The processing and mining industries work with stones and hard rocks that are difficult to crush. In this case, a special crusher is required that can quickly and efficiently complete all the assigned work. But if we are talking about crushing stone at home in order to equip a private enterprise, then a device with low power will do, and if you wish, you can do it yourself.

The mini stone crusher is practical, compact in size and has convenient functional features for use in accordance with the established standards.

Do-it-yourself crusher - crusher for crushed stone

The processing and mining industries work with stones and hard rocks that are difficult to crush.

In this case, a special crusher is required that can quickly and efficiently complete all the assigned work. But if we are talking about crushing stone at home in order to equip a private enterprise, then a device with low power will do, and if you wish, you can do it yourself. The mini stone crusher is practical, compact in size and has convenient functional features for use in accordance with the established standards.

Other designs

There are different crushers, their main difference from each other is the processed material. There is a fundamental difference between a machine that shreds cardboard or foam rubber, and a machine that is suitable for rubber (tires, tires) or, for example, expanded clay. Crushers are also made to crush bird bones. You can make a glass grinding machine yourself.

Use elements of used equipment: washing machine, meat grinder, grinder, etc. The main thing is that the principle of operation of the device is observed . Figuratively speaking, this is the principle of a meat grinder, in which the material passes through the drum/reception bowl, ends up in the crushing system and is effectively crushed. The department where the material is ground is represented by cutters and a milling cutter. The raw material will be processed until it reaches the required grinding size.

For example, until it becomes metal shavings or sawdust

With the help of a gear-rotor crusher you can crush even asphalt and clay. The roller system is most often used for grain processing. And there are a great many examples of such structures. But if you look at the step-by-step instructions for making a garden crusher, a device for any other material will be made according to the same basic plan. Only its power, size, number of saws, etc. will change.

See the video below for options for making a crusher with your own hands.

Types of crushers

Based on the type of use, this device is divided into crushers for:

- plastics;

- household waste;

- metal;

- wood;

- stone

This apparatus is also classified by size, distinguishing between large (0.3 m), small (0.02 m) and medium crushing machines (0.1 m).

Depending on the characteristics of the device, there are:

- knife devices;

- crushers with cone hopper;

- tiled machines;

- rotary knife machines.

If you need to split hard materials, you can safely use a knife apparatus . It has the power to destroy objects of this kind. And in order to crush them, rotary knife crushers are used. Their main purpose is secondary crushing of waste .

Currently, such devices are produced in small quantities, since foreign-made crushers are gradually replacing domestic ones due to their better quality. In production, devices are most often used that crush the material by bringing two plates closer together . Such crushers are called jaw crushers. They perfectly process asphalt, reinforced concrete, and building stone. In some cases, they are even used for crushing glass and ceramics.

Particularly durable building materials are processed using cone crushers. The principle of their operation is that at the moment when two cones, one of which is stationary, come together, a solid object is crushed.

Drawings and 3D models of various crushing equipment

The working bodies of the roller crusher (Fig. 3)

Rice. 3. Roller crusher: a) Design; b) Crusher diagram

are two parallel cylindrical rolls 2

and

4,

rotating towards one another. A piece of material entering the working area is carried away by friction against the surface of the rolls and is drawn into the working space, where it is crushed as a result of splitting, fracture and abrasion.

The surfaces of the rolls are made smooth and corrugated. Rolls are mounted on the frame 1

in bearings

3

and

6.

The bearings of one or two rolls have spring supports

5,

which can move in the guides when an uncrushable object enters the crusher.

The rotation of the roll is transmitted from an electric motor through a V-belt transmission with a frequency of 75...190 min-1.

The largest size of a piece of material loaded into the crusher depends on the grip angle, determined by the diameter of the rolls and the coefficient of friction on the metal surface of the rolls. In order for smooth rollers to be able to capture the initial product in the crushing zone, it is necessary that the angle of capture of the rolls does not exceed the angle of friction of the material on the surface of the rolls.

The maximum size of pieces depends on the diameter of the rolls and the size of the discharge slot. To meet these conditions, the diameter of a smooth roller should be 20 times greater than the size of the stone, and with grooved surfaces of the rollers - 12 times. Therefore, roller crushers are used only for secondary crushing of rocks of medium and low strength, as well as for grinding viscous and wet materials.

The degree of grinding is 4...12. The crusher size is characterized by the diameter and length of the rolls.

Productivity of roller crushers (M3/H) PT = 3600 aL R, where a -

width of the unloading slot, m; L—roll length, m; — peripheral speed, m/s; R is a coefficient that takes into account the use of roll lengths, the degree of loosening of the material, and uneven feeding; R = 0.1...0.3 for soft and R = 0.4... 0.5 for hard rocks.

4) Impact crushers

Impact crushers are used for crushing soft and medium hard rocks (limestone, chalk, gypsum, coal, etc.).

Crushing in an impact crusher occurs as a result of the impact of rapidly rotating hammers on pieces of material and the impact of the pieces against each other, the impact of the material on crushing plates onto which it is thrown by hammers, the crushing of material between hammers and the crushing plate, as well as between hammers and grates.

The following types of impact crushers are distinguished: hammer crushers with hinged hammers, impact crushers with rigidly fixed beaters.

Figure 1.4 Diagrams of impact crushers.

Impact crushers are classified according to the following criteria: - By the number of rotors - single-rotor crushers (Figure 1.4 a), double-rotor crushers (Figure 1.4 b), hammer crusher (Figure 1.

4 c) - According to the design of the impact surfaces - rotary crushers with grates and impact - centrifugal crushers with smooth impact plates. According to the principle of crushing in two-rotor crushers - parallel and sequential.

Advantages of impact crushers: high degree of grinding (up to 30) and low specific energy consumption. They can carry out coarse, medium and fine crushing.

Disadvantages of impact crushers: the ability to crush only non-abrasive rocks with a strength of up to 1200-1500 kg * s/cm2, mainly limestone, rapid wear of the hammers, if pieces of metal can get into the crusher, breakdown occurs, if the material moisture content is more than 15%, the crusher is smeared, the unsuitability of hammer crushers for crushing very hard rocks.

Runners.

The runners are widely used for fine and fine crushing of soft rock materials of medium hardness. Figure 1.5 Runner patterns.

Runners are classified according to the following main characteristics: - By mode of action: periodic (Figure 1.5 a) and continuous (Figure 1.5 b,c,d) - By technological purpose: for grinding and mixing and only mixing, for briquetting the raw mixture, runners are also distinguished with metal rollers and bowl and stone rollers and bowl.

According to the design: with a stationary bowl (Figure 1.5 a, b), with a rotating bowl (Figure 1.5 c, d, e), with an upper (Figure 1.5 a, c, d, e) and lower (Figure 1.5 b) drive . With a bottom drive, disassembly is more difficult, repairs take longer, but the mass is not contaminated, with rollers resting on the material with their mass (Fig. 1.5 a, b, d) with additional hydraulic, pneumatic (Fig. 1.

5 c) or with spring (Figure 1.5 d) pressing on the rollers. By unloading method: with manual unloading (Figure 1.5 a), with pressing through a grate (Figure 1.5 b), with centrifugal unloading (Figure 1.5 c), with unloading via a dump lowered into a bowl (Figure 1.5 d).

In runners with rollers rotating around a vertical axis, centrifugal forces tend to tear the rollers off, and if unbalanced, the central shaft can bend.

Advantages of runners compared to roller crushers: it is possible to unload significantly larger pieces of material, it is easier to regulate the fineness of grinding, the plastic properties of clay materials are improved due to the repeated impact of rollers. Disadvantages of runners: bulkiness, difficult repairs, increased specific energy consumption per unit of processed material.

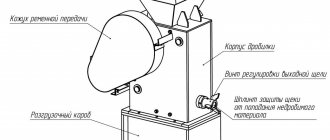

Crusher

DIY brick crusher

DIY brick crusher

It is not difficult to find out how the crusher is made and what it consists of, since all the necessary information is written in the documentation supplied with the device, which means that it will not be difficult for a skilled person to assemble the crusher with his own hands.

In your everyday life and household, a variety of crushers are widely used, which you can easily make yourself from available materials. In its simplest form, a homemade crusher consists of a small container inside with sharp blades installed one after the other. The internal shaft rotates a one-kilowatt electric motor, which allows you to gradually adjust the rotation speed.

Basically, such devices are used for chopping grass, large vegetables, for making feed for farm animals, and so on. In general, as you already understood, the crusher that you made with your own hands can be used for different purposes.

Conclusion

As has already become clear, the crusher has many options and methods of application (not only in industry, but also in agriculture), and making a crusher yourself will not be a problem. If you still have questions, we recommend watching the video:

Search your favorite song right now

1. Do-it-yourself mini brick, stone, concrete crusher!

- Published: 2 years ago

- Duration: 4:15

- By

I tested the crusher, it turned out very well.

2. DIY mini brick, stone, concrete crusher!

- Published: 1 year ago

- Duration: 29:01

- By

Making a stone crusher! With my own hands. Tests with ores will be in the next issue, it is already known.

3. DIY brick crusher VK408226779

- Published: 1 year ago

- Duration: 3:04

- By

jaw crushers to order 89657012103.

4. Jaw crusher for stone

- Published: 11 months ago

- Duration: 3:14

- By

Crushers to order. Belgorod Mini crushers, gross, shredder. +79517654312.

5. homemade mini crusher for brick and stone

- Published: 4 years ago

- Duration: 6:49

- By

A homemade jaw crusher, assembled almost on the knee, without drawings, without any hints.

6. Homemade jaw crusher + detailing (part 1).

- Published: 2 months ago

- Duration: 13:01

- By

Homemade jaw crusher for processing construction waste into raw materials for the production of blocks.

7. jaw crusher for processing construction waste!

- Published: 1 year ago

- Duration: 1:04

- By

homemade crusher for brick and stone.

8. jaw crusher 220 volt VKontakte 408226779

- Published: 8 months ago

- Duration: 4:06

- By

jaw crusher for 220 volts, description of the crusher, operation of the brick crusher.

9. Crusher

- Published: 1 year ago

- Duration: 2:06

- By

Homemade coal jaw crusher.

10. Shredder (shredder) for construction waste

- Published: 1 year ago

- Duration: 1:17

- By

We offer equipment of our own production. This model is used for crushing fragile, even.

11. jaw crusher tel. 89657012103 VKontakte408226779

- Published: 1 year ago

- Duration: 2:18

- By

Custom crushers crush brick, concrete, quartz and other similar materials. low price.

12. homemade jaw crusher for stone

- Published: 3 months ago

- Duration: 0:39

- By

- Published: 9 months ago

- Duration: 1:47

- By

Granite crusher, armor jaws 300x200mm, 7.5kW/380V Price - 36000 UAH Contacts for orders: +38 050 4571330 (Viber, .

14. Mini crusher Caesar 1

- Published: 4 years ago

- Duration: 2:25

- By

15. Recycling of concrete, brick and other stone materials as a business idea

- Published: 8 months ago

- Duration: 4:18

- By

Production of recycled crushed stone from old concrete and sand from broken bricks. Everything you need is equipped.

16. mini jaw crusher

- Published: 2 years ago

- Duration: 2:15

- By

17. Homemade mini jaw crusher. Stone crushing.

- Published: 4 years ago

- Duration: 5:28

- By

A homemade jaw crusher breaks natural stone.

18. Concrete crusher. BUCKET PLANT

- Published: 5 months ago

- Duration: 0:59

- By

19. Dsch80-100 crushed stone brick crusher marble mini

- Published: 6 years ago

- Duration: 0:19

- By

20. IVZ 2-260 - crushing bricks.

- Published: 5 years ago

- Duration: 1:42

- By

Recently Searched

Types of stone crushers

To properly establish the production process, you need to select the right type of crusher, since there are different types with characteristic technical and functional features:

- Hammer crusher for stone . A hammer crusher is a special device that breaks stone into the desired shape and structure. The hammer blows are cyclical, so the stone breaks into the required pieces, eliminating any inaccuracies and inconveniences. The absence of a large amount of waste is considered an important advantage.

- Cone crusher. This device allows you to easily and simply cope with crushing stone material, while providing the appropriate convenience. The system consists of two cones, between which there is space for moving stones for the purpose of crushing them.

- Impact crusher. The device is ideal for crushing hard and soft rocks. Crushing is carried out due to the rotor in the system, which is characterized by high power, reliability, quality and, most importantly, technical serviceability. The absence of inaccuracies reduces the amount of waste and material rejection.

- Roller crusher. The device is equipped with special shafts that rotate among themselves to crush stone and hard rocks. The devices rotate towards each other, due to which crushing is carried out evenly and efficiently, eliminating any technical inaccuracies.

- Lye crusher. The design of the device contains rectangular slabs through which the stone passes to crush and obtain the desired shape and appearance. The working space is wedge-shaped for convenient movement of the stone in order to obtain the desired structure.

Basic requirements for homemade devices

Any homemade unit must not only produce chips of a suitable shape and size, but also be adapted to work with the most commonly used materials.

Therefore, it is necessary to think through not only the working unit that crushes the wood, but also the devices that supply the material .

In addition, the design of the unit must ensure maximum safety during its use. This concerns not only the possibility of wood being processed flying out or sharp rotating parts, but also clothing being pulled under drive belts or chains, as well as electric shock.

Making a crusher with your own hands

While you are looking forward to creating this unit, prepare the following materials :

- motor ; the purchased electric motor will ensure the creation of a silent machine capable of grinding waste in small quantities. During operation, it does not emit harmful substances, and its operation is possible both outdoors and indoors. The only disadvantage of the electric motor is its direct dependence on the power supply.

- saws with a thickness of 0.06 to 0.1 m, in the amount of 10-20 pieces (the more cutters, the better the crusher).

- pin for threading saws,

- nuts and washers,

- metal corrugated pipes (to create the frame of the crusher),

- casing and hopper made of galvanized metal,

- welding machine.

How to make a jaw crusher with your own hands

The price of such mechanisms is high, their service life is long and they are generally not used in home production. Often, a homemade crusher is made according to the principle of an industrial unit and based on the information from the technical documentation that is attached to it.

For production, improvised means are used. To make one of the options for a brick crusher, take a small container into which sharp blades are mounted. Using the internal shaft, the rotation of the electric motor with a power of 1 kW is generated and the crushing process occurs.

News Week - the main news of the week | Weekly-news.ru

To keep the design simple, one movable jaw is made, and the other is fixed, from a cast iron sheet. By changing the inclination of the installed sheet, the fraction changes. In order to pass unbreakable pieces, the movable cone moves away from the movable one, thanks to a system of spring shock absorbers. The latest generation of cone crushers are equipped with hydraulic pressure.

Features of application

Typically, homemade crushers are used to grind a variety of grass, large and hard varieties of vegetables in order to prepare feed for livestock and poultry.

A do-it-yourself crusher can be made for a wide variety of purposes. In addition to preparing feed, this type can also be used in construction in order to crush gravel or crushed stone from broken bricks or for other household needs.

- Today, crushers designed for crushing crushed stone are widely used at DSC. Typically, these are mechanisms of the cone variety, which make it possible to obtain cube-shaped crushed stone that meets group 1 according to GOST.

On farms, such a unit is an indispensable assistant, because it is very difficult to manually grind the required amount of feed to feed all the livestock.

Of course, you can make a crusher with your own hands, but to do this you need to have some mechanical skills and, of course, knowledge of physics.