What is a car gearbox, what are its structure and function, how to determine a malfunction and why the oil in the gearbox needs to be changed as regularly as changing the oil in the engine and changing the oil in the automatic transmission - we will answer these questions in this article and help you do right choice.

A gearbox is a mechanism as part of a car drive that transmits and converts torque received from the engine crankshaft. The torque is reduced (reduced, hence the name) and transmitted further to the transmission units. The gearbox device is a bevel gear located inside a separate housing.

Depending on the location, the gearbox of the front and rear axles is distinguished. For front-wheel drive cars, it is combined with the gearbox and installed, respectively, at the front. For rear-wheel drive vehicles, it is installed on the rear axle. All-wheel drive vehicles are equipped with two gearboxes connected to each other by a driveshaft.

The main reasons for changing gear oil

The frictional force that is present when the parts of the gear assembly are in constant contact leads to a chain reaction. At the output of a gearbox without lubrication, the gearbox itself, the special equipment it powers, and the technological process with its participation may suffer.

- During operation of the gearmotor, heat is generated. The gearbox lubricant heats up and loses its positive properties (lower viscosity means higher friction force).

- Abrasion of assembly parts leads to the entry of small hard chips into the lubricant, which also reduces their ability to compensate for frictional force.

- Deterioration of the oil in the gearbox provokes early wear of its parts and failure of entire components.

- If the gearbox breaks down during the active stage of operation, the equipment can also suffer a serious malfunction.

The specific timing of filling oil into the gearbox depends on the type of worm gear motor and its operating schedule. Do not forget that due to the same heat, the amount of lubricant decreases naturally.

In this matter, experts recommend relying on the recommendations of the mechanism manufacturer, which are detailed in the instructions for use. You should also focus on them when choosing consumables.

Purpose

Crane units are a separate group of gearboxes used in production. Their main purpose is to change the rotation speed and torque elements. As a rule, it is advisable to use them either in lifting equipment when transporting goods, or as a drive in equipment for general use. Thus, the RK-500 special crane gearbox is designed to change torques and rotation speeds.

Conditions of use

- Work in intermittent mode, i.e. under variable loads with periodic stops, long-term operation with a constant load is allowed;

- Rotation of shafts in any direction;

- Load of one direction and reversible;

- The peripheral speed should not exceed 12 m/sec;

- The input shaft rotation speed should not exceed 1500 rpm;

- Atmosphere types I and II according to GOST 15150-69 with air dust content not exceeding 10 mg/m 3 ;

- Climatic versions: U, T – for accommodation categories 1-3; UHL and O - for placement category 4 according to GOST 15150-69.

Read also: Profile bending for profile pipes

Ordering a gearbox RK

order and buy the RK-500 crane gearbox by calling: 8-800-2000-220, +7 (8412) 233-133, +7 (8412) 233-134. PTC PRIVOD LLC supplies to such regions as: Moscow, Rostov-on-Don, Voronezh, Krasnodar, Penza. For questions regarding the cost, production, modernization and repair of RK gearboxes, please contact the contact numbers.

The designation of RK gearboxes when ordering: RK-500 -50-12M-U1-48 means that the device is of the RK type, with an axial distance of 500, a nominal gear ratio of 50, assembly option 12, output shaft end version - M and climatic version U1, number of gear coupling teeth 48

Specifications

| Gear ratio | Nominal Actual | 8 8,23 | 10 10,35 | 12,5 12,64 | 16,0 15,75 | 20,0 20,49 | 22,4 23,34 | 31,5 31,50 | 40,0 41,52 | 50,0 48,57 |

| Rotation speed, rpm | Operating mode | Permissible torque on the output shaft of the gearbox, kNm | ||||||||

| RK – 500 | ||||||||||

| 600 | Extra light PV-15% PV-25% PV-40% | 51,27 29,54 25,63 21,73 | 51,88 30,28 26,86 22,74 | 54,36 32,81 28,61 24,22 | 57,38 35,16 30,52 25,88 | 58,29 32,96 28,69 24,42 | 57,77 32,13 28,03 23,58 | 59,60 35,09 30,28 25,96 | 62,87 32,35 28,08 23,80 | 64,85 33,57 29,37 24,80 |

| 750 | Extra light PV-15% PV-25% PV-40% | 48,34 25,78 22,46 19,04 | 50,66 28,81 25,02 21,24 | 53,41 30,52 33,99 31,98 | 56,64 33,99 29,49 23,44 | 57,38 31,98 27,83 23,68 | 57,42 31,72 27,62 23,52 | 60,37 33,84 29,61 25,00 | 62,01 32,23 27,83 23,68 | 64,70 35,57 28,99 24,27 |

| 1000 | Extra light PV-15% PV-25% PV-40% | 51,50 27,01 23,46 19,91 | 54,20 28,27 24,61 20,95 | 55,85 29,66 25,82 21,97 | 55,37 30,35 26,46 22,56 | 59,12 33,17 28,84 24,51 | 61,16 31,49 27,47 23,44 | 61,16 31,49 27,47 23,44 | ||

| 1250 | Extra light PV-15% PV-25% PV-40% | 54,20 28,71 25,05 21,24 | 54,14 28,22 24,61 21,01 | 57,58 29,30 25,61 21,92 | 60,06 30,76 26,66 22,56 | 63,36 32,59 28,57 24,17 | ||||

| 1500 | Extra light PV-15% PV-25% PV-40% | 52,64 25,43 22,15 18,77 | 57,68 26,34 22,88 19,42 | 58,60 29,79 25,88 21,97 | 62,56 31,43 27,47 23,19 | |||||

- during long-term operation with a constant load, the load value should be reduced by 50% compared to the PV mode = 40%;

- the permissible radial cantilever load on double-ended shafts is reduced by 2 times.

Overall and connection dimensions

| Standard size | Center distances | L | L1 | L2 | l | l1 | l2 | l3 | l4 | l5 | |

| awt | awb | ||||||||||

| RK – 500 | 350 | 500 | 1640 | 510 | 550 | 1120 | 610 | 300 | 205 | 546 | 530 |

| Standard size | B | B1 | B2 | B3 | H | H1 | H2 | h | d | Weight, kg |

| RK 500 | 580 | 520 | 580 | 408 | 875 | 400 | 105 | 35 | 32 | 1230 |

Dimensions of high-speed shaft ends

Dimensions of low-speed shafts (for couplings)

In terms of price-quality ratio, the NMRV gearmotor is better than all similar products offered to the Russian market. In any product of a wide model range, high reliability and an optimal reasonable price are guaranteed.

The designers have provided for the unification of the connecting dimensions, which makes it easy to select a UD-RV (analogous to an NMRV) to replace a gearmotor that has encountered problems during operation and has failed from almost any company offering its products to the Russian consumer.

The design developers have selected a very effective lubricant based on high-quality synthetic and semi-synthetic oils; the lubrication scheme contributes to the trouble-free operation of the gear units and does not require replacement throughout their operation.

Performance Features

Scientists at the API Institute, operating in the United States, have created a classification that provides a comprehensive assessment of gearbox oils depending on their performance properties. Now it is distributed all over the world. The system provides five categories that indicate the level of quality and application features of products with the corresponding index. In the domestic GOST, the classification is indicated only in the letter designations placed at the beginning of the index.

Recommendations for choosing oils for the KamAZ axle

How much oil to pour into the gearbox

— The front axle gearbox holds 5.3 liters of transmission oil. — 7.75 liters of oil are poured into the middle axle gearbox. It is advisable to fill through 0.75 liters, the remaining 7 liters into the gearbox. — 7 liters of oil are poured into the rear axle gearbox of KamAZ 5320-2402010-10.

There are many types of bridges with a similar structure, but there are exceptions. Therefore, when filling oil, be guided by the level of the control holes.

Selecting oil for KamAZ gearbox

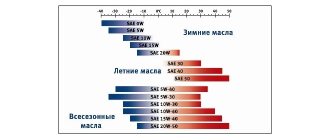

The choice of oil depends on the preferences of the driver/mechanic and his financial capabilities. It is better to choose gear oil from well-known manufacturers 75W-90 (for temperate climates), 80w-90 (for warm climates), 85W-90 (for hot countries).

— The most inexpensive: TAD-17

and (analogous to TM-5-18) - universal all-season mineral oil for truck transmissions. It has a particularly strong oil film, ensuring reliable operation of the transmission under intense friction conditions in the contact zones, and is operational in the temperature range from -25°C to 130-140°C. In the cold season at temperatures of -30..-35 degrees, the oil thickens greatly!

— Castrol Syntrax Long Life 75W-90

— Fully synthetic universal final drive oil. Particularly recommended for final drives of heavy commercial vehicles. Approved by MAN, Scania and ZF.

— Shell Spirax S6 AXME 75W-90

— unique synthetic oils for drive axles and gearboxes. It has energy-saving properties, as well as the ability to extend replacement intervals, approved by the manufacturers: Volvo, MAN, Meritor, Scania, DAF, Mack, Iveco, ZF.

— MOTUL Motylgear 75W-90

— transmission oil for heavily loaded gearboxes and hypoid axles without automatic locking and limited slip systems. Standards: API GL4 and GL5; MIL-L-2105D.

— Mobilube HD 80W-90

is a high-performance oil for heavily loaded transmissions, developed from high-performance base oils and an advanced additive package. Designed for final drives where extreme pressures and shock loads are expected.

— Esso Gear Oil GX 75W-90

— partially synthetic all-season transmission oils for use in heavily loaded modern final drives (gearboxes).

Checking the oil level in the crankcases of the main gears of the drive axles

To check the oil level, place the car on a horizontal platform and 5-10 minutes after stopping the engine, check the oil level by unscrewing the inspection hole plug on the axle housing. If there is no oil leakage from the inspection hole, add oil to the lower edge of the inspection hole through filler hole.

Why is the car not suitable?

Among automobile oils there are many special ones, with various additives, which are not suitable for walk-behind tractors.

For example, it is not recommended to use the TM 5 transmission for walk-behind tractor gearboxes. This special oil with a high content of protective and restorative sulfur-phosphorus additives is used only where it is recommended.

On the gearboxes of the walk-behind tractor, it can form protective deposits, films of considerable thickness, which cannot be washed off in this unit and are not needed. This can lead to changes in tooth sizes and problems.

The same applies to special motor oils. In addition, such oils are often much more expensive.

Therefore, it would be more accurate to say that automobile oils are suitable for walk-behind tractors, but not all. I hope we have fully answered the question and now you understand whether it is possible to pour automobile oil into a 4-stroke walk-behind tractor engine.

Classification

According to DIN

According to DIN 51517, the classification and marking of gear oils is as follows.

Class

Description

Properties

Mineral oil without additives

The most affordable product. Compatible with unloaded and lightly loaded systems

Mineral oil with anti-corrosion and antioxidant additives

Oils with extended shelf life for systems without anti-wear requirements

Mineral oil with additional anti-wear additives

Used in mechanisms that require enhanced protection against wear of parts

According to AGMA

Another generally accepted classification was developed by the American Lubricants Manufacturers Association (AGMA). This specification determines the viscosity of oils for gears and gearboxes. The viscosity ratio according to AGMA and ISO standards is given in the table below.

AGMA

Corresponding ISO grade

AGMA (EP gear oils)

AGMA (synthetic gear oils)

According to ISO (gear oil viscosity grades)

The viscosity of gear oils is assessed according to the ISO VG standard. The abbreviation VG stands for viscosity grade, which translated from English means “viscosity grade”. High-quality gear oils meet the requirements of ISO classes from 2 to 1500. ROLF Lubricants GmbH products are presented in the following viscosity range: 68, 100, 150, 220, 320, 460.

Application

According to statistics, about 40% of gear oils are used in production equipment - machines, dies, forging presses, etc. Another 40% is consumed by the metallurgical industry. The remaining 20% is distributed mainly among mine and ship equipment.

There is a separate category of gear oils used in equipment in food production. Special food grade approvals have been developed for these oils in case they come into contact with products.

Synthetic based oils are more common because they do not evaporate. In addition, they have a longer service life, several times longer than the shelf life of mineral-based oils. This allows you to change the oil less frequently or regenerate it.

Gear oils are used in difficult conditions, so they have higher performance than others, production is expensive and is controlled as carefully as possible.

The world's leading corporations are constantly improving the characteristics of oils, spending considerable funds on this; not all companies can afford such developments. Every serious equipment manufacturer has its own list of brands that it recommends for its mechanisms. Therefore, you should not try to purchase oils from little-known companies - by saving on the purchase of oils, you can subsequently lose a lot of money on the repair of production equipment.

Source

Bearings and lip seal

| Standard size | Stub | Lip seal. Input shaft. 1 PC. | Lip seal. Output shaft. 2 pcs. | Bearing. Input, shaft, motor flange. 1 PC. | Bearing. Input shaft, rear lid. 1 PC. | Bearing. Output shaft 2 pcs. |

| 030 | 032×7 | 20x30x7 | 25x47x7 | 61904 | 6201 | 16005 |

| 040 | 040×7 | 25x35x7 | 30x40x7 | 6203 | 6005 | 6006 |

| 050 | 047×7 | 30x47x7 | 40x62x7 | 6204 | 6006 | 6008 |

| 063 | 052×7 | 35x52x7 | 45x65x8 | 6205 | 6007 | 6009 |

| 075 | 062×7 | 40x60x10 | 52x72x8 | 32008* 6008 | 30206* 6206 | 6010 |

| 090 | 062×7 | 40x60x10 | 65x85x10 | 32008* 6008 | 30206* 6206 | 6012 |

| BY | 072×7 | 50x68x10 | 65x85x8 | 32010* 6010 | 32207* 6207 | 6013 |

| 130 | 072×7 | 50x68x10 | 70x90x10 | 32010* 6010 | 32207* 6207 | 6014 |

| 150 | 085×10 | 65x90x10 | 90x120x10 | 6013 | 6209 | 6018 |

*Tapered roller or radial ball bearings can be installed on the high-speed shaft (optional)

How to disassemble?

The gearbox must be lubricated as thoroughly as possible. Even noise can be eliminated if the deficiency of lubricants is replenished. But you should be as careful as possible when choosing a suitable brand of lubricant; the use of contaminated compounds is unacceptable.

It is worth considering that extraneous sounds are often associated with poor tightening of fasteners, wear of bearings and gears. To disassemble the gearbox, you need to:

- remove it;

- unscrew the screws;

- remove the protective caps;

- pull out the output shaft bushing;

- disconnect the lever and then the plug;

- remove the input shaft (in close connection with the gears);

- remove the shaft and chain bushings;

- dismantle the shaft and sprocket block;

- remove the intermediate shaft and gears;

- remove the coupling and axle shafts (assembly is carried out in the reverse order).

The opinion of experienced people about changing the oil in the gearbox

- Does the manufacturer recommend changing it every 100 thousand? Repair professionals recommend every 80 thousand.

“I changed the oil in the rear axle gearbox at a car service after 100,000 km, as recommended by the car manufacturer. However, specialists at the service station advised doing this every 80,000 km. I trust these guys, they never let me down. I don’t recommend changing the lubricant in private auto repair shops, because no one can guarantee that such a mechanic knows how much fluid to fill.”

Do you need to change the oil in the gearbox? Stop by the pharmacy first

“I drove 83,000 km, drove the car for 6 years. When the time came, I changed the oil in the rear gearbox with my own hands. In total, approximately 550 ml of lubricant was required. I filled it from a four-liter canister, so I can’t say the exact volume.

The replacement was carried out on a summer cottage; there was no overpass or lift. I placed the car on stands (17 cm high). Filling with lubricant is the simplest procedure, the cost of changing the oil in the gearbox is minimal, because the cost of lubricant is low. And you don’t need to pay for the work, because I did everything myself.

Don't know how to add liquid? Take Janet's syringe. We put a flexible nozzle on it, about 20 cm long. The syringe contains 160 ml, I filled about three and a half syringes.”

For three-liter models, the transfer case is in a different place

“If the car has a 3-liter engine, then the transfer case will be located next to the right front wheel. In this case, it will not be easy to get to the filler bolt. The automaker made an o on the head of the filler bolt to make it easier to navigate when replacing. I carried out the replacement after first studying the book from the publishing house “Third Rome”; if desired, you can download it, since it is freely available.”

We recommend

“A friend has a VAZ 4, no one has ever changed the lubricant in the gearbox, but there was no buzzing in the bridge. When I decided to change the old fluid, it was thick, like grease. After the replacement, he drove 2,000 km, and the gearbox began to hum. At the car service center, the guys said that in such cases, when no one has ever filled in new lubricant, the replacement should be carried out in several stages: first, drain a quarter, add new lubricant. And how he did it: he removed all the dirt that had gotten into every crack and crevice with new oil. And all the holes were exposed again.”

Don’t change the oil in the gearbox when it’s cold

“How to perform the replacement: loosen the drain nut, tighten it. Then you need to drive the car for 10–15 km, after which remove the lubricant. The heated liquid will drain faster. After that, inspect the filler plug. It needs to be checked in advance; perhaps it is stuck and unscrewing it will be problematic.”

What tools are needed?

To change the lubricant you will need some tools and materials. If you decide to tackle this matter yourself, prepare for work:

- a set of wrenches - box, open-end, hexagon;

- screwdrivers of different types - flat, Phillips, Torox;

- universal technical aerosol WD-40 for cleaning screws and plugs;

- container for collecting waste;

- hose;

- syringe.