Plastic processing is one of the freest niches for doing business in Russia.

However, the issue of opening it most often depends on the cost of the equipment.

Entrepreneurs often start not with a full processing cycle with finished granulate at the output, but with the collection and grinding of polymer waste.

Even in this case, purchasing a shredder and/or crusher may not be affordable . One of the most discussed solutions to the problem is making your own shredder.

Such projects are quite feasible if two “constant quantities” are known - raw materials and product.

Next, we will talk about how to make a shredder and how to avoid gross mistakes when designing and making your own plastic crusher.

Types of Shredders

There are 3 types of such devices, which can be divided according to the capabilities of processing all the material. They are divided into the following options:

https://youtube.com/watch?v=_0xPK7k66LE

- the design’s appearance resembles unusual blades on scissors; it is suitable for working with types of plastic such as acrylic, film and nylon;

- the type that is most often used in factories where plastic is made, as well as in plants for processing old material;

- hammer, cone or jaw devices, which are used for processing large plastic parts, for example, window profiles.

Materials and tools for work

To make this device at home, you will need some skills in working with welding equipment.

The entire plastic shredder is made of the following parts:

- circular saws. Their standard number is approximately twenty pieces. Since this is considered the basis of the entire device, you should choose only high-quality ones and with different tooth configurations, which helps to grind waste well;

- Instead of a drive, it is worth taking an electric type of engine. The reason is a longer choice and the ability to use not only in an open area, but also in the room itself;

- axis for fastening saws;

- for the manufacture of the frame and frame you will also need a metal profile;

- various parts for fastening;

- a hopper through which materials for processing will be supplied, and a protective casing;

- To attach the rotor, you will need a special belt, as well as a pulley and a pair of bearings.

The wrong choice of saws for a crusher can lead to problems on the axis, causing the structure to vibrate violently and quickly break.

Do-it-yourself plastic crusher - drawing up a project and assembling homemade equipment

Plastic processing is one of the freest niches for doing business in Russia.

However, the issue of opening it most often depends on the cost of the equipment.

Entrepreneurs often start not with a full processing cycle with finished granulate at the output, but with the collection and grinding of polymer waste.

Even in this case, purchasing a shredder and/or crusher may not be affordable . One of the most discussed solutions to the problem is making your own shredder.

Such projects are quite feasible if two “constant quantities” are known - raw materials and product.

Next, we will talk about how to make a shredder and how to avoid gross mistakes when designing and making your own plastic crusher.

Shafts

The standard configuration for most manufacturers for fitting under knives is a hexagon . That is, the blank for the shaft can be a rolled profile , the ends of which are machined for bearings, gears, etc.

The optimal choice is steel 40, 45, 40X with improvement (hardening + high tempering).

Bearing units

You can use ready-made bearing units of a self-aligning design.

They “forgive” errors in the alignment of the holes, in which conventional radial bearings would warp and overheat .

However, compared to conventional bearings, the cost of such units is significantly higher .

In addition, the dimensions of their housings often do not allow maintaining the required center-to-axle distance between the rotors.

To avoid misalignment , the sides of the crusher body are used as axle boxes. The mounting holes are bored in a machine with a four-jaw spindle, placing the parts together.

If it is not possible to make a housing with coaxial holes, you can select double-row spherical bearings suitable for load-carrying capacity.

Rotors

One of the main requirements for rotors is the presence of a guaranteed gap between the sidewalls of the knives. Otherwise, they will rub against each other , and the mechanism may even jam.

The width of the spacer bushings should be larger. They also need to be sanded to the same size.

Particular attention should be paid to axial adjustment.

The design of the shafts must include the ability to shift the entire set of knives and bushings by tenths of a millimeter and securely fix it when the side clearance is uniform.

Most often, threaded parts are made on the shafts, and the position of the knives is fixed with nuts.

Assembly of finished units

In order for the design to be repairable, the body should not be welded .

It is better to make a bolted connection.

Then the chopper can be disassembled at any time for resharpening or replacing knives.

One of the common problems with rotating mechanisms is increased vibration.

To avoid this phenomenon, it is necessary to align the actuator, gearbox and motor, i.e., align their axes.

Another reason for vibration is imbalance (imbalance) of the rotors . To eliminate it, you need to carry out balancing.

We invite you to watch a video on how to implement the idea of a plastic recycling business using homemade equipment:

Conclusion

Not all the difficulties that will have to be encountered in the process of designing and assembling a plastic shredder have been considered

Manufacturing can only be called independent, since it requires a whole fleet of machines, and some units have to be purchased assembled. The whole process can take months , and financial investments will be required in any case.

After developing the project “on paper,” it is worth calculating the economic efficiency of the event : sum up the costs of procurement and processing, and then compare it with the price of a “factory” shredder.

Those who have already had experience in manufacturing shredders believe that the idea is justified in two cases: if there are no strict time restrictions or if it is planned to establish serial production of such units. For practical plastic recycling tasks, it is usually easier to choose a ready-made model .

Manufacturing process

After preparing everything you need for work , you can begin the first stage of creation. First, a cutting block is created by sliding a circular saw blade onto a pre-prepared axle. To ensure that the required space remains between these improvised knives, it is worth using nuts.

Next, we mount the product on the pulley and, using the bearings, create free rotation. Then we make a rectangular frame and a strong frame from the prepared metal materials.

The second step is to weld the legs, selected in height, using welding. Next, the frame is covered with a sheet of steel; to do this, we attach it to the frame. We create a hole of the required size in it and fix the engine at an equal distance from the cutting parts. A special casing and container for supplying raw materials will be needed for the safety and efficiency of the work process.

After making the frame, we will begin the final stage of assembling the plastic crusher. To do this, we put a special protective casing on the knives and a hopper through which the material will be supplied. When changing the casing, it is worthwhile to provide a hole in it in advance for attaching an axle with a pulley.

The last step is to connect the cutting unit to the motor shaft using a belt. That's it, the design is done.

Recommendations from experts

The main advice that the craftsmen give is the need to make a drawing before starting work in order to know exactly what the structure you are planning will look like. This will help avoid inaccuracies and errors with the dimensions of individual parts .

Having planned and assembled such a device with your own hands, you can, knowing its design, calmly make changes and improve it. The processed plastic will have a size that is included in the design capabilities of a particular device.

When choosing such a device, you need to decide in advance how often the unit will be used. If there will be little work on it, and the loads planned are small, then a low-power electric motor will suffice, but for active use you will need a more powerful device with a huge number of revolutions.

And in order to avoid the need to collect processed fractional material from the floor, it is worthwhile to provide an angle under the saws for securing a strong container.

Plastic is widely used in the production of dishes, toys and even in space technology. The beauty of the material lies in the cheapness of the raw materials, which is why stores are filled with disposable cups and plates.

Therein lies the catch - plastic does not decompose and pollutes the environment. To reduce the harm to the material, they use specially designed devices - plastic crushers; making them yourself is not difficult.

How to shred a plastic bottle at home – Metals, equipment, instructions

Polymer materials have been present in our lives for quite some time, and now they can be found in any industry. But due to the fact that plastic does not decompose in the usual way, it causes enormous damage to the environment.

The possibility of its recycling is considered a positive factor. To do this, the plastic is first prepared and brought into the state it needs, then it begins to be crushed. To accomplish this, special devices were created - crushers (shredders, machines, special grinders). You can make any of them yourself.

There are 3 types of such devices, which can be divided according to the capabilities of processing all the material. They are divided into the following options:

- the design’s appearance resembles unusual blades on scissors; it is suitable for working with types of plastic such as acrylic, film and nylon;

- the type that is most often used in factories where plastic is made, as well as in plants for processing old material;

- hammer, cone or jaw devices, which are used for processing large plastic parts, for example, window profiles.

Materials and tools for work

To make this device at home, you will need some skills in working with welding equipment.

The entire plastic shredder is made of the following parts:

- circular saws. Their standard number is approximately twenty pieces. Since this is considered the basis of the entire device, you should choose only high-quality ones and with different tooth configurations, which helps to grind waste well;

- Instead of a drive, it is worth taking an electric type of engine. The reason is a longer choice and the ability to use not only in an open area, but also in the room itself;

- axis for fastening saws;

- for the manufacture of the frame and frame you will also need a metal profile;

- various parts for fastening;

- a hopper through which materials for processing will be supplied, and a protective casing;

- To attach the rotor, you will need a special belt, as well as a pulley and a pair of bearings.

The wrong choice of saws for a crusher can lead to problems on the axis, causing the structure to vibrate violently and quickly break.

Recommendations from experts

The main advice that the craftsmen give is the need to make a drawing before starting work in order to know exactly what the structure you are planning will look like. This will help avoid inaccuracies and errors with the dimensions of individual parts .

Having planned and assembled such a device with your own hands, you can, knowing its design, calmly make changes and improve it. The processed plastic will have a size that is included in the design capabilities of a particular device.

When choosing such a device, you need to decide in advance how often the unit will be used. If there will be little work on it, and the loads planned are small, then a low-power electric motor will suffice, but for active use you will need a more powerful device with a huge number of revolutions.

And in order to avoid the need to collect processed fractional material from the floor, it is worthwhile to provide an angle under the saws for securing a strong container.

Making a plastic crusher with your own hands

Polymer materials have firmly entered modern life, and there is not a single industry where they are not used, from the production of containers to space technologies. Every year about 180 million tons of various plastics are produced on the planet. Most of them cannot independently decompose into simple components and be disposed of independently.

This causes irreparable damage to nature and can cause an environmental disaster.

A positive feature of almost any polymer (plastic) is the possibility of recycling, thanks to which old plastic items can get a “new life” as useful items.

Recycled plastic is slightly inferior in strength characteristics to primary polymer, but at certain proportions, products made from recycled plastic are practically no different from the original one.

Learn more about the rotary shredder

The most common design is the impact crusher. It consists of a rotor on which the knives are fixedly mounted. Under the influence of the driving force - from a diesel, gasoline engine or electric motor, the axis with knives begins to move and with quick blows crushes the raw materials that have fallen under the knives. Depending on the purpose, there are low-speed machines and high-speed units.

A sieve or grid with a certain mesh size is installed at the bottom of the working chamber, depending on the required quality and diameter of the resulting fraction. The raw materials are processed cyclically with knives and gradually pass through a sieve.

Particular attention is paid to the quality of the metal from which the knives are made - it should be good hardened steel, which prevents rapid wear and ensures that the sharpness is maintained for a long time.

We make the crusher ourselves

There are several of the most popular types of plastic shredders that are made at home. In order to assemble this device with your own hands you will need a little patience and minimal skills. All you need as a special tool is a welding machine or a household inverter.

A do-it-yourself plastic crusher, the design of which will differ slightly depending on the level of skill of the manufacturer and his imagination, has the following common elements:

- drive unit. The most commonly used is an electric motor. Thanks to the large selection and affordable prices, you can choose the model of the required power. In addition, the electric drive crusher is quieter and can be used both outdoors and indoors;

- circular saws. This will be the basis of our apparatus. It is necessary to select a sufficient number of them and different configurations of teeth for better grinding of waste. The optimal number of saws on the axis is about 20;

- the axis on which the saws will be mounted;

- metal profile or pipe for making the support frame and frame of the crusher;

- protective cover and feed hopper. You can make them yourself at home from galvanized sheets using metal shears, a hammer and a vice;

- a pulley, two bearings and a special belt, which creates interaction between the electric motor and the rotor;

- fasteners (nuts, washers and metal screws).

Types of shredders

The plastic is crushed before the production of recyclable materials using crushers. The properties of materials served to manufacture different types of processing devices, which are reflected in the classification of the raw materials used.

By purpose

- For PET bottles and plastic with thin walls. Materials are processed by several cutters of the unit.

- For dimensional materials. Crushers are capable of breaking window frames and thick-walled device casings.

- For acrylic, PVC film, nylon. The raw materials are cut by the crusher design in the form of scissors.

By type of design

There are 4 types of crushers, each of which is designed for processing separate raw materials:

- Hammer. Hammers attached to the structure break up waste.

- Cheek. The plastic is crushed by corrugated steel plates.

- Conical. The waste passes between the cones, which look like large graters.

- Rotary. Universal type of crushers. Most often suitable for recycling plastic bottles (PET), foam materials.

The fourth type of crushers is purchased for private use. If they have the skill, craftsmen make units at home with their own hands. The crusher contains a rotor with fixed knives.

The device is driven by an electric motor, diesel or gasoline engine. The axis with the cutters rotates and chops the plastic raw materials that fall under the knives of the structure. Impact crushers are differentiated by power; there are low- and high-speed units.

When using this type of device, it is possible to adjust the size of the plastic fraction after processing. To do this, grates with the desired cell size are installed at the bottom of the crusher chamber.

What is the difference between a shredder and a polymer crusher?

Both types of equipment perform the same task - crushing.

When processing plastics, this process is usually divided into two stages :

- coarse grinding - shredders are used for this;

- obtaining fine crumbs - a crusher is used for this.

The operating principle and kinematics of both units are most often the same, and they differ only in some details, for example, the size of the sieve cell, the overlap of the knives and the configuration of the cutting edges.

The process is divided into two stages in order to increase productivity and optimize energy costs.

Materials and tools for manufacturing

To assemble a plastic shredder with your own hands, you will need knowledge in the field of welding, as well as patience. A welding unit would be useful. Homemade plastic crushers consist of the following parts:

- Elements for fastening (self-tapping screws for metal, washers, nuts).

- The metal axis on which the saws of the unit are mounted.

- Circular saws. It is better to choose about 20 cutters for deep crushing of plastic. The correct configuration of teeth and their optimal number will allow the unit to grind more efficiently.

- A pulley, 2 bearings and a belt that combines the work of the electric motor and rotor in the crusher.

- Drive unit. There are different types of devices available for sale. The electric motor of the unit can be used indoors and outdoors.

- A metal pipe or profile for the axial frame and frame.

- Plastic raw material supply container, protective casing. You can make them yourself from galvanized sheets using metal scissors, a vice and a hammer.

Where can I get the drawings?

You need to understand that manufacturers of equipment for shredders and crushers will not make drawings publicly available .

The easiest way to get diagrams for a homemade shredder or crusher is in two ways:

- Read forums on the topic , like this one. The likelihood of finding accurate and detailed drawings of plastic shredders is very low. Often, resource users recycle some unclaimed equipment from a related industry, for example, a lopper. And if a crusher is made from scratch, few people care about documenting all stages of production. Nevertheless, it’s worth reading the forums: analyzing discussions and other people’s design mistakes will help you make a more advanced plastic shredder with your own hands.

- Take measurements from the existing shredder. It will not be possible to obtain complete information, since the owner will not allow you to disassemble a working machine. But even a visual assessment will help in making your own homemade crusher.

Many attempts to make a crusher on their own reach a dead end due to the fact that the designer tries to attach to an existing unit . For example, “fit” all the elements to a worm gearbox found in the garage.

An attempt to reduce the cost of a design using secondary parts, as a rule, leads to mistakes.

Manufacturing process

After all the materials and tools for creating the structure have been purchased, you can make a plastic crusher with your own hands.

Creating a cutting block

Install disc cutters on the metal support. The elements must match in size, the distance between homemade knives is kept to a minimum. Metal washers will help with this. Secure the saw blades of the homemade crusher with nuts along the edges. Place everything on the pulley and use two bearings. This way the unit can spin.

Welding the support frame

You need to make a rectangular frame with your own hands. This can be done by taking a metal corner, a pipe, or a profile. Next, use a welding machine to give the desired look. Weld legs of the required size to the resulting element.

Cover the frame with a metal sheet and weld it to the frame. On the surface of the sheet, cut a hole identical in size to the cutting block. Attach the motor close to the blades of the device.

Now all that remains is to assemble the crusher device. Before putting a protective shell on the cutters, you need to make sure that there is space in the latter for the axle to engage the pulley. Attach a hopper for plastic raw materials in the upper part. Connect the cutting block of the crusher to the motor with a special belt.

Useful tips

- Users who make crushers for PET bottles with their own hands are advised to draw a drawing of the unit before starting. This will allow the equipment to be manufactured exactly as planned and will prevent missing parts.

- When purchasing a motor, you should understand what volumes of raw materials the plastic crusher will encounter. The quality and speed of grinding depends on the power of the device. An oversized electric motor is suitable for periodic processing of materials. If volumes will increase in the future, it is better to choose a powerful motor in advance.

- The design should be designed to be easily accessible for removing any element of the device, for example, circular saws for sharpening. To avoid having to take out the latter too often, it is better to initially choose light-alloy cutters. Their cost is higher, but the preservation of a good sharpening is high, which will make it possible to grind longer at home.

- To ensure that recycled raw materials are in one place, it is useful to consider a container for collecting plastic. It is usually installed under the crusher blades. If you want to sort the cut plastic by size, homemade gratings or mesh elements with a given cell size are mounted below the disks.

- Making your own PET crusher benefits the environment and the owner of the device. When using it, nature is not polluted by non-degradable plastic bottles, and the master has the opportunity to hand over the recycled material to a waste collection point.

- If the structural part of a home-made unit is properly designed, the shredder will not only crush the raw materials, but also process the leaves and branches - for a gardener this will be an excellent alternative to burning branches on a fire by hand.

All types of processing machines are available for DIY production. Technology develops over time, allowing users to improve the unit. A plastic crusher made at home is no worse than a factory one and will definitely be more reliable than budget Chinese devices.

In just half a century, plastics have become a part of human life. Products made from them surround us, making life convenient and comfortable. Strong and lightweight, they are so cheap that many have become disposable. The flip side of this convenience is the huge supply of used bags, bottles, broken toys, etc. They do not decompose naturally and pollute the environment.

However, plastic is recyclable. Before plastic waste can be sent for recycling, it must be shredded.

DIY plastic crusher: drawing and assembly of the crusher

Plastic recycling is a popular business in Russia, as the amount of plastic waste, such as bags and bottles, is constantly growing. The problem is the high price of finished equipment. Therefore, novice entrepreneurs are interested in whether it is possible to assemble a plastic crusher with their own hands.

Types of plastic shredders

On the production line, the primary shredding of plastic takes place in the shredder, and the secondary shredding in the crusher. Moreover, both modules can have an almost similar design, so the words “shredder” and “crusher” are often used as synonyms. There is no universal shredder design, since shredding different waste requires different device configurations :

- To shred plastic bags, nylon, acrylic waste, V-shaped scissor installations are required.

- For large waste (plastic packaging, window frames, boxes, system unit cases, etc.) hammer, jaw or cone crushers are needed. They are bulky and are installed in the workshops of recycling factories.

- Plastic bottles and thin-walled packaging are usually disposed of in rotary shredders equipped with sharp blades or teeth.

Operating principle of the crusher

To eliminate elastic waste (films, bags, ABS plastic), tearing or cutting devices are used, for example, industrial scissors. The use of rotors is not advisable because the films can wrap around the toothed drums.

Large waste must be broken down before crushing; for this purpose, special hammers and presses are used: these are heavy stationary machines that are difficult to assemble with your own hands.

Thin-walled waste - bottles, cans, small pipes - are very common, so it is better to build a homemade shredder specifically for this category of waste. This should be a single or double-shaft design, the main element of which is a rotor with cutters mounted on the surface.

The cutting elements crush the waste, resulting in a homogeneous raw material suitable for incineration, combustion in a pyrolysis plant, or sale to a processing plant.

Device design

In order for a self-assembled plastic shredder to work with the greatest efficiency, choose a design that is suitable for disposing of the waste you are going to work with. Installations vary in complexity and equipment (filter screens, bearing units, type of saws, pre-pressers, etc.)

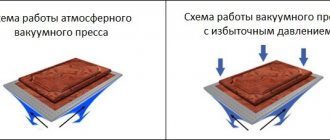

Single-shaft

This is the simplest design in which a rotor equipped with cutting edges rotates inside a stationary housing. Waste enters the device through the loading window. The crushed raw materials are sifted through a sieve under the influence of their own weight.

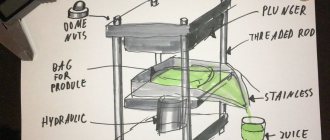

To make recycling faster, most single-shaft rotary shredders are equipped with a hydraulic pre-presser. This device presses pieces of debris against the rotor blades, reducing the risk of pieces of plastic slipping.

Single shaft shredder teeth

Some devices are additionally equipped with a pneumatic system for unloading raw materials. The single-shaft design is good for its simplicity, reliability and ease of assembly. It is better to use it for the primary grinding of particularly hard polymers.

Twin-shaft

Twin shaft shredder

In a more complex shredder, two rotors installed in one housing rotate towards each other. This design makes it possible to do without a pressing element, since the waste is pulled into the gap between the rotors. Better grinding is achieved, and the high torque allows you to load elastic plastic, rubber and elastomers into the crusher.

Where can I find a drawing or diagram

There are no drawings of shredders in the public domain, as manufacturers do not want their devices to be copied or produced without a license. Valuable tips, diagrams and sketches can be found on the forums. If you have a prototype product, carefully inspect it, or better yet, disassemble it by measuring the dimensions of the main parts.

Initial data for design

Decide which waste you will have to work with more often. Approximately calculate the amount of work and, based on it, determine the installation parameters:

- power;

- raw material supply window size;

- diameter of rotors and their number;

- configurations of knives or teeth (their size, relative position, sharpening, material).

In order not to calculate everything manually, find a factory crusher that would suit your needs, and build on its technical characteristics.

Drafting

Most people are content with a mini-crusher, which does not require expensive materials. However, for a DIY device to work correctly, you will need to study the theory of strength of materials. If you do not have minimal technical knowledge and experience in designing machines, it is better to invite an experienced person.

Designing a single-shaft shredder involves:

- choosing an electric motor of suitable power;

- calculation of shaft strength;

- determination of the diameter and length of the rotor, the width of the loading window;

- selection of bearings;

- calculation of the gear ratio, selection of a suitable factory model.

Development of the shredder element

The drawing is made on graph paper or using the AutoCAD program. Calculating parameters “by eye” without drawings is fraught with a decrease in the productivity of the installation and increased danger when working with it.

Required tools and materials

The minimum set of tools for assembling a crusher is a grinder, a set of screwdrivers, bolts, nuts, angles and other fasteners, and a welding machine. It is better to make the crusher body dismountable to simplify maintenance, so bolted fastening is preferable.

You will also need circular saws for assembling the rotor, a drive belt, a metal pipe for the shaft, a plastic, metal or rubber-fabric casing for the loading window, a pulley and bearings, and a coupling.

Step-by-step design instructions

Making a plastic crusher with your own hands is easier if you are consistent in your actions. It’s worth starting with the main thing - the rotor and drive. Processing of all components and setting up the unit are carried out last.

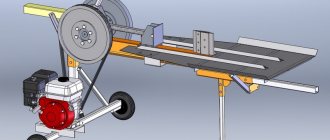

Drive Design Options

It is better to use an electric motor rather than an internal combustion engine, as it is economical and easy to operate. There are two ways to transmit rotation from the motor to the gearbox.

The belt transmission of rotation from the engine to the shaft is easy to assemble and maintain. If a large piece of plastic gets stuck in the rotor, the belt may break off and burst, but the unit will not suffer serious damage. The belt driven shredder starts up very smoothly. Disadvantages include loss of efficiency and large dimensions of the drive.

The drive via a clutch is very compact and eliminates efficiency losses. However, it is more complex, and to prevent damage when debris becomes jammed, manual or automatic reversal will have to be provided.

Material and configuration of knives for cutting plastic

A simple way is to install 15-20 blades from a circular saw on the shaft. The discs are installed so that the teeth are slightly offset relative to each other; the distance between the discs should not exceed a few millimeters. To fix the blades, install washers of equal thickness between them, and press the outer blades with nuts or weld them.

You can install special blades, in which case the unit will be able to grind more raw materials per hour. Cutting elements are made to order from spring steels 65G, 60S2, 65S2VA or die steels X12MF.

What to use as shafts for knives

Any steel pipe is suitable for the shaft of a homemade crusher, preferably from steel 40, 45, 40X. Factory installations come with hexagonal shafts, bored at the ends for attaching bearing units. Six edges protect the cutters mounted on the shaft from slipping.

At home, it is easier to use round pipes or rods. They can be threaded to make it easier to secure the cutting discs with nuts along the edges. If cutting is not possible, the discs are welded onto the shaft.

Requirements for rotors

The rotor is the main part of the crusher, therefore, for reasons of efficiency and safety, the most stringent requirements are imposed on it:

- The rotors of any shredders must be perfectly balanced relative to the central axis to avoid runout and destruction of the mechanism.

- It is necessary to use blades of the same configuration from the same material with the same strength.

- There should be a gap of several millimeters between the sides of the knives, otherwise when rotating the blades will touch each other and overheat due to friction.

- If the gap is too large, the efficiency of the unit will decrease, since debris that is not completely crushed will slip between the disks and get stuck near the shaft.

Material and appearance of the frame

A large diameter pipe can be used as a housing (stator). A hatch is cut out for loading raw materials, and holes are made at the ends for the shaft. An electric motor is mounted at a safe distance from the outer blade. If there is no pipe, use a box assembled from steel sheets.

If you want the pieces of raw materials to be of a strictly defined size, mount a filter mesh under the shredder body, and then install a container under it to collect crushed plastic.

The outside of the frame is processed with a file, sandpaper or grinder to remove any unevenness. Then it should be coated with any anti-corrosion coating to make the installation last longer. Coating the inside is of no use as it is subject to a lot of friction as the blades rotate and crush debris.

Using bearing units

The cheapest and easiest option is to install conventional radial bearings, but if you install them crookedly, the unit will skew and overheat. It is better to install self-aligning units because they are less sensitive to distortions. Their disadvantage is their high price.

If you cannot assemble a housing with coaxial holes, select double-row spherical bearings of the required load capacity; they are more wear-resistant.

Step-by-step assembly of all parts

Before installing the parts, make sure that they are free of defects. It is especially important to check the integrity of the future shaft and rotor parts, since they are subject to the greatest loads.

- Secure the blades to the axis by placing washers of equal thickness between them.

- Mount the axle with blades on a pulley; the bearings will ensure free rotation.

- From a metal profile or pipe scraps, make a supporting frame on which the stator with rotor and motor will be installed.

- Install a stator made of thick pipe or assembled from steel sheets onto the support frame.

- Weld or screw the loading hopper and the raw material unloading system to the stator to make it more convenient to work with the device.

- Place the electric motor on the frame, connect it to the shaft using a tightly tensioned drive belt or coupling.

Example of an electric motor for a plastic crusher

Run the device at idle speed and see if there is any obvious imbalance, which is expressed in increased vibration of the structure. If there is one, disassemble the housing and check how evenly the bearings and blades are installed.

Useful tips and tricks

The most valuable advice will be given to you by a person who has personally made a crusher with his own hands. The wizard will help you draw up a drawing, share your diagrams, or take measurements from your device.

It is better to fasten the housing elements with bolts and nuts so that the structure is collapsible. This is very important when servicing the rotor, cleaning it and replacing blades.

Don't make the mistake of buying the best components for your homemade shredder if you plan to use it infrequently. For a “home” shredder, a low-power electric motor and grinder blades installed in a row are sufficient.

If you intend to sell processed raw materials, install a profiled mesh under the crusher. Only pieces of plastic of a certain size will pass through it.

For serious units, it is better to buy more expensive parts, since efficiency and reliability come to the fore.

Types of shredders

Grinding equipment is divided according to purpose and design.

- Film waste. These units crush polypropylene, acrylic, polyethylene, and polyvinyl chloride films. They are equipped with V-shaped knives that cut the film like many scissors.

- Thin-walled products and bottles. Several cutters installed in series are used. Maximum performance is achieved when the device is fully loaded.

- Large and thick-walled products. Window frames, instrument housings, etc. are crushed.

By design:

Each design group of equipment is designed for grinding its own type of raw material:

- Cheek. Shredding of plastic is carried out by massive steel corrugated plates, between which the plastic is crushed and crushed.

- Hammer. Impact-type devices crush raw materials using hammers hinged on a rotating rotor.

- Conical. The raw materials are crushed between two cones resembling massive graters.

- Rotary. This is the most popular and most versatile type of plastic crusher.

So-called universal units are also used. They simply combine several types of crushers, each of which grinds its own type of waste.

Crushers for plastics, crushers for plastics

Ningbo Huare Machinery produces quality plastic impact crushers that are designed to crush sprues, defective products and other waste from plastic products manufacturing. Also, in some cases, these crushers are used for crushing rubber, paper, cardboard, and wood. The company produces a wide range of rotary crushers for plastic, which are capable of solving a wide range of problems.

Depending on the type of blades and power, Huare shredders are used for crushing sprues, canisters, PET bottles, preforms, vegetable boxes, household appliance housings, polymer films, bags, etc.

Principle of operation. Inside the crushing chamber there is a rotor with movable knives, as well as a stator with two fixed knives. The processed polymer waste is fed through the loading window of the crusher into the crushing chamber, where it is crushed using stator and rotating rotor knives. At the bottom of the crushing chamber there is a sieve with holes of the same size. As soon as the size of the crushed particles becomes smaller than the diameter, the particles fall into the receiving container. Unloading of crushed material from the receiving container is done manually or using pneumatic unloading (optional).

The most popular Huare HSS models are always in stock at our warehouse in Moscow, so you can buy a plastic crusher very quickly. Our specialists have extensive experience and will help you choose a plastic crusher based on your needs at the lowest price.

Universal series HSS

Crusher HNS

Attached crusher HFS

For cans and barrels HTS series

Machine for sharpening crusher knives

Our company also offers Italian highly efficient crushers manufactured by CMG, designed for crushing plastic products and production waste (molding and blow molding products, rejects, thermoforming waste, sheets, sprues, boxes, panels, caps, PET bottles, profiles and film, extruded foams, fibers and composite materials) into recycled materials. With the help of crushers and industrial mills it is possible to crush any engineering plastic ABS, PA, PBT, PC, POM, PE, PP, etc., as well as film, foil and paper. They make it possible to obtain grains of the desired geometry and size, followed by dosing crushed grains and mixing them with the primary material. Productivity from 10 to 2000 kg/h.

CMG crushers N17 series

CMG crushers N25 series

CMG crusher S30 series

CMG crushers N40 series

CMG crushers N45 series

CMG crushers N60 series

Operating principles of an impact crusher for polymers and other waste

The material to be processed is loaded into the hopper of the CMG crusher and crushed during the operation of the stator and rotor knives. A sieve with cells of the required size (diameter) is installed at the bottom of the crushing hopper. When the crushed granules become smaller than the diameter of the sieve cells, they are poured into a special hopper. In addition to standard configurations, CMG can manufacture and offer to buy a plastic crusher according to the specifications, productivity requirements and material characteristics received from the Customer.

Distinctive features of CMG polymer crushers

CMG plastic crushers have a rigid design. The large mass of the structure itself and the mass of the rotor ensure smooth operation under high load conditions and have a positive effect on the life of the knives. The gentle angles of the blades smooth out peak loads and guarantee ideal dynamics. As a result, the material is not damaged thermally, has sharp edges, has high uniformity and low dust content.

These properties are of great importance for a smooth crushing process. When using CMG crushers with their proprietary knives, there is no blocking of the rotating parts of the crusher due to uneven crushing of the material and the formation of a jam of material grains in the hopper due to the fact that the particles do not have breaks and dust is not generated during processing.

Thanks to its large mass, proprietary knives and special bearing design, the CMG plastic crusher has high productivity combined with low energy consumption and a long service life.

CMG crusher rotor design

The rotor inside the crusher is made of a solid, solid piece of metal. It has a lot of weight and, therefore, a high torque. The rotor has no imbalance. There are no welds on it that could prevent it from being cleaned. The rotor has inclined surfaces, so simple straight knives are used. The CMG film crusher has a fixed position of rotary knives. Only stator knives can be adjusted. This provides a number of advantages, because

Learn more about the rotary shredder

Rotary plastic crushers demonstrate high productivity and crushing depth. Thin-walled waste is crushed by high-speed devices processing up to 100 liters per hour.

For thick-walled waste, machines with low rotation speed but high torque are used; their power reaches 10 kilowatts. Capacity is limited to 15 liters per hour; they can handle the hardest plastics. Medium and large processing plants typically have both types of rotary shredders. At low speed, solid waste is pre-crushed and then finally crushed using high-speed devices.

The working bodies of such devices are the massive corrugated rotor itself and fixed side knives, numbering from 3 to 7. Raw materials enter the working chamber from the loading hopper and fall between the rotor knives and the fixed knives, where they are crushed.

Crusher with built-in shredder-thermocompactor

Rotary shredders are available with one or two rotors. Some models add a grate. It acts like a hammer grinder.

Shredder design for plastics

When choosing the design of a plastic shredder, you should pay attention to the proposals of equipment manufacturers.

It is better to take other people’s work as a basis for a project and have certain guidelines than to reinvent the wheel and end up with a non-working model.

The most popular are single- and double-shaft rotary shredders.

Single-shaft

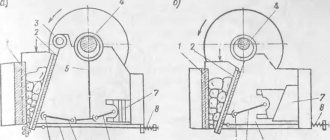

Single shaft shredders are used for the initial shredding of most varieties of polymers .

It consists of a rotor on which movable knives (2) are fixed and a housing with fixed or stator knives (1). The raw materials are fed through the loading window from above, and the finished crumbs are poured under their own weight through the calibrating sieve (3).

The shredding process involves repeated cutting and continues until all the plastic has gone into the receiving hopper.

The configuration of the rotary knives is selected depending on the material being processed:

- Dovetail and inclined – for processing film materials, PET containers and other soft waste.

- Straight – for crushing sprues, boxes, thick-walled blow moldings, PET bottle caps. Such knives are often made in the form of separate segments, which are arranged in cascades. Segmentation is performed to reduce shock loads on the drive, reduce noise and vibration.

Stator knives for single-shaft polymer crushers are made solid (type P).

Twin-shaft

The rotor and stator knives on such crushers are arranged in a checkerboard pattern, and the shafts rotate in counter directions.

Low-productivity machines with a small working chamber are made with a single drive ; the teeth on the rotary knives are used to capture and crush waste.

Grinding is also performed on the side surfaces (as in disc shears).

Operating principle of plastic crushers and scope of application

The operating principle of all crushers is similar. It consists of destroying the source material mechanically. They cause irreversible deformations in raw materials - stretching, shearing, twisting. For crushing, both sharp metal parts of equipment and large particles of raw materials that have not yet been crushed are used.

For each type of raw material, taking into account its mechanical properties, appropriate equipment is selected. For example, it makes no sense to crush the film, but it is easy to cut. And polystyrene waste is useless to cut, but, due to its fragility, it is easy to crush.

In industrial installations, water is used to reduce noise and constantly clean working parts.

The main areas in which plastic shredders are used are:

- procurement workshops of plastics production enterprises;

- factories recycling recyclable materials;

- collection points and primary processing of recyclable materials.

Do-it-yourself crusher for PET bottles

Plastic processing is one of the freest niches for doing business in Russia.

However, the issue of opening it most often depends on the cost of the equipment.

Entrepreneurs often start not with a full processing cycle with finished granulate at the output, but with the collection and grinding of polymer waste.

Even in this case, purchasing a shredder and/or crusher may not be affordable . One of the most discussed solutions to the problem is making your own shredder.

Such projects are quite feasible if two “constant quantities” are known - raw materials and product.

Next, we will talk about how to make a shredder and how to avoid gross mistakes when designing and making your own plastic crusher.

We make the crusher ourselves

Industrial crushers have excellent performance and appearance, but are not cheap. In the meantime, you can make a plastic shredder with your own hands; for this you will need a home workshop and plumbing and welding skills.

Materials and tools

To make a device with your own hands you will need:

- Circular saws - 20 pieces. The discs must be free of cracks and not bent. It is better to choose them with different shapes and numbers of teeth - this will expand the capabilities of the device.

- Electric motor.

- Working shaft.

- Two bearings.

- Two pulleys.

- Drive belt.

- Steel angle or other profile for the frame and frame.

- Fasteners

- Steel sheet 0.8-1.5 mm.

- wires, switch and junction box.

Manufacturing procedure

- Assemble the cutting unit. Circular saw blades are placed on the axle, separating them with thick washers or nuts.

- Attach the pulley and bearings to the axle.

- Weld a support frame and a vertical frame from the profile.

- Cover the frame with steel sheet, providing holes for the working shaft.

- Install the cutting unit, securing the bearings in the provided mounts.

- Install the electric motor on the frame, attach the second pulley to its shaft, and adjust the tension of the drive belt.

- Connect the wires in accordance with the electrical diagram, carefully insulating the connections.

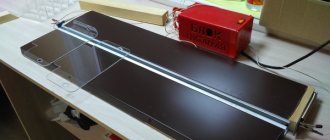

Homemade plastic crusher

A homemade plastic crusher is ready to receive raw materials.

Drive design

In factory crushing plants, two methods are used to transmit rotation from the motor to the gearbox:

- Direct drive (via clutch). Torque transmission occurs without loss, the design is compact in size. If you manage to select a ready-made geared motor, the dimensions and weight of the installation will be even smaller. However, in this case, it is necessary to provide for manual (and ideally automatic) reversing in case of jamming of the rotors.

- Belting . Efficiency losses and relatively high dimensions are compensated by the smooth start of the mechanism. If the shredder becomes jammed, the only risk is that the belt will break or slip.

The transmission of rotation between the rotors (in the case of using one engine) is most often carried out through an open gear drive. When designing, you need to be prepared to calculate it. Most likely, gears will have to be ordered .