In the case of a submersible pump, its housing is completely sealed, which allows it to be completely enclosed in liquid without causing damage to the device itself or performance. Such pumps are characterized by much greater power, since in addition to simple pumping, they also must raise the liquid to a certain height. And for this you need high pressure. If we compare them with surface-type pumps, submersible ones have the following advantages:

- Complete versatility. They are capable of pumping out contaminated water containing large elements.

- Considerable level of productivity.

- During operation, the device makes virtually no noise.

Flaws:

- Limitations regarding the immersion depth, which will be 30 cm. In addition, the motors of such equipment require constant cooling, and for this the device must be surrounded by liquid.

- The device needs to be cleaned from time to time, as does the float switch. Constantly being in dirty liquid, they become dirty very quickly.

- Repair work is difficult since the body of the float drainage pump is completely sealed.

Purpose of drainage pumps

Floatless drainage pumps are a necessary unit for use on personal plots and cottages - they relieve their owners from many problems associated with excess wastewater and groundwater. The devices are used to drain atmospheric precipitation, pumping melt water from cellars, wells, basements, ditches and ditches. Also, a floatless pump is used to pump water from swimming pools, artificial reservoirs, and pits. There are models whose design allows you to pump out dirty water. An average-power drainage pump is capable of pumping out about 180 liters of water per minute. The performance of the unit decreases in the process of immersion and removal of its location from the pumping site. Unfortunately, most sump pump models are not designed to handle hot water.

What material is used to make devices

Often, modern models of float drainage pumps are made from cast iron and stainless steel in combination with other materials that will be needed to assemble the device body and other necessary parts. They are subject to a fairly simple comparison:

- stainless steel. A fairly reliable and time-tested material with a service life of decades;

- cast iron. The strength of a device made from this material will be amazing, but its weight will be enormous, and the cost will be quite high;

- plastic. It is the cheapest material, the durability of which is low.

Equipment whose body is made of plastic, while the wheel itself is made of steel, is in considerable demand. It is excellent and the best value for money. Relatively recently, several models of these units entered the market, the working blades of which are made of technical polymer. They are cheaper than their high-tech counterparts. They are characterized by durability, strength and practicality.

Operating principle of drainage pumps

The design of the drainage unit provides for the presence of two pipes:

- inlet - through it, liquid is sucked from the filled container;

- output - through it, water is diverted outside the land plot. Liquid must not be allowed to enter the engine, as this could cause the device to break. The pump must pump wastewater faster than its level in the pit rises.

Drainage pumps are connected to the sewerage system using pipes. For this reason, when installing the unit, it is necessary to know the exact (to the millimeter) parameters of the sewer pipe. The main advantage that floatless drainage units have is mobility - the equipment can be moved to any place where it needs to be used.

Application area

Most country and private houses are equipped with autonomous water supply and sewerage systems. The main working element of the entire network is drainage pumping stations. The durability of the building depends on the power and performance of this segment.

Using a pump, the main purpose of which is to perform drainage, you can implement the following list of tasks in everyday life and industry:

- pumping liquid from natural swamps and reservoirs;

- pumping liquid from flooded areas or premises after heavy rainfall, rising groundwater levels, and melting snow;

- pumping contaminated liquids from one tank to another;

- pumping water from pits and trenches that were created during construction;

- cleaning the bottom of wells and mines from contamination;

- drainage of low-lying areas.

The equipment is quite versatile in use, as it allows you to perform a large amount of different work.

How to install a float

When installing a drainage pump with a float switch, the installation procedure for the device begins by checking the amount of current consumed by the unit. It should be less than the maximum permissible, which is indicated in the operating instructions for the float. The easiest and fastest way to install it is directly in the container. To do this, use a float with a cable and a weight included in the kit:

- the last product is put on the cable and the parameters of the free movement of the float are determined experimentally;

- the weight is fixed on the cable using a latch;

- the cable is securely fastened outside the container;

- A float switch is connected to the pump.

The float must only be installed on the supply cable if there is no danger that it could get stuck or get caught inside the container.

If several floats are placed in one tank, they are placed on a special rod, which is used as a piece of plastic pipe, and only then attached. To do this, you need the following device data:

- expose;

- adjust;

- place along the entire rod so that they do not interfere with one another and perform their functions correctly;

- The cables coming from the float switches are secured to the rod using clamps. You can see how it looks in the photo.

When a float pump is used, the number of these devices depends on the type they are and the control panels used. Also, the number of float switches is selected based on how many drainage devices and protective elements it is decided to install. There are times when for high-quality operation of the floats it will be necessary to use several rods. The number of float switches and their installation location are determined based on the design solution or directly during the installation process.

Brands

Sewage pump: features, choice

Among domestic brands it is worth paying attention to:

- "Vortex";

- “Bison”;

- "Caliber".

They may be produced in China, but with good quality.

Among the foreign options that deserve attention:

- Japanese brand “Makita”, manufactured in China;

- German brand “VMtec” or “Karcher”;

- Spanish brand “ESPA”.

There are a huge number of options; when choosing, it is important to monitor the country of origin and reviews of the chosen model. Buy high-quality original pumping equipment and enjoy trouble-free operation for a long time!

Buy high-quality original pumping equipment and enjoy trouble-free operation for a long time!

Operating principle of a float switch

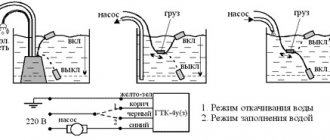

How does the float switch work when filling and emptying a container? This process is carried out as follows:

- a drainage pump with a built-in float when filling the tank turns off the switch upon ascent, when the filled tank becomes full. When lowered to the bottom, the device will turn on when the tank is empty;

- The automatic water station will be turned on when the float switch is on the surface and the tank is full. The device will turn off the station when the float sinks to the bottom and the container becomes empty;

- the switch will give a command to close the valve or valve with a servo drive in case of lifting to the surface. In this case, the tank will fill. When lowered to the bottom, the valve or latch will open and the container will become empty.

When used in a sewer system, the float will turn on the fecal drainage pump if it floats to the surface because the well is full and will turn off the unit when it sinks to the bottom because the tank is empty (pro

Varieties and design features

All drainage pumps are divided into two categories:

- superficial;

- submersible

There is also an intermediate category - semi-submersible drainage electric pumps, but they are used quite rarely for domestic purposes. To know which drainage pump to choose to solve a particular problem, you should become more familiar with each of its types.

Superficial

Surface-type drainage pumps, as their name suggests, are installed and operated on the surface of the earth, while a hose (or pipe) connected to the suction pipe of the device is lowered into the liquid medium to be pumped. This is a more powerful drainage pump when compared to a submersible one. This type of pump can be used in conjunction with a float, which is also called a liquid level sensor in the tank. When equipped with level sensors, pumps of this type are switched on automatically when the amount of liquid in the tank being serviced is exceeded, and they are switched off when the liquid is pumped out to the required level.

Example of installation of a surface pump

The design of a surface type drainage pump is:

- drive motor, the rotation of the shaft of which is transmitted to the rotor;

- the rotor itself;

- impeller (impeller) mounted on the rotor.

The operating principle of the drainage pump of this type is as follows. The impeller, rotating in the internal working chamber, creates excess pressure of the pumped liquid medium, which contributes to its ejection through the discharge pipe. The performance of surface-type pumps directly depends on both the volume of their working chamber and the power of the engine driving the impeller.

Surface pumping station for collecting irrigation water from an open reservoir

Let us list the advantages of surface-type drainage pumps with or without a built-in float.

- The technical characteristics of pumps of this type allow them to create a good pressure of the pumped liquid medium.

- The operation of surface-type pumping equipment is carried out under more gentle conditions than the use of submersible drainage pumps, therefore they are distinguished by a longer operating life.

- While surface sump pumps are more reliable than submersible models, they are also cheaper devices.

- Equipment of this type is distinguished by its rather low energy consumption, which makes its use more economically profitable.

- Surface-mounted pumps are very mobile: they can be easily and quickly moved to any location.

For greater protection, the pump housing is made of materials that are resistant to wear and aggressive liquids

It is also important that the repair of surface-type drainage pumps, if necessary, is much easier to carry out, which is also explained by their design features and operating conditions. If the malfunction of the surface drainage pump is minor, then you can fix it yourself. Videos that are easy to find on the Internet can help with the question of how to disassemble the drainage pump in such a situation.

If we talk about the disadvantages of surface-type drainage pumps, the most significant of them are:

- restrictions on the depth of the underground tank (up to 8 meters), from which liquid media can be pumped using pumps of this type;

- significant noise generated during the operation of pumping devices of this type.

If you plan to use this relatively cheap but at the same time reliable drainage pump to pump a liquid medium, you should not only prepare the site for its installation, but also take care to protect its drive motor from moisture.

Submersible

A submersible drainage pump is a deep-well pump, the body of which is completely located in the thickness of the pumped liquid medium. How does this type of sump pump work? When using it, liquid is sucked in not through a hose or pipe, but through a special hole in the lower part of the body. To immerse the hydraulic machine to the required depth (50–100 cm from the bottom of the underground tank), a cable is used, with the help of which the device is held in the required spatial position.

If you look at a submersible drainage pump in a disassembled state, then its design can be distinguished into two separate parts:

- power unit, the basis of which is the drive electric motor;

- pump part, which, like the power unit, is built into the body.

Submersible drainage pump design

Since a submersible pump is constantly in a liquid environment, its housing is completely sealed, which allows you to reliably protect the power unit from moisture entering it. It is sometimes impossible to disassemble submersible drainage pumps, since their housing is usually made monolithic. The characteristics of submersible drainage pumps provide for the maximum size of solid inclusions contained in the pumped liquid medium. To meet these requirements, the suction port of submersible pumps is equipped with a strainer with cells of the appropriate size (usually no more than 5 mm in cross section).

The strainer of a household drainage pump is usually a plastic cover with slots of a certain size.

Choosing a drainage pump allows you not only to review submersible models, but also to study the advantages that such equipment has. Among the latter it is worth mentioning:

- compact size and light weight;

- high reliability achieved by equipping the equipment with a sealed housing.

- versatility in terms of functionality (submersible drainage pumps, due to their design features, cope well with pumping both lightly and heavily contaminated liquid media);

- high productivity, the value of which can reach 40 m3/hour;

- almost complete absence of noise during operation.

Since submersible pumps are constantly in the liquid medium they pump, the elements of their internal structure are better cooled during operation.

A review of submersible pumps allows us to identify their two most significant disadvantages.

- Such hydraulic machines create an insufficiently high pressure, especially when pumping out a liquid medium from a considerable depth.

- When using models with a monolithic body, it is impossible to repair the drainage pump yourself or even by specialists from service companies.

Thus, it is impossible to definitely call drainage pumps of one type or another the best. They should be selected based on the list of tasks for which they are planned to be used, and focusing on the technical characteristics of this equipment.