Water pressure switch for a pump: operating principle, correct adjustment, step-by-step installation instructions, advantages and disadvantages, selection tips.

If suburban properties do not have a centralized water supply, you cannot do without equipping an autonomous system for supplying liquid from a well or well. In this case, a necessary part of the design is the pump. The operating mode of this device determines a lot. In turn, the functionality of the water pumping station depends on the water pressure switch for the pump, which is responsible for controlling its operation.

Water pressure switch for pump

What is a water pressure switch?

A water pressure switch is a sensor for a water supply system that automatically turns a pump or pumping station on and off when the water pressure changes. The relay has upper and lower thresholds.

UNIPUMP PM/5

Pressure switch PM/5 is a device that controls turning the pump on and off when a certain, preset pressure is reached in the water supply network.

The PM/5 pressure switch is designed to control the on/off switching of any single-phase (230 V) pumps with a power of up to 1.5 kW.

The relay turns on the pump when the pressure drops below the cut-in pressure and turns off the pump when the system pressure exceeds the cut-out pressure.

UNIPUMP PM5

Specifications:

- mains voltage - 230 V, 50 Hz;

- maximum power - 1500 W;

- maximum switching current - 12A;

- maximum operating pressure - 5 bar;

- switching pressure control range - 1 - 2.5 bar;

- cut-off pressure control range - 1.8 - 4.5 bar;

- connecting size 1/4″ (external or internal thread).

You can find the instruction manual here.

UNIPUMP PM/5-3W - pressure switch with built-in pressure gauge

Pressure switch with built-in pressure gauge UNIPUMP PM/5-3W is an original device that connects a pressure switch PM/5, a five-pin fitting and a pressure gauge.

The device facilitates the installation of automatic water supply pumping stations.

UNIPUMP PM/5-3W

Specifications:

- mains voltage - 230 V, 50 Hz;

- maximum power - 1500 W;

- maximum switching current - 12A;

- maximum operating pressure - 5 bar;

- switching pressure control range - 1 - 2.5 bar;

- cut-off pressure control range - 1.8 - 4.5 bar;

- hydraulic connection – 1” female x 1” male x 1” male.

You can find the instruction manual here.

Features of adjustment “from scratch”

If both relay springs are weakened, the pump station automation is adjusted according to the following algorithm:

- The unit is turned on to pump water into the system. The pressure level is controlled by monitoring the stream from a remote tap. If the pressure is acceptable, the pressure gauge reading is recorded and the pump is turned off.

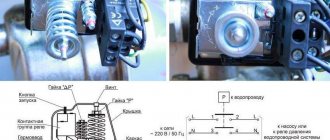

- Having disconnected the sensor from the network, open the cover and twist the nut of the large spring until the contacts are closed.

- The box is closed and the device is turned on again. The pump is turned on and left to work until the pressure on the pressure gauge reaches a mark equal to the previous value plus 1.4 atm.

- The unit and relay are disconnected from the power supply, then the nut on the smaller spring is tightened until the contacts open. The lower and upper threshold settings are completed.

Pressure switch with pressure gauge

Pumping units

Many private households are not connected to the central water main. A way out of the situation may be to place a container that is periodically filled with water, but this method will not ensure comfortable living. The best way to solve the problem of providing a home with drinking and household water is to drill a well or install a well.

Abyssinian water well

By installing a pump at a water source (or in it itself), it is possible to organize the flow of liquid into buildings or use it to water the garden. At the same time, the durability and reliability of an autonomous water supply system largely depend on the equipment used.

The pump allows you to provide the house with water

Manufacturers offer many types of pumping equipment, which are submersible (entirely or partially lowered into liquid) or surface type. They can operate both from the electrical network and from liquid fuel (gasoline and diesel equipment are available). Depending on the purpose, water (for wells or wells), fecal or drainage models of devices are used. The design of the equipment may also be different.

Sewage pump with cutting mechanism NeoClima DP 1100 DK

The pump itself can rightly be called the main driving force of the water supply system. And its brain is the pressure switch.

Gasoline pump Sadko WP-5030

The need to install a relay

The complete set of pumping stations offered to consumers today includes an automation unit, the main component of which is a pressure switch. Without it, the normal functioning of the entire system is impossible. Those who have certain knowledge and skills in laying water pipes can equip the system with automation with their own hands. The operating modes of pumping equipment are of great importance. This depends on:

- electricity consumption;

- maintaining constant pressure in pipes;

- durability of all equipment.

The standard scheme for organizing individual water supply involves the operation of an automation unit in tandem with a membrane unit - a hydraulic accumulator.

Hydraulic accumulators

This tank (its volume, as a rule, is in the range of 20...100 l) is needed for:

- compensation for water hammer that can damage components of equipment supplying water;

- creating pressure in the system and a reserve amount of liquid required to level out peaks in its consumption.

The purpose of the relay is to alternate the operation of the pump and accumulator. It connects or disconnects the contacts of the electric drive when the pressure reaches threshold values. The use of a relay helps limit the number of starts of the electric motor, which extends the life of all fairly expensive equipment and significantly reduces energy consumption.

Pressure switch device

The relay, which looks like a miniature box, is attached to the output pipe. It works like this: when the pressure in the system drops below a certain level, the water intake is turned on, and after the pressure reaches the set value as the accumulator tank fills, the pump drive is turned off. The liquid supply in the container is enough to wash your face and also pour a glass of water. In this case, there is no need to turn on the pumping unit every time.

Why do you need a hydraulic accumulator?

Hydraulic accumulator volume calculator

Go to calculations

Calculator for calculating the pressure of a well pump for a system with direct water supply

Go to calculations

Preparing the storage tank

A storage tank or hydraulic accumulator is a sealed container with a rubber bulb located inside.

The latter is connected to the water supply, as a result of which it can be filled with water. Air is pumped into the space between the bulb and the walls of the tank using a conventional automobile pump.

This air spring compresses the bulb with water and maintains the pressure in the water supply network at an acceptable level for some time without turning on the pump.

The air pressure in the accumulator must be selected correctly, otherwise the system will not operate optimally.

If it is too low or high, the pump will turn on very often, which will negatively affect its service life.

In addition, with low air pressure, the accumulator bulb stretches excessively, as a result of which it also quickly fails.

Before pumping air, as well as before checking its pressure, water from the pipelines must be drained by opening the lowest tap. At the same time, the storage tank bulb will also become empty.

Now you can pump in air and check its pressure. It should be 10% less than Pon. If the system has not yet been configured and you have not yet decided on the switching pressure, the pressure is developed to the following values:

- 1.4 – 1.7 atm with a hydraulic accumulator volume of 20 – 25 l;

- 1.7 – 1.9 atm with a volume of 50 – 100 l.

The air pressure in the storage tank should be checked approximately once a month.

Do not leave the accumulator bulb without water for a long time. Its walls may stick together or dry out.

TOP 8 surface pumping stations

| Photo | Name | Rating | Price | |

| #1 | AQUAROBOT JET 100 L | ⭐ 5 / 5 1 - voice | Find out the price | |

| #2 | UNIPUMP AUTO JET 100 L | ⭐ 4.95 / 5 1 - voice | Find out the price | |

| #3 | Marina CAM 100/25 | ⭐ 4.9 / 5 | Find out the price | |

| #4 | GILEX Jumbo 70/50 N-24 | ⭐ 4.85 / 5 1 - voice | Find out the price | |

| #5 | DENZEL PSX1300 | ⭐ 4.8 / 5 | Find out the price | |

| #6 | VORTEX ASV-1200/50 | ⭐ 4.75 / 5 2 - votes | Find out the price | |

| #7 | GARDENA 3000/4 Classic (1770) | ⭐ 4.7 / 5 | Find out the price | |

| #8 | Quattro Elementi Automatico 1000 Inox (19 l.) | ⭐ 4.65 / 5 1 - voice | Find out the price |

Which pumping station would you choose or recommend?

Take the survey

Types of devices

Manufacturers offer various options for devices that are electromechanical or electronic. They may be included with the pump unit, or this element can be installed independently.

The relay may be included with the pump unit

Important! The cost of electronic devices can exceed the price of mechanical analogues by five times or more.

Electromechanical relay

Devices of this type have long been successfully used in the installation of water supply systems. Despite the simplicity of the design, they have proven themselves to be reliable and easy to use.

Prices for water pressure switch for pump

water pressure switch for pump

Electromechanical relay

The operation of a mechanical device is based on the closure and disconnection of contacts due to changes in the position of a flexible membrane located inside the product. It is associated with two spring elements that respond to its position. One spring (larger) is set to maximum pressure, the other to the delta between the upper and lower limits.

When the pressure reaches a minimum, the plate weakens, the contacts become closed and the electric drive of the pumping equipment begins to work. If the pressure reaches the highest threshold, the contact under the spring is released and the engine is turned off. The elasticity of the springs is changed by adjusting nuts. To set the relay to operate at a higher pressure value, they are tightened. Attenuation leads to a decrease in the parameter.

Electromechanical pressure switches

Electronic device

To control the operation of the relay, models of this type use electronic sensors that measure pressure using a piezoresistive effect.

Electronic water pressure switch for pump

Electronic devices are equipped with various additional options, for example, the ability to softly start or shut down the station in an emergency. They are easier to configure, and pressure thresholds are set more accurately. It is worth noting that for domestic use, high accuracy is usually not required.

Most often, electronic models are equipped with their own small-volume hydraulic tank, which further protects the system from water hammer. The products are characterized by high reliability and durability, but are rather capricious regarding the quality of the pumped liquid. Therefore, to protect the relay it is necessary to install filter elements.

Electronic pressure switch Optima EP-1 with dry-running protection

Important! When setting up a relay that has a piezoresistive sensor, there is no need to open the box. The entire procedure is carried out using the buttons located on the front panel.

Conclusions and useful video on the topic

The standard mechanical model setup is shown here:

This video describes in detail the setup procedure and operating features of an electronic pressure switch using the BRIO 2000 model as an example:

The pressure switch is an extremely useful device. Once you have figured out how to set it up, you will be able to regularly adjust the state of pressure in the water supply system and reliably protect the pump and other equipment from possible breakdowns.

Do you have any questions or want to share your personal experience in choosing, installing and using a pressure switch? Please leave comments on the article and participate in discussions - the contact block is located below.

How to choose the right device

When considering possible options for devices, before purchasing it is necessary to focus on a number of aspects. To avoid problems with the installation and operation of the product, it is important to study:

- operating pressure;

- Manufacturer pressure threshold settings;

- operating current indicators;

- supply voltage;

- conditions of use (there are devices that do not operate at temperatures below +5 degrees and humidity exceeding 70%);

- dust and moisture protection;

- thread characteristics;

- weight and dimensions of the product.

How to choose a pressure switch

For many, the selection criterion is also the country of manufacture of the device and its brand. Relays are produced for use in various pumped media. In everyday life, as a rule, you need a product that works with ordinary water.

The “dry running” protection included in the design allows you to prevent damage to the pump if for some reason water is not pumped into it. Such a device will turn off the unit when the flow of liquid stops, preventing the motor from overheating.

Location of terminals on the water pressure switch housing

An important nuance that influences the choice of model is its cost. It depends on many factors: manufacturer, type of device, its parameters, availability of additional functions.

Table. Comparison of the characteristics of some popular products.

| Model | Pressure adjustment, bar | Pump power, kW | Degree of protection, IP | Note |

| RDM-5 Gilex | 1,0…5,5 | Up to 1.1 | 44 | A simple and budget-friendly device option |

| RM-5 | Pump on: 1…2.5, pump off: 1.8…4.5 | Up to 1.5 | 44 | No dry run protection |

| Grundfos PM 2 | 1,5…5 | Up to 1.5 | 65 | Installed protection against “dry running”, pressure indication, internal hydraulic tank with a capacity of 0.1 l, which reduces the number of pump starts at low flow rates |

| UNIPUMP PM/5-3W | Switch-on pressure: 1…2.5, switch-off pressure: 1.8…4.5 | Up to 1.5 | 54 | The product is equipped with a pressure gauge for monitoring parameters, a three-terminal fitting for quick connection to the pump and accumulator |

| MDR 5-5 | Threshold adjustment in the range of 1.5…5 | Three-phase - up to 5.5, single-phase - up to 2.5 | 54 | There is an output for a pressure gauge or dry-running sensor |

The cost of the relay varies in a wide range: 6...200 US dollars.