Bending a metal strip into a ring and onto an edge

Not everyone knows how to bend a metal strip without losing strength and achieving configuration accuracy. To avoid reinventing the wheel, read our tips!

When working with metal, you often have to deal with the manufacture of products from steel strip - staples, clamps, brackets. But not everyone knows how to bend a metal strip without losing strength and achieving the required configuration accuracy. However, this is a fairly simple operation that does not require particularly sophisticated tools. Only in the case of bending a strip on an edge, a rather complex device is needed, which is not easy to make yourself.

Bending of the strip at an angle (60, 90, 120 0 ...) towards the plane is done on a regular bench vice if you need to make a single product or several pieces. In the case of small-scale production, you will need a machine for bending metal strips. If necessary, you can do it yourself.

How to bend a profile pipe

Greenhouses of various sizes and purposes, gazebos and other structures on the site are built using profile pipes. Such metal structures have one distinctive feature: bending the pipe with or without a pipe bender leads to deformation of the workpiece (flattening or cracks may occur). It doesn’t hurt to know how to bend a profile pipe at home correctly so as not to damage the material.

The solution to this problem is quite simple: it is also filled with sand or water, which is subsequently frozen. Following these simple steps reduces the risk of pipe damage and allows you to achieve the desired result. The same method can be used when deciding how to bend an aluminum or brass pipe without a pipe bender (about

Bending strips using a vice

First, let's consider the option of bending on a bench vice at an angle of 90 0. To do this, you need a square block of steel. We clamp the strip together with the block so that the block is located on the side of the fixed jaw of the vice and protrudes 1-2 cm above the upper edge.

After such a “sandwich” is firmly clamped, take an ordinary hammer and bend the strip towards the block with light blows. If it is required that the bend surface is not damaged by impacts, then you need to use a copper or brass gasket, which we will hit with a hammer, and from it the force will be transferred to the strip.

In this way, you can bend the strip at any angle; it is only important to select a support block with the desired cutting angle. Without such solid support, achieving the desired angle will be very difficult.

Similar operations are performed in the manufacture of clamps, only in this case we use a thick-walled pipe or rod of the required diameter as a matrix. As in the case of a rectangular bend, blows with a hammer are applied towards the stationary jaw of the vice. This kind of strip bending is a slow process and requires care.

Bending strips into a ring

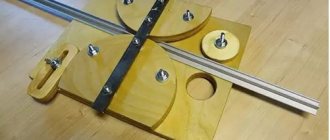

The strip is placed between the rollers and pressed using a screw mechanism. When the drive roller rotates, the strip begins to move between it and the support rollers and bend towards the drive. After a complete pass of the strip, an almost perfect ring is obtained. If you make the handle telescopic so that the arm can be made longer, then you can bend strips of almost any thickness onto the ring without much physical effort.

This homemade strip bending machine is practically no different from the factory one. With the right choice of metal for the rollers and clamping device, small-scale production, for example for the manufacture of decorative fences, gates or frames of canopies and awnings, is possible even in a home garage, not to mention a metalworkshop.

Self-production of the machine

Sometimes you need to make a machine at home . This will make bending metal easier and increase productivity. Here you will need a corner, a metal beam, hinges with bolts, clamps, handles, a table and a welding machine. The procedure is as follows:

- The base is made of metal; an I-beam profile is suitable.

- The corner is attached to the top of the beam using bolts.

- Three hinges are welded under the corner using a welding machine.

- We bend the aluminum sheet by turning the corner.

- Two clamps ensure tight pressing of the metal.

- The corner does not have to be removed; you can raise it. Place the product between the profile and the corner. Then a metal sheet is aligned along the edge.

Check the bolts to ensure they are secure. Turn the crossbars and bend them so as to form the desired angle. This will avoid wasting time on angle calculations.

Whatever the devices, the main principles remain the same . By following them, you can obtain products that meet the standards and wishes of the customer.

Bending strips on edge

If bending is often done on strips of different widths, then you need to make several blocks with slots corresponding to the gauge that is being processed. But a homemade tool, for all its attractiveness and cheapness, is still inferior to an industrial one, the functionality of which is much higher.

Hand tools are produced in the form of universal devices, in which only the attachments and levers are changed, or in the form of entire sets, where each mechanism performs only one, maximum two functions. An example of such a kit is “Cold forging” of industrial production.

Moreover, their cost is not too high even for a home craftsman. Finding the necessary parts for a homemade machine, assembling, fitting and tuning will not cost much less, even with proper metalworking qualifications. If you do not buy the cheapest tools, then bending machines will work for decades.

Strip metal bending

A series of articles devoted to metal processing continues on our website. We talked about how sheets and rolls from the delivery state are unraveled into strips (strips) in the article “Metal slitting lines.”

Metal bending is done using specialized equipment or manually. We described how this happens with imported equipment using the example of products from the Italian machine tool concern WARCOM. We talked about the use of domestic sheet bending machines for these purposes in an article about the Lipetsk sheet bending plant.

Today we will talk about manual bending of strip metal.

- Manual bending of strip metal

- Right angle bending

- Bending at an acute angle

- Manufacturing of staples and clamps

- Bending connection

- Edge bending

Manual bending of strip metal

Manual processing of metal strips is a labor-intensive operation, in most cases requiring special training of the worker and the appropriate tools. This operation is performed by a mechanic at a specially equipped workplace:

- a mechanic's workbench equipped with an appropriate vice;

- set of locksmith tools.

Let's look at a few simple operations with strip metal.

Right angle bending

We will bend the strip steel in a bench vice. Place the workpiece (clamp it) in a vice.

Bending in a vice.

We do this in such a way that the side with the bending point faces the stationary jaw of the vice (away from the worker). In this case, the mark should be approximately 0.5 mm higher than the jaw of the vice. Hammer blows should be applied in the direction of the stationary jaw of the vice. To avoid injury (if the workpiece springs back), the mechanic, when performing this operation, should not be positioned in the path of the hammer.

Bending at an acute angle

In this case, a mandrel having the required angle is used. It is installed in a vice along with the workpiece, as shown in the figure (with the high side facing the workpiece). The workpiece is deformed by hammer blows until it touches the bevel of the mandrel.

Manufacturing of staples and clamps

To make a bracket, you should use a frame block, the thickness of which will be equal to the opening of the bracket. Next, you should fasten the strip with the mandrel in a vice, as indicated in the figure, and bend first one side, and then the other.

Manufacturing of staples and clamps.

To make a clamp, fix the frame in a vice and bend a strip on it (see figure). Then, bend the ends of the clamp, release the equipment from the vice and use a hammer to give the part its final shape on the workbench table.

Hammer blows should not be applied to the clamp itself, so as not to leave scratches, nicks and dents on it. They should be carried out through a copper plate of small thickness, since it will well redistribute the impact force.

Bending connection

Strip bending is widely used for bending joints of parts. The connection can be completely bendable, as shown in the figure. Here, the fastening force is created by bending one part (often all connected parts are deformed).

In a number of cases, strip bending plays a supporting role. It can, for example, strengthen a threaded connection.

Examples of bending connections.

The figure shows examples of strip bending and strengthening of a nut-bolt threaded connection: a cotter pin and a lock washer.

Edge bending

The operation is performed on the roller machine shown in the figure.

Bending steel strip “on edge”.

There are two features of this machine to consider:

- the upper guide of the base bar must have a groove that exactly matches the size of the deformed metal strip;

- The working roller and the top of the strip must be lubricated with grease.

These are the basic simple techniques for manually bending strip metal.

At the addresses indicated here you can select and purchase a metal bending machine.

Metal fittings

Metal reinforcing bars are bent only when cold. It is unacceptable to file or heat the bend area. By making your work easier, you greatly weaken the rod; during subsequent use, the rod is destroyed under load.

An acceptable bending radius is 10–15 bar diameters. Correct bending up to an angle of 90° (right angle) does not damage the quality characteristics; then a gradual decrease in strength begins. Strict adherence to the process technology is the key to the absence of damage to the rod in the form of folds or kinks. If you are not sure how much you can bend reinforcement of a particular radius, please clarify this issue with our managers when choosing reinforcement in our catalog.

How does bending happen?

The basic principle of operation of most devices for bending steel reinforcement is as follows. The reinforcing bar comes into contact at the point of future bending with a stationary central roller. On the other side of the rod there are two stops - bending and fixing.

After the operation begins, the bending stop begins to move, puts pressure on the rod and forces it to rotate around the central roller, as in a balance swing. At this time, the locking stop prevents the other end of the rod from moving to the side under the influence of the lever mechanism, as a result the rod bends. The bending radius corresponds to the radius of the central roller.

The above diagram is the most common, but it does not exhaust the variety of bending methods.

Bending devices

The choice of bending equipment is determined by the diameter and profile of the reinforcement, as well as the volume of work.

Electrically driven machine . Indispensable for the construction of large objects or bending of reinforcement with a diameter of over 20 mm. Capable of bending several rods at once. The permissible range of rod diameters depends on the power of the equipment.

Hand mechanical tool . A more mobile portable version, attached to a workbench. Powered by muscle power, no electricity required. Designed for a small amount of reinforcement. The working diameter is usually up to 20 mm, although tools are also available for larger rods. The price of the equipment is low, this is a reasonable solution to the problem when building a private house.

Homemade devices . There are two types: 1) copying factory hand tools, 2) other improvised methods. The latter includes bending rods with two pieces of pipe, with a sledgehammer after clamping in a vice, or using driven stop pins. Homemade devices, like hand tools, are only suitable for small diameters. The main disadvantages are the low quality of bending, the possibility of damage to the reinforcement, and the risk of injury. Our company’s employees warn that it’s not worth the risk; it’s better to buy or rent real equipment, not homemade equipment.

How to bend a steel strip on edge and make a ring

Manually bending a strip flat into a ring is not difficult and does not require much effort, while bending it on an edge (along the narrow side) is not so simple and is quite labor-intensive. This work is for a strong man, especially if the transverse dimensions of the strip are large. But if you use a little trick, then even a high school student or an elderly person can handle it.

Edge bending process

We place the anvil on its side on a massive and durable base. We cut out a pair of approximately square plates from different sized corners. Using a grinder and pliers, we round two corners of each of them.

Approximately in the middle of one side of the large plates, we mark and make a horizontal cut with a length equal to the height of the rail base. From its end downwards at an angle coinciding with the inclination of the rail neck, we make a second cut.

We place the steel strip that is to be bent across the anvil.

To the strip held on the edge, we apply smaller plates on both sides, which with their flat edges are in contact with the side of the rail head.

Holding the plates in this position, with the workpiece located between them, we attach them to the anvil by welding.

After making sure that the workpiece slides freely between the stops, we weld along their perimeter.

In the same way, using the strip as a template, we weld large plates to the base and neck of the rail thanks to the cutouts. We make sure that the strip moves freely, without jamming, between two pairs of limiters in the longitudinal direction in both directions.

We place the workpiece with one end between the smaller stops welded to the base of the anvil, and begin to strike the upper edge of the strip measuredly and with equal force, gradually pushing it from the head to the base of the anvil.

If the strip bends to the side, we remove it by hitting it with a hammer in the opposite direction.

When I reach the middle of the strip, we bring its other end into the limiters and repeat the previous operation.

Gradually, the free ends of the workpiece will begin to converge, and depending on their relative position, by adjusting the location and force of the blows, we ensure that its ends rest against each other.

If there is lateral curvature, the product is straightened on a flat and hard surface.

Bend a ring from a metal strip.

There was a need to make several rings from a metal strip 8mm thick and 55mm wide. The outer diameter of the ring is 400mm, and the inner diameter is 300mm. After bending and welding, it is finally processed on a lathe. Maybe someone has encountered a similar problem and can suggest bending technology. Perhaps there are devices for bending similar parts. I would be grateful for advice and suggestions.

Stupid question, but won't thin tape work? In general, I would contact a decent forge with this question.

eug28 wrote: There was a need to make several rings from a metal strip 8mm thick and 55mm wide. The outer diameter of the ring is 400mm, and the inner diameter is 300mm.

Something is unclear, how can this be, the outer diameter is 400 mm, the inner diameter is 300 mm, with a wall thickness of 8 mm? (400-300): 2 = 50mm, the wall thickness should be, not 8mm, if we are talking about a ring. Will scraps of pipes of the required diameter be suitable?

Suever wrote: Something is unclear, how can this be,

The strip should bend along its width, not its thickness, if I understand correctly. For such parameters it is necessary to use something like an industrial pipe bender with a powerful electric drive with appropriate mandrels.

It’s easier to cut it out of an 8 mm sheet using gas and trim it on a machine. If this is not possible, then really go to the blacksmith.

Madman wrote: For such parameters it is necessary to use something like an industrial pipe bender with a powerful electric drive with appropriate mandrels. __________________

In this case, you need to bend it on the “edge”, 8mm on the edge is something not ice, then it’s easier to draw it on an 8mm sheet, and even cut it out with a jigsaw. I understand, but it’s necessary.

In general, try to do this with a cardboard model, manually bend it on its edge, it either folds correctly or breaks, IMHO the same will happen with metal, so it’s better to cut it from a sheet.

Yann: - It’s difficult to bend. Usually cut from sheet. You go to the local boiler house or water utility, take a bottle and go to the mechanics. They are aware of these issues. I have several 400 * 10 mm nickels lying around at home, these are plugs from equipment. But how can I give them to you?

2eug28 Never bend this strip into a flat, smooth ring using any equipment. It is necessary to cut from a single sheet with gas, EMF, a jigsaw, a grinder or directly on a lathe

Vidis wrote: You need to cut from a single sheet with gas,

I think that after gas it will only end up as scrap metal.

You won't be able to bend it. If there is no solid sheet for the ring, you can weld it from a strip - in sectors (chords) with cutting and then on the machine. Something like this, if the width is 55:

Suever wrote: I think after gas he will behave like this

I assure you, it won’t lead.

You just need to make a ring X mm wide Y mm, then cut out a piece (sector) to form a sort of letter C and bend it on an anvil along the diameter until the edges meet... accordingly, do everything on a cardboard model... plus allowances for manual processing, and forward.. They usually make a cone that way.. but in general, to the pipe plant.. just order what you need..

Suever wrote: I think that after gas it will only end up as scrap metal.

Yann: - It doesn’t matter, this is usually done everywhere, and this work itself is well known to welders. You can do it yourself, find a cutter and the necessary hardware. Well, you can bend the rod, weld it and take it to the forge, where it will be heated and flattened. I see the way out as follows: - “Either to the forge, or to the welder.”

If you use a forge to forge, the thickness may turn out to be uneven. Easier to cut from a sheet. Yes, even with a jigsaw. (I won’t say anything about how many files it takes)

Medtech wrote: You just need to make a ring X mm wide Y mm, then cut out a piece (sector) to form a sort of letter C and bend it on an anvil along the diameter until the edges meet .. accordingly, do everything on a cardboard model .. plus manual allowances processing, and forward.. They usually do a cone like that..

I didn’t understand anything: why “cut a piece” out of a finished ring and then bend it? The author has a 55x8 strip, but he needs to make flanges (it looks like the 299th pipe).

Yann wrote: find a cutter and the necessary iron.

You forgot about a normal carver.

Yann wrote: It doesn’t matter, that’s how they usually do it everywhere

Once upon a time they cut an 8 mm sheet, for gates, bicycles, with a continuous cut. They began to cut with dotted lines, the result was a little better.

Suever wrote: Something is not clear, how can this be, the outer diameter is 400 mm, the inner diameter is 300 mm, with a wall thickness of 8 mm?

Where did the wall come from? I asked to share the technology. And there is one. If you have nothing to offer, it is better to remain silent. IMHO.

Malevich wrote: you can weld from a strip - in sectors (chords) with cutting and then on the machine.

It’s theoretically possible, of course, to weld from segments, but practically 12 (in your drawing) segments in one plane, but no matter how you cut it, you can’t weld, IMHO.

How to bend a metal strip at a right angle?

1. FITTING PROCESSING

Editing

is a technological operation to eliminate bends, local irregularities, waviness, bulges or dents of various shapes and other defects on metal workpieces.

Manual straightening of sheet metal blanks is carried out on a massive steel plate (Fig. 1.6, a) using wooden hammers or hammers made of copper, aluminum or lead. To straighten the sheet, place it on the plate with the convex side up. Use chalk or colored pencil to outline the boundaries of the convexity. Then, holding the sheet with the left hand, the right hand strikes with a hammer in rows from the edge of the workpiece in the direction of the convexity (Fig. 1.6, b). The straightening continues until the convexity disappears, then the workpiece is turned over and its entire surface is finally straightened with light blows of the hammer.

Rice. 1.6. Straightening sheet steel with a hammer (a) and striking pattern for straightening the convexity in the middle of the sheet (b)

If there are several bulges, blows begin to be applied from the gap between the bulges, gradually approaching them. If the bulge is located at the edge of the sheet blank, then editing should begin from the middle of the sheet to the edges.

Metal hammers used for straightening must have a round, well-polished head without dents or burrs. It is not recommended to use a hammer with a square striker for straightening workpieces, since its corners leave nicks after impacts.

Workpieces made of strip, rod and profile steel are straightened with steel hammers with a round convex striker on a plate or anvil (Fig. 1.7).

Rice. 1.7. Straightening parts made from strip (a), rod (b) materials and thin sheets on a plate using a block (c)

When straightening strip metal curved along a plane, the strip is placed on the straightening plate with its convex upward, touching in two places, then they begin to strike the edges of the convex alternately from both sides, approaching its middle.

Straightening of strip, crescent-shaped workpieces is carried out on a plate by applying blows across the strip (Fig. 1.7, a). Moreover, the blows are applied first from the shorter side of the strip, i.e., from the one where the metal is most compressed and it must be stretched so that the workpiece leveled out. At the beginning of straightening, the hammer blows along the edge of the concave side of the strip should be strong, and as they approach the opposite side, they should be weaker. In this case, the shorter side of the strip, which takes the most powerful blows, is gradually stretched and the workpiece is straightened. The linearity of the strip is checked with a ruler.

Straightening a round steel bar on a plate is carried out similarly to straightening strip metal (Fig. 1.7, b).

Straightening of thin sheet metal (foil) is carried out using wooden or metal bars (strokes) on a smooth metal plate (Fig. 1.7, c).

When straightening a round steel bar in prisms, the workpiece is placed in the prisms so that the bend is between the prisms with the convex part upward (Fig. 1.8, a). The blows are applied with a hammer from the edges of the bend to its middle part. The quality of straightening (linearity of the rod) is checked with a metal ruler or square: the number of gaps between the surfaces of the rod and the ruler should be minimal.

Rice. 1.8. Straightening a round bar on a plate:/center>

a – using prisms; b – on a manual screw press

For straightening profile workpieces, pipes and shafts, when the force of a hammer blow is not enough, manual screw presses are used (Fig. 1.8, b).

Flexible

is a technological operation in which a workpiece or part thereof is given a curved shape. Bending includes actually bending or bending (producing bent profiles), profiling (corrugating, bending), rolling (producing welded pipes), coiling springs, etc.

Rice.

1.9. Examples of metal bending and the use of mandrels: a – strip at right angles; b – strip at an acute angle;

c – double bend; g – bending “on edge”;

d – rod into a ring in a bending device;

e – sheet in a bending die; g – pipe in a roller device

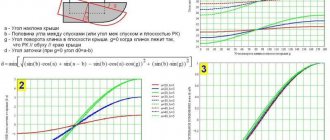

During the bending process, the metal undergoes deformation: its outer layers are stretched and lengthened, while the inner layers are compressed and shortened. The middle layer, the so-called neutral layer, retains its length unchanged during deformation and is used to calculate the length of the workpiece to be bent. For workpieces that are symmetrical in cross-section (square, sheet, etc.), this layer is located in the middle of the cross section, and for asymmetrical profiles (triangular, semicircular, etc.) it passes through the center of gravity of the section.

Bending of a strip workpiece is carried out by bending it to the desired angle around any mandrel, the shape of which it takes, in a bench vice according to a template or on a plate (Fig. 1.9, a, b, c, f).

When bending square, rectangular or round metal, special hand tools are used, the main working tool of which is a rolling roller (Fig. 1.9, d, e).

Pipes are bent in a cold and hot state, using various devices, or on special pipe bending machines (Fig. 1.9, g). Pipes with a diameter of more than 20 mm are filled with sand or rosin before bending.

Parts made from thin (up to 0.5 mm) sheet material are bent with mallets, from round-section material with a diameter of up to 4 mm * using pliers or round-nose pliers, from sheet material with a thickness of more than 0.5 mm * on mandrels with a plumber's hammer. The design of the mandrel must correspond to the profile of the workpiece being bent. When bending parts at an angle of 90* without roundings (fillets) on the inside, the bending allowance is taken equal to (0.5...0.8) S, where S * thickness of the part being bent, mm.

Sheet metal after rolling has a fibrous structure. To avoid cracks when bending, it must be bent across the fibers or in such a way that the bending line makes an angle of 45* with the direction of the rolled material (fibers).

Bending technology - basic information

Metal bending is performed without welding seams, which avoids corrosion in the future and produces a product of increased strength. Deformation does not require significant effort and is usually performed in a cold state.

The exception is hard materials such as duralumin or carbon steels. Sheet metal bending technology is developed according to the assigned tasks in such options as:

- radius,

- multi-angle,

- single-angle,

- U-shaped.

A special case is flexion with stretching. This technology is used in the manufacture of parts with large bending radii and small diameters. When making parts with your own hands, the process is combined with operations such as cutting or punching.

Soft types of metals and alloys, such as brass, copper, and aluminum, are well suited for home processing. The production of products by bending is carried out on rolling or rolling machines, or manually.

The last procedure is quite labor-intensive. Bending is done using pliers and a rubber hammer. If the sheet is thin, use a mallet.

How to bend at right angles

To bend a bracket from a metal sheet, you will need a set of tools and accessories, consisting of:

- vice,

- hammer,

- power saws,

- bar,

- frames

The length of the strip is made according to the scheme, with the calculation that there should be a margin of 0.5 mm for each bend, plus another millimeter for folds on both sides. The workpiece is placed in a vice with squares. Clamping it along the fold line, process it with a hammer.

After this, the future bracket is unfolded in a vice, clamped with a frame and a block, and the other side is formed. The workpiece is pulled out, the required length of the sides is measured, making bends along the bottom.

Use a triangle to check the correctness of the angle, correcting inaccuracies with a hammer. When performing both operations, the workpiece is pressed with a block and a frame. The finished staple is filed to the desired size.

How to make a sheet bending machine yourself

To give the metal the desired configuration, tinsmiths use a sheet bending machine. But what should a master do if he doesn’t have special equipment at hand?

In fact, the question of how to bend sheet metal at home is easily resolved. It is enough to use your own ingenuity and basic equipment to make a simple machine.

To make a bender for a metal profile, you will need:

- I-beam 80 mm,

- fasteners (bolts),

- loops,

- corner 80 mm,

- clamps,

- a pair of handles.

You will also need a welding machine and a stable table on which the finished machine is mounted.

The basis of the device is an I-beam, to which a corner is screwed with two bolts, holding the workpiece during the bending process. Three door hinges are attached under it by welding. Their second part is welded directly to the corner.

In order for the machine to easily turn while bending sheet metal, handles are attached to it on both sides. The finished machine is secured to the table with clamps. Before laying the workpiece, the corner is unscrewed or lifted. The sheet is pressed, aligned along the edge and folded, turning the machine by the handles. The homemade device is only suitable for processing workpieces of small thickness.

Bending a metal sheet with a hammer

In order to bend a sheet up to 1.2 mm thick at a right angle, use the simplest tools - pliers (clamps) and a rubber hammer.

The processing is carried out on a flat wooden block. The fold line is drawn using a pencil and ruler. Then the sheet is clamped with pliers so that their ends fall exactly on the marking line.

The edge is gradually bent upward, moving along the fold. Once the angle approaches 90 degrees, the sheet is placed on the block and finally leveled using a hammer.

Narrow parts, such as tin edges, are made in this way.

Tip: Use a rubber or wooden hammer to prevent dents from forming on the metal. If bending is performed with a conventional tool, you need to take a textolite plate as a gasket.

It is convenient to bend sheets up to 2 mm thick on a desktop. The metal is positioned so that the marking line falls on the edge. A steel corner is placed under the material being processed.

The sheet is clamped in a vice using two wooden blocks. Bending is done using a hammer, tapping the metal from one end to the other. At the same time, the edge of the sheet is directed downward so that it ultimately lies completely on the corner fixed along the edge of the table. This method can be used to make products of any width, including boxes or barbecues.

Making pipes without using a machine

Home craftsmen have invented a lot of ways to bend a metal sheet into a pipe without using a machine.

We propose to consider the simplest option using a blank of suitable size. It is made from an old pipe of suitable diameter.

A sheet of metal is laid out on the floor and a piece of the required length is cut from it. To determine the required size, the required pipe diameter is multiplied by 3.14 and added 30 mm for the seam.

A pair of tubes are welded to the blank on both sides, perpendicular to one another. The crowbar should be freely inserted into their holes.

Master's recommendation: by bending a metal sheet using a blank, it is convenient to make pipes no more than a meter in length.

To use the device, the effort of three people is required. The blank is placed on the edge of the sheet. One person stands on top, two others screw the metal onto the blank, turning the crowbar 90 degrees.

The entire length of the sheet is rolled in this way, the remaining edge is hammered. The seam is secured by welding.

It must be taken into account that the bend radius of sheet metal depends on its thickness and manufacturing method. Hot rolled steel is more suitable for pipes; profile products are made from cold rolled steel.

Simple ways to bend pipes

Bend by hand

Do not despair if you have to install a complex structure using curved pipes, but there are no professional tools available. Even if you were unable to purchase blanks with the desired bending angle in advance, you can make parts for the work yourself, at home and with a minimum of tools.

How to proceed? Grab the structure with your hands, squeeze it tightly and gradually bend it. Proceed carefully so as not to damage the part. Smoothly, centimeter by centimeter, move along the length of the pipe. You need to repeat the manipulation in 5-6 approaches. Manual work is not suitable in all cases, since bending an aluminum pipe, for example, is much easier than doing the same with a metal product.

Advice: practice on an unnecessary section before starting “finishing” work. Act smoothly so as not to deform or break the part; the number of “approaches” depends on the diameter and length of the structure.

The manual method is effective when working with pipes with a diameter of 16-20 mm. With a larger cut, the process will be longer and more labor-intensive, but it is possible.

We use the hot method

We've sorted out the aluminum, but how to bend a metal pipe yourself so that the result doesn't disappoint? A gas burner will solve the problem.

- We fix the metal piece in a vice.

- We warm up the area of the future bend.

- When scale appears, we begin bending.

How to determine when you can start working? If the material is aluminum, hold a sheet of paper to the surface of the pipe. The signal will be if it ignites or produces smoke. If the other metal is metal, the heated area will turn red.

Please note: the heating method is not suitable for working with galvanized parts - damage to the coating is guaranteed and the coating will become unusable.

Tip: since it is more difficult to bend a square pipe without creases and deformation, use a powerful blowtorch or torch and heat all sides of the product before starting work.

We use fillers - sand and water

The use of fillers allows you to bend both corrugated pipe and large-diameter aluminum sections.

Principle of working with sand:

- pour sand inside the structure, put plugs on the ends of the pipe (watch for tightness);

- fix the part in a vice;

- We warm up the bending area with a soldering iron or gas torch;

- when the area heats up, bend the structure with a rubber mallet or a wooden mallet, gently tapping it on the heated surface;

- Upon completion of the manipulations, remove the plugs, remove the sand from the cavities - everything is ready.

Sand protects the pipe from deformation and uneven bending.

- Galvanized parts are bent in this way without heating

- Fill the cavities tightly so that the interior is filled to the brim.

- Treat square pipes on each side to help avoid unevenness.

The principle of working with water is almost identical - pour water into the part and install plugs. Before bending a PVC pipe or product made of other material, let the water freeze (expose it to frost or place it in the refrigerator). Once the liquid freezes, we apply the required bending radius to the structure using translational movements.

Using this principle, you can either bend a sheet of metal into a pipe (only without using water and sand), or bend the pipe itself.

Bending and bending of sheet metal

Bending sheet metal allows you to obtain a product of the desired shape with relatively little effort. Because welding requires more effort, both physical and financial. A sheet of metal can be bent manually or using automation, but the general principles of operation remain the same. It is the features of this process that will be discussed.

- Basic principles

- Types of bending of metal products

- Types of equipment

- Handmade

- Self-production of the machine

Basic principles

Metal bending is carried out using various methods. Welding is often used, but temperature exposure can change the shape and properties of the finished product. This reduces performance properties and manufacturing accuracy.

Since when bending metal, the outer layers of the metal stretch, and the inner ones begin to compress, it is necessary to bend part of the rolled metal relative to another by a given angle. The angle can be found using calculations.

The product is deformed to those values that are within the specified limits. They depend on the following parameters:

- Thickness of the metal sheet;

- How much is the bending angle?

- How durable is the material;

- Speed and time of the procedure.

The permissible deformation indicator will depend on them. The next step is to select the type of bending.

How to bend a strip of metal into a circle?

In the field of metal processing services, metal bending in St. Petersburg occupies one of the first places in popularity.

This process allows you to make the desired geometric shape of a sheet of steel, while maintaining its strength and physical properties. The equipment for performing this procedure is a CNC press brake, which bends the product at a given angle and radius, thereby creating the product of the required shape.

As a result of this technologically complex process, we obtain a seamless, high-strength structure from a flat blank.

Thus, metal bending in St. Petersburg helps to produce the majority of functional steel products, as well as long products: channel, profile, steel angle and others.

Many rolled metal products for mechanical engineering are produced by welding metal: brackets, trays, steel boxes, etc.

Let us note that bending sheet metal to order is a popular technical procedure. Its implementation is aimed at changing the shape (configuration) of the workpieces.

This is achieved by the fact that the outer layers of the material are subject to tension (their sizes increase), and the inner layers are subjected to compression (their sizes decrease).

In everyday life, this procedure is carried out using improvised tools, for example, pliers.

https://www.youtube.com/watch?v=CU1uNY0N8fM

However, in manufacturing enterprises, when a large product or workpiece needs to be changed in shape or configuration, pliers are not enough. Moreover, in production conditions, metal bending of any complexity is often carried out.

That is why it is carried out using special professional equipment, represented by roller machines, press brakes and rollers. The latter are characterized by manual or hydraulic control.

In recent years, a lot of equipment equipped with electric drives has appeared in the area under discussion.

Metal bending in St. Petersburg

What is custom metal bending used for in St. Petersburg ? It is used to change the shape (configuration) of a wide variety of products and workpieces.

By the way, the equipment mentioned above is successfully used to carry out the discussed technical procedure on products made of copper, aluminum, as well as those whose surfaces have paint and varnish and zinc coatings.

offers to order professional metal bending:

- Bending of rolled products at any angle

- High radius and angle accuracy

- Perfect processing quality

- Maintaining the technical characteristics of the design

- Short order execution time

Next, we will discuss the variety of this procedure in more detail.

This is radius bending of sheet metal, which is, in essence, plastic deformation to which sheet blanks are subjected at given angles with given radii.

It is used to produce a whole range of products: special profiles, elements of curtain walls, cornices, interior elements, metal furniture, cabinet parts, advertising stands, compensators, etc.

Favorable prices and modern CNC equipment will ensure high quality and short turnaround times for metal processing services. The preliminary cost of bending ferrous metal can be calculated by calling or through an application on the website.

Sheet metal bending

Such a popular procedure as sheet metal bending in St. Petersburg is carried out by a professional steel processing specialist.

Technologically, we can bend and laser cut metal up to 6 meters long and up to 17 mm thick. The bending angle can vary from 9° to 178°.

The discussed procedure is an alternative to other metalworking methods, for example, welding, cutting, riveting. Moreover, sheet metal bending in St. Petersburg, in comparison with the mentioned methods, has a number of advantages: savings in materials due to the complete absence of waste; maintaining the mechanical strength of products.

And also sheet metal bending in St. Petersburg (its price is affordable ) is characterized by the absence of any joints (seams, as in welding); maintaining product strength and anti-corrosion resistance; attractive appearance of products.

If you are interested in metal bending, the price of which will suit you, contact St. Petersburg. Our activities are related to the production and supply of rolled metal products.

In addition, we provide a wide range of services related to metalworking and sell construction materials.

All the services we provide and the goods we sell are of excellent quality and very affordable prices, and therefore working with us is pleasant, convenient and profitable!

How to bend a strip of metal into a circle? — Machine tools, welding, metalworking

page » Metalworking - metal bending

A series of articles devoted to metal processing continues on our website. We talked about how sheets and rolls from the delivery state are unraveled into strips (strips) in the article “Metal slitting lines.”

Types of bending of metal products

Metal bending is done manually and using automatic devices. In the first case, the process will be quite labor-intensive, requiring the use of pliers and a hammer, as a result of which this procedure will take a lot of time.

It will be much easier and better to mechanize the process with the help of machines and corresponding devices. The cylinder shape is given to the product by special rollers. With their help, chimneys, gutters, and pipe products are created.

The development of machine tool production has made it possible to achieve bending of material for the manufacture of the most complex products. And the quick replacement of the working tool allows you to reconfigure the machine device as efficiently and quickly as possible.

Types of equipment

For the modern metal bending process, there are many options for the latest devices. In production, presses are usually used , which can be divided into the following types:

- Rotary, bending metal by moving between special rollers. Suitable for the production of large-sized products in small batches.

- Rotary presses bend the plates using bending beams and two plates. The stationary plate is located at the bottom, and at the top there is a rotating plate. The optimal option for processing sheet metal products with a simple relief and small dimensions.

- Standard pneumatic or hydraulic presses are used for mass or small-scale products made of stainless steel or other metal. Bending is done between the punch and the die. Due to this, even thicker products can be processed. It should be noted that hydraulic presses are used more often than pneumatic ones due to their simpler operation and cost.

Of all the types of equipment described above, the most modern is rotary. It operates automatically, and the worker does not need to calculate the optimal force value in advance.

Rotary presses are also considered automated. Here one sheet is sent to the device, which must be positioned as required by the task. Most often used in small enterprises where they work with metal parts.

How to bend a sheet of metal evenly? Stages:

Tip: when bending parts, its thickness, ductility are taken into account and the radius of curvature is determined.

Metal bending technology

Bending sheet metal involves performing certain actions that cause the material to take the desired shape. The process of bending metal is performed without the help of welding or other connections that reduce the durability and strength of the material.

When folded, the outer layers of the product are stretched, and the inner layers are compressed. The technology is to bend one part relative to the other at the required angle.

During bending, the metal sheet undergoes deformation. Its value depends on the thickness of the product, ductility, bending angle and bending speed. The process itself is performed on equipment, due to which no damage is caused. If a part is bent incorrectly, various defects may occur on its surface, as a result of which the metal receives various damage along the bending line, which can lead to its breakage.

The bending stress must be greater than its stiffness limit. Plastic deformation may occur as a result of bending. Moreover, after the bending operation, the finished structure will retain the shape that was given to it.

Advantages of the process of smooth bending of metal sheets:

- High process productivity.

- As a result of bending, you can obtain a workpiece without a seam.

- The finished structure is highly resistant to corrosion.

- No rust will form at the bend.

- The design is solid.

- High strength.

- Special equipment is quite expensive.

- Manual bending is quite labor-intensive.

Unlike structures made by bending metal, welded structures have a weld that is susceptible to rust and corrosion.

Product bending is done manually or using special devices. Manual bending is a complex and time-consuming procedure that is performed using pliers and a hammer. If you need to evenly bend a sheet of metal of small thickness, use a mallet.

Bending of sheet metal is carried out using rollers, roller machines or a press. To shape the material into a cylinder, hydraulic, manual or electrically conductive rollers are used. Pipes are produced using a similar method.

Sheet metal bending is used for home construction purposes to produce gutters, metal frames, profiles, pipes and other structures. When bending the material with your own hands, you can make pipes of different diameters. Using machines, zinc-coated products are bent. To do this, you should make a machine, preferably using a template.

When bending any product, its parameters should be determined. The length of the structure is calculated taking into account the radius. For workpieces that are bent at right angles, without the formation of roundings, the allowance should be 0.6 mm of the total thickness of the sheet.

You can bend the following metals with your own hands:

The bending radius will depend on the quality of the metal and the bending option.

How to bend a sheet of metal evenly with your own hands?

To make brackets using the bending method, the following tools and materials are used:

- vice;

- a metal sheet;

- frame;

- hammer;

- power saw for metal;

- bar.

In advance, according to the scheme, the length of the workpiece strip is calculated and the bending of the metal sheet is calculated. For each bend, a reserve of 0.5 mm of thickness is made and 1 mm for bending the ends to the side. According to a pre-drawn diagram, the workpiece is cut out and the bending point is marked. In order to bend the material, use a vice with squares.

First, at the bending level, you need to clamp the workpiece in a vice. Then the first bend is made using a hammer. The workpiece is rearranged in a vice and clamped by the frame together with the block, after which a second bend is performed.

How to bend a sheet of metal evenly: making a machine with your own hands

In order to create a device that allows you to bend a metal sheet at home, you need to prepare the following materials and tools:

- corner 80 mm;

- bolts;

- metal beam I-beam 80 mm;

- loops;

- welding machine;

- clamps;

- handles;

- table.

All work begins with preparing the base of a homemade machine from a profile - an 80 mm I-beam. After this, an 80 mm corner is screwed onto the top of the I-beam with two bolts. During bending, it will secure the workpiece. Three hinges from steel doors are welded under the corner, the other halves of which are welded to the corner itself.

To perform bending, two 800 mm handles are welded to the corner, with which you can turn the machine. The sheet bender is pressed to the table using two clamps. The clamping angle is unscrewed. Then the workpiece is laid, and the corner is moved into place.

If necessary, it can be raised without removing it. After this, the material is threaded between the I-beam and the angle. The metal sheet is carefully aligned. The bolts are tightened and by turning the workpiece is bent to the required angle.

A homemade machine is not a universal device, since it is used for bending sheets of small thickness. If there is a need to bend material with a large thickness, you should use machines made in production.

Handmade

This work is usually done with hand scissors . Marks are placed in the right places along which manual bending of the metal will be carried out. The sheet is securely fixed in a vice. The first fold is made with a massive hammer. The product is moved to a new bend location, clamped with a block of wood, and bent in the desired direction.

Upon completion of the work, you must ensure that the product meets the established standards. The check is carried out using a square and, if necessary, defects are eliminated.