What is an adapter for a walk-behind tractor?

An adapter for a walk-behind tractor is a module that allows you to ride a walk-behind tractor. Thanks to it, a person sits and controls the operating equipment, which greatly simplifies the process of cultivating arable land. Using an adapter, the speed of operation increases several times. The adapter simplifies the use of equipment, since you can change the nozzle to perform specific jobs.

Features of the adapter for walk-behind tractor

An adapter is a special device for riding a walk-behind tractor. Using it, you can simultaneously drive a walk-behind tractor and cultivate the soil.

An adapter for a walk-behind tractor will help turn it into a mini-tractor

Working with a walk-behind tractor will be greatly simplified if you use an adapter. You will be able to change attachments, depending on what work you need to do - hilling, planting, weeding, transportation. With the help of this device, all processes will be doubled.

This unit allows you to sit comfortably on the seat with which it is equipped. Now you can do household chores, but with more comfort. Steering adapters are available on the market. However, you can make them yourself.

What types of adapters for walk-behind tractors are there?

Externally, the adapter design is a small frame with two wheels, a platform for feet, a drawbar and a seat for the operator. By equipping a walk-behind tractor with such a “new thing”, you will actually turn it into a mini-tractor - working will become much more convenient, faster and easier, and the ability to adjust the seat will make the work process more comfortable.

There are several types of adapters for walk-behind tractors. In order to buy or make the most suitable option for you, you should familiarize yourself with all types of this equipment.

Based on the type of clutch, adapters are divided into adapters with steering and movable joints. Depending on the location - on the front adapters and rear ones.

Adapters can also be classified into a separate classification based on the purpose of use: with an extended drawbar for powerful large walk-behind tractors, with a shortened drawbar for small, lightweight units.

Adapter with steering

This type of adapter will turn your walk-behind tractor into a fully-fledged, comfortable vehicle. The adapter is in close contact with the walk-behind tractor itself and is securely connected to it. Wheels can be located both at the back and at the front of the structure.

Description

The adapter for the Neva walk-behind tractor is an additional module that allows you to use the device for riding by equipping a special place for the operator and connecting a second wheel pair to the unit. The result is a four-wheeled walk-behind tractor with a steering wheel that can be used as a mini tractor. You can make such attachments with your own hands or purchase ready-made options designed for specific models. Additionally, it becomes possible to use special attachments for hilling potatoes, a plow and other devices. Such an adapter reduces the time and labor required to perform certain agricultural work.

Front adapter

Such additional equipment options allow you to use the walk-behind tractor as a mini tractor by installing a steering mechanism, a second wheel pair, and a driver’s seat in front of the walk-behind tractor. In such a situation, the factory engine power of the unit itself is maintained. Fastening occurs due to the coupling located on the back of the adapter. At the same time, the structure can be completely disassembled, which significantly simplifies the process of transporting such agricultural machinery. On average, the parameters of the front adapter are as follows:

- Height/width/height is 1.9/0.81/1.4m.

- Ground clearance – 0.75 m.

- The distance between the wheels on one axle is 0.75 m.

- The total weight of the structure is 65 kg.

Application area

Using an adapter allows you to turn a regular walk-behind tractor into a universal and at the same time multifunctional device. You can use such a unit while sitting, which greatly facilitates the operator’s work. In addition, the accuracy of the work and the stability of the walk-behind tractor increases. It is very convenient to have a steering mechanism located in front. Complete with various attachments, it is possible to use the unit to perform the following types of work:

- Removing snow or leaves.

- Harrowing (leveling) the soil.

- Transportation of goods.

- Hilling up the earth.

Types of adapters

Depending on the attachment to the device, walk-behind tractors can be:

- rear - the hitch is located in the front part, and therefore the adapter itself is in the rear part;

- in the front - the hitch - in the rear, respectively, it is located in front of the unit, but with a steering wheel.

By area of use:

- shortened – small in size. Used with units designed to perform light work;

- elongated – large and heavy, used with heavy-duty walk-behind tractors.

Depending on the selected walk-behind tractor, you can choose an adapter that suits it

Depending on the body:

- bodywork – there is a body available for transporting cargo of different sizes;

- bodyless - used exclusively for coupling with a walk-behind tractor.

In addition to the above classification, they can also be divided into simple and universal. The latter are used, in addition to their direct purpose, for transporting goods.

Preparatory stage of adapter manufacturing

The adapter has a simple design, but its manufacturing procedure cannot be called simple

Initially, you need to take into account the drawings and dimensions that will help create a device without defects

You need to acquire the following materials and tools:

- Electric drill;

- Welding;

- Electric hacksaw;

- File;

- Square;

- Sheet of steel with a thickness of 5 millimeters;

- Several square pipes with a diameter of one inch;

- A set of fastenings.

Key structural elements are manufactured as follows:

- Hitch. Installed on the frame and secured with bolts. The coupling is two welded pieces of square pipes and a piece of water pipe. The latter is inserted into the rod with a welded tee;

- Wheel fixation unit. Two pieces of pipe 10 centimeters long are welded at right angles. The horizontal section is inserted into the mounting pipe and securely fixed with a bolt. An axle and bearings with wheels are attached to a vertical blank.

When all the tools are prepared and the main parts are made, you can assemble the adapter.

Composition of the adapter for the walk-behind tractor

Visually, the device is similar to a cart attached to a walk-behind tractor. Some people call such a device a “tractor car”. The mechanism includes:

- frame;

- sitting;

- wheels thanks to which he moves around the garden. The wheels can be rubber (with tread, allowing you to ride on compacted roads) or iron (used for working with large volumes of arable land). In most cases, the wheels are sold as a set, but if you want to change them, remember that there are options to choose from;

- cast iron or steel device for fastening with a working unit. This element is the most important component; it allows the vehicle to be stable.

Purpose of the adapter

The adapter for a walk-behind tractor in its classic form is a trailer with a seat on two wheels, attached to the walk-behind tractor, and to which attachments are mounted. It is the adapter that allows you to install additional equipment as easily as possible. The adapter turns the walk-behind tractor into a mini tractor and thereby makes it not only universal, but also as comfortable as possible.

The adapter allows you to sit while working, thereby making work easier. In addition, the adapter gives the walk-behind tractor greater stability, which also simplifies and facilitates work. It is also convenient that the immediately adjusted attachments will not go too deep or, on the contrary, rise too high. The attachments on the adapter are adjusted using a manual device. You can safely use the adapter even with light walk-behind tractors such as Neva and Cascade.

Maximum comfort can be achieved by using a steering adapter or a front adapter for a walk-behind tractor. In this case, the steering wheel allows you not to use the handles of a walk-behind tractor for control, which, of course, is much more convenient. Thanks to this device, you can get an ideal mini tractor - multifunctional, easy to operate and with an operating speed of about five kilometers per hour.

The dimensions of such an adapter for a walk-behind tractor are usually about two meters long, eighty centimeters wide and one and a half meters high. The adapter with the steering wheel is not small in size, since it is practically the front part of the mini tractor. This adapter is also suitable for the Neva walk-behind tractor - the lightest on the market today.

Considering all of the above, the adapter can be called necessary for a walk-behind tractor.

Steering devices

Such devices make it possible to rebuild the walk-behind tractor into a full-fledged mini-tractor; the only difference, as already mentioned, is the preservation of the power of the engine used in the unit. It is attached to the walk-behind tractor using a hitch, which is placed in front of the adapter. This block is perfect for motor engines such as Sadko, Don, Plowman, Forza, Huter, Champion, Profi.

In particular, such an adapter includes: steering; pair of wheels; clutch; brake and gas pedal; driver's seat; frame structure.

Behind such an adapter there is a special lifting mechanism, to which it is possible to connect additional trailed and mounted equipment.

As for the steering adapter specifically for the Neva walk-behind tractor, the cost of which, as a rule, is approximately 45 thousand rubles, it has the following technical characteristics:

- wheel track - 60 cm;

- total weight - 105 kg;

- ground clearance - 35 cm;

- speed indicators are about 15 km/h.

Design and principle of operation

Essentially, the adapter is presented in the form of a trolley that is attached to the walk-behind tractor. After which the structure turns into a mini-tractor. The main details of such a unit:

- a frame to which other constituent elements are attached;

- driver's seat with lift lever;

- 2 wheels;

- clutch device;

- wheel axle.

In this video we will analyze the front adapter:

Frame

It is one of the most important elements of the device, since other elements are connected to it. Therefore, it must be made of high-quality and durable materials.

Driver's seat

One of the main advantages of the adapter is a comfortable seat for the operator.

Wheels

There are 2 types of wheels available - metal and rubber. The former are used for heavy types of work in the field. The latter are designed for driving on dirt roads.

Clutch device

The hitch is responsible for connecting the attachments and the mechanical unit itself. This fastening is defined as one of the most important, therefore it is made of high-strength metals - steel or cast iron.

The length of such a device is about 2 meters, width – 80 centimeters.

Depending on the clutch, the following design options can be considered:

- with movable clutch. This device is the lightest. The clutch here is located in the front, but control in this case is more difficult, since it is necessary to deploy the entire power unit;

- with steering. The clutch here is rigid, and control is achieved through a mechanical steering unit. This control is easier to use, but more difficult to produce.

There are different adapters for walk-behind tractors of different performance. For mechanisms with low power - with a short mount, for powerful ones - with a long one.

Arrangement of a multifunctional model

To manufacture a multifunctional device, you need to prepare:

- Steel pipes and angles;

- Sheet steel;

- Two wheels;

- Comfortable seating;

- Welding machine and set of tools.

This adapter is a multifunctional model. It can be used for basic agricultural work and transporting goods over uneven terrain over short distances. The structure can be equipped with agricultural implements such as a plow, harrow, hiller, and potato digger. During the winter months, you can attach a snow scraper to the adapter for clearing snow.

The main elements of the equipment are: frame and coupling devices, as well as wheelset and seats

The process of producing an adapter at home takes place in several stages.

And this is an idea! How to upgrade a walk-behind tractor into a snow blower: https://diz-cafe.com/tech/kak-peredelat-motoblok-v-snegouborshhik.html

Stage #1 – drawing up a kinematic diagram

To ensure the balance of the structure and prevent additional overloads at the design stage, it is necessary to draw up a kinematic diagram. You can make it yourself or use a ready-made version.

This circuit is designed for the manufacture of an adapter designed to work on the Neva walk-behind tractor.

Stage #2 - production of main parts

When making and assembling a frame, it is important to provide for the arrangement of a fork with a bushing. It is necessary to ensure free rotation of the trailer.

The frame of the structure is made of metal pipes and angles

The body of the structure is made of steel sheet. The height of its sides is made no less than 30 cm.

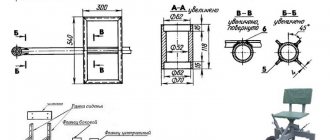

When making stands for the adapter wheels, you can use the diagram below.

The simplest option for manufacturing a coupling assembly is a 15 cm long pin, which is stuck into the hole in the drawbar of a U-shaped walk-behind tractor. The disadvantage of this option is rapid wear: under the influence of a freely rotating trailer, the holes for the hitch quickly break. To reduce wear, it is advisable to lengthen the U-shaped chain.

Types of adapters for walk-behind tractors

Externally, the adapter looks like a two-wheeled trailer with a driver's seat. When installing such a trailer, almost all work performed is automated. The walk-behind tractor itself becomes almost a mini-tractor. In addition, several models have a special lever that allows you to raise and lower the seat, making work even more comfortable.

Adapters for walk-behind tractors can be of several types. To make the unit yourself, you need to decide which type will be more convenient and comfortable for the owner. Depending on the type of clutch, they come with steering and a movable joint. Depending on how the main power plant is located, there are two types: front and rear adapters.

How to make an adapter for a walk-behind tractor with your own hands?

A homemade adapter for a walk-behind tractor will not require any special financial or material costs or specific knowledge from you.

It will be enough to think through the drawings and dimensions, acquire some materials and the appropriate set of tools. The required minimum of accessories for self-assembly of an adapter for a walk-behind tractor is as follows:

- metal corners;

- square metal profile;

- 2 wheels of suitable size;

- welding;

- dense sheets of metal (for support under the feet);

- small hand tools (screwdriver, saw, tape measure, etc.).

We have already given a general idea of what the adapter should look like at the beginning of the article. Now let's take a closer look at the other main elements of its design.

- Frame. The main component of future equipment. The design of some adapters allows for integration with a walk-behind tractor into one unit, but such an adapter requires reconstruction of the walk-behind tractor itself (a new stand for the engine will be needed).

- Suspension.

- Hitch. Provides stability and reliability of the entire structure. The type of coupling device should be taken into account depending on the type of adapter. If the adapter is with the steering wheel, the hitch must be rigid. With a movable joint, the hitch must be rotatable, on a horizontal hinge.

- Sitting. The finished product is created or selected based on the designer’s preferences.

- Control system. Suitable for rigid coupling. You can also cook it yourself or buy it.

The drawings below show in detail the dimensions of the adapter structure, as well as its main connecting units.

Trailed trolleys for Oka walk-behind tractor

The trailed trolley is a drawbar on which are attached:

- pair of wheels;

- trailer (body);

- seat;

- coupling mechanism.

A trailer is used to transport various cargoes (bulk, piece goods, etc.). Trailers can be either manually unloaded or equipped with a dump truck function. Load capacity can vary from 200 to 1500 kg. For the Oka walk-behind tractor, the most acceptable option is trailed trolleys with a load capacity of up to 500 kg.

Let's take a closer look at some models of factory-made trailers:

- PMG 300-1.

- TM-360.

- TM-500.

Factory trailer PMG 300-1

This is a single-axle device with a lifting capacity of up to 350 kg. The manufacturer of this trailed equipment is the Kaluga plant “KaDvi”, which also produces Oka walk-behind tractors.

Factory trailer PMG 300-1

Characteristics of the PMG-300-1 trailer:

| Body size: | 1200 mm/920 mm/1050 mm. |

| Weight: | 95 kg. |

| Dimensions: | 2800 mm/1300 mm/1050 mm. |

| Transport gauge: | 1178 mm. |

| Load capacity: | 250-300 kg. |

Rating of the best models for 2022

If you are not sure that you understand how to make an adapter yourself, then it is better to turn to ready-made options. Today the market offers the widest range of products from the best manufacturers. Asking which adapter from which company is better is pointless, since each manufacturer offers a product designed for specific models (although they may also offer universal devices).

There are a large number of varieties of such devices: different load capacity, different power, with a body, without a body, long, short, etc. Different models have different functionality and direction of operation, as well as different diameters of the joint mechanism (unless it is a universal coupling mechanism). The most popular ones are usually suitable for both land cultivation and transportation. They have a body and are more expensive, while the bodyless versions are only suitable for cultivation and are not as expensive.

This review presents only the best and highest quality (according to buyers and popularity) models available in 2021, as well as our recommendations on how to choose a decent unit at the right price.

APM 350 PRO

Another high-quality Russian product produced at the machine-building plant in Gagarin (Smolensk region). The purpose of the device is no different from the two previous models. It is equipped with a mechanism for adjusting the length and height when installing the hitch, which allows it to be equally freely aggregated with any type of motor vehicle - from the lightest to the heaviest.

Thanks to its versatility, the APM 350-PRO is considered a class higher than the devices already listed, although they are in no way inferior to it in terms of functionality. However, this does not affect the cost in any way.

Another important nuance: since the company producing this series is also engaged in the production of Mobil K walk-behind tractors, an attachment was released from the factory especially for them, which greatly simplifies the work with the rotary mower. Most of them have a classic design, completely unsuitable for connecting rotary mowers, while this model, in combination with Mobile K series walk-behind tractors, has a special rod that allows you to lift the mower above the area of cut grass when turning, so you don’t need to remove the mower. Very convenient and practical.

Brake belt

| Length | 160 cm |

| Width | 70 cm |

| Weight | 45 kg |

| Price | RUB 17,500/piece |

APM 350 PROAdvantages:

- has a mechanism for adjusting the length and height of the clutch;

- universal;

- The kit includes an attachment for working with the mower on the MB Mobile K.

Flaws:

- not noticed.

APM 350 with body

Another brainchild of the Gagarin Machine-Building Plant is the APM-350 riding adapter with a body. Many owners of garden equipment do not consider the presence of a built-in trailer vital, because you can always buy it in addition. The average cost of a trailer varies, depending on the total weight of the goods being transported and the width of the trailer itself (usually from 260 to 500 kg). The problem is that any owner quickly gets tired of walking behind the MB, after which he will want to buy a trailer. And this is one of the most common mistakes when choosing adapters.

Since in this article we not only describe existing types, but also recommend which one is better to buy, here is our advice for those who need a walk-behind tractor with a trailer: buy options with a body right away! Although its cost will be slightly higher compared to an ordinary trailer, it will be much more profitable than buying both a trailer and an adapter separately.

APM-350 is an excellent representative of this “combined” type. Its carrying capacity is 350 kilograms. The body dimensions are 800 x 1000 mm. The design includes the following components: frame, floating attachment, operator's seat, band brakes and body.

The manufacturer guarantees compatibility with MB of the following series: AGAT, OKA, NEVA, AVANTGARD and Tselina. Both passive and active equipment can be installed. It can be easily aggregated with walk-behind tractors equipped with a power take-off shaft of the UGRA and MTZ types. However, such devices can only be used with a passive hitch (that is, one that does not have moving units and works only when the walk-behind tractor moves directly across the field: plow, hiller, ripper, potato digger, etc.).

Length160 cm

| Width | 700 cm |

| Brakes | tape |

| Weight | 92 kg |

| Body type | tipper, non-galvanized |

| Price | RUB 23,120/piece |

APM 350 with bodyAdvantages:

- presence of a body;

- installation of active equipment.

Flaws:

- not found

Tselina PM-05

First in the top is Tselina PM-05 - a classic and inexpensive option for those who need a budget “workhorse” with good driving characteristics. It has a fairly simple design: frame, brakes, seat and lift. The operator's seat is adjustable. “Tselina” is equipped with wheels 4.00 x 10 or 19 x 7.00*8, and wheel weights are included.

In reviews of the product, there is mention of a rather weak braking mechanism and a not very high-quality floating hitch system. Active attachments (that is, all those tools that are driven by a rotating mechanism: rotary mower, sweeper, snow blower, etc.) are installed here only on the drawbar, from the front of the walk-behind tractor. Models with this design include units of the following series: MB, Neva, Agat, Tselina, Avangard, Mobile K.

Length165 cm

| Width | 62 cm |

| Brakes | Tape |

| Weight | 50 kg |

| Price | RUB 12,450/piece |

| Working speed | 10 km/h |

| Dimensions | 165 x 75 x 110 cm |

Tselina PM-05Advantages:

- low price;

- seat adjustment;

- good ride quality.

Flaws:

- weak brake mechanism;

- active equipment is installed on the drawbar.