The job description of a CNC machine operator describes the rights of the employee, the grounds for holding him accountable and other issues necessary in professional activities. An additional argument for using the instructions in business processes is that it is recommended for use by Rostrud, and its availability is checked by specialists from the Pension Fund of the Russian Federation and the Social Insurance Fund.

- Form and sample

- Free download

- Online viewing

- Expert tested

FILES

CNC Machine Operator Job Description Example

CNC machine operators ensure that CNC machines produce excellent products. Image Source: Trainingcenters.org

CNC Machine Operator Job Description Example

A CNC machine operator is a person who creates a pattern for various computer programs that assist in the functioning of a mechanical device in drilling, shaping and cutting materials used for industrial production.

The job description of a CNC machine operator is to evaluate the elements and characteristics of the required items and arrange them in the correct order.

As a programmer, the operator writes or creates unique translation patterns by entering instructions into the computer system with specific command modes to which the device responds accordingly.

Haven programs the machine to operate as directed, he/she manually places all the items needed for production into the machine and watches it work on the computer.

He/she uses his/her programming experience to closely monitor the machine to identify any problems that may arise. This includes paying proper attention to the sound coming from the machine to notice if there is too much vibration in the cutting tools as this may affect the quality production.

He/she is responsible for ensuring that the products come out in good condition by ensuring that the workpiece i.e. metal or plastic used for production is properly lubricated or lubricated to avoid breakage.

Their responsibilities include using their creativity and experience to produce customized products as requested by customers, as well as inspecting equipment on a daily basis to identify problems and correct them immediately.

A good CNC machine operator avoids wasting resources and materials by producing large numbers of individual parts at a time based on the job specification, and doing the same with other parts until the job is completed.

They work with other team members in the course of their job duties and are always open to learning something new from them in order to get the job done.

They are always on their feet, moving, bending and stretching to keep everything in place and ensure successful production.

CNC Machine Operator Job Description Example

The duties, tasks and responsibilities of a CNC machine operator job description are shown in the job description example below:

- Setting up computerized machines to perform machine functions on a workpiece

- Instructions for controlling input into the machine

- Evaluate software drawings to indicate machine operations and dimensions

- Installation of machines and fixtures using hand tools

- Replace old machines when worn out with new ones

- Use network links to enable the transfer of commands from computer servers to computer numerical control modules.

- Perform accurate workpiece measurements and gauges for production

- Carrying out maintenance activities to ensure the machines are in good condition.

- Drive three or more cars with little or no assistance

- Replace or replace switches and cylinders

- Make sure all machines are running at a moderate and correct speed.

The job description example shown above provides good information for creating a job history section of a resume for a CNC machine operator job search.

Requirements - Skills, knowledge and abilities for the position of CNC machine operator

Below are the vital requirements that a CNC machine operator must meet in order to be effective on the job and to be hired by most employers:

- Good knowledge of setup and operation

- Good knowledge of drawings and micrometers

- Good knowledge of edits and G-codes

- Have basic knowledge of materials production.

- Highly skilled in VTL, VTC and overhead crane

- Good communication skills.

You may need to take a job test to get a job to increase your chances of scoring well today!

Performance assessment tests: how to win the competition

As part of the hiring process, most candidates who pass the initial CV/CV screening phase are required to take an assessment test for the job or position for which they are applying.

The purpose of this stage is to determine whether the candidate has the appropriate set of skills and attributes to succeed in the job.

Find out what tests you will need to pass to get the position you are applying for; Get plenty of field-tested practice materials for your preparation now: a sure-fire way to score high on your job tests.

,

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. If situations arise that can lead to accidents and incidents (for example, in the event of a breakdown of insulation in the circuit, leaking hoses, faulty water cooling or interruption of water supply), it is necessary to stop work, turn off the power supply, remove people from the dangerous area and report the situation. the work manager. 4.2. If an accident occurs, immediately take measures to provide first aid to the victims and call an ambulance. 4.3. If a fire is detected, immediately notify the fire department by calling 101, notify management and, before firefighters arrive, begin to extinguish the fire using available means, depending on the material that caught fire. 4.4. In the event of an accident, provide the victim with first aid and report the incident to management. Preserve the situation as much as possible if doing so will not result in an accident or injury to others. If necessary, call an ambulance by calling 103 or help transport the victim to a medical facility.

Difference between CNC operator and CNC machinist

If you've ever looked for a job in the manufacturing industry, you've probably come across two different job titles: CNC operator and CNC machinist. If you've thought to yourself, "What's the difference between the two?" I know that you are not alone.

CNC operators and machinists have similarities and differences when it comes to their job responsibilities. While both positions address CNC machines and equipment, there are key differences to note.

Keep reading to learn about CNC operators, machinists, and how these roles differ.

What are CNC machines used for?

Before we get into the differences between operators and machinists, let's talk about what CNC machines are used for.

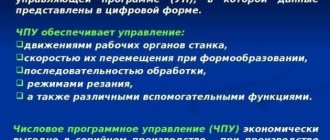

Computer Numerical Control (CNC) machines use a process in which pre-programmed computer software dictates the movement of factory tools and machinery. This process is used to run various types of machines, including grinders, lathes, mills and routers. This equipment cuts, drills, grinds and shapes a variety of materials, from metal to plastic.

CNC machines are used to create complex parts for a wide variety of industries. These include:

- Aerospace

- Transport

- Defense

- Firearms

- Commercial

- Electronics

- Medical

- Optic

- Oil and gas

- Marine industry

Understanding roles in the CNC environment

As in many industries, there are many different roles that can be performed in a CNC environment. These roles are dependent on each other and are critical to the industry. In general, there are three main types of positions:

- Operator: This position is often filled by beginners or those just starting out in the industry. In short, the operator's job is to load the workpiece and run the parts. These are the so-called “buttons”.

- Setup Operator: This person is responsible for loading the program, selecting and configuring tools, testing the program, and making sure everything works correctly. They also step in and fix things when they break or go wrong.

- Programmer: This person is the one who takes the project and figures out how to make the part. This includes choosing tools, determining speeds and fees, and writing the program. Check out this article to learn more about the role.

At this point, you may be wondering, “What about the machinists?” It is important to know that in the CNC environment there are no machinists in the traditional sense of the word.

If you come across a job posting for a CNC machinist, it is most likely for setup operators. This is because customization operators are the most self-sufficient and by nature must understand both programming and operation in addition to customization.

How do these roles work together?

So how do operators, setup operators (or machinists), and programmers work? Typically, the programmer will hand their program to the machine operator, who loads everything into the machine and sets it up. They then hand the keys to the operator, whose job is to make the parts.

In smaller companies one person may be responsible for all three things, but in larger companies these are separate positions with little overlap. Programmers can rarely, if ever, be found on a machine, expect them to be testing their program.

In years past, machinists had complete control over all of their part and process variables (speeds, feeds, tooling, and approach method). However, now all of this is controlled by the programmer and the machine. The person who actually interacts with the operator, the operator, can download someone else's program, load and configure tools, and run the program.

Now that we have defined the various positions in the CNC environment, let's take a closer look at the role of CNC operators and machinists.

What is a CNC operator?

CNC operators are responsible for procuring materials and running parts. They ensure that specific instructions are followed to create a final product that meets the required specifications. This is typically an entry-level position and can serve as a starting point for those who want to work in the industry.

To be successful in this role, operators must possess the following qualities:

- Keen eye for detail

- Mechanical ability

- Ability to perform mathematical calculations

- Basic understanding of computer programming and CAD/CAM software

- Ability to comply with safety regulations

- Strong problem solving and multitasking skills

What does a CNC operator do?

The primary role of a CNC operator is to set up and operate CNC machines and equipment. On any given day, the operator may unload raw materials, prepare a test run to ensure the machine is operating properly, and inspect and measure finished products to ensure they meet specifications .

Depending on the type of parts they specialize in, an operator's daily responsibilities may vary. However, the following operator job description can be applied to a wide range of industries.

CNC operator

Description of work

- Loading and unloading of raw materials and equipment

- Setting up and calibrating accessories and equipment

- Maintain detailed records of equipment and procedures

- Perform necessary maintenance and cleaning of equipment

- Monitor machines while they are running and make adjustments if necessary

- Inspect the finished product to ensure it meets required specifications

- Follow company safety regulations

What is the difference between CNC operators and CNC machines?

The role of a CNC machinist is more advanced than that of an operator. Machinists can accurately print machine parts using a variety of machines and methods. They rely on their skills and experience, which they often gain through an accredited vocational school or years of on-the-job experience.

Some of the additional responsibilities of a CNC machinist include:

- Machine programming

- Quality control

- Troubleshooting and fixing mechanical problems

- Monitoring and control of CNC operators

Many machinists start out as operators and work their way into this role. The CNC industry is very complex, and it is important for machinists to have an understanding of the basic principles of machine operation before taking on more responsibility.

Successful machinists have the following skills:

- Ability to read blueprints and parts drawings

- Programming and setting up CNC machines

- Ability to set up and operate drilling, milling and grinding machines

- Knowledge of the properties of metal and other materials

- Math skills

- Knowledge of reading calipers and pressure gauges

- Experience working on CNC machines

- Leadership and effective management skills

How to become a CNC machinist?

Since machinists often start out as operators, you may ask, “How long does it take to progress to the machinist role?” This depends on several factors, including job performance, skill level and education.

A great way to get on the path to becoming a CNC machinist is to take a training program like UTI's 36-week program in CNC machining technology at NASCAR Technical Institute.

Created in collaboration with Roush Yates, a leading brand in the industry, this program will teach you everything from reading blueprints to programming, setting up and operating CNC lathes and mills.

Students in this program are trained using industry tools and technologies from brands such as Mastercam, Mitsubishi Materials and Mitee-Bite. They receive the hands-on training and high-tech skills needed to prepare for a career as a CNC machinist in today's world.

Completing such a formal training program can gain the attention of employers and give you a competitive advantage when applying for a job. It can also improve your chances of advancing faster in the industry, such as from operator to machinist. Choosing to invest in your education now can have incredible benefits for your career in the long run.

Preparing for a Career in the CNC Industry

The UTI CNC Machining Technology program runs every six weeks, giving you the opportunity to get started faster. Plus, with UTI scholarships and grants and FAFSA resources, getting an education can be more affordable than you think.

To learn more, visit our CNC Program page and request information to contact one of our hiring representatives today.

, CNC Machinist Resume Samples for Machinists [Tips]

CNC machinist resume sample

Daniel McCabe, driver

linkedin.com/in/danielqmccabe

-4339

Professional summary

Hardworking CNC Machinist with over 6 years of experience, skilled in CNC and Kaizen. Committed to reducing lead times and improving quality at Standard Castek, Aero Turner Materials contributed to installation cost reductions that reduced lead times by 23%. Operated a CNC machine for 5 years with an average efficiency of 95%. Performed daily equipment maintenance, which reduced equipment downtime by 15% below the department average.

experience

Driver

Aero Turner materials

April 2014 – May 2019

- Worked on a customization reduction team, contributing 24 ideas that helped reduce production time by 23%.

- Launched a CNC milling machine in a high-volume workshop with a production efficiency of 95%.

- Serviced equipment, checking all sensors, lubricant levels, air filters, belts and chains. Regular maintenance is performed and downtime is maintained 15% below average.

- Worked 5 hours a month on a CNC laser cutting machine.

Machine operator

Wright Davis Tech

January 2013 – February 2014

- Worked on a CNC lathe in a busy shop.

- led the Total Productive Maintenance project, which reduced machine downtime from 65% to 20% in 9 months.

- A pokayoke joystick was created in which defects due to incorrect placement of the tool were up to 0%.

Education

2011–2013 Bethel University

Associate Degree in Business

- Excellence in CNC coursework.

- Carried out a machining project to produce laser cutouts for 3 companies.

Skills

- Hard skills: CNC work, Kaizen, SMED, reduction setup, Kanban

- Soft skills: collaboration, communication, problem solving, time management

Events

Scoutmaster, BSA Troop 432, Tennessee

Little League coach 2 times a week for children 10–12 years old

Is a resume for machinist workers your best bet? See these guides:

Want to save time and prepare your resume in 5 minutes? Try our resume builder. It's fast and easy to use. Plus, you'll get ready-made content to add with just one click. See 20+ resume templates and create your own resume here .

CNC Machinist Resume Sample - See more templates and create your own resume here .

One of our users, Nikos, said the following:

[I used] a nice template I found on Zety. My resume is now one page, not three. With the same things.

Create your resume now

Here's how to write a CNC Machinist resume that gets jobs:

Choose the Best CNC Machinist Resume Format

9014 CNC machines operate on CNC lathes and machines in production areas. CNC operators must be proficient in G-code programming, tooling, setup, and teardown of CNC machines. A CNC Machinist resume should show that you are tech savvy, lean, and have “street smarts.”

You are not a sloppy CNC machinist.

Don't write a sloppy CNC Machinist resume.

One look and they should know you're on it.

Use the following formatting tips:

Pro Tip: Restart your layouts. Do good to the eyes. After the title, add your resume, then your experience, education, skills, and then extras such as hobbies or interests.

Write a CNC Machinist Resume or Resume Resume.

.

Most employers are skimmers. They won't read your great resume for typists.

Stop them with a professional profile that leaves them wanting more.

Do you have a lot of experience as a driver? Use a resume summary.

Equip it with the skills and achievements of an expert-level machinist.

For a CNC machinist resume with no experience, talk about job skills that are transferable from other jobs in your resume objective.

Pro Tip: Have your machinist resume working on the CNC machines with the last problem you solved. Writing will be much easier if you have already made your complete resume first.

Customize your resume to match CNC Machinist Job Description

Some resumes have an attractive appearance.

This is because they are better suited for the job.

Don't make your square tool in a round fixture.

Setting up experience on your resume.

Do this:

- First, list your most recent position as a driver.

- Indicate your position, company name and dates of employment.

- Sure, include responsibilities, but add professional achievements.

- These achievements must be consistent with tight tolerance work. If the job wants SMED and you used it to cut your lead time in half, say so.

- Add metrics like 95% to show you're not gaming.

- Use good summary words to keep things clicking.

Pro Tip: Are you switching to handling from another profession, such as a material handler? You want to write a career change resume for this.

4.Customize your CNC Machinist Resume Education Section

Most people are wrong.

Education does not prove that you are smart.

In a CNC machinist resume, it must show passion and skill.

Here's how to write a resume:

Include school name, degree, and years. But -

Show a few classes in which you excel: projects, teams or groups.

Do not show GPA unless it is very high or recent.

Pro Tip: With resumes for machinists, school achievements should be skill-related. The leadership position of a group shows leadership potential.

Show CNC machinist skills on your resume

Use this list of CNC Machinist resume skills.

He shares skills and abilities:

CNC skills

Skills:

- CNC operation

- SMED

- Kaizen

- Standard work Reduced setup

- Equipment service

- G code

- Troubleshooting

- Kanban

- Quality control

Soft Skills:

Attention -

Use this list sparingly.

Go on a hunt to find what's most important. (They are in the list of vacancies.)

Then use achievements to show off your machinist skills.

Pro Tip: Have a good mix of soft skills and hard skills in your resume for machinists. Too much of this or that makes Jack a boring boy.

When making a resume in our resume builder, drag and drop bullets, skills, and auto-fill in the boring stuff. Spell check? Examination . Start building your resume here .

When you're finished, Zeti's Resume Builder will evaluate your resume and tell you exactly how to improve it.

Add More Sections to Your CNC Machinist Resume

What kind of employee are you?

Employers need to know.

You can show excitement and energy with a few “other” sections on your CNC mechanic resume.

Choose from:

Of course, if you have a Six Sigma or CNC programming certification, you can get one. Place it in a separate “Certificates and Licenses” section.

Pro Tip: Sections added must demonstrate machinist skills or software skills. If you coach a children's sports team, it shows interpersonal skills.

Submit a cover letter with your CNC machinist resume

Should I write a cover letter for my CNC Machinist resume?

In an instant.

But make your machinist cover letter different:

How long should an email cover letter be? Just like a paper letter: three paragraphs.

Pro Tip: Write a secondary email address for your job application. It should be a couple of lines long and remain positive. Send it a few days later and again after a week or so.

That's all!

Here's how to write a resume for CNC machinist positions.

Don't think your CNC Machinist resume will get results? Are there major problems with your CNC machining resume? Give us a shout in the comments. We'd like to talk!

.

OCCUPATIONAL SAFETY REQUIREMENTS DURING WORK

3.1. Exposed live parts of installations must be either electrically insulated from live parts, or grounded, or covered with electrical insulating material. 3.2. Devices for automatic and semi-automatic processing must have a lock that prevents bypassing of normally open contacts in the power circuit of the starter or contactor coil in the absence of a welding arc. 3.3. Automatic and semi-automatic processing must be controlled remotely. The supply of no-load voltage to the installation until the pilot arc appears must be done by the “Start” button of the contactor without self-locking. The “Start” button should be blocked automatically after the pilot arc is excited. 3.4. The operation of the installation occurs in the following sequence: - when an open circuit voltage is applied to the power source between the electrode and the plasma torch nozzle, periodically repeating current pulses are generated using an arc exciter, which create a visible auxiliary arc torch; — the main cutting arc is excited automatically when the auxiliary arc torch comes into contact with the edge or surface of the product; — after the cutting arc current reaches the set value, the cutting process proceeds stably; — the end of the cutting process occurs when the power circuit of the power source is turned off or automatically when the installation is removed from the product and the arc breaks; — when the arc breaks or the installation is turned off, the voltage from the output terminals of the power source is automatically removed. 3.5. Do not look at the arc formed during cutting with unprotected eyes. It is necessary to use a protective mask with a light filter. 3.6. It is prohibited to leave the power supply cabinet and control panel open while working on the unit. 3.7. It is prohibited to leave the unit unattended with compressed air, water and voltage connected. 3.8. During operation, do not hold the hoses under your arms, on your shoulders, or clamp them with your feet. Do not allow hoses to come into contact with live wires. 3.9. If the torch overheats, work should be stopped until it cools completely. 3.10. Do not expose hoses to sparks, fire or heavy objects, or expose them to high temperatures. 3.11. It is prohibited to attach forks, tees, etc. to the hoses. to power multiple cutters. 3.12. It is necessary to ensure stable arc ignition. Unstable arc ignition indicates complete burnout of the cathode zirconium insert in the copper water-cooled electrode. In case of untimely termination of work on the spent electrode, it may burn through. This can cause burning of the water pipe, electrode nut, nozzle and lead to emergency destruction of the plasma torch. 3.13. If, while observing the operating mode of the device and the plasma torch, the replaceable electrode and nozzle tip are destroyed, it is necessary to check the pressure and flow of cooling water and air, the tightness of the plasma torch to water and air, and ensure that the replacement parts are tightly pressed. 3.14. The operator of plasma installations is prohibited from repairing equipment, cutters, etc. In case of malfunction, immediately stop work and inform the technician. 3.15. It is prohibited to cut workpieces while they are in weight, as Dropping the workpiece can cause injury and damage the cutter. 3.16. Do not allow unauthorized persons into the workplace. 3.17. To ensure uninterrupted and long-term operation of the power source, it is necessary to carry out daily and periodic inspections to eliminate minor faults. 3.18. During daily maintenance, it is necessary to check the serviceability of the supply wires; serviceability of contact clamps and connectors on the panel with clamps; grounding the power supply; grounding the product being cut or the cutting table. 3.19. During periodic maintenance (once a month), it is necessary to check the protective barriers (temporary or permanent); safe location of live parts; insulation of live parts (working, additional, reinforced, double); workplace isolation; low voltage; protective shutdown; grounding of installation housings, pipes in which wires are laid; serviceability of door locks; grounding of the rack and the sheet being cut; warning alarms, locks, safety signs. 3.20. The serviceability of protective equipment should be checked before each use. Protective equipment whose next test period has expired is prohibited from being used. 3.21. Before starting work, it is necessary to place insulating mats or supports on the workplace. 3.22. Immediately report all cases of broken electrical wires, malfunctions of grounding devices and other damage to electrical equipment to the foreman. 3.23. To prevent fires, the following requirements must be observed: - do not block access and passages to fire-fighting equipment, fire extinguishers, hydrants; — store flammable and flammable substances in specially designated areas in compliance with fire safety measures; - smoke only in specially designated areas equipped with fire-fighting equipment and trash cans; — store used cleaning material in a metal box with a tight-fitting lid; - do not approach the hoses with open fire; — do not clean or wash work clothes with gasoline or other flammable liquids. 3.24. The work area must be provided with fire safety posters and inscriptions.

see also

- The basics of weaving from rubber bands on a machine

- Drilling machine 2n125 technical characteristics

- Curved knives for woodworking machines

- Programs for working with CNC machines

- Machine for the production of sip panels

- Woodworking machines for the home workshop

Description of milling machine

Household milling machine- Maintenance of CNC machines

- 2054M thread cutting machine

- What a CNC machine operator should know