The collapse of the secondary specialized education system in Russia and the CIS countries has caused an interesting paradox: a good specialist in working with his hands earns more than the average specialist with a tower, and it is easier for him to find a job - after all, there are few specialists, the old ones have retired, and no one is 20 years old taught, there was a shortage of qualified workers in the market. Therefore, now young people have finally begun to seriously consider the professions of turner, mechanic, carpenter...

Today our guest at Reconomica is a 6th grade general-purpose turner who will tell those who want to get this profession the whole truth about his work.

My job is a bus depot turner

Hello. My name is Shevchenko Vasily Petrovich, I am 41 years old, I live and work in the city of Minsk. I have been working as a turner in the branch “Bus depot No. 6” of the state enterprise “Minsktrans” for more than 15 years (currently I combine the profession of a turner with the profession of a master of industrial training in college). Having graduated from the Mozyr State Pedagogical University named after I.P. Shamyakin in 2002, I was immediately sent to the city of Minsk (there was a personal request from the Minsk enterprise where I did my internship, usually after graduating from this university they are sent to work as a foreman of industrial training in some some colleges, technical schools).

What does a turner do?

We can say that a lathe is a specialist who processes metals on a lathe.

The profession is, of course, ancient, but the principle of operation has not changed much, the workpiece rotates - you cut into the metal with a cutter to give it the required shape. And not only metal, it can be wood, plastic, and glass.

The mechanical department, where I work as a turner, is engaged in performing work on mechanical processing of metals, manufacturing new parts and normals, and restoring spare parts (including consumables). In a small department of 178.8 square meters there are 6 machines, 7 people work in 2 shifts, a continuous work week (this is according to the schedule approved by the chief engineer).

What should a universal turner be able to do?

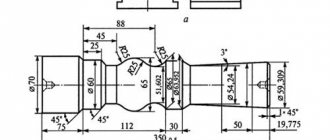

A turner, of course, works on a lathe. But here too there are some peculiarities, based on the operations to be performed. For example, I am a generalist turner , i.e. I work at a universal lathe, making single parts. In fact, I perform a full range of work on a lathe, including threading, drilling, boring, reaming, countersinking holes, and processing external cylindrical and conical surfaces. In this case, a special place is occupied by checking the dimensions in accordance with the drawing; this has its own nuances. You need to have a good understanding of tolerances and fits.

What education do you need to work on a lathe?

You can work as a turner both after receiving secondary specialized education and after higher education. I graduated from university, and it turned out quite funny. The university is a pedagogical one, upon graduation they give a diploma of “Engineer-teacher”, and also degrees of “Turner”, “Miller”, “Mechanic”. In my second and third years, I took qualifying exams, and there were two for a turner (the first was for obtaining the 3rd category, the second was for obtaining the fourth). And they gave the certificates only after defending their diploma (I don’t know why, they could have already worked part-time as turners if they had given them out earlier).

At one time I thought a lot about which turner it would be better to study. After all, there is a rotary turner who processes massive parts with large diameters, a milling turner, a universal turner, and a boring turner. The most popular profession has always been and is considered to be a universal turner.

This is me at work.

As I already said, for a turner you can also have a specialized secondary education; in the process of work, you increase your rank at the enterprise by performing qualifying work. But sometimes it’s useful to get a higher education, it gives you the opportunity to manage several turners on a site, work as a shop manager; in our case, half of the workers received a “tower” in absentia.

Where should a young specialist go to work?

The vacancy “Turner” can be found everywhere, and vacancies appear at enterprises every now and then. Usually, after receiving secondary specialized education, future turners already know where they will work. Very often, like me, they stay at the same enterprise where they did their internship.

Description of the profession

Wood carving tools

Turners work on specialized or universal machines. They can be automatic or semi-automatic, vertical or horizontal depending on the direction of the spindle, metal and woodworking, powerful and lightweight. There are nine main types of equipment in total.

The name of his specialization depends on what machine the turner works on and what production operations he performs:

- the carousel operator makes flanges, with their help the pipes are connected;

- a revolver is a craftsman engaged in the production of all kinds of parts, the blank for which is a calibrated rod;

- the boring machine enlarges the internal cavities and gives them the desired shape;

- the sharpener brings the product to the required parameters and calibrates it;

- The all-rounder can do all of the above.

A turner is a profession that combines the art of using a machine and the ability to see the final product in a faceless workpiece. The number of operations performed in this case is very large: cutting threads, reaming holes, countersinking, drilling, turning all kinds of surfaces. Craftsmen who know how to work on numerically controlled machines are valued.

Turner's working day

Now I already have the 6th category, which I received at the enterprise. As with a lower rank, at the beginning of the work shift I receive an assignment (per shift or daily allowance) from the site foreman. At the end of the work shift, it is necessary to put the workplace in order, i.e. remove consumables, tools, incl. measuring, and devices.

What are the differences between the categories?

The sixth category is the maximum. Qualities appear here, starting from the fifth and ending with the first. You need to be able to literally do everything: polish parts, achieving a high level of accuracy, cut all types of threads, sharpen particularly complex tools. To save processing time, process several sizes with one cutter. And I’m generally silent about tables with processing modes. Even the cutting speed must be increased and decreased, relying on experience.

At one time, it was interesting to observe the colors of tarnish (this is the formation of an oxide film on the surface of the metal due to high temperature); from these colors you can roughly determine what the heating temperature of the steel is. This all comes with experience, at first they usually give 3-4 ranks, work with devices (dividing head, steady rests), alignment with indicators, cutting almost all types of threads begins.

I was always told: proper sharpening of a cutter is the key to its long service life.

Nowadays, cutters are sharpened less often due to the fact that the same cutters with a replaceable plate are used (the plate is simply mechanically fixed to the cutter body, and not by soldering, as before).

Tolerances

Even in a secondary school or university, they always hammer in tolerances and qualifications. The point is that we need to get, for example, a hole with a certain diameter and depth. Tables of tolerances and fits immediately open (it’s like a turner’s bread, one might say so). In the table, the turner looks for the hole diameter (in the “Nominal” column). The drawing always indicates the quality to which this surface (well, in this case, the hole) needs to be processed. Again, look at the table, after finding the diameter of the hole on the side of the table, the quality is searched. That's all, on the intersection lines there is a number that we need (qualities are written as H6, H11, etc.), the value in the table is measured in microns. Moreover, if the letter h is a lowercase letter, then the hole must be made smaller than the size given in the drawing; if it is a capital letter, then it must be larger.

Working at a bus depot, I can say that turning work here is not entirely ordinary; after all, the company primarily repairs parts and produces a minimum of new ones. Usually this is the processing of complex surfaces (for example, crankshafts, but more often bushings) using 6-8 grades with alignment using flying calipers, and cutting of threads, most often metric, multi-start.

Soviet lathes vs CNC machines

Over all the years of operation, it stood for 16K20 (this machine has been produced since 1973), using the appropriate equipment. These include rests (if the workpiece is too long, I can’t do without a steady rest; it serves as an additional support), faceplates (if the part is not strictly cylindrical in shape, which cannot be installed in a regular chuck, a faceplate is used), center (for securing long workpieces on the machine by pressing them with this center installed in the tailstock quill), and much more. But now preference at the enterprise is gradually given to CNC (computer numerical control) machines; three years ago we bought several HAAS TL-1. This is pure automation, like a computer; the precision of manufacturing a part, of course, increases significantly. Most likely, in six months you will need to retrain at the enterprise (there are special courses) on these new machines, learn to write programs. Training, of course, is free.

Manual lathes

Small-scale and single orders for turning are carried out on manually operated lathes.

These machines are designed for finishing and semi-finishing processing, as well as for cutting threads of various types and are characterized by versatility, high rigidity, sufficient power and a wide range of spindle speeds and tool feeds, which allows processing parts in economical modes using modern hard and super-hard tools materials. The main function of manual lathes is to perform turning, drilling, facing and threading operations.

| Specifications | Shaublin 120N | SV18RA | T-28 |

| Maximum processed length, mm | 300 | 750 | 55 |

| Maximum processed diameter, mm | 120 | 380 | 20 |

| Maximum spindle speed, rpm | 3000 | 2800 | 4300 |

If you haven't fallen asleep yet... you need to think with your head here

Interesting and funny incidents sometimes happened in the workplace. Here is one of them that happened to me about 12 years ago.

The task was given: to process 320 bushings in the first shift (they calculated something incorrectly in the design department, it turned out that one batch of bushings for MAZ 103.060 was defective), i.e. the work needs to be done in a fairly short time. I was still “green” then, although I had the 4th category. The cutters were such that it was possible to increase the feed or plunge speed, i.e. It is impossible to somehow increase productivity, the cutter will immediately break (even though it was made of hard alloy, the cutter had a large clearance angle, such work was carried out very rarely). At least cry.

You need to quickly go to the sharpening machine and change the angles of the cutter. The job is done, I start sharpening. Then the shop manager comes running and shouts that there is no defect, leave everything as it is. In general, I only managed to “spoil” 2 details. Since then, there have been no such oddities, but I still wonder how the Quality Control Department missed this?!

And recently there was a case where the company bought two automatic measuring machines (this is a device that has a head with a ruby tip; this tip (probe) goes around all the surfaces of the part, identifying defects). So, when measuring, they did not take into account that after processing the part must be allowed to cool (hot metal expands, which increases the error), as a result, several batches had to be rejected, then at least they thought of measuring the part in a cold state.

History of the profession

In ancient times, people processed hard objects (stones, metals, animal bones) mainly using the impact method, breaking off particles of material from the surface. Over time, in Ancient Rome (approximately in the 7th century), a technology appeared that required the participation of two people in the process: one rotated the workpiece mounted on an axis, and the second processed it.

To produce a high-quality part, it was necessary to achieve fast and uniform rotation. In France in the 16th century, a water wheel was adapted for this purpose, but a real breakthrough in turning occurred after the invention of the electric drive. This made it possible to process hard metals and use only one worker.

Salary level - how much a turner receives depending on the category

Wages have never been high for turners. Its size depends entirely on the company where you work.

My form of payment is time-based, the salary is calculated by dividing the monthly rate by the number of days, and the resulting number is multiplied by the time you worked.

For remuneration at the enterprise there is a distribution according to tariff categories and tariff coefficients. For example, if you have a second rank , then the coefficient will be 1.16; third – 1.35; fourth – 1.57; fifth – 1.73; and sixth – 1.9.

Moreover, as a turner in the mechanical department, increases are set, which are calculated based on hourly tariff rates. For example, depending on the complexity of the turning work performed, the increase varies from 15% to 25%.

An additional measure of labor incentives is also being established - hourly tariff rates are increased to 50%. In fact, the hourly tariff rate for the mechanical department in which I work is determined by the summation of hourly tariff rates according to the UTS and the amounts of increases (for the complexity of the work, plus an increase of up to 50%). The full salary is 847 Belarusian rubles (about 26,000 Russian rubles) . Once a year, the company provides a two-week stay in a sanatorium (food is at my expense, everything else is at the expense of the company). The canteen is quite cheap; 50% of the order amount is paid by the company.

Full-time or distance learning format in St. Petersburg

The training program at our training center meets state standards. Upon completion of the course, you will receive a standard certificate and access to the workplace.

Since training in turner courses takes place remotely, specialists from any region of Russia can take it. It will take 1 business day to receive the “crust”. The received certificate will contain a mark indicating the date of passing the knowledge test, the signature and seal of a Rostechnadzor specialist. The document can be presented to regulatory authorities.

Pros and cons of working as a turner

Like any other profession, this one has its advantages and disadvantages.

Among the advantages, I will immediately include its demand (I do not specify what kind of turner, but in the realities of today it is undoubtedly an operator of CNC machines), creativity (I am always improving in this specialty, it even seemed that the same work could be done different methods).

I can list a lot of disadvantages.

- You must be far from a “wimp” if you plan to work on a universal lathe (it is not entirely easy to move a 100-kilogram tailstock, but there is a nuance; in general, the machine system has devices on the guides that make it easier to move the headstock; they can be hydrostatic, there is a small layer of lubricant under pressure; also with boundary lubricant; with mixed lubricant, but aerostatic guides with air lubricant have always been more convenient for me; thanks to them, the working body of the machine could be moved with a light touch of a finger).

- Next - safety precautions (this is more likely not a disadvantage, but an element in the work, the disadvantage here is the risk of injury), this is a special discussion, these several pages of safety regulations need to be known inside and out. Have you heard the joke that “I know safety precautions like the back of my hand”? Now, this is not a joke. Even in our department there was a case when a turner was almost wound up on the machine. The safety regulations say in black and white that all sleeves and the robe should be buttoned. The unlucky turner somehow managed to get his sleeve wrapped around the spindle of the lathe (he later admitted that the sleeve was not fastened and was hanging). It was lucky that the foreman was nearby and turned off the machine in time, otherwise it would go to shit. It is not without reason that they say that safety precautions are written in blood.

- It is a fairly well-established myth that a turner, like a school teacher or a shoemaker, must reek of fumes. This, of course, is a blatant lie, just imagine that you are driving a dangerous machine, the working element (spindle) of which makes up to 1600 revolutions per minute. There were cases at the enterprise when they lost limbs (the Internet is full of such photos, far from having the happiest ending). Another disadvantage I would consider is that you constantly need to be on alert, you can’t even leave the machine for a minute, constant vigilance.

- The outgoing chips can reach temperatures of up to 500 degrees, just imagine what it’s like for a turner standing next to you? Not only is the heat from the shavings, but also the clothes are thick, buttoned up with all the buttons.

- What else? You can “catch” dozens of diseases at work, from arthritis and radiculitis to loss of vision (yes, glasses are needed in the first place; hot shavings can get into your eyes). The main thing in the profession of a turner, in my opinion, is compliance with safety regulations and high concentration of attention.

Turning centers

The latest world-class CNC turning centers used by , (MAZAK QT-COMPACT 100MY; MAZAK QSM 100M-S) combine advanced technology, high productivity and quality to meet the needs of absolutely any customer. All high-precision custom metal turning work - from workpiece installation to finishing - is carried out on one machine. This allows you to significantly reduce the duration of the production cycle, reduce the area for equipment installation, maintain high accuracy of turning parts and products, and reduce operating costs.

The metal turning and milling work we carry out to order:

- external turning;

- boring;

- drilling;

- deployment;

- thread cutting;

- milling;

- gear hobbing

| Specifications | MAZAK QT-COMPACT 100MY | MAZAK QSM 100M-S | Hwacheon Cutex-160B MC | |

| Workpiece parameters | Maximum installed diameter, mm | 695 | 580 | 260 |

| Maximum processed diameter, mm | 340 | 280 | 204 | |

| Maximum rod diameter, mm | 51 | 52 | 45 | |

| Maximum processed length, mm | 554 | 430 | 225 | |

| Maximum rotation speed, rpm | 6000 | 6000 | 4500 | |

| Maximum power, kW | 15 | 22 | 11 | |

| Upper turret | Number of tools, units | 12 | 12 | 12 |

| Maximum rotation speed, rpm | 4500 | 4500 | — | |

| Maximum power, kW | 5 | 5,5 | 3 | |

| Movements along the axes | X-axis, mm | 215 | 190 | 170 |

| Y-axis, mm | 100 | — | — | |

| Z axis, mm | 605 | 515 | 335 |

Turning machining centers are equipped with an integrated motor-spindle for high-precision and high-speed processing, roller guides on all axes, which, in combination with the rigid design of the machine, allows one to obtain excellent characteristics of the accuracy and roughness of the workpiece, not only in turning, but also in metal milling.

The use of innovative technologies and high-performance equipment not only improves the quality of the finished product, but also increases productivity, which allows us to offer attractive prices for metal turning work.

How to get a normal discharge and how long it will take

As I wrote above, the profession of a turner has 6 categories. Without work experience, it is quite difficult to get a job as a turner at an enterprise (they can first hire a turner as an apprentice, to do this straight to the personnel department, taking with them a diploma of education), therefore in educational institutions during practice you need not to shirk, if possible, learn to perform work at a higher level discharge. Moreover, you can retrain for another profession, for example, mechanic, milling machine operator, etc.

Theoretically, you can approach the machine and work on it starting from the second level; these are the simplest jobs that do not require special skills. Then, over the course of a year, the turner learns to do work for the third category; after it is assigned, a year passes, during which time the turner acquires the skills to work for the fourth category, then a trial work is performed and an exam is passed. Already after two years from the date of receiving the fourth category, the turner is preparing to receive the fifth. During these two years, the turner must be able to perform 30% of the work to the fifth level. The sixth (highest) turner receives only three years after receiving the fifth grade.

Moreover, I have also observed cases where the grade was lowered, the worker was “under the spell” (no, they don’t demote him for this), but when he begins to make defects in this state (and an irreparable defect), coupons are torn out of the turner’s certificate (or certificate) . When the number of torn coupons reaches three, the rank is automatically lowered, or the unlucky turner is sent to retake the rank.

Issued documents

The documents are valid throughout Russia

Have full legal force and are accepted by all employers in the Russian Federation

According to Article 60 of Federal Law No. 273 “On Education in the Russian Federation”, vocational training is confirmed by a certificate of the profession of a worker or the position of an employee.

Based on the results of training, students receive a certificate of assignment of a profession

, a certificate of the established form and an extract from the protocol. The package of documents is a permit to work: it is valid throughout Russia and is accepted by all employers in the country.

The certificate confirms receipt of qualifications and assignment of a qualification rank, class, category.

All documents are entered into the unified Federal Register of Education.

A certificate of assignment to an employee position is often confused with a certificate

, which is an error in concepts. An official document confirming the acquisition of a specialty is a certificate of the established form, but certificates do not have any legal force and do not allow one to find a job.

If you want to study to become a turner

If you are seriously planning to learn to become a turner, you should know that the work, although not easy, is quite interesting. It’s not the first year I’ve been at the machine, but I enjoy the process itself, constant improvement, and simply watching how the chips come off the metal. Of course, a universal turner is not very popular now, because in the era of the development of computer technology and electronics, working with a CNC machine is most preferable, and not so dirty. But I don’t want to retrain yet (but I already have to), especially since for a long time the profession of a universal turner will be, although not the highest paid, but quite in demand.

You can also easily change your specialization, for example, retrain as a CNC turner (operator); today there are much more offers for such a turner compared to the same general-purpose turner. In general, go for it. And if something doesn’t work out, don’t worry, everything will come with experience; at one time, the book “The Young Turner’s Handbook” helped me a lot, which contains all the necessary tables, formulas, and tips. And you will be really lucky if you have a good partner at the enterprise who is ready to give you some advice. Good luck in your endeavors!

Personal qualities

First of all, it is worth understanding that a turner is a very hardy person, since he has to be on his feet for a long time. Even at high temperatures in the workshop, he must not remove his protective clothing. In addition, not everyone can master the skills of a turner. A professional turner must have the following qualities:

- responsibility;

- patience;

- analytical mind;

- organization;

- technical thinking;

- sustained attention to detail;

- high concentration;

- good imagination.

If a person has such qualities, then it will be very easy for him to master the basics of turning. Also, a true professional in this profession must have a good memory, sharp eyesight and an accurate eye.

Guarantees of training at the educational center "Kupol"

Entering data on received training documents into the register You can always confirm your training with us if required by the employer or inspection authorities, as well as restore documents in case of their loss or damage.

Conclusion of an agreement for the provision of educational services We work only under an agreement that clearly states the obligations of our educational center to applicants.

As a result of training, documents of the established form are issued. Each student receives a diploma or certificate of the established form, which are valid throughout the entire territory of the Russian Federation.

Distance learning without interruption from work We implement the learning process using remote access technologies. At the same time, the specifics of the method of acquiring knowledge are not reflected in the final papers and diploma.

We provide discounts when registering for several programs. There is a favorable discount system for legal entities and individuals. If you need to arrange several packages, please contact our managers, we will provide a special offer

Flexible options for paying for training There are several options for paying for training at UTsPO "Kupol": cash on delivery, payment by bank details or online, through state secure payment systems.

Feedback from our listeners

Kupriyanov Ali

I applied and on the same day I received the 3rd grade axing crust I needed.

Demin Ruslan

Confirmed the turner's discharge in 1 day. I respect this approach. Minimum body movements and maximum results.

Pakhomov Bogdan

Everything is done for people. You fill out an application on the website - you take distance courses - you get credits.

Alekseev Rodion

Received a certificate of profession and a turner's certificate. Minus: there is no delivery of documents by courier to the door.

Kiselev Emil

What a pleasure it is to collaborate with professionals! We got the ID quickly and without unnecessary delays

Popov Nikita

All! I have the documents! Tomorrow I’ll take my 5th grade turner’s license to the personnel officers and see what they tell me.

Mikhailov Nikolay

Thanks to the managers of this center, renewing the turner’s certificate took a minimum of my time, so

Zubkov Ilya

Confirming your professional rank in UCP Kupol is easy. I myself am a 7th grade turner. I have dealt with the company twice already.

Bykov Artem

I renewed my turner license in 1 day. the price is reasonable

Maslov Evgeniy

This is not the first year that we have been sending employees to improve their skills at Kupol. This year it was the turners' turn. We will continue to cooperate with this company.