Plumbers recommend thoroughly rinsing the float with a hose at least once a month to prevent it from sticking to the pressure pipe or pump walls during daily operation. In such a situation, installation is performed using a special rod. It is worth noting that the ability to provide reliable protection for pumping systems during dry-running operation is not the only positive quality of such devices.

The tilt at which the ball moves from one position to another is most often 70 degrees, but you should check this when purchasing the device. Water level sensor in the container (tank) // Automatic filling of the container // In addition to this, a considerable amount of electricity is saved, since the float switch allows you to use the pump only when necessary. Light elements attract customers with a low price, but can only work in clean water intended for drinking and domestic needs. Due to the lack of pores on plastic cases, dirt appears on them.

They should be located on the sides of the body inside, so that the ball, falling between them, makes contact.

If the difference is more than a meter, two separate sensors are used, installed at the required heights. This type of sensor is most effective when working with bulk solids.

The voltage level is usually V.

Tackle for summer fishing rod. Sliding float and weight. My fishing.

Principle of operation

Drainage pumps are used in cases where there is a need to pump out liquids. They are especially important when working with liquids that have a significant degree of contamination. An example of the latter could be, for example, the contents of a sewer or dirty water with debris. The device will be especially useful when the main part of the liquid has already been removed, and what remains is its mixture with solid elements.

There comes a time when almost all the work is finished, and the pump is about to start pumping in a dry environment. If it is not stopped in time, it may result in breakdown. To prevent this from happening, the technician must carefully monitor the situation and turn it off at the right time.

Operating modes of the drainage pump Source nasosovnet.ru

Some designs include a float switch. It automatically detects the moment when there is no liquid left and turns off the pump itself. In this case, supervision by a specialist is not necessary.

There are different types of floats. Their design depends on what tasks they are intended for. Sometimes several types of switches are used simultaneously, each of which performs its own function.

Pumps with float switch Source nasosovnet.ru

Floats, for example, can be designed for the following:

- Main pump operation control.

- If there is an auxiliary one, a float switch can also be used for control.

- The level sensor sets the operating mode of the main device depending on the remaining volume of liquid.

- The overflow sensor is activated when the tank is completely full.

The float is a small hermetically sealed container with a mechanism that responds to changes in position. When such a sensor touches the bottom, the circuit breaker is triggered and the equipment is turned off. Sometimes information about the angle of inclination of the float can be taken into account, by which the existing liquid level is judged.

The switch in question can be remote, connected to the pump using a special cord. There are also brands where it is built-in. When choosing a suitable float model, you first need to determine for what purpose you plan to use it.

An example of using a float to supply water to a house Source nasosovnet.ru

Advantages of the device

Among the advantages of a float switch, the first thing to highlight is that this device can serve as a regular sensor for determining the water level in a tank. It performs this task regardless of the purpose of using the container and its volume. This device will make the operation of the pump more convenient and simplify control of the functions of domestic and industrial water supply systems. Sometimes it can be used to successfully drain fluid.

The switch can be an element as part of the equipment during the construction of sewer communications. Simplicity and efficiency have ensured its widespread use in a variety of systems where it is necessary to control water levels. The ability to protect pumping systems in dry running mode is not the only advantage of the devices. With their help, you can prevent situations where water overflows in containers.

Connecting the float to the pump

To make the connection, you need to adjust the length of the cord that connects the switch. Usually it is selected experimentally. During installation, you need to pay attention to securely fixing the cable. In this case, it is necessary to ensure that during operation it does not cling to foreign objects.

Some pumps may use two switches - one to turn off and one to start once the water has reached the required level. The operation of each of them will have to be regulated separately. In some cases more than two floats may be used. This is usually needed in situations where you need to control the execution of a corresponding number of actions.

Design of a drainage pump with a float switch Source nasosovnet.ru

To connect to the drainage pump, you must use moisture-proof terminals to ensure reliable connection. When choosing a switch, you need to take into account the amount of current consumed. It should be equal to or slightly less than that used when operating the pump.

By watching the video, you can learn more about the operation of the drain pump float switch:

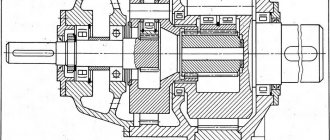

Device design

The floating plastic switch housing contains an electrical switch and a lever that moves the switch contacts. There is also a steel ball that adjusts the position of the lever when the float position changes. of three wires is connected to the switch , the first of which is common, and the rest are connected to the normally closed and open contact of the device.

The circuit is completed by the black and blue wires when the float is in the down position. When you move it to the top position, the brown and black wires become the closing contacts. The wire that does not provide connection to the device must be insulated.

It is important that the supply cable has moisture-proof properties; the plastic box must be sealed. The cable outlet is sealed using a mechanical seal, and it also has a special device that eliminates mechanical stress in the cable. The insulated cable gland cavity contains a polymer resin that prevents water from entering.

The chemical properties and heat resistance of the housing and cable sheath, made using thermoplastic rubber, determine the switch’s ability to withstand interaction with the following aggressive substances:

- uric acid;

- alcohols;

- fecal water;

- gasoline;

- other things.

Due to the lack of pores on plastic cases, dirt appears on them. Because of this, sand, paper and other solids slide off, and the float remains buoyant.

Characteristics of the water level control sensor:

- Maximum switching current, A;

- Mains voltage, V - 220±10%;

- 10A - for active loads (starters, lamps, switches, heating elements, etc.);

- 8A - for reactive load (compressors, pumps, fans, etc.);

- Operating temperature range: 0−60°C;

- Protection: IP 68.

Video description

Automatic float switch.

The connection method depends on the pump power. If this characteristic does not exceed 1.2 kilowatts, then a wire connection is used. For more powerful equipment, it is necessary to use special relays or similar switching devices for this purpose.

Pump with float Source nasosovnet.ru

Possible faults

In most cases, problems with float operation are caused by contamination. To restore serviceability to this unit, you need to rinse it under running clean water. If, despite the measures taken, functionality has not been restored, it is recommended to replace the mechanism. Carrying out repairs is not always profitable, since its cost can be comparable to the price of purchasing a new unit. The following are the most common types of breakdowns:

- Sometimes the float may get stuck. In this situation, it will remain motionless and will not be able to perform its functions. The worker must inspect the pump regularly and, if this occurs, release the float manually.

- The shock absorber may be loose. To repair, you will need to remove the cover and tighten it.

- During prolonged use, the cable may become frayed or otherwise damaged. To restore functionality, it will need to be replaced with a new one.

If the pump is seriously damaged, it must be taken into account that repairs in some cases can be more expensive compared to purchasing new equipment. Therefore, you need to choose from these options after finding out its cost.

The cable for connecting wires is filled inside with polymer resin Source dab-info.ru

The degree of equipment wear depends on the characteristics of its operation. The following factors may influence this:

- Equipment service life.

- Presence of large elements in the pumped liquid.

- Distance from the tank being drained.

If too hot water is pumped out, this can also cause damage.

A drainage pump can be used to drain the area Source makipa.ru

Preventative measures and regular maintenance

As you can see, the cause of wear of parts can be both inevitable wear and tear and violation of equipment operating rules. To make the device last longer, try to follow the manufacturer's recommendations. For example, position the housing so that the suction device is at a certain distance from the base of the tank and does not capture coarse particles.

At least once a year, check the serviceability of the cable and internal parts by disassembling the case as much as possible. Perform preventive cleaning, which will increase the service life of parts several times. Do not confuse the drainage device with the fecal one - it does not have a special grinder and cannot cope with the movement of large inclusions.

How to disable the float

Sometimes the float becomes completely unusable and cannot be repaired. In this case, it becomes necessary to disable it. To do this you need to do the following:

- This unit is part of the electrical system of the drain pump. Therefore, before carrying out work, it is necessary to turn off the equipment.

- After this, the wires are disconnected.

- Then you need to install a new one instead of the non-working switch.

After this, you can turn on the pump and continue to use it. Sometimes there is not enough time for this procedure. In such a situation, it is enough to connect the control wires directly, without using a float. In this case, automatic actions will not be performed, so constant control by the wizard will be required, carried out manually.

A drainage pump will help fill or drain the pool Source makipa.ru

Making your own float switch

If necessary, the device in question can be made with your own hands. To get started, you will need to prepare the following:

- A housing that must ensure tightness. It is usually made of two parts placed one inside the other.

- A metal ball that is necessary to control the operation of the device.

- Two magnets.

- Contact plates that will close when the device is triggered.

It is advantageous to make plates from copper or other material with good conductivity, since they must ensure reliable operation of the mechanism. When selecting magnets, you need to take into account their strength. It must be precisely selected to fix the position of the ball without being able to easily lift it.

For the body you can use plastic or textolite. It is important that it is made of a material that will not conduct electricity. The wires leading to the pump need to be soldered to the contact plates. It is enough to take ones whose cross-section is approximately equal to 2 square meters. mm.

There must be good insulation inside the float to prevent accidental operation. For this purpose, polyurethane foam is used. Loops are installed on one or both sides for connecting the cord. Depending on which one is selected, the device will be triggered to start or turn off the equipment.

This video describes in detail the disassembly and repair of the drainage pump:

How to choose a float switch

First you need to decide what use the sump pump is for. Next, you need to clarify how many switches are needed. Most often we are talking about a single or two-phase device.

When purchasing, you need to make sure that the float box is completely sealed and the wire insulation is of high quality. These features are important to ensure the reliability of the switch. Sometimes the kit includes devices for relieving tension from the float wires during operation.

Detailed design of the drainage pump Source makipa.ru

Drainage pumps - types, design and characteristics, selection rules, repair details

A drainage pump, the design of which allows for pumping heavily contaminated liquid media, is now part of the arsenal of many owners of country houses and summer cottages. Such a compact, easy-to-use, but at the same time effective device is able to solve many problems associated with the need to pump out contaminated liquid media both from open areas and from well shafts, various premises located below ground level (basements, cellars, etc.) .d.). The most optimal option for equipment for this purpose is a drainage pump with a built-in float, the operation of which can be easily automated, which minimizes the risk of emergency situations.

The name of this category of pumps comes from the word “drainage”, which means drainage, pumping out groundwater or other contaminated non-aggressive liquids