters are produced, designed for fairly high powers. But if you need a simple 12/220 voltage converter for your dacha or garage for lighting (TV, drill, pump), then you can make it yourself. The proposed scheme differs favorably from similar ones by the presence of a low battery alarm.

This is very important if you use a car battery to power the circuit. Although it is better to take another battery, or buy a new battery for the car and use the old one for the converter. The circuit uses a minimum of parts, but the device copes with its function quite well. Such devices that convert direct voltage into alternating voltage are also called inverters.

12/220 V voltage converter circuit

The diagram indicates:

- FU1 - 10A fuse.

- R1 - resistor MLT-0.5, 150 Ohm.

- R2 - variable resistor SP-1, 22 kOhm.

- R3 - trimming resistor SP3-16, 1 MOhm

- R4 - resistor MLT-0.125, 330 Ohm.

- R5, R7, R8 - resistors MLT-0.125, 2 kOhm.

- R6 - resistor MLT-0.125 1.5 kOhm.

- VD1 - zener diode KS 191A.

- C1 - capacitor K53-1, 50 µF x 50 V.

- C2, C3 - capacitors KM-5, 0.1 µF.

- C4, C5 - capacitors KM-5, 510 pF.

- VT1 is a unijunction transistor KT 117A.

- VT2, VT3 - KT 827A transistors.

- L1 - LED AL 307A.

- DD1 - K561TM2 chip.

- T1 - transformer.

Description of the circuit operation

The generator, assembled on transistor VT1, generates oscillations with a frequency of 100 Hz, the frequency can be adjusted by trimming resistor R3. Trigger DD1.2 divides the frequency in half and at outputs 12 and 13 of the trigger, pulses of opposite amplitude with a frequency of 50 Hz are formed. The pulses alternately open transistors VT2 and VT3, which are connected according to the circuit of a push-pull power amplifier. The load of transistors VT1, VT2 is windings 1 and 2 of step-up transformer T1, on the secondary winding 3 of which an alternating voltage of 220V, 50 Hz is generated.

The stabilizer made on VD1, R1 and smoothing capacitor C1 serve to power the microcircuit and generator and eliminate the influence of the operation of key transistors VT1, VT2 on the operation of the circuit, and capacitors C5, C4 reduce the time of the transition process (help these transistors switch faster). Trigger DD1 turns on the signal LED L1 when the battery voltage drops to a predetermined value, which is set by variable resistor R2.

Setting up the circuit

- Disconnect “+” from the connection of windings 1 and 2.

- Check the frequency at the bases of transistors VT2 and VT3 using an oscilloscope, adjust, if necessary, with resistor R3 to 50Hz.

- Reduce the power supply voltage to 10-11V. Achieve constant lighting of LED L1 using variable resistor R2.

- Connect “+” back to the connection point of windings 1 and 2.

- Check the operation of the device on a fully charged battery.

Circuit details

Transistors VT2, VT3 KT 827 can be taken with any letter index, but preferably with the highest base current transfer coefficient.

Zener diode VD1 can be replaced with any other with a stabilization voltage of 8-9V.

The transformer can be made on the basis of the PLM 27-40-58 magnetic circuit. Wind primary windings 1 and 2 with PBD-2 (PSD-2) wire, 15 turns each. Wind the secondary winding 3 with PEV-2 wire, 0.64 mm - 704 turns.

Install capacitor C2 directly at the terminals of microcircuit DD1.

If you do not have the required value of resistors and capacitors, you can make up the required one from several parts, as described in this article.

A printed circuit board can be made using the technology described in this article.

Converter parameters 12/220

This voltage converter was tested with a load of 100 W. The current consumption of the converter is no more than 10A, the current consumption without load is no more than 1A. The converter can withstand the starting currents of an electric pump and electric drill. The maximum output voltage drop is 10 V.

To power equipment that requires a sinusoidal signal, a capacitor can be installed at the output to smooth out the squareness of the pulses; its capacitance must be selected to achieve the best result; the selection can begin with a capacitance of 1 μF. The capacitor must be designed for a voltage of at least 400V.

It will be interesting to read:

Automatic light switching

Motion sensor for indoor lighting.

Air ionizer (Chizhevsky chandelier)

Headings: Useful devices, Electronic devices, Electrical circuits Tags: electronics, electrical appliances, electrical circuit

Simple transistor inverter

This scheme is not very different from those presented above. The main difference is the use of a rectangular pulse generator built on bipolar transistors.

The main advantage of this circuit is the ability of the converter to remain operational even with a very low battery. In this case, the input voltage range can be from 3.5 to 18V. But there are also disadvantages of such an inverter. Since the circuit does not have any stabilizer at the output, voltage drops are possible, for example, when the battery is discharged. Since this circuit is also low-frequency, a transformer is selected for it, similar to that installed in the inverter based on the K561TM2 microcircuit.

Improvements to inverter circuits

The above diagrams cannot be compared with factory products. They are simple and poorly functional. To improve their characteristics, you can resort to fairly simple modifications that increase the performance of the device.

ATTENTION: Any electrical and electronic installation is carried out with the power source disconnected. Before checking the circuit, test all inputs and outputs with a multimeter - this will avoid unpleasant consequences.

Increased power output

The circuits discussed above are based on the same principle - the primary winding of the transformer is connected through a key component (arm output transistor). It is connected to the input of the power source for a time specified by the frequency and duty cycle of the master oscillator. In this case, magnetic field pulses are generated, exciting common-mode pulses in the secondary winding of the transformer with a voltage equal to the voltage in the primary winding multiplied by the ratio of the number of turns in the windings.

Accordingly, current passes through the output transistor. In this case, it is equal to the load current multiplied by the inverse ratio of turns (transformation ratio). It turns out that the maximum current that the transistor can pass through itself sets the maximum power of the converter.

Two methods are used to increase output power:

- Installing a more powerful transistor.

- Using parallel connection of several low-power transistors in one arm.

For a homemade converter, it is preferable to use the second method, since it allows you to maintain the functionality of the device if one of the transistors fails. In addition, such transistors cost less money.

In the absence of internal overload protection, this method significantly increases the survivability of the converter. It also reduces the overall heating of internal components when operating at the same load.

Automatic shutdown when battery is low

These schemes have one significant drawback. They do not provide a component that can automatically turn off the converter in the event of a critical voltage drop. But solving this problem is quite simple. It is enough to install a regular car relay as a circuit breaker.

The relay has its own critical voltage at which its contacts close. By selecting the resistance of resistor R1, which will be approximately 10% of the resistance of the relay winding, the moment of contact breaking is adjusted. This option is demonstrated in the diagram.

This option is quite primitive. To stabilize the operation, the converter is supplemented with a simple control circuit that maintains the shutdown threshold much better and more accurately. The response threshold setting in this case is calculated by selecting resistor R3.

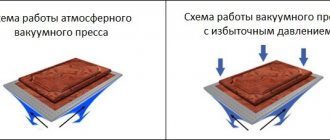

Filter elements

After the rectifier there is a filter. Its main purpose is to cut off the entire alternating component of the rectified current. For a clearer picture, you need to draw up a substitution diagram. So the plus goes through the coil. And then an electrolytic capacitor is connected between plus and minus. This is what is interesting about the replacement scheme. If the coil is replaced by reactance, then the capacitor, in the presence of varying current, can be either a conductor or a discontinuity.

As was said, the output of the rectifier is direct current. And when it is applied to an electrolytic capacitor, nothing happens, since the latter is an open circuit. But there is a small variable in the current. And if alternating current flows, then in the equivalent circuit the capacitor becomes a conductor. Consequently, there is a short circuit between plus and minus. These conclusions were made according to Kirchhoff’s laws, which are fundamental in electrical engineering.

Inverter fault detection

The circuits described above often have two specific defects:

- No voltage at the transformer output.

- Low voltage at the transformer output.

Let's look at ways to diagnose these faults:

- Failure of all arms of the converter or failure of the PWM generator. You can check the breakdown using a diode. A working PWM will show ripple on the diode when it is connected to the gates of the transistors. It is also worth checking the integrity of the transformer winding “for an open” in the presence of a control signal.

- A strong drop in voltage is the main sign that one power arm has stopped working. Finding a breakdown is not difficult. A failed transistor will have a cold heatsink. To repair, you will need to replace the inverter key.

Voltage converter from 12 to 220 V for a car

Automotive inverters are low-power devices (up to 0.1 kW), with an output signal in the form of a modified sine wave, activated by plugging into the car's cigarette lighter.

Currently, the following models are popular in this group of products:

"ORION PN-70" (Russia).

Device power – 0.9 kW, output signal – modified sine wave, output voltage 220 V, frequency 50 Hz. Provides short circuit protection. The device is equipped with one plug connector (socket) and a USB port.

"AIRLINE API-150-01" (Russia).

The output power of the device is 0.15 kW, the output signal is a modified sine wave. The device is plugged directly into the car's cigarette lighter and is equipped with one plug connector for a voltage of 220 V. The model is equipped with a USB port, its weight is 400.0 grams.

"AIRLINE API-200-02" (Russia).

This model is connected to the cigarette lighter using connecting wires. Device power – 0.2 kW. This model has protection against short circuit currents, one USB port and one socket for a voltage of 220.0 V.

"WESTER MSW250" (Germany).

Power – 0.25 kW, the model is equipped with a short-circuit current protection device, a USB port and a socket for a voltage of 220.0 V. The output signal is a modified sine wave.

"MYSTERY MAC-1000" (China).

Device power – 1.0 kW, number of sockets for 220 V voltage – 2 pcs., USB port.

The weight of the model is 2.6 kg.

How things are now

Modern element base makes it possible today to simplify the above-described design to a minimum.

Chip KR1211EU1

- To do this, you will first have to replace the bulky generator with a special microcircuit of the KR1211EU1 brand. Please note that this microcircuit is domestically produced; you will not find foreign analogues.

- Instead of power switches, it is best to use IRL2505 transistors; they are powerful and are used in car electrical circuits. By the way, their resistance is 0.008 Ohm, which is not comparable to mechanical contacts.

Installation of radio elements

All that remains is to assemble the device. Since there are not so many components in the circuit, they can be placed not on a printed circuit board, but mounted mounted to a radiator, that is, to the device body. We solder the pin legs with a solid copper wire of a sufficiently large cross-section, then the connection point is strengthened with 5–7 turns of thin transformer wire and a small amount of POS-61 solder. After the connection has cooled, it is insulated with a thin heat-shrink tube.

High-power circuits with complex secondary circuitry may require a printed circuit board with transistors lined up on the edge for loose attachment to the heatsink. Fiberglass with a foil thickness of at least 50 microns is suitable for making a signet; if the coating is thinner, reinforce the low-voltage circuits with jumpers made of copper wire.

Today it’s easy to make a printed circuit board at home - the Sprint-Layout program allows you to draw clipping stencils for circuits of any complexity, including double-sided boards. The resulting image is printed by a laser printer on high-quality photo paper. Then the stencil is applied to cleaned and degreased copper, ironed, and the paper is washed away with water. The technology is called “laser ironing” (LIT) and is described on the Internet in sufficient detail.

You can etch away copper residues with ferric chloride, electrolyte, or even table salt; there are plenty of ways. After etching, the baked-on toner needs to be washed off, drill mounting holes with a 1 mm drill and go over all the tracks with a soldering iron (submerged arc) to tin the copper of the contact pads and improve the conductivity of the channels.