As you know, internal combustion engines are 2-stroke and 4-stroke. In short, one stroke in an engine is actually the movement of the piston up or down, with two strokes completed per revolution of the crankshaft. The stroke during which fuel is burned and gas energy is transferred to the piston to perform useful work is usually called the power stroke of the piston.

It is important to understand that although two-stroke and four-stroke engines are similar in operating principle, they also differ significantly from each other in a number of features (both design and others). Next we will talk about how two-stroke engines work, as well as which oil for two-stroke engines is best suited for use in internal combustion engines of this type.

Features of two-stroke engines

Two and four stroke designs are internal combustion power plants. A 2-stroke drive carries out a full cycle of operation of the piston in the cylinder during one complete rotation of the crankshaft around its axis. During this period, the piston travels completely from bottom to top and back. This distinguishes the two-stroke design from its four-stroke counterpart, in which this process takes place in two turns of the crankshaft. Two-stroke units are not equipped with clean air intake and carbon monoxide exhaust valves. Fuel injection, smoke purging, and injection of clean air occur due to the pressure and vacuum created by the piston during operation.

The two-stroke engine combines the cleaning and filling procedure of the cylinder. This does not happen in separate strokes, but is performed over a short period of time, as the piston approaches its lower position. During its movement, it opens the exhaust and purge channels. Additional equipment for this purpose is a purge pump.

A two-stroke engine has a liter power greater than a 4-stroke engine, approximately 1.7-1.9 times. This value is obtained because with the same number of revolutions and cylinders, the working stroke of the pistons is twice as fast.

A negative feature of a two-stroke unit is the ability to overheat. This is a consequence of the release of a large amount of heat during operation. To dissipate heat, characteristic fins are made on the engine block. The air flow acts on the fins that cool the engine. Additionally, forced cooling can be used.

Choice

It is worth buying oil based on operating conditions. The highest demands are placed on the fuel mixture of high-speed two-stroke engines. The mixture should burn well and not leave soot. This can be achieved if you use low-ash oils and achieve an ideal ratio with fuel. The proportions of fuel dilution with oil are calculated by the engine manufacturers and these regulations must be fully observed. If you constantly act contrary to the rules and do not add enough lubricant, you can get the engine overheating, jamming and rapid wear of parts. A larger amount of oil threatens such troubles as increased smoke content in the exhaust, the formation of severe carbon deposits on injectors, spark plugs and pistons.

High-quality two-stroke engine oil is selected as follows: it should contain a minimum or no metal-based additives. Such additives, when burned, form substances endowed with abrasive qualities - ash. Ash particles can be deposited on the tips of the spark plugs and cause glow ignition, that is, something that occurs not from a given spark, but from overheated deposits.

Design and principle of operation

A two-cycle drive is installed in places where small dimensions and low weight are important. The design of the unit includes: a crankcase with channels, a cylinder block, a crankshaft, pistons. The unit operates in two strokes: compression and stroke.

When compression occurs, the piston begins to move from its lowest to its highest position (top and bottom dead centers). As it moves, it blocks the purge and exhaust holes, forming a sealed chamber. At the moment the holes close and the piston moves upward, gasoline is supplied to the cylinder. The gasoline-air mixture is compressed to its maximum when the piston reaches its highest point. A discharged space is formed under the piston, in the crank chamber. It facilitates the flow of fuel from the carburetor through the inlet channel.

Reviews

If you believe the reviews, then on the Russian market the lubricant from is quite good. At a very low price, the company makes a good lubricant, which is not inferior in quality to products from world brands. There are also good reviews about the manufacturer Makita, which supplies the market with excellent mineral oils. True, they are very expensive. And if the cost of a liter of Gazprom Neft lubricant is 120 rubles, then the price of a liter of Makita lubricant is on average 500 rubles.

Husqvarna, LIQUI MOLY, LUXE are expensive foreign lubricants that also receive good reviews. You can often read good expert comments about Sadko oils. The products of this company consist of 85-98% of the base - a lubricant, the rest is allocated to additives to give the composition the necessary characteristics described above. Moreover, all base oils are suitable, from selectively neutral lubricants to synthetic polyalphaolefins.

Lubrication system

Oil for lubrication of 2-stroke engines for various operating mechanisms can be supplied in two ways. It can be poured into the fuel tank along with the fuel or use an individual fuel system.

When oil is poured into the fuel tank, it is mixed with fuel. The gasoline-oil mixture from the tank enters the carburetor through the fuel pipeline and is injected into the cylinder. As a result of this, a gasoline-oil cloud is created in the cylinder, which lubricates the internal parts of the engine and removes a significant part of the heat.

The oil-fuel mixture ratio should be within 1:35. This value is considered optimal, but sometimes the characteristics of the oil, operating conditions and engine features are taken into account. In this case, the proportion of the oil-fuel mixture can change up or down, but no more than 15 points, from 1:20 to 1:50. It is necessary to add oil liquid to the fuel tank in a mixed state in accordance with the proportion. Oil combustion occurs together with gasoline in the engine cylinders.

On more modern mechanisms, lubrication can be supplied from an individual oil system. Such a system includes:

- Oil tank.

- Tube system.

- Plunger pump.

- Oil filter (can be installed separately or located in the oil tank).

Lubrication in the oil system is supplied in small doses, depending on the volume of gasoline and air supplied.

Types of oil

Two-stroke oil is a separate lubricant for internal combustion engines. These lubricants differ from others in their properties. As already noted, special requirements are imposed on two-stroke oils.

For gasoline 2-stroke engines, oils must have the following qualities.

- The minimum amount of ash and coke that are formed in the cylinder during combustion. The lubricant, ideally, should burn out completely.

- It should dissolve easily and completely in the fuel.

- The lubricant material must have lubricating, anti-wear, and protective properties at elevated temperatures. It should also provide good protection against corrosion.

If the lubrication system is separate , then it is necessary that the oil remains fluid and pumps well. If we take into account the scope of application and specifics of 2-stroke engines, which serve as engines for scooters and mopeds, engines for lawn mowers, boat engines and others, then there are separate requirements for the toxicity of the material.

If the lubricant gets on the ground, it should be as safe as possible for the environment, and if it gets into water, it should decompose very quickly.

Such oils must comply with TC-W3 and 2 T standards. Very often they can be distinguished from analogues by color, since they are additionally colored. They are mostly blue in color. Even when mixed with gasoline, it is clearly visible.

According to the 2 T standard , such lubricants are used in air-cooled engines ranging from lawn mowers and chainsaws to (light) motorcycles. But for use in water-cooled outboard motors and jet skis, oils of the TC-W3 standard are designed.

There are low-viscosity oils for winter use. Lubricants may have the following base:

- synthetic;

- semi-synthetic;

- mineral.

Recommendations and tips for choosing

You may notice that on the modern market there is a wide range of oils for outboard and other 2-stroke engines. You can also find ready-made products in which the oil is already diluted and ready for use. To do this, it is poured into a fuel canister, mixed well and poured into the equipment tank.

Products may vary greatly in properties and price. Synthetic oil is more expensive than mineral oil. This is what makes purchasing difficult. It is worth noting that, first of all, when choosing, you need to focus on the information provided by the engine manufacturer.

If it is said that oil of the TC-W3 standard should be poured into the equipment, then any oil that meets this standard will do. In this case, it does not matter whether it is synthetic or mineral water. You need to choose brands with a good reputation and beware of fakes.

If the instructions for use contain separate recommendations for oils, then it is strictly forbidden to add other types of lubricants.

The thing is that initially the engine is designed only to work with the specified material, and if you start using other lubricants, this will quickly lead to the unit going out of working condition. Simple equipment, especially those produced in the USSR, can work successfully on the MS-20. But an imported engine can become coked and stop working after just a few hours.

diesel or automobile gasoline oils into engines , and even more so, “working off”. Such lubricants contain a large number of additives; when burned, they form a lot of ash. It is worth considering that if you ignore all these rules, then soon not only imported, but also domestic equipment, which is distinguished by its endurance, will break down.

Application in practice

From all of the above, it is worth noting that choosing two-stroke oil must be done responsibly. The main task before pouring lubricant into the motor is to study the operating instructions. If the manufacturer allows the use of different oils, then you can fill in mineral water or more expensive synthetics.

Before adding, ensure that the lubricant meets the recommended standards . In practice, the difference between synthetics and mineral water will be insignificant. But still, with synthetics, the engine can start a little better and wear out less at high speeds. There may be less soot and coke in the combustion chamber.

But if the instructions indicate that you should only pour in certain synthetics, then under no circumstances should you use mineral water, even if it is of the same standard. In such a situation, mineral oil is still not suitable for a number of important parameters. And all because the engine lubrication system is not designed for the use of oils with a mineral base.

Standards and characteristics

Current standards provide for the use of two brands of oils. These brands are designated as 2T or TS-W3.

2T oil for lubrication of two-stroke engines is used on mechanisms with air-cooled engines. This could be a chain saw or chainsaw, a lawnmower, a motorcycle or a scooter.

TC-W3 oil is used for engines designed for water cooling. For example, the Mercury boat drive. If the boat has an air-cooled drive, then you can use 2T motor oil to lubricate outboard motors.

In areas with low atmospheric temperatures, a special lubricant with low viscosity is used for drives of units such as a snowmobile.

The table summarizes the characteristics of 2T and TC-W3 motor oils.

| Name | Unit | Index | |

| Brand 2T | BrandTS-W3 | ||

| Kinematic viscosity, t=100°С | mm2/s | 13.5-15.5 | 6.8-7.1 |

| Minimum viscosity index | 90 | 85 | |

| Maximum ignition t in an open crucible | °C | 210 | 110 |

| Minimum pour t | °C | 16 | 19 |

| Minimum Base Number | mg KOH/1g oil | 2.0 | 1.8 |

| Density at t=20°С, no more | g/cm3 | 0.9 | 0.86 |

| Sulfate ash content, no more | % | 0.16 | 0.11 |

Types of motor oils

Manufacturers offer users lubricating fluids on different carrier bases:

- Mineral lubricants are produced by hot distillation of oil. After evaporation of the light fractions used as fuel, long molecules remain. They are the main component for the production of oil;

- Synthetic lubricants are a product of artificial polymerization of short molecules of natural gas (mainly propane). As a result, monomers (long molecules of a plastic substance) are formed. The resulting fats are used to create a lubricant;

- Semi-synthetic oils are the result of mixing mineral and synthetic components. Usually the mineral part is present in amounts up to 30...35% of the total volume.

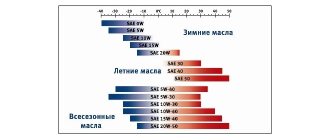

For ease of use, SAE classification has been developed. It provides for the separation of lubricants by viscosity. Different manufacturers indicate operating temperature conditions. They provide for use not only in the warm season. The presence of the letter “W” in the designation implies use at subzero temperatures. There are winter, summer and universal types of motor oils.

In addition to domestic manufacturers of consumables, foreign companies sell their products on the market. They use API and ACEA classifiers.

Mineral or synthetic

2T motor oil is divided into types, depending on the method of its production. The type of oil liquid can be:

- Mineral. This type is not distinguished by high quality and positive characteristics. Obtained as a result of oil refining. As the temperature rises while the engine is running, it loses its thickness. The consequence is a loss of the ability to properly lubricate rubbing parts and destruction of the power unit. Has a low retail price.

- Synthetic. Manufactured in laboratory conditions. To improve the quality of the lubricant, the necessary fillers are added. Oil molecules have the same size, resulting in reduced friction of parts and engine heating. It has a somewhat high cost.

- Semi-synthetic. Mineral water and synthetic are mixed in prescribed proportions. It has the necessary technical characteristics and is affordable.

Without experience, you can select the oil by studying the markings on the container. It contains information about the oil and what it can be used for.

Compound

Various additives are added to oils, which is why two-stroke and four-stroke differ from each other. In addition to the main components, two-stroke oils contain a solvent. It is thanks to it that the miscibility of fuel and oil increases, pumping and atomization are facilitated. But at high temperatures, solvents (20%) negatively affect lubricating properties. Additives increase viscosity, so you should choose a product with a higher viscosity coefficient - this oil is of better quality.

In addition to the solvent, two-stroke oil contains the following substances:

- Oil base - approximately 60%.

- The vacuum residue (the result of the primary distillation of petroleum products) is 5−17%.

- Solvent - 20%.

- Additives that are used to reduce smoke and soot from the waste product - the rest.

Additives

Despite the abundance of modern engines presented in stores, there are often boats with mechanisms that are 30-40 years old. And in terms of efficiency, they are not inferior to the new options: they provide maneuvering in dangerous, difficult areas and rapid acceleration. At the same time, the resources of most of them are gradually exhausted, and tiny cracks appear in the cylinders, invisible to the eye. Despite their small size, they increase noise during operation, increase fuel consumption and lead to a decrease in power.

In such situations, two-stroke oil becomes indispensable, the price of which does not exceed 600 rubles, with special additives. Compared to lubricants, they are characterized by a higher degree of viscosity, due to which the surface coated with additives becomes smoother. Thanks to this, the characteristics of a worn motor are improved. Of course, sooner or later repairs will still be required, but as a temporary measure there is no better option. It is worth noting that there is an opinion that additives harm the engine, but it has no basis. Quicksilver two-stroke oil with additives is optimal for medium-intensity engine use.