Lego is a variation of the familiar masonry brick. Is it possible to make a machine for Lego bricks with your own hands, where can I look for drawings? These questions interest some residents of the country.

Lego bricks are highly durable and resistant to high temperatures.

Lego contains almost all the best qualities of masonry products. This building material has good sound insulation and environmental friendliness. Lego bricks are very durable and fireproof. Its production can become a family business. You just need to purchase a press for making bricks. Nothing will work without him.

DIY Lego brick. Brief overview of equipment and manufacturing technology

Before you think about organizing production, you need to accurately weigh the pros and cons, including cost and cost data in the analysis.

The first and main thing you need to understand is the scale and organization of the technological process. Brick making is not a garage-sized job. This process is large-scale, requires large production areas and precise logistics for the supply of materials and delivery of finished products. This is if we are talking about business. If you make Lego bricks for yourself, you need to calculate the profitability of this idea based on the volume of your construction and the cost of production at the construction site.

According to standard technology for making Lego bricks, the following composition and proportions of the mixture are recommended:

- Sand – 10%

- Crushed stone screening – 70%

- Cement M500 – 20%

Cost of materials:

- Sand – 520 rub/t

- Elimination – 185 rub/t

- Cement – 175 rub/bag

Consumption and estimated cost per 1 ton of mixture

- Sand – 52 rub.

- Elimination – 130 rub.

- Cement – 700 rub.

1 ton of mixture produces 285 bricks. Costs for purchasing materials – 882 rubles. The cost of one unit is 3 rubles 09 kopecks. The number of finished Lego bricks per shift is from 900 to 4000 pieces in 8 hours (depending on the power of the machine).

The price does not take into account:

- Possibility of purchasing unpackaged cement, which is significantly cheaper

- The cost of plasticizer, they vary in consumption and efficiency. This needs to be analyzed separately.

- Cost of transport services for delivery of materials

- Workers' salaries

- Equipment depreciation and maintenance

- Cost of electricity if the press is not manual

Equipment for the production of Lego bricks is presented in a wide range on the Russian market. The simplest and cheapest solution to the problem is a manual molding press and a small concrete mixer. The cost of this device will be around 45-65 thousand rubles. Of course, you can’t count on significant production volumes in manual mode; here we are talking about 500-800 pieces per shift when working intensively with a partner.

The obvious advantages of manual equipment are low cost, compactness, mobility and the possibility of simultaneous use. For example, if you have a manual machine for producing Lego bricks on your farm, you can provide yourself with briquettes for heating from wood sawdust.

The cost of the equipment directly depends on the force produced by the press and the amount of automation that speeds up the production process. Also, the higher this indicator, the better the quality of the products. The cost of such equipment starts from 200 thousand rubles for a simple hydraulic press with a productivity of 1,500 pieces per shift and reaches 7-8 million for complete lines with an output of up to 10,000 products per shift.

Semi-automatic machine

Serious manufacturers offer services for calculating and drawing up a business plan for such production, develop mixture recipes based on local conditions, and provide technical support to the manufacturer at all stages of operation.

Automatic equipment with high productivity

The point of this article is not limited to advertising of individual manufacturers and does not provide a 100% solution to get rich quick. Here we tried to formalize an idea, a dream direction for a person with an active lifestyle. Reviews on numerous forums are also not the ultimate truth; here you can easily fall into advertising techniques that sometimes do not provide real information.

The main thing is to show persistence, common sense and determination, and the rest will follow and will definitely work out.

Modern, high-tech brick, which is assembled into a single structure according to the principle of a children's Lego construction set. Lego brick is an innovative building material, characterized by excellent performance characteristics, as well as clear geometry of all edges

The tolerance of each size does not exceed one millimeter, which is very important for the coincidence of depressions and convexities during laying

This building material appeared quite recently, but has already gained enormous popularity among DIY consumers and professional builders. One of the reasons for this phenomenon is the ease of working with this type of brick. When used for construction and cladding, it is not necessary to use many tools and equipment, as a result of which the construction process is significantly simplified and cheaper.

What assortment to offer consumers?

Whatever manual press for Lego bricks you choose, it will be equipped with special dies. And it is these matrices that will determine what shape, what size and what type of finished products will be produced.

The matrix for Lego bricks will allow the entrepreneur to offer consumers a full range of manufactured blocks. By replacing molds on the machine, the following types of products can be obtained:

- Standard brick. This is the most popular type of all possible. And the sale of machines today is mainly carried out specifically for such bricks. Even if there is no extra money to purchase additional matrices, blocks of standard shape must be present in the assortment.

- Brick fitting. The dimensions of Lego bricks here are exactly the same, only they can be connected to each other by the side parts, and not just the top and bottom.

- Rail-shaped brick. Such blocks are laid like rails. Among professional builders, such Lego bricks are quite in demand. Therefore, if you want to enter a large market with your products, you must definitely acquire such matrices.

The price of the matrix is quite high - 25,000-50,000 rubles. But it is quite justified, taking into account the technology of their manufacture and the raw materials used (high-quality hardened steel 54-65 HRC)

And when ordering this “part” from a supplier, it is important to know what types of matrices there are:

- Simple. Such matrices are intended for making bricks individually. This is the simplest option, affordable for many.

- Combined. The dimensions of the matrix in this case are designed for the simultaneous production of 2-3 bricks

- Original. Such matrices are made to order according to individual measurements. It makes sense to purchase such “templates” only when there is a specific order for a specific brick. And there is absolutely no need to keep such matrices in reserve - a waste of money.

When deciding where to buy matrices for Lego bricks, it is worth considering that you need to choose them especially carefully. In order to last as long as possible, they must meet all quality standards. Otherwise, even a couple of technological cycles of the matrix will not last.

Review of mini equipment for gas silicate.

Production and sale of polystyrene concrete blocks as a business.

Production of expanded clay concrete blocks as a business.

Homemade machine for Lego bricks, drawings, diagrams

Lego brick is a modern version of an excellent building material. It has concentrated all the best properties of brick - sound insulation, strength, environmental friendliness, thermal insulation, fire resistance. And it also has a lot of its own advantages. Therefore, producing it yourself can become a very profitable business.

Production technology

The main difference between a Lego brick is not its shape. The production technology eliminates the firing stage! This greatly simplifies and reduces the cost of finished products. Therefore, many are interested in drawings and diagrams of equipment for its manufacture.

The production is based on the hyperpressing method. The finished mixture in molds undergoes compression with a pressure of more than 29 tons. Under such a load, water and cement are sintered or so-called cold welding occurs.

Raw materials for the production of Lego bricks:

- sand;

- clay;

- slags;

- travertine;

- dolomite;

- cement;

- limestone.

The best raw material is considered to be finely ground limestone, and the finer the particles, the stronger the finished product. To give the material an attractive appearance, dyes are added to the solution.

The most common mixtures:

- clay-cement-water in the ratio 9:3:1;

- sand-clay-cement in the ratio 2:1:0.5, add water;

- Melusa-Portland cement in a ratio of 3:1.

- preparation of the mixture;

- supplying the mixture to the matrix (forming device);

- pressing;

- settling or steaming.

Machines and equipment for the production of Lego bricks

The production line contains:

- mixer;

- belt conveyor;

- bunker;

- press.

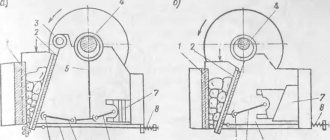

For a beginner doing small production with his own hands, it is enough to limit himself to a mixer and a press. Presses can be:

- manual;

- automatic or semi-automatic.

The manual machine is very easy to operate, inexpensive and reliable. But a Lego brick made according to this design is characterized by low strength, it absorbs more moisture and cracks in the cold.

Automatic and semi-automatic lines can be self-propelled or stationary. They produce from 1.5 thousand pieces per work shift.

Main characteristics of pressing machines:

- pressure on the form;

- bottom or top pressing;

- performance.

To produce bricks with your own hands, you need to equip a room that will house a press and a warehouse for “ripening” the finished product. The platform for vibrating equipment should be strengthened, and a 380 W power supply should be supplied according to the drawings. In addition, it is necessary to ensure a water supply to the workshop. The room temperature should be maintained all year round within +5... +40 degrees.

The factory machine comes with a set of pallets and racks, but these may not be enough. Prepare several additional racks and pallets.

Homemade machine

Before starting work, carefully study the drawing of the machine and make patterns for the parts. To make your own Lego brick press, you will need:

- Sheet steel;

- channel;

- pipe for piston and handle;

- metal corner;

- bolts and nuts;

- welding machine;

- Bulgarian.

- We make the cylinder posts from two sections of channel about 1 m long. The width of the cylinder according to the drawing should correspond to the length of the future brick.

- In the upper part, between the posts, we weld two rectangles of metal, forming a cross-section.

- On the resulting structure we place a channel about 70 cm long with the ribs up and weld it with an outlet on one side. We weld supports under the protruding part. We cut a hole above the cylinder equal to its perimeter.

- We weld the hopper according to a pre-prepared drawing from a metal sheet; the length and width of the outlet must correspond to the dimensions of the mold. The hopper is installed on 4 legs made of metal strips and welded over the protruding part of the channel. The form should slide freely along the ribs of the channel; this must be taken into account when preparing the legs for the hopper.

- The piston is welded from a metal sheet in the shape of a rectangle through which two pipes pass.

- From a pipe and metal strips we make a handle that opens and closes the lid. The handle is attached according to the drawing using long bolts and nuts.

- From the corner we make a base for the machine.

Using a homemade machine, you can make two types of bricks with your own hands: Lego with holes and regular solid brick. It’s easier to purchase a ready-made matrix.

Business registration

At the first stage of implementing the idea, it is enough to register your activities as an individual entrepreneur. This form requires a minimum package of documents:

- application in form P21001;

- receipt of payment of state duty (800 rubles);

- copy of the passport.

Then you should choose the form of taxation. The most profitable option in this case will be a simplified system (15% of profit or 6% of revenue). To start working immediately on the simplified tax system, at the time of registration, add to your package of documents an application for the transition to a simplified taxation system in form No. 26.2-1.

It will take 5 working days to complete all permitting documentation.

If you are planning large-scale production at the start, it is better to register as a limited liability company.

Making Lego bricks at home

This building material is in demand by professional builders due to its quality characteristics. The high demand for products is due to the following advantages of brick:

- high strength indicators;

- light weight;

- ease of installation and reliable adhesion;

- durability;

- environmental friendliness;

- aesthetics.

A properly organized advertising company will always find a consumer who needs high-quality and reliable building material.

The main disadvantage is the lack of GOST for Lego brick products due to the novelty of its use. This disadvantage is easily offset by compliance with all recommendations on the technology of production and storage of products. Time will pass, and you yourself will not notice how rumors about the quality of your high-tech building material will spread among people.

We suggest you familiarize yourself with How to come up with a nickname, how to come up with a beautiful nickname, pseudonym

Business relevance

Despite the crisis, the pace of construction in our country continues to increase in both the private and public sectors. Along with them, the popularity of building materials is growing. It is known that almost no construction is carried out without bricks, among which Lego can be called in demand.

A business idea to open an enterprise for its production can lead to the construction of a successful and quickly profitable enterprise, giving high profits, since there are still few competitors in this niche. By properly planning your activities, you can find your niche in the construction market and increase production turnover.

Equipment

The construction equipment market offers a wide selection of equipment for making Lego bricks. Here you will find both large lines and mini installations for organizing a workshop in a small room.

The price of equipment for the production of Lego bricks depends on the power, output and pressure that is exerted on the raw materials when forming the block.

From the equipment you will need a crusher, a vibrating sieve, a mixer, a hopper, a dispenser, a hyperpress, a mold for the production of Lego bricks and a steaming chamber.

The best equipment for making Lego bricks

We will look at the best installations that are suitable for organizing a mini production of Lego bricks.

Below are both cheaper mechanical (manual) and hydraulic (semi-automatic) machines, the price of which is an order of magnitude higher. These installations are produced in many cities of Russia. You can buy a machine for producing Lego bricks in Saratov, Krasnodar, Kirov, Blagoveshchensk, etc.

1. Hydraulic machine “Lego 180” – $2,540, manufactured by TekhTron LLC, Kirov; Allows you to make bricks with dimensions: length - 250 millimeters, width - 125 millimeters, height - 65-90 mm. The weight of the block depends on the raw materials used - 3.5 - 4 kg.

Specifications:

- Dimensions: 150 by 65 by 120 centimeters;

- Weight: 202 kilograms;

- Motor: 3 phase, 380V;

- Productivity: 180 pieces per hour, 1440 pieces per shift (3.8 m3);

- Pressure on the product: 8-10 tons (adjustable).

2. Mechanical machine “Lego 120” - cost 680 dollars, produced by TechTron LLC, Kirov. Allows you to produce bricks with the following parameters: length - 250 mm, width - 125 mm, height - 65-90 mm. The weight of the block depends on the raw materials used, from 3.5 kg.

Specifications:

- Dimensions: 160 x 50 x 110 cm;

- Weight: 89 kg;

- Productivity: 120 pieces per 1 hour, 960 pieces/shift (2.5 m3);

- Product pressure: About 2 tons.

3. A mechanical machine worth $630, manufactured by Stanki-Saratov LLC, Saratov. Allows you to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Dimensions: 20 x 50 x 14 cm;

- Weight: 99 kilograms;

- Hopper volume: 40 liters;

- Productivity: up to 1000 pcs/shift;

- Pressure: 2 tons.

4. Hydraulic machine for Lego bricks SGU-2000 – $2,370, manufactured by Ferrum LLC, Kirov. Allows you to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Occupied area – 3 sq. m.;

- Productivity: up to 130 pcs/hour;

- Product pressure: 20 tons;

- Power consumption – 7.5 kW;

- 12 month warranty

5. Hydraulic machine for making Lego bricks – $6,360, manufactured by ImportTechKom-Invest LLC, Blagoveshchensk. Allows you to make bricks with dimensions: length - 300 mm, width - 150 mm, height - 100 mm / length - 250 mm, width - 125 mm, height - 75 mm.

Specifications:

- Machine type: hydraulic;

- Productivity: up to 1900 pcs. per shift;

- Size: 350*500*1000 millimeters;

- Pressure: 80 - 100 kN;

- Weight: 450 kg.

6. Hydraulic machine 5BRICKS40S – $4,650, manufactured by GlobImport LLC, Krasnodar. Allows you to produce bricks with the following parameters: length - 250 mm, width - 125 mm, height - 75 mm.

Machine parameters:

- Hydraulic machine;

- Productivity: 200 bricks in 1 hour;

- The kit includes equipment for the manufacture of 3 types of products;

- Dimensions - 0.94 x 0.65 x 1.45 m;

- Hopper volume – 95 l.;

- Weight: 198 kg.

Homemade machine for Lego bricks, drawings, diagrams

Lego brick is a modern version of an excellent building material. It has concentrated all the best properties of brick - sound insulation, strength, environmental friendliness, thermal insulation, fire resistance. And it also has a lot of its own advantages. Therefore, producing it yourself can become a very profitable business.

Production technology

The main difference between a Lego brick is not its shape. The production technology eliminates the firing stage! This greatly simplifies and reduces the cost of finished products. Therefore, many are interested in drawings and diagrams of equipment for its manufacture.

The production is based on the hyperpressing method. The finished mixture in molds undergoes compression with a pressure of more than 29 tons. Under such a load, water and cement are sintered or so-called cold welding occurs.

Raw materials for the production of Lego bricks:

- sand;

- clay;

- slags;

- travertine;

- dolomite;

- cement;

- limestone.

The best raw material is considered to be finely ground limestone, and the finer the particles, the stronger the finished product. To give the material an attractive appearance, dyes are added to the solution.

The most common mixtures:

- clay-cement-water in the ratio 9:3:1;

- sand-clay-cement in the ratio 2:1:0.5, add water;

- Melusa-Portland cement in a ratio of 3:1.

Production stages:

- preparation of the mixture;

- supplying the mixture to the matrix (forming device);

- pressing;

- settling or steaming.

Machines and equipment for the production of Lego bricks

The production line contains:

- mixer;

- belt conveyor;

- bunker;

- press.

If an accelerated production cycle is planned, a steaming chamber is purchased. Here the products gain strength faster. In the workshop conditions they settle for 1 - 2 days, depending on the air temperature.

For a beginner doing small production with his own hands, it is enough to limit himself to a mixer and a press. Presses can be:

- manual;

- automatic or semi-automatic.

The manual machine is very easy to operate, inexpensive and reliable. But a Lego brick made according to this design is characterized by low strength, it absorbs more moisture and cracks in the cold.

Automatic and semi-automatic lines can be self-propelled or stationary. They produce from 1.5 thousand pieces per work shift.

Main characteristics of pressing machines:

- pressure on the form;

- bottom or top pressing;

- performance.

To produce bricks with your own hands, you need to equip a room that will house a press and a warehouse for “ripening” the finished product. The platform for vibrating equipment should be strengthened, and a 380 W power supply should be supplied according to the drawings. In addition, it is necessary to ensure a water supply to the workshop. The room temperature should be maintained all year round within +5... +40 degrees.

The factory machine comes with a set of pallets and racks, but these may not be enough. Prepare several additional racks and pallets.

Homemade machine

Before starting work, carefully study the drawing of the machine and make patterns for the parts. To make your own Lego brick press, you will need:

- Sheet steel;

- channel;

- pipe for piston and handle;

- metal corner;

- bolts and nuts;

- welding machine;

- Bulgarian.

Work progress:

- We make the cylinder posts from two sections of channel about 1 m long. The width of the cylinder according to the drawing should correspond to the length of the future brick.

- In the upper part, between the posts, we weld two rectangles of metal, forming a cross-section.

- On the resulting structure we place a channel about 70 cm long with the ribs up and weld it with an outlet on one side. We weld supports under the protruding part. We cut a hole above the cylinder equal to its perimeter.

- We weld the hopper according to a pre-prepared drawing from a metal sheet; the length and width of the outlet must correspond to the dimensions of the mold. The hopper is installed on 4 legs made of metal strips and welded over the protruding part of the channel. The form should slide freely along the ribs of the channel; this must be taken into account when preparing the legs for the hopper.

- The piston is welded from a metal sheet in the shape of a rectangle through which two pipes pass.

- From a pipe and metal strips we make a handle that opens and closes the lid. The handle is attached according to the drawing using long bolts and nuts.

- From the corner we make a base for the machine.

Using a homemade machine, you can make two types of bricks with your own hands: Lego with holes and regular solid brick. It’s easier to purchase a ready-made matrix.

The whole process of assembling a machine for making bricks with your own hands in the video:

https://youtube.com/watch?v=6vgoIwctuQw

How to make cinder blocks

You need to put a heaping mixture into the mold, turn on the vibrator for 3-5 seconds, the solution will settle. If there is not enough solution, report it, insert the clamp and turn on the vibrator again. After the clamp “sits” on the stops, the cinder block is formed. Turn on the vibrator and remove the uniform.

Note! The form is removed with the vibrator turned on, i.e. Harvesting is carried out at the “flight”.

Cinder blocks must dry within 5 days to a week, and the required hardness must be gained within 30 days at a temperature of at least 20°C in conditions of high humidity.

Machine for producing cinder blocks

Product characteristics and their applications

Lego brick is widely used in construction as a facing and wall material.

The mixture for pressing it consists of:

- screening out marble or crushed stone;

- sand;

- cement;

- water.

The grade of cement to obtain such a high-strength material should not be less than M500. The proportion of water in the mixture prepared for pressing is 10%. The Lego brick production technology is based on vibration pressing of the prepared mixture using special machines.

The features of this brick include:

- high frost resistance and very low absorption of moisture from the external environment;

- accuracy of geometric dimensions;

- attractive appearance;

- smooth and very even edges;

- high strength;

- durability and wear resistance;

- large variety of colors;

- with vertical and horizontal reinforcement, high seismic resistance of the structure.

Anyone who has been involved in laying Lego has noticed the convenience of this activity. After all, it has two guides, with the help of which it quickly and accurately fits into place. This creates a perfectly flat and even surface.

Holes and protrusions reliably fix the bricks in the overall masonry and at the same time can serve as channels for laying a wide variety of construction communications. These holes additionally retain heat.

Due to the excellent geometry of each brick, for a monolithic wall connection, not an expensive cement mortar is used, but a special adhesive composition. This reduces the mason’s labor costs, and hence the cost of all installation work as a whole.

Lego has a wide range of uses. It is used both for cladding cottages, dachas, houses and fences, and for the quick construction of buildings of several floors.

The affordable cost of equipment for brick production is explained by the fact that all the technological equipment and equipment of the line refers to standard machines for the production of various products by vibration pressing.

Basic properties of the material

Lego brick is a high-quality facing material formed by hyper-pressing without firing. Outwardly, it is similar to a not little-known designer. This form makes the erected structures much stronger, and the masonry process simple and accessible to everyone. The peculiarity of using Lego bricks is their fixation thanks to a special adhesive mass (15 kg of such glue is enough for 1 m³ of brick). The use of standard mortars and cement is not allowed. The channels that are obtained through the holes of the materials can be used as highways for infrastructure nodes. Each brick has two holes protruding above the surface. During laying, the lower one is attached to the upper one. The result is a smooth surface that does not need to be plastered.

DIY machine

On the Internet, there are many drawings available for various models of machines for making Lego, like this one.

Before starting work, study the drawings of the production machine, watch the video and prepare the necessary tools. You will need:

- Sheet of steel;

- Channel;

- Metal pipes for the piston, pipe for the handle;

- Corner;

- Accessory bolts and nuts;

- Welding installation;

- Bulgarian;

- Sandpaper;

- Dye.

Sequence of work:

- The stands for the machine are made of two channels approximately 1 meter long. The size of the brick produced will depend on the selected width of the cylinder.

- We connect two channels with blanks in the form of two steel rectangles, thus forming a section.

- We weld a channel on top of the resulting rack to create a running gear for the bunker. On one side, we weld a stop made of reinforcement. The channel will serve as a rail. We cut a hole in it according to the dimensions of the original cylinder.

- The bunker is welded from steel sheets according to the drawing. The dimensions of the hopper must correspond to the dimensions of the mold. The hopper is installed on a metal sheath, which is in the form of strips. It should move freely along the upper channel.

- The piston system is welded from metal sheets in the form of a rectangle, at the base of which two pipes are installed.

- To close and open the hopper lid, we make a handle from a pipe. It must be bolted to the hinge.

More details can be found in the video.

It is better to purchase the matrix separately, but if you wish, you can make it yourself, according to this scheme:

Technological production process

The main raw materials are:

- Filler (the filler can be sand or a mixture of sand, slag or limestone);

- Binder (the main binder remains cement, the amount per 1 brick is 10-20 percent);

- Water (it is better to take purified demineralized water so that white stripes do not appear on the brick);

- Dyes (a variety of dyes are added to give a suitable color, has a purely decorative purpose).

The smaller the filler parts, the better the final product. Lego bricks are also made from clay. Take 9 parts clay to 3-4 parts Portland cement, mix and add 1 part water.

To understand the manufacturing technology, let’s consider what sequence is used:

- The dry mixture is poured into the hopper, it is thoroughly mixed in advance;

- After the bunker, the mixture passes through a dispenser, in which the required amount of mixture for one brick is separated;

- The dispenser pours the mixture into the matrix, where the pressing process begins;

- After pressing, a finished building material is obtained. It is placed on pallets and sent to a warehouse for further drying. The brick must dry for at least 20 days before it gains strength. The instructions for some units indicate the drying time for the brick.

Additional components

To simplify the work on the machine for the production of Lego bricks, many components are sold on the market. Among them:

- Additional molds (matrices) of various types, shapes and sizes. With their help, you can change the linear dimensions of the brick, as well as give it different decorative styles.

- Conveyor feeders. To automatically feed the dry mixture into the bunker, you can purchase a tape. They can deliver bulk mixture to a height; the cost of the belts starts from 90,000 rubles.

- For large production volumes, you can purchase a dry mixture mixing unit. It will make the work much easier.

In addition to the above, you will need pallets for storing finished bricks, shovels, buckets, empty containers, brushes for washing equipment.

Purchasing a machine for making Lego bricks or making them yourself can be an excellent business. Or a good way to save on bricks. Such a machine can be installed at a construction site and produce your own bricks at the site of use. The cost of Lego bricks is quite low compared to ordinary bricks purchased on the market.

In addition to the article, we are posting a video about the materials that are used to make Lego bricks on a machine:

Comments:

- kadyr 04/2/2015 10:33

Send to Kazakhstan by mail

Yes, you can by EMS service - 125 USD, delivery time is 3-5 days or by mail - delivery time is 2-3 weeks, delivery cost is 65 USD

Kadyr, good evening. What city do you live in? It will be cheaper for me to come for the matrix than EMC delivery. I'm interested in a set for $160 which will be next in line.

Kadyr, what city in Kazakhstan do you live in? It’s cheaper for me to get there than EMC costs. I'm interested in $160, when will it be my turn?

Read also: How to check a pulse transformer for interturn short circuit

Good afternoon Mikhail! We are located in Alexandria, Kirovograd region. Ukraine, location map here: //msd.com.ua/img/map.php Lego matrices are produced almost to the warehouse (there are no queues, i.e. they are in stock now). In Ukraine, delivery is by cash on delivery, abroad - by full prepayment.

Can you send me by bus to Volgograd?

Unfortunately, we do not have representatives at the border, we can send cash on delivery to any city closest to the Ukrainian border to the Nova Poshta warehouse, for example, look for the nearest branch here: https://novaposhta.ua/office

We don't have a bus to Volgograd. We have a representative in Russia (Stary Oskol) - you can make an official prepayment for it 20% more, after the prepayment the matrix will be sent to you within 3 working days.

Hello Rashid, I’m interested in a kit for 160 dollars, how much should I send to Stary Oskol and how will it be sent? I live in Kazakhstan in the north and you make matrices with steel and there are drawings for a hydraulic machine

Good afternoon There is no drawing for hydraulics, we are not ready for a manual one yet, but you can take as a basis a brick machine, which we have been producing for more than 7 years (there is no strong demand for it): //msd.com.ua/zip/kirpichnitsa.zip If you want to Stary Oskol, send money 20% more, if there is no trust, send it to me. Can you please contact me: Shakhidov Rashid Sultanovich ind. 28000, Ukraine, Kirovograd region. Alexandria Any translation system, preferably one of these: Golden Crown PrivatMoney Unistream WesterUnion Contact Coinstar MoneyGrim With delivery to Kazakhstan, the Lego matrix set, welded box and void boxes cost 285 USD (i.e. delivery by EMC service - 125 USD, it takes 3- 5 rubles, you receive it at your address customs-free and duty-free!)

Hello. I would like to buy a matrix set for 120 and an additional upper and lower punch. How much will it cost with delivery to Almaty. Kazakhstan.

I want to purchase a die set and an additional upper and lower punch. Please tell me how much it will cost with delivery to Almaty?

With delivery to Almaty it will cost 210 USD

A matrix with a box is available in Sevastopol for 160 US dollars, with delivery to Almaty it will cost 170 US dollars, i.e. GlavDostavka shows that delivery is only 10 dollars. We will not disassemble the matrix in Sevastopol.

Rashid give me your Crimean phone number. number, I live in Crimea, I want to purchase one set, we need to talk on the phone. I'm waiting for the phone. numbers on email mail.

Rashid assalam alaikum I want to buy a matrix for Lego I live in Chechnya how to contact swami

Here is my number 89604416568

In Chechnya (or the North Caucasus of Russia) you can contact my close relative and make an advance payment through him: +7 928 7893104 Ilyas The cost of a complete matrix with a box and cylinders is 160 US dollars, the cost of delivery to Chechnya or Russia is 120 US dollars total - 280 USD

I want to purchase a die set and an additional upper and lower punch. Please tell me how much it will cost with delivery to Belarus

Good afternoon. Is the kit available in Sevastopol? Or do I need to order it? What is the price of the matrix today? And is it possible to purchase the machine itself?

I want to order a matrix with cylinders and shipping throughout Ukraine, how much will it cost?

Great. I wanted to ask how much delivery will be in Kyrgyzstan and how we will buy manual machines

My number is 702257562

A manual machine with delivery to Kyrgyzstan costs 970 USD

two side plates on a Lego brick with milling and a matrix, top and bottom, with delivery to Belarus, how much will it cost?

220 USD with delivery to Belarus

HELLO ONE ONE LEGO BRICK MACHINE HOW MUCH IS IT IF WE BUY HERE FOR RUSSIA I AM MAADANBEK

I HEARD THE MOST DISH 40 THOUSAND RUBLE THAT'S CORRECT

How much does a ready-made matrix cost from welded boxes in Kyrgyzstan?

How to contact you?

Good afternoon, I am interested in the cost of the matrix with delivery to Perm.

Hello. We are engaged in the manufacture of matrices for Lego bricks and more. The matrix is made on professional CNC equipment from wear-resistant, hardened steel, characterized by increased strength (45 steel is not suitable for the manufacture of matrices used for pressing.) For mechanical and hydraulic presses. Delivery throughout the Russian Federation and the CIS The price is lower than the market price, the quality is higher.

Read also: Acid for processing welds on stainless steel

There are ready-made matrices available.

+79688639475 WhatsApp or Viber [email protected]

approximately how much the machine will cost with delivery to Uzbekistan

answer if possible in a telegram to the number +998919861701 or in VK Jurabek Khafizov

We don’t use telegram, we have WhatsApp, Viber +38 050 4571330. Matrix with box and cylinders with delivery to Uzbekistan - 360 US dollars

Rashid primerno skolko videt ruchnoy stanok s dostavkoy v Turkmenistane…

1150 US dollars If only the matrix is 480 US dollars

Good afternoon, I am interested in the cost of the matrix with delivery to Scotland where I live.

Good afternoon A complete set of molds for Lego bricks, such as in the video:

Cost US$180, delivery to Scotland – US$150, total US$330 with delivery to your address.

Good day! A complete set of a Lego brick form, such as on the video:

costs $180, delivery to Scotland - $150, a total of $330 with delivery to the address.

Any site materials can be published with a link to the source Website promotion © 1999–2018 Site map

Lego bricks appeared on the construction market not long ago and quickly gained popularity. While retaining the advantages of ordinary brick, it also has its own advantages. You can buy such bricks ready-made, or you can purchase or independently make a machine for their production. It will be cost-effective for large production volumes of Lego bricks.

Lego bricks: composition of the mixture

In this regard, there are several varieties. Lego bricks can be made from the following compositions:

- Clay-cement. Components such as clay (90%), cement (8%) and water are used here.

- Composition based on various screenings. This also includes screenings (85-90%), cement (8%) and water.

- Clay-sand. This includes four components: sand (35%), clay (55%), cement (8%) and water.

When planning production, the availability of raw materials should be taken into account. This is an important condition. Bricks produced by pressing require raw materials with a fine fraction. This must be taken into account to achieve the required strength. Lego bricks obtained from screenings have the highest strength characteristics.

The content of a large amount of sand in the product contributes to the deterioration of the strength indicator due to the presence of large sand fractions.

The production of products such as Lego bricks, reviews of which indicate their reliability and efficiency, requires special molding dies. With their help, a surface is created with the required smoothness and with certain parameters of given geometric dimensions. For the full production of these products, you must have the entire set of matrices that allow you to obtain halves of these bricks and fitting products. They are used for finishing work.

Advertising and sales of products - marketing plan

Such bricks are actively gaining popularity, although not yet known to all potential customers.

To sell them successfully, private consumers must learn:

- what is the advantage of your products;

- where, how and for what price it can be purchased;

- What promotions do you have for the product?

Residents of the private sector will see your advertisement:

- on local TV;

- in advertisements of gardening associations;

- on banners and leaflets;

- on the pages of local newspapers;

- in social networking groups of dacha associations and cottage communities;

- on your website;

- in videos on YouTube.

The construction of structures from finished products clearly promotes the product. For example, lay out a Lego fence and place an advertisement on it.

Product advertising is especially effective if it is used in several channels at once: the Internet, television, local press, advertisements and banners, meetings with owners.

Increasing production volumes will expand the client niche. Small construction and repair companies will become your customers. To do this, they place advertisements in specialized publications and hold personal meetings to conclude contracts.

When alternating different types of advertising, the budget for monthly promotion will be 15,000 rubles.