Article reading time: 20 minutes

Author of the article:

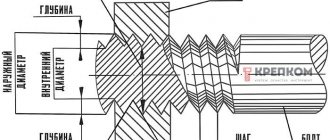

Bolted connections are widely used in construction, mechanical engineering, instrument making, and many other industries. Their distribution is associated with the possibility of fastening most parts and structural elements, ease of assembly and disassembly, wide availability of tools for installation, unification and interchangeability of fasteners, and other advantages.

Threaded connections allow for reliable fastening, designed for significant static loads. However, they are characterized by insufficient resistance to vibration and alternating loads. They cause a gradual decrease in the tightening force. As a result, self-unscrewing of fasteners is observed. This can lead to serious consequences, including destruction of structures, failure of mechanisms, and accidents.

To prevent self-unscrewing, bolted connections include additional special elements - self-locking nuts and lock washers. Parts of the second type are used most often. To install reliable connections, you need to know what types of lock washers there are and in what cases they are used.

Types of lock washers

All lock washers are divided into several main types:

- grower's room;

- toothed;

- disc-shaped;

- with protrusions and paws;

- with notches and corrugations.

- wedge washer (nord-lock type).

Among them, the most widely used are groove washers .

They are rings with cuts made in such a way that their ends are in different planes.

Since bushing washers are made of spring-loaded steel, after installation they are subject to elastic deformation, due to which they prevent spontaneous unscrewing of threaded connections.

All bushing washers have a square cross-section and can be manufactured with or without anti-corrosion coating.

Serrated lock washers can have either a flat or conical shape, and their teeth, depending on the type of fastener, can be either external or internal.

They are divided into three types: A, J, V. As you can easily guess from the name itself, disc lock washers have the shape of discs, and the rest have notches, corrugations, claws and protrusions.

How does a Grover washer work?

The grower is installed under the nut or under the head of a bolt (screw). The principle of operation of the grower is based on the fact that when the nut is rotated (clockwise), the sharp edges of the cut do not prevent the washer from being fully compressed.

As a result, an elastic tension is created in the thread turns, which creates additional guaranteed friction between the threads, preventing spontaneous unscrewing of the fastener.

In addition, spontaneous unscrewing (counterclockwise rotation) is prevented by the sharp cutting edges of the spring washer cutting into the base material.

Lock Washer Standards

In Russia, all lock washers are produced in accordance with GOST 13463-77, according to which steel must be used for their manufacture, the hardness of which ranges from 41.5 to 49.5 HRB.

In cases where bronze is used for this purpose, this indicator should be twice as high. The cut edges of groovers must be sharp, and the surfaces of lock washers of other types must be free of burrs, cracks, signs of corrosion and scale.

The quality of these fasteners is checked in accordance with GOST 17769-83.

During this process, several products are selected from each batch produced in order to check their appearance, dimensions, quality of coating (if any), viscosity, hardness and springiness.

Recommendations for choosing a washer-grower

When choosing, you should consider that:

- The bore diameter and winding direction of the washer coil must correspond to the diameter and thread direction of the bolt. This is usually right-handed (clockwise). On the market you can find washers for fastening left-hand threads;

- The type of washer (N, T, OT or L) must correspond to the expected loads on the fastener;

- Having chosen the type of grower, select a calibrated wrench (screwdriver) with a calibrated torque corresponding to the type of washer;

- The thickness and type of galvanic coating must satisfy the operating conditions of the mechanism. If there are none, select in advance the type of additional coating (grease, paint, glue).

Installation and removal of lock washers

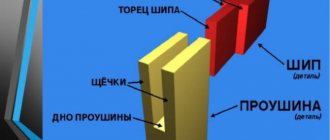

In order to install a lock washer, it is placed between the head of a threaded fastener (bolt, screw, etc.) and the surface into which it is screwed.

When the connection is tightened, it contracts, which is prevented by its elasticity.

As a result, a friction force is created that prevents the connection from self-unwinding.

Since the strength of the connection using lock washers is quite high, dismantling them is a more difficult task than installing them.

It should be noted that in some cases this requires the use of tools such as a hammer and chisel.

The main task is to slightly move this fastening element from its place, as a result of which the connection will loosen, and the threaded element can simply be unscrewed.

Another method is to use pullers designed specifically for “eliminating” lock washers and rings from connections.

However, it should be borne in mind that their use almost always leads to damage to these parts.

What is such a puck supposed to stop?

What can we do with such a locking connection? The main structural elements of these washers include the presence of teeth, tabs, notches, as well as a variety of shapes (grower, curved, disc-shaped and wavy). The material used for manufacturing is special spring steel. Unlike flat washers, lock washers provide sufficient contact area with the threaded surfaces, which prevents unscrewing. In fact, any washer that is not flat can be safely classified as a lock washer. Their use is envisaged in almost all connections.

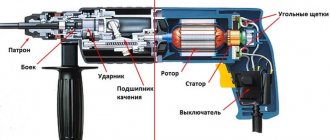

When should you use lock washers ? These are situations in which during operation of the connection there is a possibility of exposure to large external loads, especially vibration ones. These conditions can cause the threaded connection to loosen or become loose, which this washer will not allow. This also includes the situation when they are used simply as insurance to provide additional strength and greater reliability. From this the following conclusion is drawn: locking washers can and should be used in any threaded connection, provided that the design conditions of the product or device provide such an opportunity.

The prospect of using a washer-grower

About 20 years ago, German, followed by American and British researchers, came to the conclusion that in many modern mechanisms and structures with increased vibration and dynamic effects, traditional lock washers do not provide sufficient protection of fasteners from spontaneous unscrewing.

This is explained by the fact that:

- After the final tightening of the nuts and bolts, the groover turns into a simple washer, which gives only a slight tension in the threads, only slightly increasing the friction force;

- The effect of “biting” the ends of the cut into the base material, especially if it is not hard, when unwinding is insignificant;

- Significant residual deformation of the Grover washer after disassembling the connection does not allow its reuse.

As a result, the use of Grover washers in critical mechanisms and structures is prohibited.

You can make sure that these recommendations are followed by looking at modern examples of European technology - there is no grower there.

Instead, it is recommended to use other spring washers, special nuts, and other locking methods.

NORD-LOCK washers

NORD-LOCK washers are progressive fasteners in threaded connections. Its use prevents the connection from self-unwinding. The special design of such fasteners not only prevents spontaneous unscrewing, but also maintains pre-tension in the connection.

The NORD-LOCK fastener uses a wedge-locking effect to maintain the strength of the connection. The basis for fixing a connection with the help of such hardware is primarily pre-tension (in conventional friction). Structurally, the NORD-LOCK washer consists of 2 washers, the lower and upper sides of which are shaped like teeth (wedges) that prevent spontaneous unscrewing. Thanks to the cone-shaped shape, the pre-tension is maintained in the connection for a long time, even if the bolt and nut are made of a “relaxing”, soft material.

The Krepcom online store offers you to buy washers, bolts, nuts, studs and other fasteners at attractive prices. We have a large selection of payment methods, sending goods by transport companies to any city.

Articles about products Updated: 12/03/2020 16:42:45

Varieties and selection criteria

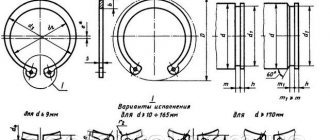

Growers are produced in two versions: simple and complex . The first is distinguished by different spring diameters and heights, but the deflections of the coils are always at the same angle to the center line. Complex parts are used for loaded connections and differ in design.

There are four versions of bushing washers with a square cross section:

- normal - designation N;

- heavy - T

- especially heavy - OT.

There is also a light version , its cross section is made in the form of a rectangle, it is designated by the letter L. The models differ in their load-bearing capacity and the force of deformation at which the gasket is deformed.

When choosing, take into account the thickness of the insert and the size of the gap between the cut ends. Select the gasket according to the diameter of the stud, screw, bolt along the external thread. The quality of the coating and the accuracy of processing are also important. Cracks, areas of corrosion, and scale are not allowed. Such effects are resolved only at the cut sites.

Design

The spring washer is similar in appearance to an incomplete turn of a spiral. The location of its ends, located in different planes, is of fundamental importance.

In the working position, the gap is oriented in the direction of the rotational movement carried out when tightening the fastener. This design solution reduces the possibility of loosening the connection to a minimum, since the washer acts as a stopper.

What can be replaced

Self-locking nut

The locking washer can be successfully replaced with other designs:

- self-locking nuts - the fastener contains a circular plastic plate, which collapses under load and prevents the nut from unscrewing;

- a disc-type washer is also suitable for replacement and is inexpensive;

- a crown nut is used when a hole for a cotter pin is needed;

- The toothed flange has notches for a tight fit with the nuts.

Belleville washer

Crown nut Serrated flange

There are many stopper options, so there is always a choice based on technical properties, strength and application conditions.

Why is a washer needed in fastening joints?

The installation of the washer can be omitted when creating fasteners. However, in this case there are risks in operating the entire structure. The washer increases the maximum permissible loads on structures. Even with constant exposure to vibration, shock, shaking, the washer fixes the position of the part and prevents unwinding. The range of applications for washers is quite large - from furniture elements with minor loads to aircraft wings, where the reliability of fasteners is put above all else.

When using washers, you can increase the service life of the product, slow down wear, reduce the risk of damage and other deformations. Based on this, you need to understand the importance of using washers.

Advantages and disadvantages

1. Possibility of obtaining a strong threaded connection that is resistant to vibrations;

2. High strength and wear resistance of washers;

3. Small weight and size;

4. Very low price even compared to other fasteners;

5. Ease of use;

6. Resistance to moisture due to the presence of an anti-corrosion (usually galvanized) coating;

7. Versatility of application.

This product has few disadvantages. The main ones are the following:

1. If there are very high loads on the engraving washer, over time it becomes flat and the tension force decreases significantly;

2. Reuse is practically impossible due to the presence of residual deformation;

3. If you use soft metal bolts or screws, the edges of the washer may damage the threads.

Technical requirements

GOST 6402-70 also prescribes the rules that must be followed by the manufacturer of spring washers. Below are just some of them.

- The raw material for the manufacture of these products must be wire that meets the requirements of GOST 11850, adopted in 1970. It is also allowed to use blanks made from alloys of the following grades: heat-resistant, corrosion-resistant high-alloy structural steel 3X13; spring-spring structural steel 65G; unalloyed spring structural carbon steel 70; bronze grade BrKMts3-1 or other non-ferrous alloys.

- The hardness index, determined by the Rockwell method: steel spring washers, must be in the range of 40.0...41.5≤HRC≤48.0...49.5; bronze growers must have at least 90HRB

The hardness of growers made from grade 70 steel can be increased to 50.0≤HRC≤51.5.

- The surface of the products should not contain traces of corrosion, signs of cracking, flash residues - burrs, as well as scaly particles - scale. At the same time, the remains of inseparable scale do not classify the product as defective.

- The cut at the ends of the turns of the washers should be flat. Metal chips that do not bring the value of parameter “m” (see design drawing No. 1) beyond the limits of permissible deviations are not included in the number of rejection criteria.

- The edge formed by the supporting surface of the product and the cutting plane should be as sharp as possible.

- The trapezoidal configuration of the cross-section of the spring washer, which does not go beyond the parameters “s” - in the drawing this is the height of the coil, is not considered a defect.

- The bushing should not crack or break if the ends are bent at an angle of 45°.