The use of an air pneumatic relay allows you to automate the filling of the compressor receiver with compressed gas. The operator of equipment with a pressure switch does not need to monitor the process, trying to fix the limit parameters. As a result, engine damage is prevented. Significant results, right?

If you are planning to purchase a pressure switch for your compressor, then you have come to the right place. Here you will find a vast amount of extremely useful information about the principles of operation of the device, its configuration and connection methods.

We have described in detail the existing types of pneumatic relays. They provided options for connecting to a household and industrial network with extremely clear diagrams. We looked at typical breakdowns and ways to prevent them. The information and useful tips we provide are supplemented with graphic, photo and video applications.

Operating principle of a pressure switch

The name of the relay is determined by its purpose - controlling a piston compressor to maintain the required atmospheric pressure in the receiver. It is rarely found on a screw type device responsible for compressing and supplying air.

I take into account the magnitude of the pressing force in pneumatic automation; the device acts on the voltage line, closing or opening it. Thus, insufficient pressure in the compressor starts the motor, and when the required level is reached, it turns it off.

This standard operating principle, based on connecting a normal closed loop to a circuit, is used to control the motor.

The design of all ejectors contains a cylinder containing air at a certain pressure. Reducing it requires turning on the engine to replenish the supply. If the situation is the opposite and an excess is detected, the supply is stopped so that the container does not burst. These processes are controlled by a pressure switch

Modifications with the opposite operating algorithm are also presented: when reaching minimum values in the compression circuit, the pressure switch turns off the electric motor, and at maximum values it activates. Here the system operates in a normally open loop.

The operating system is made up of spring mechanisms with varying degrees of rigidity, reproducing the response to fluctuations in the air pressure unit.

During operation, the indicators formed as a result of the elastic force of tension or compression of the springs and the pressure of the atmosphere pressed by the device are compared. Any changes automatically activate the action of the spiral and the relay unit connects or disconnects the electricity supply line.

However, it is worth considering that the design of the review model does not provide for regulatory influence. Exceptional impact on the engine. In this case, the user has the opportunity to set a peak value, upon reaching which the spring will fire.

Homemade production

A homemade pressure switch is very difficult to manufacture. Complex technologies and excellent knowledge are required. The mechanism is triggered when electric current passes through certain elements. At certain current values they heat up and turn the device on or off. Even with extensive experience, such a mechanism is difficult to manufacture. For homemade compressors, relays from old refrigerators are used.

The pressure switch for the compressor wears out when working in difficult conditions and fails. Repairing it is unprofitable and difficult. It is more profitable to simply buy a new relay. There are inexpensive models. If you choose branded devices, then for that kind of money it is better to buy a new compressor.

An air compressor is a universal tool that is necessary for various repair and construction work.

Homemade pressure switch from the refrigerator

A pneumatic device is safe and convenient, unlike a gasoline or electric one. There are also additional devices that work with air under pressure: tire inflation guns, paint guns, wash guns, blow guns, extension cords and others.

Using a relay for the compressor, the system operates automatically; the required pressure in the receiver is constantly maintained.

Complete set of compressor automation unit

The relay design is a small-sized block equipped with receiving pipes, a sensing element (spring) and a membrane. Mandatory subassemblies include an unloading valve and a mechanical switch.

The pressure switch sensing unit is made up of a spring mechanism, the compression force of which is changed by a screw. According to the factory standardized settings, the elasticity coefficient is set to a pressure in the pneumatic chain of 4-6 at, as reported in the instructions for the device.

Inexpensive models of ejectors are not always equipped with relay automation since such devices are mounted on the receiver. However, during long-term operation, to eliminate the problem of overheating of engine elements, it makes sense to install a pressure switch

The degree of rigidity and flexibility of the spring elements is subject to the temperature of the environment, therefore absolutely all models of industrial devices are designed for stable operation in an environment from -5 to +80 ºC.

The reservoir membrane is connected to the relay switch. During movement, it turns the pressure switch on and off.

The unloading unit is connected to the air supply line, which allows excess pressure to be released into the atmosphere from the piston compartment. This relieves the moving parts of the compressor from excessive force.

The unloading element is located between the ejector check valve and the compression block. If the motor drive stops working, the unloading section is activated, through which excess pressure (up to 2 atm) is released from the piston compartment.

With further start or acceleration of the electric motor, a pressure is created that closes the valve. This prevents overloading of the drive and simplifies starting the device in switched off mode.

There is an unloading system with a time interval of activation. The mechanism remains in the open position when the engine starts for a specified period. This range is enough for the engine to achieve maximum torque.

A mechanical switch is required to start and stop the automatic system options. As a rule, it has two positions: “on.” and "off". The first mode turns on the drive and the compressor operates according to the established automatic principle. The second one prevents accidental starting of the engine, even when the pressure in the pneumatic system is low.

Shut-off valves allow you to avoid emergency situations when elements of the control circuit fail, for example, a breakdown of the piston unit or a sudden stop of the motor

Safety in industrial structures must be at a high level. For these purposes, the compressor regulator is equipped with a safety valve. This ensures system protection in case of incorrect relay operation.

In emergency situations, when the pressure level is higher than the permissible norm, and the telepressostat does not work, the safety unit comes into operation and vents the air. Safety valves in heating systems operate according to a similar scheme, the operating principles and devices of which are described in the article we recommend.

Optionally, a thermal relay can be used as additional protective equipment in the review device. With its help, the strength of the supply current is monitored for timely disconnection from the network when parameters increase.

To avoid burnout of the motor windings, the power is turned off. The nominal values are set using a special control device.

How to check the compressor for performance?

In order to determine whether the device is functioning or not, you need to prepare a tool - a multimeter. Before fixing the terminals of the device, you must make sure that the body of the device is not energized, otherwise the technician runs the risk of electric shock.

If everything is normal, then you will need to apply the terminals of the device to the contacts one by one. The device is considered working if “∞” is displayed on the screen. If an incomprehensible set of numbers is displayed, then there are winding faults.

In order to continue testing the equipment, it is necessary to dismantle the compressor. So that you can understand how to do this, let's look at the process in more detail.

Dismantling the compressor: step-by-step instructions

Step one: first you need to disconnect the conductors from the contacts.

Use wire cutters to disconnect the engine pipes.

Step two: now you need to unscrew the fasteners.

You will have to unscrew the screws to get the relay out.

Step three: next we need to determine the degree of contact resistance. The terminals of the device should be connected to the output contacts. If everything is normal, then the value should be 30-35 Ohms (this depends on the type of device). If a value is obtained that is not within the normal range, the component should be replaced.

If the value does not deviate from the norm, then test with a pressure gauge:

- Connect a hose with a branch to the blower.

- Turn on the engine.

- Check the pressure.

Compressor pressure measurement process

If the compressor is working properly, the pressure will be within six atmospheres. Therefore, when testing, you should immediately turn off the pressure gauge. Otherwise, high pressure will cause it to break. If the compressor does not work, the pressure will remain within four atmospheres, so the component will need to be replaced.

If the pressure remains normal and the device does not function, then most likely the problem is a faulty start relay.

Replacing the compressor: step-by-step instructions

Replacing a compressor is a complex process that requires certain skills from the technician. However, if you decide to do it yourself, then you must follow the steps of the instructions.

Step one: you need to prepare the tools that will be needed for the job. This includes the following:

- oxygen-propane burner;

- pliers;

- freon storage;

- valve;

- portable refueling devices;

- pipe cutting device;

- clamps;

- a cylindrical device for high-quality connection of the device with the pipe during refueling;

- copper tube;

- filter for installation in a pipeline;

- refrigerant cylinder.

Tools that will be required during the work process

Step two: Next you need to release the refrigerant.

You can do this in the following way:

- Using pliers, pinch the tubes that connect to the cooling system. At the same time, such work should be done carefully, because if you saw off the tubes with force, dust will form, which can get into the condenser and damage the elements.

- Then turn on the refrigerator for five minutes. This time is enough for freon to condense.

- Then the hose that comes from the cylinder should be connected to the filling line.

- Then open the valve on the cylinder to collect the refrigerant. Typically this takes less than 60 seconds.

- Next, you need to disconnect the relay block with wiring (dark box).

- Leave the markings to install it correctly.

- Then, using pliers, you need to remove the clamps.

- Next, you need to disconnect the wiring that goes to the plug.

- Then you can unscrew the device.

- The tubes must now be cleaned before installing another device.

It is necessary to bleed off the freon

Step three: Now you should check the degree of resistance again. You will need an ohmmeter here. As in the previous case, it is necessary to alternately apply the terminals of the device to the contacts. The resulting values must be checked against the nominal values for the specific device.

If the measurement is made with a charging device, then the following manipulations must be performed:

- Attach the negative terminals to the 5 V lamp body.

- Secure the positive terminals to the winding from above.

- Touch the ends of the winding one by one with the base.

If the device is working, the light should light up when touched.

Measuring resistance

Step four: now you need to measure the current. First, the device checks the start relay connected to the engine. After which the terminal must be connected to the device. The obtained values must correspond to the motor power. If its power is 130 V, then the current will be 1.3 A.

Measuring device

Step five: installing a new compressor. The first step is to fix the new device on the crossbar of the refrigeration unit. You will have to remove the plugs from the tubes to complete the installation. Next you have to measure the pressure.

Types of pressure switch devices

There are only two variations in the design of the automatic compressor unit. The determination is made based on their operating principle. In the first version, the mechanism turns off the electric motor when the established limits of the air mass pressure level in the pneumatic network are exceeded. These devices are called normally open.

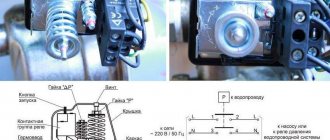

Schematic structure of a membrane pressure switch: 1 – pressure converter; 2 and 3 – contacts; 4 – piston; 5 – spring; 6 – membrane; 7 – threaded connection

Another model with the opposite principle - turns on the engine if a drop in pressure is detected below the permissible level. Devices of this type are called normally closed.

Adjusting the compressor pressure

As mentioned above, after creating a certain level of air compression in the receiver, the pressure switch turns off the unit’s engine. Conversely, when the pressure drops to the switching limit, the relay starts the engine again.

Important! By default, relays, both single-phase devices and units operating from a 380 V network, already have factory settings. The difference between the lower and upper engine start threshold does not exceed 2 bar. It is not recommended for the user to change this value.

But often situations that arise force you to change the factory settings of the pressure switch and adjust the pressure in the compressor at your discretion. You can only change the lower switching threshold, since after changing the upper switching threshold upward, the air will be released by the safety valve.

Read also: Specification sheet sample filling procedure

Pressure adjustment in the compressor is carried out as follows.

- Turn on the unit and record the pressure gauge readings at which the engine turns on and off.

- Be sure to disconnect the device from the power supply and remove the cover from the pressure switch.

- After removing the cover, you will see 2 bolts with springs. The large bolt is often designated by the letter “P” with the signs “-” and “+” and is responsible for the upper pressure, upon reaching which the device will be turned off. To increase the level of air compression, turn the regulator towards the “+” sign, and to decrease it, turn towards the “-” sign. First, it is recommended to make half a turn with the screw in the desired direction, then turn on the compressor and check the degree of pressure increase or decrease using a pressure gauge. Record at what indicators of the device the engine will turn off.

- Using a small screw you can adjust the difference between the on and off thresholds. As mentioned above, it is not recommended that this interval exceed 2 bars. The longer the interval, the less often the device’s engine will start. In addition, the pressure drop in the system will be significant. Setting the on-off threshold difference is done in the same way as setting the upper on-off threshold.

In addition, you need to configure the gearbox if it is installed in the system. It is necessary to set the compression level on the gearbox to a level that corresponds to the operating pressure of the pneumatic tool or equipment connected to the system.

Finished compressors are delivered to customers with factory settings. Developers optimize the operating mode of the unit to extend its life, increase productivity and simplify maintenance. Sometimes it is necessary to decide how to configure a compressor so that it meets operating conditions that differ from conventionally standard ones. Manufacturers allow some changes, describing in the instructions exactly which settings can be adjusted.

Structure of pneumatic relay symbols

The marking of the air pressure switch indicates the entire optional set of the device, design features, including information about the factory settings for the pressure differential.

Condor's production models offer a wide range of pressure control equipment. The MDR series is aimed at using ejectors of various powers

Let us examine the designations in more detail using the example of devices for air ejectors RDK – (*) (****) – (*)/(*):

- RDK – series of relays for compressors;

- (*) – number of threaded ports: 1 – one port with 1/4”NPT internal thread; 4 – four connectors;

- (****) - type of housing design: T10P - version 10 with a “lever” switch; T10K – “button” switch; T18P – execution 18 with a “switch” switch; T19P - 19 s;

- (*) – factory settings of the threshold response: 1 – 4…6 bar; 2 – 6…8 bar; 3 – 8…10 bar;

- (*) – diameter of the unloading valve: the absence of a symbol means a standardized parameter of 6 mm; 6.5 mm – 6.5 mm.

The difference between the minimum and maximum pressure thresholds is set by the manufacturer and, as a rule, has a value of 2 bar.

However, it is also possible to manually adjust the range of two values – maximum and minimum, but only downward.

The specifics of setting up pressure switches for pumping stations are outlined in the following article, the contents of which we recommend that you familiarize yourself with.

Connection and setup

The general diagram of the compressor installation shows that the pressure switch is located between the unload valve and the secondary control circuit. Most often, a pressure switch for a compressor has four threaded heads, one of which connects the device to the receiver, and the other connects a pressure gauge to monitor readings. The third can be fitted with a safety valve, and the last has a quarter-inch threaded plug in the thread. With a free connector, the user can install a control pressure gauge at his discretion.

The pressure switch is connected according to the following sequence:

- The device is connected to the unloading valve of the receiver.

- Install a control pressure gauge or plug.

- The engine control circuits are connected to the contacts.

- If there are fluctuations in the voltage network, then the connection is made through a surge filter, including when the contact power is greater than that available for the motor load current.

- If there is a need for this, the relay is adjusted through the adjustment screws to the required air pressure.

The connection is accompanied by checking that the voltage in the network matches the factory settings of the pressure switch. For example, a three-phase network of 380 Volts requires the use of a three-contact group, and for 220 Volts a two-phase group must be used.

The adjustment is made when the receiver is at least two-thirds full. The relay is disconnected from the network, the top cover is removed and the compression of the two springs is changed. The operating pressure limit is determined by an adjusting screw with an axis of larger diameter. On the board next to it there is a pressure mark in the form of the letter P and an indication of the direction of rotation of the screw, with the help of which the specified parameter is changed. The second screw helps set the required difference ΔP and has an indicator in which direction it rotates.

To speed up the adjustment process , in some cases the adjusting screw is pulled out, which changes the upper pressure level. Control is carried out according to the readings of the pressure gauge on the pressure regulator for the compressor.

Air relay connection diagrams

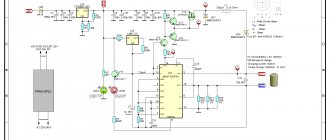

The compressor pressure switch is manufactured for connection to electrical circuits of different loads. In accordance with the rating of the power supply line, the appropriate model of the relay unit is selected.

Option #1: to a network with a nominal value of 220 V

If the drive motor is a single-phase device, then a 220 V relay with two groups of contacts is installed.

To work with a single-phase load, manufacturers recommend equipping the unit using models of the RDK series: xT10R-x; xT10K-x; xT19P-x, since these devices have two contact groups

Option #2: to a three-phase network with a voltage of 380 V

For a three-phase load of a 380 V circuit, one of the options can be used: a modification of the relay for 220 V or 380 V, with three contact lines, to simultaneously disconnect all three phases.

Both methods have different schemes. Let's consider the first option:

To operate in a three-phase electrical circuit, a pressure switch RDK-xT18P-x is used. This model is equipped with three contacts and facilitates simultaneous switching of all phases

By choosing the second method, power is supplied from one phase (zero) and in this case the relay rating should be 220 V. For more details, see the following diagram:

It is allowed to use telepressostats of the RDK series: xT10R-x, xT10K-x and xT19P-x with a three-phase load, however, the use of such a circuit requires incomplete disconnection from the supply network. More specifically, one phase will be permanently connected to the load

After connecting to the power supply, you need to understand the additional capabilities provided in the air blocks for ejectors.

Conclusions and useful video on the topic

Details about the design of the pressure switch, as well as a visual process for adjusting its parameters in the plot:

It is also possible to independently assemble the control unit for the compressor; see this video:

Pneumatic devices are considered safer and easier to use than electric or gasoline models. There is a wide selection of additional equipment that works with compressed air: guns for washing, inflating tires or painting and many others.

With the help of a relay, it becomes possible to operate automatically while maintaining the required compression level in the receiver.

Please write comments in the block form located under the article test. Share your own experience in operating a compressor with a pressure switch, ask questions, post photos on the topic. It is possible that your recommendations will be useful to site visitors.

One of the main indicators of air compressors is operating pressure. In other words, it is the level of air compression created in the receiver that must be maintained within a certain range. It is inconvenient to do this manually, referring to the indicators of the pressure gauge, so the compressor automation unit is responsible for maintaining the required level of compression in the receiver.

Installation of relays and auxiliary elements

In some modifications of pressure switches, you can find additional equipment in the form of flange connections, through which additional equipment is connected. These are basically three-way parts, with a ¼-inch diameter.

By means of several flange connectors, additional elements can be introduced into the system: safety valve, pressure gauge and other necessary mechanisms

To put the device into operation, it must be connected to the receiver. Installation consists of the following steps:

- The device is connected to the compressor through the main outlet.

- A pressure gauge is connected to the device with flanges. There may also be other auxiliary mechanisms that require activation: a safety or unloading valve.

- Channels that are not used for connection must be closed with plugs.

- Next, according to the electrical diagram, the relay is connected to the contacts of the motor control circuit.

Motors with low power can be connected directly; in other cases, additional installation of an electromagnetic starter of appropriate power is required.

Before moving on to setting the threshold response parameters, it is worth paying attention to the operating conditions. First, adjustments are made under pressure. Secondly, the electrical supply to the engine must be cut off.

Check before first start

Once again, we emphasize the importance that the first start-up of the compressor should be carried out by a trained and experienced service technician. It is his responsibility and responsibility to conduct a thorough check of compliance with the standards and requirements for the operation of installations of this type. This pre-start check should include:

- Visually checking whether the compressor installation instructions have been followed;

- Inspection of the installation itself, checking the reliability of all connections, especially the power cable connection contacts;

- Checking for mechanical damage on cables and air ducts;

- Monitoring whether the compressor installation rules have been followed, according to which there must be a free space of at least one meter from the external panels of the station to the walls;

- Checking the oil level. The amount of lubricants must be within acceptable values. Both insufficient and excess oil have a negative impact on the operation of the installation. It is necessary to control and eliminate the possibility of oil leakage through poorly clamped connections, and in no case should oil be allowed to get onto the surface of the installation;

- After a visual inspection, the compressor is connected to the power source. At this stage, it is important to observe the order of connecting the phases, since the direction of rotation of the motor shaft will depend on this. And if the phases are connected incorrectly, this will lead to rotation of the shaft in the opposite direction, which can cause engine failure;

- Starting the air compressor, as well as stopping it, must be done exclusively using the standard switch provided by the design of the equipment. The operating pressure level is also adjusted using the appropriate regulator.

Adjustment and commissioning process

Factory set parameters do not always meet consumer requirements. In most cases, this is due to insufficient compression force at the highest point of disassembly.

The operating range of the pressure switch may also not be suitable. In this case, independent adjustment of the actuator will be relevant.

Standard factory settings: upper limit 2.8 atmospheres, lower limit 1.4 bar. The parameters are monitored visually using a pressure gauge included in the standard pressure switch kit. New models, for example, Italtecnica, have a transparent body and are equipped with a compression scale indicator directly on the relay

To begin setting the operating compression value, you will need to inspect the engraved plate, which indicates the parameters of the electric motor and compressor.

We only need the largest value that the device produces. This indicator indicates the maximum pressure force that can be set on the relay for the correct operation of the entire pneumatic system.

If you set the specified value (in the figure 4.2 atm), then taking into account all factors - differences in power supply, exhaustion of the service life of parts, etc. - the compressor may not reach the maximum pressure, and accordingly it will not turn off.

In this mode, the working elements of the equipment will begin to overheat, then deform and eventually melt.

The maximum ejector value must be taken into account when determining the maximum relay value. This indicator should be less than the rated pressure of the compressor. In this case, all elements of the system will work uninterruptedly

For reliable operation without shutdowns, it is necessary to set the highest shutdown pressure on the relay, which does not reach the nominal value engraved on the compressor, namely 0.4-0.5 atm lower. According to our example - 3.7-3.8 atm.

The pressure limits at which the compressor is turned on/off are regulated by a single bolt. In order not to make a mistake with the choice of direction for increasing/decreasing, arrows are placed on the metal base

Having determined the level that will be set, it is necessary to remove the relay housing. Under it there are two adjusting elements - a small and a large nut (in Figure 1.3).

Nearby there are arrow indicators for the direction in which the twists will be made - thereby compressing and unclenching the spring mechanism (2.4).

A large screw clamp and spring are provided to control compression settings. When twisted clockwise, the spiral compresses - the compressor switch-off pressure increases. Reverse adjustment - weakens, and accordingly, the pressure level for shutdown decreases.

It is worth remembering: by increasing the shutdown compression strength, we are changing the factory settings, which were set taking into account the regulatory requirements for the operation of the equipment. Before making adjustments, check the technical documentation of the device so as not to exceed the limits stated by the manufacturer

When reproducing settings, the receiver must be at least 2/3 full.

Having understood the purpose of the elements, let's proceed:

- To ensure the proper level of safety, we turn off the power supply.

- Changing the compression level of the springs is done by turning the nut several turns in the required direction. On the board, near the large-diameter adjusting screw, according to the standards, there is a symbol in Latin letters P (Pressure), a smaller one - ΔР.

- The adjustment process is monitored visually on a pressure gauge.

For convenience, some manufacturers place the adjusting fittings for changing the nominal value on the surface of the device body.

Recommendations from experts

StarKraft's experienced engineers also provide the following recommendations on how to start your compressor. Below we list the most important points that you need to pay attention to, regardless of the model of the station being used. The primary requirements are visual inspection of the integrity and absence of mechanical damage on the pipeline and power cable. It is also mandatory to inspect the compressor housing, during which you need to ensure not only its integrity, but also the absence of foreign objects on it. It is imperative to ensure that there is no condensation.

After you have started the piston compressor (or screw), before connecting the installation to the load, check the functionality of the lubrication pump and that oil is supplied to the system. To control the oil level, a special oil indicator is provided in the design of each installation.

Important: 30 seconds after starting the compressor, the pressure gauge should display a minimum pressure of 0.1 MPa.

The installation can be started with a load only after checking the serviceability of the cooling system valves, which must produce an air flow with the specified characteristics. After turning on the station and transferring it to normal operation under load, it is necessary to periodically monitor pressure levels, checking the pressure gauge readings. The levels and values of operating pressure must be clarified in the technical documentation for the equipment, since they may differ depending on the model.

If a screw compressor (or piston compressor) is started, but the pressure readings do not correspond to the parameters specified by the manufacturer, the station must be stopped and measures must be taken to detect and eliminate the causes of the malfunction. A similar procedure is carried out in any other emergency situation, for example, if extraneous sounds appear during the operation of the station. This is also the reason to stop the compressor and call a specialist.

The first start-up of the compressor by StarKraft specialists and its regular maintenance are a guarantee of stable and durable operation of the station.

Sources

- https://sovet-ingenera.com/elektrika/rele/rele-davleniya-dlya-kompressora.html

- https://nasosovnet.ru/avto/rele-dlya-kompressora.html

- https://hd01.ru/info/kak-podkljuchit-vozdushnyj-kompressor/

- https://yorkly.ru/holodilniki/chasti-holodilnika/shema-podklyucheniya-kompressora/

- https://oboiman.ru/ingeneer/rele-davlenia-dla-kompressora-ustrojstvo-markirovka-podklucenie-i-regulirovka.html

- https://stroyday.ru/remont-kvartiry/elektropribory-i-osveshhenie/sxema-podklyucheniya-kompressora-xolodilnika.html

- https://www.starkraft.ru/article/zapusk-kompressora/

Possible malfunctions of the device

Several malfunctions characteristic of pressure switches are noted. In most cases, they are simply replaced with new devices. However, there are minor problems that you can fix yourself without the help of a repairman.

If the cause of the malfunction was determined to be a pressure switch, the technician will insist on replacing the device. All service actions for cleaning and replacing contacts will cost the user more than purchasing and installing a new device

The most common malfunction is characterized by air leakage from the relay when the receiver is turned on. In this case, the culprit may be the start valve. It is enough to replace the gasket and the problem will be eliminated.

Frequent starting of the compressor indicates loosening and displacement of the adjusting bolts. Here you will need to double-check the threshold for turning on and off the relay and adjust them according to the instructions in the previous section.

Diagrams for connecting the pressure switch to the compressor

The connection of the relay that controls the degree of air compression can be divided into 2 parts: the electrical connection of the relay to the unit and the connection of the relay to the compressor through the connecting flanges. Depending on which motor is installed in the compressor, 220 V or 380 V, there are different connection diagrams for the pressure switch. I am guided by these diagrams, provided that you have certain knowledge in electrical engineering, you can connect this relay with your own hands.

Connecting the relay to a 380 V network

To connect the automation to a compressor operating from a 380 V network, use a magnetic starter. Below is a diagram of connecting automation to three phases.

In the diagram, the circuit breaker is indicated by the letters “AB”, and the magnetic starter by “KM”. From this diagram it can be understood that the relay is set to a switch-on pressure of 3 atm. and shutdown - 10 atm.

Connecting the pressure switch to a 220 V network

The relay is connected to a single-phase network according to the diagrams given below.

These diagrams indicate various models of pressure switches of the RDK series, which can be connected in this way to the electrical part of the compressor.

Connecting the pressure switch to the unit

Connecting a pressure switch to a compressor is quite simple.

- Screw the pressure switch onto the receiver pipe using its central threaded hole. For better thread sealing, it is recommended to use fum tape or liquid sealant. The relay can also be connected to the receiver through a reducer.

- Connect a relief valve to the smallest output from the relay, if present.

- The remaining outputs from the relay can be connected to either a pressure gauge or a safety relief valve. The latter is installed without fail. If a pressure gauge is not required, then the free output of the pressure switch must be plugged with a metal plug.

- Next, wires from the electrical network and from the engine are connected to the sensor contacts.

After the complete connection of the pressure switch is completed, it is necessary to configure it for proper operation.

Troubleshooting methods

A more difficult problem lies ahead if the compressor does not work. There may be several sources. Let's consider one of them - melting of the pressure switch contacts due to erosion arising from electrical sparks.

Burning of the contact group occurs due to electric spark erosion, which is formed as a result of the opening of the contacts. However, it is not always possible to replace elements - some modifications are no longer available for sale

To eliminate this type of malfunction, you can use one of the following methods: clean the surface, which extends the service life by at least 3 months, or repair it by replacing the contacts in the terminal clamps.

Step-by-step instructions for the second option:

- Bleed all air from the receiver and turn off the power to the ejector. Remove the pressure switch.

- Having removed the protective housing, disconnect the wiring connected to the group of contacts.

- Using a screwdriver, you need to remove the terminal with contacts and drill out the burnt lines from it.

- You can replace the wire with copper wire. It is necessary to select it taking into account the diameter of the hole, since it must fit tightly into the seat. It is inserted into the hole and pressed on both sides.

- Similar actions are performed with the remaining burnt lines.

- After the contact group is assembled, it is mounted in its original place and the pressure switch cover is screwed on.

The compressor relay operates in difficult conditions, subject to wear and failure.

Although the repair is not cost-effective, those familiar with the device can perform the repair themselves. However, the option of replacing it with a new device still remains profitable.

DIY pressure switch

Having taken on the task of making an air compressor on their own, some amateur craftsmen may decide to make a pressure switch with their own hands.

Making your own equipment is interesting, practical and very economical

On the Internet you can find options for homemade devices, for example, made from a thermostat from a refrigerator or made using parts from CDs and plastic bottles. However, it should be noted that their design cannot be compared with the design of a commercially produced compressor pressure switch. In addition, the use of a homemade device, in the event of a sudden failure, can lead to an emergency with unpredictable consequences for others.

TIP: given that the air pressure switch is one of the most critical components of the compressor, it is better to install an industrial pressure switch even in a homemade compressor.

How to make a relay yourself

A new relay costs from 300 rubles (the price depends on the manufacturer, quality, operating parameters). If you wish, you can make the element yourself. Typically, a working relay removed from a regular household refrigerator is used as a basis. The optimal choice is devices with a reverse firing sequence. The relay turns on as the temperature inside the refrigerator rises, and turns off when the values drop.

You can construct a relay with your own hands according to the following scheme:

- Set the location of the contacts using the chain ring.

- Modify the area where the relay connects to the compressor by connecting the pipe with a pressure gauge to the valve mechanism, and the contacts to the terminal elements inside the engine circuit.

- Find the adjustment screw under the cover. Turn on the compressor, observing the correct sequence of rotations and at the same time monitoring the numbers on the pressure gauge.

- Set to the bottom position, start moving the button rod from the front part.

- Put the cover back and make a blind adjustment.

In order to increase the overall safety of the device during operation, pressure adjustment intervals are set at 1–6 atmospheres. When using devices with reinforced bellows, the limit values increase to 10 atmospheres, and this is sufficient in most cases.

Additional checks

When the homemade relay is ready, you need to check its functionality. To do this, cut off the capillary tube and remove the accumulated refrigerant. The end of the tube is inserted and soldered into the loading valve.

Reconnect the self-made pressure switch to the compressor control circuit. The nut connecting the relay to the board is cut into the rod thread, the lock nut is tightened, setting the optimal pressure adjustment limits. Since the contact group of a standard refrigerator relay is designed for significant currents, you will be able to connect a high-power circuit.

If you do everything correctly, you will get a reliable, durable device for adjusting the operation of the electric motor drive. A self-designed pressure switch is not as versatile and practical as a purchased one, but it is suitable for solving simple problems.

When it is necessary to increase the power and functionality of the device, a reinforced siphon is used.

What is a pressure switch?

Pressostat is a pressure switch for a compressor, the main component of compressor automation. He is responsible for starting and stopping the system if it reaches the specified air mass supply parameters. As the required values are obtained, the following operations occur:

- the engine turns on when the pressure is critically high;

- The system shuts down if the pressure is unacceptably low.

That is, the compressor pressure switch regulates the operating process of the system from the moment it is turned on until it is completely turned off. It does not allow the compressor to operate under increased loads and prevents its premature wear. In many ways, the success of the system depends on the coherence of all its components: the air reducer, pressure gauges, supply-type communications (fittings, tubes), the relay itself.