When constructing any object, it is impossible to do without the use of special technical devices. Modern builders use a variety of equipment that greatly facilitates and speeds up the process. Among the equipment needed at a construction site are machines for cutting bricks and other materials. They are comfortable, lightweight, and even beginners without experience can handle them.

The machine used to cut bricks easily fits in a car, so transporting it will not be a hassle. It is also suitable for cutting any natural stone and building material, be it ceramic, concrete, limestone or the like. Indispensable when processing small blocks of raw materials and facing tiles.

We study machines for cutting and sawing bricks: characteristics, reviews and comparison

When constructing any object, it is impossible to do without the use of special technical devices.

Modern builders use a variety of equipment that greatly facilitates and speeds up the process. Among the equipment needed at a construction site are machines for cutting bricks and other materials. They are comfortable, lightweight, and even beginners without experience can handle them. The machine used to cut bricks easily fits in a car, so transporting it will not be a hassle. It is also suitable for cutting any natural stone and building material, be it ceramic, concrete, limestone or the like. Indispensable when processing small blocks of raw materials and facing tiles.

Types of stone cutting machines

Brick cutting machines are divided into various types. Thus, there are double-head and single-head machines, stationary and manual, with mechanical or pneumatic clamping, with and without a cooling system.

The cutting machine consists of a bed, a cutting element, a brick feeding system and a process control system. The cutting element is a circular saw and chain, which are powered by an electric motor. To perform loading and unloading operations, special loading rings are used.

Since brick is highly durable, the machine must be durable and reliable. And for its production, high-strength metal is used: steel or cast iron of special grades. They allow the process to be carried out efficiently, provide reliable control, and absorb vibration during operation. Brick cutting machines can operate on 220V or 380V. The first option is more common and is used in small workshops and households. The second option is more powerful equipment, used for mass work.

Cutting machine design

When making brickwork, it is not always possible to use a whole brick, since there are areas where it will not fit completely. The material will begin to violate the integrity of the structure, falling out of its appearance. The one-piece element is suitable only for monolithic, flat surfaces that are durable and reliable.

Problem areas of a brick wall are various transitions and corners, as well as many other elements. To complete all the work correctly, it is necessary to cut the brick. For many years it was done by hand, but modern devices that allow sawing stone or brick greatly simplify human labor.

Widely used specialized machines from well-known manufacturers make it possible to give various materials the required shape. Cutting bricks with a grinder is no longer so popular. The design of the device consists of the following elements:

- drive motor;

- special table for cutting material;

- installation legs or racks for fixation;

- steel frame with a disk for cutting bricks;

- water container for the irrigation system to minimize the volume of dust.

Some home craftsmen have learned to make brick cutting machines with their own hands. In any case, it is more profitable to purchase professional equipment, since it will serve for many years. In general, the structure of the entire structure is not particularly complex, but it greatly simplifies the construction work of laying building materials with your own hands. The cutting element of the machine is a diamond disk having a certain diameter. It must be of high quality so that all masonry work is carried out at the proper level.

Video description

How the Stihl GS 461 chain cutter works is shown in this video:

Specialized equipment not only for professional builders

Professional machines greatly simplify the work of cutting bricks. With their help, you can obtain artificial ceramic stone of even complex geometric shapes. Moreover, working on such machines is much safer than when using an angle grinder and a gas cutter. The productivity of masonry work increases by 20%. The level of quality and aesthetics of masonry will also increase.

The basis is a frame with a gripping and fixing system. Cutting is done using diamond discs. Depending on the machine model, large blades (up to 420 mm) and smaller ones with a diameter (230 mm) are installed. It is worth considering that large circles are expensive, and in many cases you can get by with a regular 230 mm circle.

Large machine for cutting stone Source generaltool.ru

Using an Angle Grinder

How to cut bricks with a grinder correctly? To carry out the operation, you need to take a model that is designed to use a disk with a diameter of 230 mm . The use of grinders with smaller circle sizes will lead to a decrease in work accuracy and productivity. The cutting element will not be able to penetrate the entire thickness of the product; the blocks will have to be turned over. Recommended power of the tool is 2 kW.

When choosing the type of disc - abrasive or diamond , you need to consider the pros and cons of their use. The first option is cheaper, but loses in safety and durability. Diamond wheels are made on the basis of durable steel, so they are reliable, do not crack, and are characterized by a long service life.

Solid brick crossbar format

The product is used only for cladding, has an unusual shape - length more than 29 cm, width - about 4 cm . You can cut such bricks with a saw, grinder, electric jigsaw and other tools mentioned above.

Facing hollow brick

The building material is distinguished by the presence of internal voids , which often make up about half of its mass. In terms of shape, you can find various options on sale (with ready-made bevels or roundings), so craftsmen often do not have to cut. If such a need arises, then any tools with diamond cutting elements will do.

What kind of disk to cut bricks with?

It is also very important to choose the right disk for processing bricks. Cutting tools that are used for such operations are divided into two main groups:

- diamond;

- abrasive.

The main advantage of the abrasive disc is its relatively low cost. However, it should be said that such products fail quite quickly, so they need to be changed frequently. In addition, abrasive discs are subject to deformation and cracking, and therefore are quite unsafe.

Diamond blades are best suited for this operation. They are made from durable steel. This product is reliable and has a long service life. Also, such disks are more secure. Diamond cutting elements are also divided into several groups:

Simple products with a continuous edge . Such products provide a smooth surface of the newly formed edges and are low cost. The disadvantages are rapid wear and strong heating during processing.

Segmental . The main design feature of such products is the presence of cuts on their edges. This design ensures high-quality waste removal from the working area and slow heating. These blades are well suited for dry cutting.

Discs equipped with a serrated edge . The main advantage of such products is a large margin of safety. They have a long service life and can be used for wet and dry cutting.

To improve the quality of cutting building materials, experts recommend using a grinder bed. Using this design, the cutting tool and the workpiece can be rigidly secured. Using the bed, you can cut bricks lengthwise or in half at different angles.

Return to content

DIY brick cutting machine

Let's talk about how to make a brick cutting machine at home. The time has long passed when masons worked with their hands, without tools to facilitate the construction process.

Nowadays the market offers a huge selection of tools that allow even a beginner to work quickly and efficiently.

Naturally, not everyone has enough money for all the tools, and why buy when you can make them yourself. Moreover, the material for the machine is available; it can be assembled literally from what lies under your feet. For example, from an iron corner for a bed.

It is also important that creating something with your own hands is very interesting! Since doing it yourself is often tantamount to creating a tool for yourself. And what can you compare the satisfaction you get from work to when you manage to realize your ideas and thoughts?

- 1 Design of a brick cutting machine

- 2 Alternative options

- 3 Safety precautions

- 4 Brick cutting machine, video 4.1 We recommend reading:

Brick cutting machine design

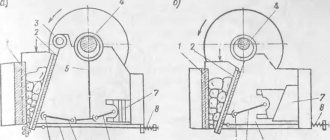

The design of the machine looks like a circular saw, only in smaller sizes. Of course, there are differences in how the cutting blade is mounted.

When designing a machine, you can use existing diagrams and drawings with exact dimensions.

Or you can create something fundamentally different from others, according to your own ideas and calculations. The main thing is that the resulting result does its job and is safe to maintain.

The machine consists of:

- The disc itself on the engine, or a fixed angle grinder.

- Carriages, that is, the moving part on which the brick is laid for cutting.

- A fixed frame to which the entire structure of the machine is attached.

You can attach legs to the machine, or you can fix it on any place convenient for this (table, workbench, etc.).

In addition, some craftsmen prefer to work on a machine using water. To prevent brick dust from scattering throughout the room.

If you think the same, then you should think in advance about the mechanisms for supplying water to the cutting site.

Alternative options

What to do when you need a brick cutting machine here and now? That is, there is no time to make it, and it will only be needed for a short time.

Of course there is a way out. You can use the same circular saw mentioned above for cutting building materials.

Naturally, we cannot do without some changes in the design, but, believe me, they are not critical.

You just need to remove the saw and iron disk from the circular saw. Then, replace it with an abrasive, fiberglass-reinforced wheel.

It is mainly used for cutting steel and is sold at any hardware store. The preferred marking is K480STZB, but another one will do, at your discretion.

The cutting part of the circle should protrude above the surface of the circular table by at least 70 millimeters. Taking into account that the thickness of a standard brick is 65 millimeters.

But it is not recommended to install a circle that is too large. Since during operation it will begin to “wiggle”, that is, bend from side to side.

Safety precautions

When working on a machine for cutting bricks, care should be taken, especially in cases where the cutting part of the disk is not covered with a casing.

There is a high probability of getting injured by accidentally touching a rotating disk.

- It is recommended to cut outdoors, as the process produces a lot of brick dust if work is carried out without water supply;

- Before starting work, make sure that the machine is stable;

- You should also protect your respiratory system with a cotton-gauze bandage or a respirator;

- It is best to wear safety glasses while working. They will protect your eyes not only from dust, but also from small particles.

Brick cutting machine, video

From this video you will learn that it is quite possible to assemble a machine with your own hands from scrap materials. With minimal investment of money and time, you will receive a useful, valuable device that will make your work easier.

We recommend reading:

- home

- Adviсe

This site uses Akismet to reduce spam. Find out how your comment data is processed.

Household tile cutters, electric

Entry-class equipment will reduce the preparation time for finishing tiles. Initially, it is assumed that the cutting accuracy will be maintained within the permissible deviations of the tiles: for ceramic – 0.5-1 mm, for porcelain stoneware products – no more than 0.5 mm from the declared linear size. But due to a poorly ground shaft, a pressure washer or a low-quality disk from the basic kit, the surface and edges of the cut may differ from the ideal. Monitoring the position of the working elements, the tightening torque of fasteners and careful adjustment of the machine will increase the accuracy of linear processing. A correctly selected disc will protect the tiles from chipping.

Diam SP-200/0.8 – from 13,980 rub.

When working on the DIAM SP-200/0.8, loud noise and uncontrolled splashing of water attract attention first.

These phenomena can be tolerated if the glaze does not chip too much during the cutting process. To achieve acceptable quality, you need to clean the threads of the landing shaft from burrs, tighten all the nuts and replace the standard disk with a more serious version. I liked the very simple design of the machine - a tray covered with a work table on the main frame and a direct drive cutting part that is manually moved along a guide. Here, in case of repairs, large investments will not be required. Characteristics of the machine Diam SP-200/0.8

| Characteristics | Meaning |

| Cutting depth (max 900/450), mm | 30/21 |

| Cutting length (max), mm | 500 |

| disc diameter (external/internal), mm | 200/25.4 |

| Disc rotation speed, rpm | 3000 |

| power, kWt | 0.8 |

| Weight, kg | 32 |

| Homeland of the brand/country of origin | RF/China |

Review of the older model from the same SP line. Identical machines, but different dimensions. Before purchasing, for a general idea, it will be useful to familiarize yourself with:

Hammer Plr 900 – from RUB 14,999.

The height of the supplied legs is not always enough for comfortable work; it is best to install the machine on a table.

The design is strong, but not tenacious - by feeding squares of porcelain stoneware onto the disk, you will move the machine along the table. Therefore, the surface under the machine should be covered with waterproof and not very slippery material. The Hammer Plr 900 stands much more stable on its legs than on a table without them. During assembly, I tightened all the fasteners and installed my old segmented one instead of a new solid diamond disc. The work left a positive impression. Characteristics of the Hammer Plr 900 machine

| Characteristics | Meaning |

| Cutting depth (max 900/450), mm | 36/29 |

| Cutting length (max), mm | 630 |

| disc diameter (external/internal), mm | 230/25.4 |

| Disc rotation speed, rpm | 3000 |

| power, kWt | 0.8 |

| Weight, kg | 29.3 |

| Homeland of the brand/country of origin | Germany/PRC |

Review of the model from the specialists of the 220 Volt store:

Tool cutting

Things will go much faster, more accurately and with better quality if you use a tool for cutting bricks. Its choice is not too extensive: usually an angle grinder (grinder), a gas cutter or a special machine for cutting bricks is used for this.

In these cases, you cannot do without a construction square and a pencil for marking. In addition, you will need personal protective equipment, since the cutting process is accompanied by the formation of a large amount of dust and small fragments. These are gloves, goggles and a respiratory mask.

Let's consider each option separately.

Bulgarian

How to cut brick if you need a small amount of non-standard stones?

An angle grinder, popularly called an angle grinder, is best suited for this purpose. Unlike the equipment discussed below, almost every home craftsman has such a tool.

Advice. It is recommended to use an angle grinder with a power of about 2 kW. A less powerful tool may not cope with the task, but a tool that is too powerful may be difficult to work with.

The brick cutting disc installed on the machine can be of two types:

- Abrasive - inexpensive, but not very practical. It quickly “wears off” and can become deformed or crack during the cutting process, which will affect the quality of the cut and the safety of the craftsman.

Abrasive cutting wheel

- Diamond - a disc made of durable steel coated with diamond is very reliable and durable. It is more suitable for this operation, as it easily cuts bricks, making an even and neat cut. But its price is much higher than abrasive.

In any case, the optimal diameter of the disk is 23 cm. A smaller circle will not cut through the entire thickness of the brick, so it will have to be turned over during the process. And it is not so convenient to work in circles that are too large.

Diamond blades, in turn, differ in the type of edge and are:

- With continuous edge. The cheapest of analogues give a smooth surface on the cut. But they heat up during operation and wear out faster.

- With serrated turbo edge. The teeth on it are arranged in a spiral, so dust and other waste are well removed from the working area. These blades can be used for dry and wet cutting, they have the longest service life and the best performance characteristics.

- With segmented edge. Such disks have cuts along the edge, dividing the working plane into separate sections. When working with such a disk, the cutting area is constantly ventilated, so it heats up more slowly. But with wet cutting there is a risk of waste sticking in the slots, so it is used mainly for dry cutting.

How to cut bricks and what kind of blade to use is up to you to decide. Now you know about the features of any cutting attachment.

You just need to remember that you need to cut not exactly along the marking line, but stepping back a little from it so that the marking remains “in the body” of the part you need. Otherwise, due to the backlash of the tool and the thickness of the cutting part of the disk, it will turn out to be smaller than the required size.

Holding an angle grinder suspended makes it difficult to make a quality cut. It is better to secure both it and the brick in the clamping frame. With its help, you can make neat cuts not only along or across the brick, but also at any angle.

A special bed for angle grinders will make your work easier

It is very important not to forget about safety precautions when performing such work.

The instructions require the following points:

- The tool must be held with both hands so that when it is kicked back, it does not break out of your hands and cause injury to you or others. This requirement will also ensure higher cutting accuracy.

When working, a stable position and correct grip of the tool are very important.

- The electrical power cable should be located as far as possible from the work area to avoid it being cut or wrapped around the disk with all the ensuing negative consequences.

- You can release the grinder from your hands and place it on the ground or other surface only after the rotation of the disk has completely stopped.

- The cutting wheel must be covered with a protective cover.

You cannot use an angle grinder without a casing.

Advice. To reduce dust formation, water can be poured into the working area when cutting bricks.

Brick cutting machine

Special machines for cutting bricks are expensive; it makes no sense to buy them for a one-time job. This sophisticated equipment is intended for those whose activities are related to masonry work.

It consists of the following nodes and elements:

- Metal frame;

- Power unit with electric motor and diamond wheel;

- Brick or stone fixation system;

- Most models are also equipped with a water supply system to the cutting area.

Brick cutting machine DAKAR PLUS

This equipment allows you to quickly and accurately perform cuts of any complexity. At the same time, the cutting process is always visible to the master and he can control it.

And the irrigation system minimizes the amount of brick dust emitted into the air, making work as comfortable and safe as possible.

How to cut brick using this machine?

- It must be marked and installed in the work area, secured in the desired position;

- The cutting part of the tool is lowered to the working area and oriented towards the markings;

- Then turn on the engine and adjust the rotation speed, after which cutting is carried out.

The photo shows the process of cutting bricks on a machine

Petrol cutter

Sometimes it becomes necessary to cut not individual bricks, but to cut various niches, door and window openings in the brickwork. In such cases, the most effective tool will be a gas cutter, which is used for diamond cutting of brick walls.

How to cut at an angle correctly

When performing masonry or facing work, the master is faced with the need to cut the brick at an angle. The simplest and most reliable method is to perform this operation using a machine. To do this, the unit has a system that allows you to fix the brick at the desired angles for precise positioning.

But if there is no such equipment, this does not mean that cutting at an angle is impossible. You can use a grinder. First, precise markings are made, and during the cutting process you need to hold the angle grinder tightly and control that the specified cutting angle is maintained. To prevent the brick from sliding sideways during the cutting process, it must be provided with vertical support.

Of course, not everyone will be able to complete this job the first time. It will take some training to acquire the skill and get the desired result. But literally a couple of attempts will be enough for you to understand that everything will work out.

In order to get a brick of a certain shape, you need to make some effort. First, you should take the necessary security measures. Safety glasses must be purchased. They are needed to prevent brick chips from getting into your eyes. You will also need gloves and a respirator.

There are the following methods for cutting bricks:

- chisel splitting

- cutting with a circular saw

- machine carving

- cutting with a gas cutter

- cutting with a grinder

The brick cutting process consists of several technological stages. In order for the cut to be smooth, you should first apply markings. Pre-calibrated dimensions are applied to the surface of the brick using a ruler and chalk. You cannot start cutting solely along the marking line. This way you can get a part of the brick that does not correspond to the desired size and shape. Cuts should be made taking into account an error of 1.2 cm.

Manual splitting of irregularly shaped bricks

The easiest way to obtain custom-shaped bricks is by hand cutting. The brick splitting operation is simple to perform. To work, the master will need a medium-sized hammer and a regular chisel. The following procedure should be followed in your work.

To ensure stability, the brick should be placed on a flat surface. A marking line is applied to the workpiece using chalk along a ruler. Next, a chisel is applied perpendicular to the surface of the brick with the tip down. Then you should give a sharp blow to the instrument. If everything was done correctly, the brick should split into two identical halves.

Unfortunately, this method has many disadvantages. In particular, it is impossible to determine in advance how smoothly a brick will crack, even if everything was done correctly. In addition, the newly formed brick edge is not perfectly smooth. Its uneven edges have to be hidden inside the masonry.

Much higher quality can be achieved if special cutting tools are used. There is no need to cut bricks to create a perfectly rectangular shape. It is enough that the edges of the brick are smooth. Unfortunately, due to the heterogeneity of the structure, the brick may crack not along the marking line, or may completely crumble.

Cutting bricks with a circular saw

A circular saw is great for cutting brick evenly. The tool was originally intended for logging work. In order to prepare the saw for cutting hard brick, you need to replace the working blade on it. The hard cutting wheel should be a glass fiber reinforced abrasive wheel designed to cut steel. The K480STZB model is perfect for working with bricks.

Cutting bricks with a circular saw

Make sure that the cutting edge of the working disk protrudes 7 cm above the table of the circular saw. Then use a ruler to set the required size. When turning on the circular saw, you need to smoothly bring the brick to the cutting edge of the saw. The material should be cut smoothly, without pressing on the tool, avoiding sudden jerks.

Standard Electrical Equipment

Anyone planning to start a renovation or construction project should have standard electrical equipment that will help make almost every aspect of the job easier. A drill and a jigsaw will not help us, but we will have to resort to the help of an angle grinder. It is popularly called a grinder, if you didn’t immediately understand what we were talking about.

I’ll tell you about a few aspects that you need to know:

- select the correct drive. To work with materials based on concrete, you need to use specialized diamond blades. Don't worry, they aren't made entirely of diamonds and don't cost millions. All that distinguishes them is diamond coating, which allows you to carry out work without damage to the tool,

- get ready to clean up. Stoves, pipes and other structures that are made of heat-resistant bricks are mostly located indoors. It should be remembered that when working with an angle grinder, a lot of dust is generated. So either be prepared to clean for a long time, or go outside and do the work there,

- do not forget about safety precautions. It is worth remembering that wearing protective gloves and glasses will help maintain your health.

Once, being still an inexperienced, but already adequate person, I came to work and saw this picture. An “experienced” man of about forty was sitting and screwing a milling cutter for cutting wood onto an angle grinder.

I asked in bewilderment what he wanted to do with it, since we were doing masonry. He said that you need to cut off a small piece. I was shocked, but all I heard in response to all my objections was that I was still young and didn’t understand anything in this life.

In the end, as soon as he touched the clay brick with the disk spun at high speed, the cutter began to break, and the teeth, one by one, stuck into the board on which the work was being done. For this imaginary builder everything turned out to be a fright, for me it was a grin, but it’s good that everyone remained safe and sound.

Top models for 2022

One of the ways to decide which tile cutter to choose is to study the rating of the best models according to users. Criteria such as performance, quality and cost are considered here. Consider the options for hand tools:

- TM-70 from Germans Boada.

Here the permissible thickness of porcelain stoneware is 21 mm. Chrome-plated guide tubes are made of high-strength steel. The cutting angle of the tiles can be equal to 90 and 45 degrees.

- Sigma 3C3M.

This tile cutter can cut workpieces with a textured surface. The carriage is equipped with wide bearings. The work is also simplified due to the built-in ruler with centering, the position of which can be changed at the desired angle.

Model Sigma 3C3M Source allegroimg.com

- Montolit 26PB.

This is a professional tool. Here the platform is cast with stiffeners, the guide is represented by a steel strip. You can work with tiles up to 25 mm thick. The quality of cutting is ensured by the ability to adjust the depth of the formed groove.

- Stayer 3310-60.

Here, an additional advantage is the second carriage for forming through holes in tiles up to 15 mm thick. The diameter can be from 3 to 8 mm. It is also possible to work with an extension ruler and a square (rotate 45 degrees).

- Basic PLUS 60.

This manual tile cutter from the rating has an aluminum frame and chrome-plated guide tubes with an oval cross section. The carriage is made with a chrome plated base, which eliminates the need to use lubricants.

Model Basic PLUS 60 Source yandex.net

Features of cutting bricks

The working surface of the tool must be very thin and sharp

Features of working with blocks at home:

- Fragility and brittleness of the material. The chipper and hammer drill are not suitable for cutting.

- The working surface of the tool must be sharp and thin to avoid chipping.

- Before starting work, the item should be secured using available means.

- To prevent dust from scattering, the element must be wetted with water .

- During work, you must use personal protective equipment to prevent dust and brick fragments from entering the respiratory and visual organs.

- Power tools must be properly grounded.

- For precision cutting, markings (using a piece of chalk and a square).

At home you can always find something to cut bricks with. There are two types of cutting and sawing tools: manual and electric.

Hand tools include:

- hammer;

- mason's pick;

- mason's chisel (special alloy of metals and special sharpening of the blade);

- manual tile cutter.

- grinder (angle grinder);

- a special machine for cutting building blocks;

- electric hacksaw (jigsaw);

- laser tool (for cutting openings in a brick wall).

If there is no electricity at the site, a gas cutter can be used to solve production problems.

My choice

An inexpensive machine is suitable for self-repair in your own premises. Practice with the adjustments, replace the standard disc. You can be sure that in comparison with hand tools, each model in this class will have obvious advantages. With a small difference in cost, the Hammer Plr 900 is more convenient to use. There is a chance that ease of use, minimal dust and relatively neat cutting will push you to purchase a professional machine for future repairs.

When making a living doing repairs, don't ignore the lightweight CGW 1-25-1 Compact : 66 kg useful weight; accuracy ±0.5 mm per 500 mm cut; the opportunity not to overpay for a disk from the basic configuration, but to buy one that is designed for a specific material.

The EMMEDUE ES-300 A , a precision stone-cutting machine with the potential of industrial equipment, can provide stable work for a small workshop The model corresponds to the production requirements of an industrial enterprise. In the case of a full-fledged workshop, it increases the profitability of the business.

How often do you service your power tools?

How to cut bricks

During cutting, in addition to special tools and devices, you will need a square and a construction pencil. In addition, any master must understand and remember that this operation is extremely dusty. The use of a respirator and safety glasses during work is an urgent, even vital necessity.

To ensure the accuracy of sawing bricks, it is advisable to make the necessary markings before cutting. To do this, the cutting line is drawn using a pencil. The cut itself is made next to the line. If cutting is done strictly along the line, the brick may end up smaller than necessary.

The question of how and with what to cut a brick is often decided based on the amount of work to be done.

Using an Angle Grinder

How to cut brick with a grinder

Cutting bricks with a grinder (angle grinder - angle grinder) is most often carried out during small-scale production. To do this, you need to choose a tool that can work with a 230 mm wheel. If the circle has a smaller diameter, then it will not be possible to cut the brick through its entire thickness. Therefore, it will have to be turned over, and this reduces both productivity and quality of work.

The grinder used must have a power of at least 2 kW. An overly powerful tool is inconvenient to use because it is large and heavy.

In addition, when working with a grinder, you should choose the right disk for cutting bricks. The disks used to perform these operations are of two main types:

- abrasive;

- diamond

The only advantage of an abrasive disc is its apparent cheapness. It really is only apparent, since such a disk wears out quite quickly and requires frequent replacement. In addition, using an abrasive disc is quite dangerous, since it is quite easily deformed and destroyed.

Diamond blade is more preferable in cutting process. Its basis is durable steel. The disk is reliable, much less dangerous, and is characterized by a constant diameter during operation. At the same time, diamond discs come in several types:

- regular with a continuous edge. Such discs are cheaper than others and provide high quality cuts. But they get very hot and wear out faster than others;

- segmental, the cutting edge of which is divided into separate sections using radial cuts. With this disc design, the cutting area is well ventilated and sludge is well removed. Segment discs are convenient for dry cutting;

- wheels with turbocharged lip. This edge has a serrated surface and is highly rigid and durable. These discs are the most durable and convenient for wet and dry cutting.

To ensure better quality cuts using a grinder, it is recommended to use a special device called an angle grinder bed. With the help of such a frame, the angle grinder can be mounted on a special lever, and the brick can be secured in a special device provided for this. The bed allows you to make not only straight cuts, but also cut bricks at an angle.

Cutting with a gas cutter

Cutting bricks with a gas cutter

A petrol cutter, or, in other words, a special saw, is quite inconvenient when cutting piece bricks, since this device is quite heavy and large in size.

If a gas cutter has a disc installed, it resembles an angle grinder with a powerful gasoline engine. If a chain cutter uses a chain as a cutting tool, then it looks very similar to a chainsaw. The chain of the petrol cutter, like the circle, is manufactured in accordance with special technology and equipped with a diamond coating.

A saw for cutting bricks is especially convenient when creating openings in brick walls or when demolishing them. The great advantage of such saws is that almost all of them have a forced water supply. This fact makes it possible to provide greater comfort during such dusty work as sawing bricks.

Cutting bricks using a special machine

A brick cutting machine is a device that includes:

- durable metal frame;

- drive motor;

- diamond disc;

- workpiece fastening system;

- an irrigation system that allows you to almost completely eliminate the formation of dust.

The decision to buy a brick cutting machine gives you the opportunity to:

- perform work at high speed;

- carry out all sawing operations with a high level of precision, as a result of which the seam between the joined elements obtained as a result of cutting is barely distinguishable;

- significantly increase operator safety by minimizing dust formation that accompanies the brick cutting process.

Operating instructions for Fubag stone cutting machines

Stone cutting machine FB 73R

Stone cutting machine FB 350 (400V)

Stone cutting machine A-36, A-46, A-551, PK 35A44

Stone cutting machine A-44 M, A-44 M3F, A-44/420M, A-44/420 M3F

Stone cutting machine PK 70 NM

Stone cutting machine PK 30M

Stone cutting machine PKH 35A 150M, PKH 35M 120M, A 100 KM, A 100 KM 3F

Stone cutting machine TC 470, TC 670

Stone cutting machine TS 350E

Stone cutting machine MasterLine 6 Star

Stone cutting machine PK 100LM

Operating principle of a stone cutting machine

A stone cutting machine consists of a base to which a saw is attached to a pulley. The bed can be either table-top or floor-standing. A band saw or a diamond blade of various sizes is used as an executive tool. Due to the correctly selected inclination of the saw, the cutting angle of the workpiece can be varied within 45 degrees. The required power from the electric motor is transmitted to the saw via a belt drive.

The stone slab is fed to the cutter using a caliper, which is capable of moving along the guides both automatically and using manual traction. The screw drive facilitates smooth and gradual feeding of material. On the machine, the slab is usually secured using metal clamps, the inside of which is covered with wooden dies for better adhesion.

Advantages of modern stone cutting machines:

- Compact and light weight.

- Reliability and durability.

- The optimal combination of quality and price.

- Easy to use and maintain.

- High maintainability.

- Versatility and high performance.

Features of FUBAG stone cutting machines

Buying an IK stone-cutting machine in Minsk from a German manufacturer means appreciating the legendary quality of the equipment and its unique features:

- The cut is at an angle of 45°, which allows you to chamfer and tilt the cutting head at any angle.

- Forced cooling system. The presence of a powerful fan cooling the machine engine allows the device to work intensively for a long time.

- Availability of a pneumatic cylinder. This element is designed to smoothly raise and lower the cutting head.

- Possibility to set the cutting depth. FUBAG machines allow cutting not to the full depth of the workpiece, for example, making notches, technological cuts, pilot seams.

- Unpretentious in terms of maintenance.

- Convenient storage and transportation of the unit thanks to folding legs and the ability to dismantle the movable carriage.

Advantages of purchasing from us:

Sales of stone-cutting machines from well-known manufacturers is one of the priorities for. We work only with tested and certified equipment, which is characterized by high functionality and performance. For your maximum convenience, our consultants will provide professional assistance in choosing, and the possibility of wholesale or retail sales, a variety of payment methods and fixed prices from the manufacturer will pleasantly please you!

vote

Article rating

Tools and technology

There are different ways to cut bricks:

- Hardware: on the machine;

- on a miter saw.

- grinder or petrol cutter;

- using a jigsaw or file;

Return to contents

Brick machining

A device for convenient, safe and quick cutting of bricks using nippers, in halves and non-standard shapes. Available in two types: industrial and household. The second one is better used in home construction, as it is small in size and practical. The cutting element is a diamond disk of a certain diameter. Tool design:

- metal frame with cutting wheel;

- water container;

- cutting table;

- mounting feet.

The device cuts types of bricks such as red, refractory, oven, silicate, and trim.

The main advantages of the machine are:

- performing dry and wet circular cutting;

- high speed;

- accuracy of size and shape due to convenient location when cutting - a person sees the markings.

Return to contents

Work algorithm

Grinder as a cutting tool

When performing small-scale work, use a grinder. To cut the material, use a device with a 23 cm disk. For an angle grinder with a circle of smaller diameter, the brick must be turned over, as a result of which the evenness of the cut side is disrupted. To avoid defects, the material is fixed and then processed with a grinding machine in the cut areas. A grinder is used with a large circle when cutting a brick wall. To cut brick at home, the main thing in use is to hold the working tool correctly: the cutting edge should be perpendicular to the material being processed.

Important points when working with an angle grinder:

- The cutting process should be carried out outside the premises due to the large amount of dust. Use personal protective equipment - goggles and a mask.

- The tool is held in a strictly perpendicular position to the marking line.

- Do not apply pressure to the instrument.

- If the diameter of the circle is small, make a cut along the entire perimeter, and then remove the excess with a hammer and process the defects and irregularities with a grinder.

Return to contents

Working with a petrol cutter

Brick cutting is carried out by a device similar to an autonomous circular saw with a more powerful engine almost instantly. But along with the high speed of operation, the device is large in size, making it difficult to transport. The large cutting disc in the gas cutter resembles the same one as in the grinder. Due to the high power of the tool, you can saw fireclay bricks for laying stoves and barbecues. Due to the large accumulation of dust, it is recommended to use a respirator when working with the tool.

A circular saw

This tool is used for working with wood, but can also be used for sawing bricks and blocks. Processing material on a circular saw requires replacing the wheel with a reinforced disc model K480STZB. The cutting edge should protrude 7 cm above the table. Here you will need a ruler to measure the height. It is necessary to cut the brick smoothly, without sudden movements and without pressing the tool.

Miter saw

Small-sized stationary equipment, convenient and safe to use. Serves as an option for cutting facing bricks. The miter saw is used in wood processing, replacing discs for concrete, and performs the function of sawing at any angle, the required size and accuracy. Cutting facing bricks is easy and does not require much experience. But it is important to follow safety precautions and use PPE.

Laser cutting

The method is used when necessary to cut a brick or concrete wall. Laser installations operate on gas-discharge lasers. But the tool is an expensive piece of equipment when working at home and requires knowledge and experience in operation. If you cut a brick using this method, you need to take into account the following points:

- type of brick;

- complexity of the cut;

- thickness of the product being cut;

- presence of reinforcement if a wall is being cut;

- accessibility to a power source;

- availability of water communications for dust suppression.

Return to contents

Stone cutting machine

Mainly used in large-scale construction. The components include:

- metal frame;

- drive unit;

- cutting block with diamond blade;

- water supply system in the cutting area;

- construction of fastening blocks or bricks.

After fixing the material, it can be cut by a machine.

The operating principle of this machine:

- Performing markings.

- Fixation of working material.

- Putting the cutting head into working condition.

- Smooth movement along the marking line.

Return to contents

Briefly about the main thing

Before carrying out masonry work, you need to clearly decide whether it is more profitable to cut bricks than to cut them. Such work can increase the estimated cost and lead to unnecessary expenses. When constructing an interior partition, you can use the simplest and oldest method of cutting brick - cutting stone. It will save time, effort and money. To cut out shaped elements, a miter saw with a diamond blade will come to the rescue.

For small construction, for example, a bathhouse or a garage, you can get by with a grinder with a diamond blade. It will significantly speed up the work and allow you to complete the laying more accurately. If you cut through a thin wall, it will also come to the rescue.

If you are planning a more full-scale project, such as building a house, then it is best to purchase a specialized machine.

If it is necessary to make an arch, through cuts in already erected wall structures, and even reinforced ones, then you cannot do without a gas cutter (for a small amount of work) and laser cutting (for large-scale projects).

Ratings 0

How to choose a tile cutter

In modern construction and renovation work, you almost always have to lay tiles. Tiles made of ceramics, porcelain stoneware, marble and other materials are still very popular today. So, you have made your choice and are going to purchase tiles. First of all, you need to decide on the design, texture and size of the material. When the tile is selected and purchased, the greatest difficulty becomes the method of cutting it for further adjustment. It is important to cut tiles very carefully, accurately and patiently. This article is intended to tell you how to choose a tile cutter?

Types of tile cutters

The tile cutter is a fairly easy-to-use unit, which comes in two types: manual and mechanical. When thinking about which one to choose, go back to your measurements and examine the tile itself. If you don't have to do anything particularly complicated, and the thickness of the tiles is small, you can check the nearest hardware stores in search of a manual tile cutter. If the tiles are quite impressive in size, made of a rough, non-deformable material, and you need a lot of them, it is not necessary, but it is advisable to think about choosing an electric tile cutter or a special machine.