What can you build on your own?

The market for industrial walk-behind tractors offers customers a fairly wide range of products to suit every taste. But not many people can afford the prices for such agricultural machinery. Therefore, in gardens in rural areas, it is quite common to come across a homemade walk-behind tractor, which in terms of performance characteristics is almost inferior to its factory counterpart.

When creating universal designs, craftsmen in most cases use parts of old bikes and scrap metal

Morally outdated bike models often serve as the basis for the production of various homemade products and small-scale mechanization tools needed in the household.

Since homemade walk-behind tractors are often created from scrap old materials, the motor of the Druzhba saw, which is recognizable to many, is often used as the motor of the unit.

On the basis of homemade walk-behind tractors, craftsmen make more important tools in agriculture, for example: plows, as well as hillers for hilling corn or potatoes

One of these masters is the inventor Valentin Arkhipov, who is the creator of the production of a number of necessary devices and the construction of various household equipment.

A professional designer has made a multifunctional device with which you can not only plow and harrow the land, but also plant and hill up tuber crops, also collect and rake tops

Therefore, thinking about how to make a walk-behind tractor with your own hands

, it is better to suspend your choice on this tested and successfully used option. Any person can handle a simple and easy-to-use agricultural implement.

What is good about this particular design?

There are dozens of analogues of a similar model, but in comparison with them, the unique model of the Kaluga master’s walk-behind tractor has a number of irrefutable advantages.

- Swivel joint. Processing tools and tractors of most similar models have a rigid connection, which complicates the maneuvering of the unit and makes it difficult to work with it. The parts of this agricultural unit are connected by means of hinges. This makes it possible to change the direction of movement as needed during work without removing the plow from the furrow.

- Shift of the axis to the direction of movement. Many owners, when cultivating soil using a walk-behind tractor, have encountered such a difficulty that in the process of moving forward under the influence of the resistance of the earth, the unit moves to the side. To level the furrow, a lot of effort must be made. To compensate for this drift, the master positioned the plow axis at a slight angle in the direction of movement. When plowing, the structure is slightly turned to the left. The required position can always be adjusted using 3 rod joints.

- The level of a given plowing depth. If in other models the plowing depth is maintained by lowering or raising the plow, then when working with this walk-behind tractor it is done automatically. The adjustment is carried out by the configuration of the angle of the plow in relation to the furrow. The structure is equipped with a field board, which acts as a lifting force when burying the plow. If, on the contrary, the opener appears above the surface of the earth, then its angle of attack instantly increases, under the influence of which it again plunges into the ground to a given depth.

Design features of the unit

The walk-behind tractor is a self-propelled machine on two wheels, equipped with an engine removed from a VP-150M scooter. The prerequisite for choosing this particular motor was that it has a design solution that allows forced cooling of the cylinder head with air.

Such a motor from a scooter is capable of operating at lower speeds at fairly large loads

To build the walk-behind tractor, the master used control cables, motor suspensions taken from a motor scooter, as well as a double frame arc, handles and chains. Other design details were industrial production

Separately, the designer made a U-shaped frame welded from pipes and a wheel axle turned on a lathe. He also made 3 homemade hinges for the main and control rods. They will be used as connecting parts between the walk-behind tractor itself, its steering wheel and the plow.

An iron pipe is attached to the frame of the unit by welding, ending with an axis, which is needed to implement the tension of the cables going to the motor box. The tension itself is carried out by means of a swinging rocker arm, the gear shift knob of which is a welded piece of metal pipe.

READ How to Make a Boat Motor From a Stihl Trimmer

The pitch of the chains used to create the device is 12.7 mm and 15.9 mm. Number of teeth on sprockets: output shaft – 11, secondary shaft – 20 and 60, drive axle – 40.

How this whole thing works - an example

A nice example of the implementation of a walk-behind tractor:

Step-by-step device assembly technology

The assembly of the structure begins with the arrangement of the drive shaft. To do this, a housing with bearings is attached to it, a sprocket is welded and overrunning clutches are mounted, which during operation will perform the function of a differential. After which the structure is equipped with wheels and a frame. A telescopic rod, a plow and a steering wheel

.

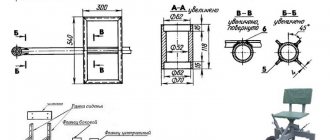

The main elements of the running shaft: 1 – shaft, 2 – sprocket, 3 – cover, 4 – bearing housing, 5 – support platform, 6 – bearing No. 308, 7 – freewheel housing, 8 – pawl axis, 9 – pawl, 10 – ratchet, 11 – bearing No. 307, 12 – washers, 13 – wheel, 14 – pawl spring

The agricultural walk-behind tractor is equipped with special wheels, which, unlike rubber counterparts, are able to provide the best traction with the ground.

Such iron wheels do not become clogged with earth. When they come into contact with the soil, they do not compact it, but rather loosen it.

To connect the frame of the unit with the motor suspension and the frame of the scooter itself, two arched pipes are used. Between them there is a place for placing a fuel tank.

To equip the motor, a bracket is used, ending with a metal axis 150 mm long. The bracket is welded cantilever to the U-shaped frame of the structure. The motor with suspension is suspended on the axle itself. The assembled structure is connected to the arc-shaped arcs of the frame. Only then do they mount the secondary shaft, stretch the control cables and tighten the chains.

The main elements of the control unit: 1 – connecting axis, 2 – bar, 3 – pipe, 4 – handles

Connecting elements of the structure: 1 – main rod, 2 – control rod

Recommendations for use

Regardless of the type of assembled and connected product, you need to start working with it by taking into account safety regulations. Before starting the engine, you need to conduct a visual inspection of the equipment to eliminate visible damage and malfunctions. Do not add fuel to the fuel tank while the engine is running.

If you hear an unusual noise when you turn it on, you need to stop the engine and identify the cause of the problem.

Do not use gasoline of inappropriate brands or fuel mixed with oil and other impurities. Before each start, you need to check the oil level, since this is often the reason the engine stops.

In order to extend the service life of motorcycles, a new product must be run-in. It will contribute to the trouble-free functioning of the walk-behind tractor.

During this process, the working surfaces of the parts are usually worked out. The duration of running-in, as a rule, varies for products of different brands and modifications. In some varieties it can be up to 20 hours or more. At this time, you should not load the equipment to the maximum extent.

One recommendation is to change the oil after the first five hours of operation. As for warming up the engine, this should be done at medium speeds without load for about three minutes.

Based on the modification of the walk-behind tractor, for the first hours of its operation it is necessary to operate the unit in first gear (with the gas lever in the middle position). It is important to try to avoid not only maximum, but also minimum speed . At the end of using the equipment, you need to check the tightness of the threaded connections.

As for the cultivated soil, it is better to cultivate simple soil in the first hours. In addition, you need to take into account that rolling in is not done on rocky and clay soil.

Before work, you need to inspect the area and remove stones and large debris. In general, when working with motorized equipment, you need to constantly monitor its cleanliness and check the fastening strength of the accessible elements of the adapter and walk-behind tractor, including attachments.

Don't forget to tighten any loose fasteners. You also need to remember about timely maintenance.

How can you upgrade a homemade walk-behind tractor?

Walk-behind tractor

Arkhipov is multifunctional. It can be used as a plow or a cultivator. To do this, replace the removable parts for the plow with parts with removed moldboards for the cultivator. As it progresses, the walk-behind tractor will deepen furrows into the ground and place potato tubers in them. To plow the tubers, you just need to put the moldboards in place and walk the unit between the planted rows.

The agricultural unit is also comfortable during harvesting. Using different blades you can change the working width. The unit is also good in that it is capable of collecting missed potatoes and plant tops remaining after harvesting. For these purposes, it is equipped with a rake or harrow.

The universal design can be used not only for agricultural work. In winter, it is successfully used for snow removal. A faithful assistant will also be needed to clean the paths around the house. By installing roller with a round brush and an additional sprocket on the walk-behind tractor, the owner will make it easier for himself to clear the sidewalks.

How to install?

Let's look at the principle of installing an adapter with a steering wheel using the example of a model for a KTZ walk-behind tractor with a steering column. Connecting the adapter to the walk-behind tractor begins with installing the trailer on the pin of the walk-behind tractor, which is located in its front part. The knot is secured with a cotter pin. After this, you need to move the gas to its place under the seat, carrying it with the original cable. To do this, use a 10 mm wrench and a screwdriver, remove the throttle control lever, remove the top plug under the seat, and lay the cable. If necessary, change the bolt, since depending on the adapter model, it may be larger than necessary.

Next, tighten the bolts with a 10mm wrench. When moving the gas, make sure that the cable does not interfere anywhere. Remove the steering wheel from the walk-behind tractor and unhook the clutch and gearbox release cables. Next, remove the steering wheel using a stand for ease of use. Having removed the steering wheel, remove the support and begin installing the pedals. At this stage of work, use a cable with an adapter plate, which is included with the adapter.

The plate is installed on the wing of the walk-behind tractor and secured with a bolt and nut. The lever screwed to the cable is placed in place of the roller bracket. After this, install the second cable, secure it and attach it to the installed bracket, fix it until the moment allows the cable to move.

Now you need to set the forward gear to the right pedal. There is no need to remove it for this. At the same time, adjust the components, checking the forward tension . After this, reverse is installed.

Types of front adapters for walk-behind tractors

Reincarnated technical devices are of the following types:

- With telescopic drawbar type. Thanks to this part, the width of the adapter for the walk-behind tractor is adjustable.

- With drawbar of various lengths. The small clamp is intended for simple weight devices, the long one is suitable for heavy devices.

- The purpose of the equipment is to transport goods. The models have a special body that can withstand increased loads.

- With lifting lever mechanism. Equipment that has attachments is easy to operate and move.

Instructions for making the adapter

Now we’ll tell you how to make a front adapter with steering for your small tractor yourself.

To produce an adapter for a walk-behind walk-behind tractor, you will need the following materials:

- Two identical wheels on an axle. The radius of the wheels ranges from 15 to 18 inches. Even wheels from an old Soviet Volga might work.

- Bearings for steering wheels and columns.

- Steel for the frame (channel, pipe or angle).

- Fastening elements (washers, bolts, nuts).

- Lubricants (litol or grease).

- Consumables (drills, electrodes, discs for grinders).

- Set of wrenches.

- Bulgarian.

- Welding machine.

- Drill.

Before starting work, it is important for Honor that the wheels should not have a very large or small radius.

Sources:

https://zemlyconsalt.ru/motobloki/kak-sdelat-rulevoe-dlya-motobloka.html https://topkarting.ru/kak-sdelat-svet-na-motobloke.html https://zemlyconsalt.ru/motobloki/ rulevoe-upravlenie-na-motoblok-svoimi-rukami.html

Advantages and disadvantages

After the walk-behind tractor has undergone modernization, the designers note the positive properties of the front adapter:

- ease of operation;

- disclosure of traction resource - available opportunities are growing;

- the ability to work is expanded - land cultivation will speed up;

- if necessary, the unit is disassembled and assembled;

- excellent balance in weight and axles;

- You can move around on the device.

The disadvantages include the fact that in the presence of a movable coupling, durability deteriorates.

The adapter for the walk-behind tractor consists of the following structural parts:

About the device

In terms of its design, the 4x4 adapter intended for the Neva walk-behind tractor is a fairly simple device. It consists of several main components:

- frame structure on which other components are installed;

- driver's seat;

- wheelbase, as well as wheel axle;

- mechanism for connecting the adapter and walk-behind tractor.

Simply put, the adapter is a regular cart with a seat that is attached to a walk-behind tractor. Walk-behind tractors can be such as Cayman, Patriot, Texas, Foreman, Crosser, Viking, Loplosh (loplosh video) and others. After coupling the adapter and walk-behind tractor, it can be compared in functionality to a mini tractor, but such a comparison is a little arbitrary, because the power remains the same, i.e. from the walk-behind tractor engine.

In addition, additional attachments can be attached to the adapter, which further expands the potential scope of work.

Making a front adapter for a walk-behind tractor with your own hands

Adapter with steering type control

How to do

control adapter for walk-behind tractor?

The type of design in which the steering wheel must have a rigid fixation.

The control transmission is made into a separate independent unit. A pair of wheels and an axle, which serves as a control drive, are installed in the front and rear parts. Places of fixation are selected based on personal characteristics. The position of the control mechanism depends on the type of spare parts. When assembling, it is recommended to make this particular improved model. READ How to Make a Front Hitch on a Motoblock

A motor cultivator with control control has many positive properties:

- the operator will not waste energy when moving behind the unit;

- the equipment is maneuverable and highly functional;

- traction force is realized at 100%;

- you can drive a walk-behind tractor to your workplace without the need for additional equipment;

- ease of control compared to other variations.

Tools and consumables:

- iron corners, square profile;

- bearings for the steering wheel and column;

- metal sheets;

- a pair of wheels, preferably on an axle;

- drills, electrodes, discs for grinders;

- fasteners;

- wrenches of different sizes;

- electric welding machine;

- lubricants – grease;

- Bulgarian;

- screwdriver;

- drill.

how to make, drawings, front, homemade with steering wheel, wheels, dimensions

Making a high-quality, reliable and durable adapter for the Neva walk-behind tractor with your own hands is not too difficult. To make such a device yourself, you will need to prepare the correct drawings, as well as become familiar with the features that factory units have.

READ How to Make a Rotary Plow for a Motoblock

Construction device

The adapter for the walk-behind tractor is a special trailer with a seat. This unit is made on the basis of a two-wheeled frame and makes it easier to work with a walk-behind tractor. You can make your own device with steering control, characterized by a rigid connection with the walk-behind tractor and the steering drive in the form of a separate unit. The steerable wheelset can be located in front or behind. In the design of the movable joint, you can change the angle relative to the vertical axis located from the walk-behind tractor to the trailer.

The main elements of the device are presented:

- ladder or spine frame;

- bridge, axial, portal or rotary suspension;

- if the adapter is located at the rear, an attachment portal is used;

- if there is a front location, a walk-behind tractor portal or blade mount is used;

- workplace for the driver;

- steering with a rigid coupling.

The most important structural element is the coupling device, which is designed to provide the most reliable connection between the adapter and the walk-behind tractor and is necessary to create vehicle stability. The presence of steering requires a rigid coupling. When changing the angle of articulation, the rotating device requires fastening of a horizontal hinge.

Description of the adapter for the walk-behind tractor

The adapter is a special module for moving on a walk-behind tractor. With its help, you will be able to operate the unit in a sitting position and at the same time cultivate the land. For example, the adapter for the MTZ walk-behind tractor has steering control. It is quite possible to do it yourself. to how this can be done . In the meantime, let's talk about the purpose of this attachment.

Using an adapter can greatly simplify the use of this home appliance. You will have the opportunity to change attachments for hilling or planting potatoes, a flat cutter, a plow and other devices. The adapter also speeds up absolutely any garden work. In other words, if such a device is used in practice, the speed of the workforce will increase from 5 to 10-11 km/h.

Features of the adapter for walk-behind tractor

An adapter is a special device for riding a walk-behind tractor. Using it, you can immediately drive the walk-behind tractor and cultivate the soil.

Working with a walk-behind tractor will be greatly simplified if you use an adapter. You can change the attachments, depending on what kind of work you need to do - hilling, planting, weeding, transportation. With the help of this device, all processes will be doubled.

This unit allows you to sit comfortably on the seat with which it is equipped. Now you can do household chores, but with more comfort. There are control adapters on the market. But they can be done without the help of others.

Maintenance and storage

As a rule, you need to check the oil level every time you turn it on, and replace it at least once every six months. The air filters are checked before turning on the unit. Clean it when it gets dirty or once every three months. The sump tank is cleaned every six months. If it is necessary to replace consumables, they try to buy original parts or those with similar quality characteristics.

They will help extend the life of agricultural equipment and will not cause engine failure. As for cleaning the air filter, this is necessary to maintain the working condition of the carburetor.

Do not use a solvent with a low flash point for this, as this is flammable and can lead not only to a fire, but also to an explosion. You cannot use equipment without an air filter, because this causes accelerated engine wear.

Repairs are carried out in a well-ventilated area with the engine turned off. In this case, it is necessary to ensure a sufficient level of ventilation in the work area. Exhaust gases are hazardous to human health and inhalation can be fatal. Motor vehicles should be stored in a dry, ventilated area .

During the summer season, it is not recommended to leave it outside, especially if the base of the operator’s seat is made not of plastic, but of wood. In order to extend the quality and performance characteristics, when storing the unit outdoors, you need to cover it with a tarpaulin cover.

If you do not plan to use agricultural machinery for more than three months, gasoline is poured out of the fuel tank, it is cleaned, and the position of the gas lever is checked. If necessary, disconnect the wheels.

The following video is about the adapter for a walk-behind walk-behind tractor.

Cultivation of agricultural land involves quite labor-intensive work . Owners of personal farms and gardens usually use manual labor or small-scale mechanization to make this process faster and easier.

A technical device such as a walk-behind tractor can significantly simplify any agricultural work, which distinguishes it from other devices.

The walk-behind tractor can be used separately, as well as a variety of additional equipment can be attached to it.

Devices such as a mower, harrow and cultivator can significantly increase the potential range of work that a walk-behind tractor can handle.

In addition to this, you can use a walk-behind tractor as a means of transportation if you provide a special adapter for it. This device allows you to sit quite comfortably on the seat with which it is equipped, and then perform exactly the same work, but with a fair amount of comfort.

In particular, you can purchase an adapter for a Neva walk-behind tractor with steering control in specialized stores, or make it yourself. Fortunately, there are plenty of drawings on the Internet, which greatly simplifies the assembly process.

Application area

The adapter turns the walk-behind tractor into a universal, functional mechanism. When using this equipment, the operator can be in a sitting position. It is important to see that it imparts stability to the walk-behind tractor and generally simplifies the process of doing the work.

Initially fixed suspended equipment will not move up or down when moving.

The control mechanism has great advantages. You no longer need to use the handles of the walk-behind tractor. Now there is a special control unit that allows you to reach speeds of up to 5 km/h.

When used in conjunction with attachments, you can expand the range of work performed:

- cleaning leaves, snow, terrain;

- soil hilling;

- land leveling;

- transportation of cargo of various sizes.

Owner reviews

On forums, adapter owners express their opinions on the use of this design, its characteristics and how you can make the device yourself. Here are reviews from some owners of this equipment.

Sergey Petrovich, 53 years old, farmer

For several years, when using a walk-behind tractor, I had to constantly walk behind it and hold it by the handle. Our site is located at a great distance from the house. Therefore, on the advice of friends, we purchased an adapter that comes with a steering wheel and a seat. Now it has become convenient to work. Labor productivity has increased. In addition, with the help of the new device it is possible to transport crops over long distances.

Victor, 42 years old, summer resident

Great difficulties were experienced when clearing snow in winter. For this purpose, we used a walk-behind tractor and a snow blower that is mounted on it. My neighbor helped me make drawings and assemble the design of the adapter for the walk-behind tractor. After the device was manufactured, snow removal work became much easier. The trailer turned out to be durable and reliable.

The walk-behind tractor is a mechanized gardener's assistant, which reduces labor costs and the user's health. If such a device is supplemented with an adapter with steering control, it increases the comfort of control and further reduces physical strain.

In fact, the adapter allows you to turn a walk-behind tractor into something like a mini-tractor. From the material in this article you will learn the device of the adapter, its purpose, types, installation nuances and subtleties of operation.

Walk-behind tractor with steering control

With this method, the unit will be placed behind the driver and rigidly attached to the front adapter. As a result, the coefficient of adhesion of the driving wheels to the soil will increase. This, in turn, will increase traction force, which will make it possible to work with any attachment. For such tests, the lightweight Salyut walk-behind tractor, which weighs about 75 kg and has a power of 6.5 liters, is ideal. With.

In this case, a control column with a gearbox is useful. But this is for this option, if you dare to make a walk-behind tractor with front control. This procedure is much more difficult and painstaking than a regular joint, but the result will be fun - you will get a walk-behind tractor with a steering wheel and a seat, and all the necessary levers will be at your fingertips.

Not only the steering wheel

and a gearbox, and control rods with plowshares. The accelerator, clutch and brake pedals located under your feet will certainly be needed. They are connected to standard control elements with homemade rods or iron cables.

On the right side of the seat, a lever is installed to raise or lower the hanging equipment, as well as a parking brake handle. Fenders with lights are installed on the front wheels. And the mini-equipment finally takes on the finished look of a walk-behind tractor with a front adapter.

It must be emphasized that. With all this, the adapter has good technical properties, allowing you to fully appreciate the advantages of working on your own mini-equipment.

Front and rear adapters

The front adapter is similar in design to the control adapter. But the clutch mechanism is located at the rear. This type of design is very comfortable because it can be disassembled and easily transported.

In the rear, the layout is reversed from the front - the hitch is in front of the unit, respectively, the adapter itself is at the back.

The frontal one is in most cases used in those jobs where the power of the unit plays a major role, namely digging and loosening.

READ How to make a mulcher for a walk-behind tractor

Algorithm of actions

We begin to manufacture suspended equipment for the walk-behind tractor.

Fundamentally! Before you start working on the drawings, make sure that the dimensions and numbers correspond to each other.

To produce a control adapter for a walk-behind tractor, you will need a frame with a bushing and fork. This will ensure free rotation of the walk-behind tractor using the steering wheel.

- Everything will start with the production of the frame. It can be made from cut pieces of selected steel of the required length. The metal can be divided with a grinder and the elements can be fastened with electric welding or bolts.

- Next we build the chassis. If the motor of your walk-behind tractor is placed in front, as it should, the track size must be determined by the main wheels. The rear ones are installed to the frame using an axle. It can be made from a piece of pipe of suitable width. At the ends of this pipe we press bearings with bushings. Wheels will be installed on them. If the walk-behind tractor engine is located at the rear, then the track width should be larger, otherwise the minitractor will not be able to move normally during operation. In a similar situation, it would be best to remove the base wheels of the walk-behind tractor and reinstall it, but on a more spacious axle.

- To make a steering wheel for the unit, you do not need to additionally remove the handles from the car or bike. Stop using a pen. In other words, the operator will have the opportunity to control the minitractor with a steering wheel that looks like a motorcycle. In general, with it the operator will not be able to reverse normally. That’s why it would be better to mount the control column on a mini tractor.

- When using an all-metal frame, the control regulation will be built into the front axis of the walk-behind tractor. You can make

an articulated support, then the control column will rotate the front half-frame completely. To do this, the master will need to attach a gear to the front half-frame. The second gear is installed on the control column. - The seat, which can be previously removed from any passenger car, must be welded to the frame of the slide. The technician needs to make sure that it is adjusted, especially when controlling the front adapter attached to the walk-behind tractor.

- If you intend to use the minitractor to work with plows and cultivators, then you will need additional welding of the bracket. An auxiliary hydraulic system must be installed to operate the attachment. The pump for it can be removed from agricultural machinery without any problems. If you have to work with semi-trailers, then you need to take care of additionally welding the towbar to the rear of the frame. It can also be successfully borrowed from a passenger car.

- You can do the fastening (coupling) yourself . For this, drawings are useful, which are simply searched for in articles based on the top results of a suitable topic. And we will talk about how to specifically perform the coupling.

To do

U-type hitch, you will need an iron channel of suitable thickness and size. The hitch is attached to the walk-behind tractor under the control column through previously drilled holes in certain places. A bracket and pins are inserted into them. It is important to ensure that the parts are of high quality; this will avoid unnecessary problems in the future and waste of real time. All parts must be made from high quality durable steel.

This completes the installation of the front adapter on the Neva walk-behind tractor. After completing the assembly, all that remains is to lubricate the minitractor and check it for functionality. After which the adapter assembly can be assessed as complete. Now you can safely carry out the required work on earthen plots using the latest technology.

Adapter with movable hitch

It involves a movable connection of the trailer to the walk-behind tractor. This system is more difficult to control, but making such a module with your own hands is even easier. When turning it means more effort. The module can be mounted either rear or front. Even the primitive structure of a walk-behind tractor involves dispersing loads. Therefore, it is recommended to place the seat in the module close to the drive axle. Under the weight of the operator, the wheels of the walk-behind tractor will be pressed to the ground, which prevents slipping during movement.

There is nothing complicated in designing an adapter and working with a mini tractor. This is available to anyone who has set out to own a home tractor on their own property, which will make a person’s work easier once a day. So try to design, build and create - and cultivate the land with pleasure.

With steering

The control adapter makes it possible to transform an ordinary walk-behind tractor into a real mini-tractor. The motor power remains constant, but the number of functions performed will increase significantly.

The fastening is achieved thanks to the coupling, which is located in front of the adapter.

The design includes the following elements:

- a pair of wheels;

- clutch mechanism;

- brake and gas;

- operator's seat;

- frame.

At the back there is a mechanism to which suspended additional equipment can be attached as needed.

Sources:

https://glav-dacha.ru/peredniy-adapter-na-motoblok-svoimi-rukami/ https://instrument16.ru/interesnoe/kak-sdelat-rulevoe-upravlenie-na-motoblok.html

Purpose

An adapter for a walk-behind tractor was created for the convenience of gardening. If you attach a hinge to it, you can expand the scope of application of the device:

- remove hay;

- level the soil surface;

- transport goods;

- harrow the ground;

- clear the area of snow.

An adapter is a device that is designed for movement on a motor cultivator. With it, you can control the unit while sitting in a chair, and at the same time cultivate the soil. The trailer for the Neva motor-cultivator is equipped with a steering control. It makes it easier to use the walk-behind tractor.

You can install different attachments for harvesting, a plow, a mower, etc.

This trailer speeds up work in the field. Using this design, you can increase the speed of the cultivator from 5 to 10 km/h. Let's look at the adapter device. The adapter for the motor cultivator consists of:

- frames;

- operator seats;

- two wheels;

- axles;

- coupling mechanism.

After attaching the adapter, the cultivator looks and is used like a mini-tractor. To create an adapter for a cultivator with front steering, you need a frame. The operator's seat is installed on it. The frame is fixed to the chassis.

The seat is fixed to the frame. This will make it easier for the operator to control the cultivator. The wheel system will help move the unit around the site. There are 2 types of wheels: metal (used in the field) and rubber (used for driving on the road).

The hitch for a walk-behind tractor is made of steel or cast iron by welding. She attaches the cart to the cultivator. The U-shaped fastening system is considered the best. With this design the device will be stable.

Specifications:

- The highest travel speed on a walk-behind tractor with a trailer is 12 km/h.

- Maximum load capacity - 100 kg.

- The track diameter is 67 cm.

- Dimensions are 130x70x71 cm.

- The weight of the device is 22 kg.

- The warranty period is 5 years.