Any devices or systems that work with water will function without problems if they are equipped with electronic or electrical devices that prevent equipment failures and breakdowns. The main task for water supply and heating systems is to ensure their uninterrupted operation. Help in this case is provided by pumping equipment, which is especially sensitive to the lack of liquid in the water supply. To prevent possible emergency situations, owners of autonomous systems use a water flow sensor, its second name is a flow switch. This small device plays an important role, so it is necessary for almost any system in which a pump operates. You need to know in advance what a flow sensor is and how the device operates. “Close acquaintance” with the devices will make it possible to select and correctly configure the device.

Flow sensor malfunctions

Design and principle of operation of a rotary pump

Common malfunctions that may occur during operation:

- The DHW mode does not start, the equipment is unstable. To make sure that it is the regulator that has failed, you need to take a multimeter and measure the resistance. If it is approximately 2.5 kOhm, then according to the table this indicator should be achieved when heated to 60 degrees. But if the device is cold, then the problem is definitely in the water flow sensor. The regulator will “say” that the water is already heated and additional temperature is not needed. To fix the problem, you will have to completely replace the failed sensor. But we must not forget that it has direct contact with water and before removal it is necessary to drain all the water from the boiler (Baksi or other companies) and shut off its supply.

- If error No. 201 appears on the indicator, this means that there is a break or damage to the wires that are connected to the regulator. For the regulator to work normally, you need to restore its original position.

- Error No. 202 - short circuit. In this case, you need to check the device itself or the wires that are connected to it.

Allowable relay failures

There are several distinctive failures for pressure switches. In many cases, they are simply replaced with new devices. But there are small problems that can be removed personally without the help of a professional.

If the pressure switch was found to be the source of the malfunction, the professional will insist on replacing the device. All service activities for cleaning and replacing contacts cost the client more than purchasing and installing a new device

The most common failure is characterized by air leakage from the relay.

when the receiver is turned on. In this case, the culprit may be the start valve. You just need to replace the gasket and the problem will be fixed.

Frequent activation of the air blower indicates loosening and displacement of the pressure bolts. Here you will need to double-check the threshold for turning the relay on and off and adjust them in accordance with the instructions in the previous section.

What is and why do you need a water flow switch?

Generator voltage regulator relay: diagram, principle of operation

In household water supply systems, the action of a pumping station without water quite often occurs and threatens an accident. This problem is called “dry running”.

As a rule, the liquid cools and lubricates the elements of the system, thereby ensuring its normal operation. Even short-term dry operation leads to deformation of individual parts, overheating and failure of the equipment motor. Negative consequences apply to both surface and deep-well pump models.

Dry running occurs for various reasons:

- incorrect choice of pump capacity;

- unsuccessful installation;

- violation of the integrity of the water pipe;

- low fluid pressure and lack of control over its level, for which a pressure switch is used;

- accumulated debris in the pumping pipe.

An automatic sensor is necessary in order to completely protect the device from the threats posed by a lack of water. It measures, controls and maintains constant water flow parameters.

Pumping equipment equipped with a sensor has many advantages. It lasts longer, breaks down less often, and uses energy more economically. There are also relay models for boilers

Purpose and benefits

When operating domestic water supply systems, there are often situations when the pump turns on when there is no liquid in the pipes. Such situations, if they occur frequently and continue for a long time, cause overheating of the pump motor and deformation of its parts, which ultimately leads to failure of the entire device. The water pumped by pumping equipment simultaneously performs lubricating and cooling functions, so “dry running,” as it is also called, negatively affects the technical condition of both circulation and submersible pumps.

In order to prevent the occurrence of the described situations, they use a water flow sensor for the pump, operating in automatic mode. Sensors that monitor water flow are successfully used to control the operation of pumping stations serving hot and cold water supply systems, as well as heating systems.

Sensor location diagram in the water supply system

The automatic device in question monitors the parameters of the flow of water that passes through it, and in cases where they differ from the standard ones, it automatically turns on or off the pumping equipment. Working on this principle, the sensor not only protects pumping equipment from “dry running”, but also ensures constant water flow parameters.

Among the advantages of operating pumping equipment on which a fluid flow sensor is installed are:

- reducing energy consumption and, accordingly, reducing the cost of paying for it;

- minimizing the risk of failure of pumping equipment;

- increasing the service life of pumping equipment.

Where are they used?

Screw pump: principle of operation, scope and design features

Flow sensors are used in devices where control of the water supply system to an apartment or private house is necessary. By installing this type of equipment on a gas boiler, you can significantly reduce your monthly payment, and the heat generator will also become much safer to use.

For gas boilers

There is a water flow regulator in all boilers (Buderus and other models). Thanks to the device, the heat generator can work as a device for heating a home and heating water.

The gas boiler water pressure sensor is mounted on the pipeline. Once installed, it begins to respond to flow as soon as the hot tap is opened.

The regulator transmits a signal to a special board installed inside the boiler. After this, the circulation pump automatically starts and the pressure in the gas injectors decreases. As a result, the water circulation valve closes. After this, the water heating nozzles turn on, and the liquid begins to warm up in the heat exchanger. After closing the valve, the mounted sensor for the gas boiler records this action and transmits the corresponding signal to the board.

For pumps

In many private houses, an autonomous water supply system is installed. This is necessary if there is often low pressure on the site and the owner wants his yard to be independent of the centralized water supply. The equipment is installed so that the water pressure in the house always remains at a high level.

The system includes:

- special pump;

- a tank where water is poured;

- control system.

You can connect various household appliances to the pump, for example, dishwashers or washing machines. In this case, the regulator is necessary for timely activation of the pump, ensuring a stable water supply.

And it doesn’t matter whether the wash has started, the tap is open in the kitchen, or water is draining from the toilet tank - the regulator performs the same functions for any type of household equipment connected to the system.

Also, the owners of the living space in question often connect the sensor in question to automatic watering in the country or in a private house. Here the device not only performs the opening function, it regulates the amount of water that should be consumed at a time.

This function is very useful if dosed watering is used so as not to over-moisten the soil. For stable operation, the flow regulator is mounted to the central pipeline, and it transmits all information to the system control panel.

Classification of pumps for increasing water pressure

The technical characteristics by which pumps are distinguished are highlighted:

- operating mode;

- cooling principle;

- application.

Pump classification

Device types

By purpose

Such pumps are divided into two types: Universal. These are the ones that are used for any type of water. Same type. This refers to pumps that can only be used for cold or hot water.

By cooling method

The devices have different cooling systems, in particular, the following types are distinguished: Wet rotor (implies water cooling). Cooling is achieved through the pumped liquid. The rotor with impeller is located in the water. Dry rotor (assuming air cooling). Cooling is achieved through fan blades that are mounted on a shaft. However, the motor does not have direct contact with water.

By operating mode

There are two types of pumps, manual or automatic: Manual. The pump operates entirely in continuous mode. The pump is turned off/on manually

It is extremely important to prevent the motor from overheating. Auto. In this case, the pump is equipped with automatic

As soon as the tap opens, the pump is activated, and when the tap closes, the pump stops working.

Pump and pumping station: advantages and disadvantages

The pump and pumping station have their own characteristics, which are noted in the table:

| Pump type | Advantages | Flaws |

| Pressure booster pump | Here we can note its small size, which allows it to be installed in different rooms. The pump is light in weight. Some models are silent. This is especially convenient for apartments. You can install the pump directly on the water pipe. Such equipment has a relatively low cost. | One of the obvious disadvantages is that such pumps are not capable of increasing the pressure level by several orders of magnitude. |

| Pumping station | One of the differences between such a station is that it is able to provide the living area with the necessary pressure. Its operation is carried out automatically, which greatly simplifies the operation process. | There are more disadvantages here, however, they are rather relative. Pumping stations are more difficult to install. It also has large dimensions, which limits its use. During operation it produces significant noise, which is unacceptable for apartments in a multi-storey building. Taking this into account, it is better to allocate a separate room for installing the station. Among other things, it has a high price. |

Sensor types

Today, the most popular and advanced water flow devices are reed switch relays and Hall sensors.

Description:

- A flow meter or Hall sensor is a small turbine with a magnet. As soon as the turbine begins to rotate, the magnet creates a field and generates electrical pulses that are transmitted to the boiler board (for example, Ferroli).

- The reed switch regulator also uses magnetism. A float magnet is installed inside the chamber. As soon as the water pressure increases, the float moves and begins to act on the reed switch (several magnetic plates that move apart under the influence of the float).

Design and principle of operation

The operating principle of the flow switch is based on the mechanical effect of the water flow in the pipeline on the sensor that controls the electronic circuit for turning on and off the electric pump. Relays have different operating principles and, depending on the design of the sensor, are divided into several types.

Petal relays

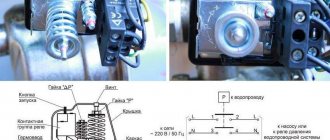

One of the most common types, the main elements are a petal sensor with a magnet located in the water flow and a reed switch placed in the device body and securely insulated.

As water flows through the pipeline, the vertically located petal sensor rotates along its axis and deviates from the vertical position, bringing the built-in magnet closer to the reed switch. Its contacts inside the cylinder are closed and the pump is connected to a source of electricity through a triac (double symmetrical thyristor).

If there is no water in the pipeline, the petal returns to its original position, moving the magnet away from the reed switch and thereby opening its contacts.

This leads to the cessation of supply voltage to the pump through the semistor, as a result of which it turns off.

When does automation need to be reconfigured?

There are various reasons why a pump may not deliver the required value. Let's briefly list the most common ones:

- the equipment operates at a large suction depth and cannot achieve the required water supply;

- wear of the pump impeller, cannot drive water to the required force;

- increased wear of sealing seals, air leaks;

- the need to supply water with high pressure to a multi-story building or a highly located storage tank;

- mechanisms that consume water require more pressure.

In these and other similar cases, you will need to change the factory settings.

Connecting and adjusting the sensor

The efficiency of the sensor that monitors the flow of water and controls the operation of pumping equipment largely depends on the correct installation of this device. It should be borne in mind that such a sensor, regardless of the type and purpose of the pipeline, can only be installed in horizontal sections. In this case, it is necessary to ensure that the sensor membrane is located strictly in a vertical position.

When installing a liquid flow sensor, it is connected to the drain part of the pipeline using a threaded coupling. In this case, the distance at which such a device should be located from the pipe itself cannot be less than 55 mm.

Flow sensor installation diagram

On the housing of factory water flow sensors there is always an arrow that indicates in which direction the liquid should move through them. When installing the sensor on the pipeline, you must ensure that this arrow coincides with the direction of water movement. If the sensor is installed in a system through which heavily contaminated liquid is transported, filters must be placed in front of it for the correct operation of such a device.

Electrical connection diagram

Despite the fact that fluid flow sensors are supplied from manufacturing plants with already adjusted parameters, independent adjustment must be performed periodically. For this purpose, special bolts are provided in the design of the sensors. With the help of the latter, the degree of compression of the springs is increased or decreased, setting the level of pressure at which this device will operate.

Leaf type flow sensor adjustment controls

So, to adjust the water flow sensor with your own hands, you need to perform the following steps:

- drain the water from the pipeline system and make sure that the pressure has reached zero;

- turn on the pump and start filling the system with water;

- when the pump is turned off, which occurs due to a signal from the sensor, record the value of the liquid pressure;

- Draining the liquid from the system again, record the pressure value of its flow at which the pump will turn on;

- by removing the sensor cover and using a special bolt, adjust the degree of compression of the large-diameter spring (this way you will set the minimum pressure level at which the device will operate and the pump will turn on; it should be borne in mind that compression of such a spring increases the pressure level, and weakening reduces it);

- Having filled the system again with water and starting to drain it, check whether the sensor is adjusted correctly and whether it turns off the pump at the required pressure level (if the device is adjusted incorrectly, the entire procedure described above should be repeated);

- by changing the degree of compression of a spring of small diameter, set the maximum pressure level at which the pump will turn off (the difference between the sensor response thresholds increases when such a spring is compressed and decreases when it is weakened);

- after adjusting the degree of compression of a small-diameter spring, check that this procedure is performed correctly by starting to fill the system with water and recording the pressure value at which the pump turns off (if this adjustment is performed incorrectly, it should also be repeated until the desired result is achieved).

Payment for goods

Payment by bank card - payment for goods by bank card is carried out ONLY at the pick-up point.

Cash payment - payment for goods is made in cash to the courier. Payment is accepted in Russian rubles strictly in accordance with the price indicated on the sales receipt. When picking up goods at your own expense, a 3% discount is provided.

Cashless payment - payment for goods by bank transfer is possible for all legal entities and individuals. After receiving your order, you will be sent an invoice by email or fax.

Please note that our company is NOT a VAT payer

FLU-25 is a traditionally reliable control of the presence of water flow in heat and water supply systems. Produced at a plant in Germany.

The FLU25 flow switch is used to monitor the presence of water flow in an autonomous heating system with forced circulation, down to minimum flow rates. Depending on the connection diagram, the flow switch can turn on or off the corresponding element of the autonomous heating system when the coolant flow disappears or appears. For example, when the circulation pump is turned off, the burner may be turned off. The flow switch can also be used to protect the circulation pump from dry running. The FLU-25 flow switch has a metal housing and can be installed in rooms with high humidity. The presence of a spring bellows seal makes the flow switch also suitable for diesel fuel. The delivery set includes plates (lamellas) of various lengths for pipes from 1 to 8 inches. Installation: To ensure perfect operation, the flow switch must be installed on a horizontal pipeline so that the plate (lamella) is vertical. The distance between the pipe and the device must be at least 55 mm, and the distance to subsequent fittings, bends or fittings on the pipeline must be at least 5 DN. The flow switch must be oriented so that the direction of the arrow on the body corresponds to the direction of flow in the pipeline. If there are foreign mechanical inclusions in the coolant and high contamination, a mechanical cleaning filter should be installed in front of the flow switch.

Technical characteristics: Microswitch (relay) 6 A - 220 V Maximum operating pressure 10 bar. Maximum coolant temperature 110° C Maximum ambient temperature 60° C Protection class IP 54, internal diameter of cable entry 6 mm (included) External thread G1

Installed on pipes DN25…DN-200mm

Adjusting the flow switch: The table below gives the required lamella length in accordance with the pipe diameter. The response threshold (operating point) is determined by the spring tension (10), the installation of the screw (8) and the length of the lamella (A). The table shows the diameters of the pipes, the corresponding lengths of the lamellas and the water flow in m3/h at which the microswitch contacts close or open, both when setting the minimum value (the screw is tightly tightened) and when setting the maximum value (the screw is completely loosened). The device comes with the calibration screw tightly tightened (set to the minimum value). Contact 1 – 2 is open. After starting the pumps or when the nominal water flow is established, the lamella must move in the direction of the water flow, as a result of which contact 1 - 2 closes and the burner starts working. If the lamella does not move, this means that the water flow is too low and the device cannot respond. However, in practice this is almost completely excluded, since the water flow rate is usually significantly higher than the established minimum value (for example, 6.3 m / h with a 3" pipe diameter). If the actual water flow is known, the device can be precisely adjusted (see table in the Specifications section, PDF file). Flow switches in heating systems with simple ON-OFF control do not require precise calibration. It is enough to set the minimum value so that the contact that controls the burner closes as soon as the set water flow is reached (see table).

More details in SPECIFICATIONS (PDF file below)

Design features

The main tasks that water flow control sensors installed in domestic pipelines solve are to turn off pumping equipment at a time when there is no liquid in the system or its flow pressure exceeds the standard value, and turn it on again when the pressure drops. An effective solution to these important problems is provided by the sensor design, which consists of the following elements:

- a pipe through which water enters the sensor;

- a membrane that makes up one of the walls of the inner chamber of the sensor;

- a reed switch that provides closing and opening of the pump power supply circuit;

- two springs of different diameters (the degree of their compression regulates the pressure of the fluid flow, at which the water flow switch for the pump will operate).

Main components of an industrial flow sensor

The device of the above-described design works as follows:

- Entering the inner chamber of the sensor, the water flow puts pressure on the membrane, displacing it.

- The magnetic element fixed on the back side of the membrane, when it is displaced, approaches the reed switch, which leads to the closure of its contacts and the pump being turned on.

- If the pressure of the water flow passing through the sensor drops, the membrane returns to its original position, the magnet moves away from the switch, its contacts open, and accordingly, the pumping unit is turned off.

The operating principle of a flow sensor based on a permanent magnet and a reed switch

Sensors that monitor water flow are installed quite simply in pipeline systems for various purposes.

The main thing is to choose the right device, paying attention to its operating parameters and characteristics of the pumping equipment

Main characteristics

When choosing water flow sensors to equip a pipeline system, the following parameters must be taken into account:

- material for manufacturing the body and internal elements;

- operating pressure for which the sensor is designed;

- temperature range of the liquid to control the flow of which the device will be used;

- protection class and requirements for operating conditions;

- diameter of mounting holes and thread parameters in them.

Each of the above parameters affects the operational features of water flow sensors, so it is worth considering them in more detail.

The reliability of such a device, its ability to withstand loads arising during operation, as well as its durability depend on the material from which the sensor body and its internal parts are made. When choosing a fluid flow sensor, it is better to give preference to models for the manufacture of which various metals were used - stainless steel, brass or aluminum. During operation, both the body of the flow sensor and its internal elements experience significant pressure from the liquid passing through it. Only durable materials can withstand such a load for a long time. In addition, phenomena such as water hammer are common in pipelines, the consequences of which can quickly damage the sensor if inappropriate materials were used for its manufacture.

Flow sensor with brass body

The operating pressure at which the fluid flow sensor can operate correlates with the power of the pump used, so special attention should be paid to this parameter. In addition, this parameter also determines what characteristics the liquid flow transported through the pipeline will have. Those models of water flow sensors, which are designed with two springs, can control the operation of the pump at the lower and upper pressure levels. It is better to give preference to devices of this particular type.

The temperature of the liquid for which the sensor is designed has a direct impact on the systems in which it can be used. Naturally, when choosing such a sensor to equip a heating or hot water supply system, you should pay attention only to those models that can work with water heated to a high temperature. For pipelines through which cold water is transported, flow sensors are used, designed to work with liquids having a temperature of 60–80°.

Boost pump with flow sensor

The level of humidity and ambient temperature at which the fluid flow sensor can be operated are also important parameters. The protection class of such a device indicates what loads it can withstand when working in tandem with pumping equipment.

Sensors that monitor water flow are usually chosen for ready-made pipeline systems or for those whose design has already been developed. That is why you should pay attention to the dimensions of the mounting holes: they must fully correspond to the dimensions of the pipeline elements on which the sensor is planned to be installed.

Device connection diagram

The operating efficiency of the relay greatly depends on its correct installation. It must be remembered that the device can only be installed on those sections of the pipeline that are located horizontally. In this case, you will need to ensure that the sensor membrane is in a vertical position. The correct relay connection diagram looks like this:

During installation, the sensor must be connected to the drain part of the pipe using a threaded connection. The distance at which the relay should be located from the pipe should be more than 5.5 cm.

There is an arrow on the body of the device indicating the direction of liquid circulation. When installing the device, you need to make sure that this arrow coincides with the direction of water flow in the system. If dirty water is used for domestic purposes, then cleaning filters should be installed in front of the sensor.

Step-by-step instructions on how to connect

A detailed installation diagram for the pressure sensor is in the instructions with which the device is sold. In general, the sequence of steps is the same.

Connection to frequency converter

The sensor is connected to the inverter in the following order:

- mount the sensor on the pipeline, connect the device to the high-frequency converter with a signal cable;

- in accordance with the diagram given in the documentation, connect the wires to the appropriate terminals;

- configure the software part of the converter and check the operation of the connection.

To prevent interference and ensure proper operation of the inverter, a shielded signal cable is used for installation.

To the water supply system

A typical sensor for installation on a pipeline requires a fitting with five terminals:

- water inlet and outlet;

- exit to expansion tank;

- under the pressure switch, usually with external thread;

- branch for pressure gauge.

A cord from the pump is connected to the sensor to control turning it on or off. The power supply is provided by a cable that is laid to the panel.

Rotary relays and flow type sensors

Rotary sensors are mainly used to measure and control fluid flow. Structurally, they are made in the form of a paddle wheel rotating in a fluid flow; its rotation speed is recorded by sensors. The electronic circuit allows for analog, frequency or discrete control of the operation of the equipment.

Piston devices

The piston is placed in the valve seat and, under the influence of water pressure, moves in the vertical direction to a height proportional to the force of the flow. A permanent magnet mounted on the piston approaches the reed switch and the contacts in it close. Piston devices can be installed on horizontal and vertical pipelines thanks to the built-in return spring, which returns the piston to its original position in the absence of flow.

appearance

Construction of a double-circuit gas boiler

In order to understand the principle of operation of a gas double-circuit boiler, it is necessary to understand its structure. It consists of many individual modules that heat the coolant in the heating circuit and switch to the DHW circuit. The coordinated work of all components allows you to count on trouble-free operation of the equipment. Knowing the structure of a double-circuit boiler, you can understand its operating principle.

We will not consider the design of double-circuit boilers with precision down to the screw, since it is enough for us to understand the purpose of the main components. Inside the boiler we will find:

Design of models with two circuits: heating and DHW circuit.

- The burner, located in an open or closed combustion chamber, is the heart of any heating boiler. It heats the coolant and generates heat for the operation of the DHW circuit. To ensure accurate support of the set temperature, it is equipped with an electronic flame modulation system;

- Combustion chamber - the above burner is located in it. It can be open or closed. In a closed combustion chamber (or rather, above it) we will find a fan responsible for pumping air and removing combustion products. It is this that is the source of quiet noise when the boiler is turned on;

- Circulation pump – ensures forced circulation of coolant through the heating system and during operation of the DHW circuit. Unlike the combustion chamber fan, the pump is not a source of noise and operates as silently as possible;

- Three-way valve - this is the thing that is responsible for switching the system to hot water generation mode;

- The main heat exchanger - in a double-circuit wall-mounted gas boiler, it is located above the burner, in the combustion chamber. Here the coolant used in the heating circuit or in the DHW circuit for heating water is heated;

- Secondary heat exchanger - this is where hot water is prepared;

- Automation - it controls the operating parameters of the equipment, checks the temperature of the coolant and hot water, controls modulation, turns on and off various components, monitors the presence of flame, records errors and performs other useful functions.

At the bottom of the buildings there are pipes for connecting the heating system, cold water pipes, hot water pipes and gas pipes.

Some models of gas double-circuit boilers use dual heat exchangers. But the operating principle remains almost the same.

You may notice that the design of the geyser differs only in the absence of a heating circuit.

We found out the structure of a double-circuit wall-mounted gas boiler - it seems a little complicated, but if you understand the purpose of certain components, the difficulties will disappear. Here we can note the similarity with a gas instantaneous water heater, from which a burner with a heat exchanger remains here. Everything else is taken from wall-mounted single-circuit boilers. An undoubted advantage is the presence of a built-in piping - this is an expansion tank, a circulation pump and a safety group.

When analyzing the operating principle and design of a gas double-circuit boiler, it should be noted that water from the DHW circuit is never mixed with the coolant. The coolant is poured into the heating system through a separate pipe connected to the heating. Hot water is prepared using part of the coolant circulating through the secondary heat exchanger. However, we will talk about this a little later.

Installation of a relay on a pump or station

If installation of the device is required, the work can be done independently, especially if you have to be away and there is no way to constantly monitor the operation of the pumping equipment.

When you do not need to install a relay:

- if water is pumped from a well with a large volume, that is, liquid reserves are not limited, and the pump power is minimal;

- It is possible to turn off the installation when the water level drops.

Equipment installation rules:

It is important to monitor the membrane - the part must take a vertical position. Installation is carried out to the drain pipeline section using threaded couplings. There is a special slot for this. Before starting work, the threads are sealed with linen or other plumbing thread

Winding the thread towards the end clockwise will increase the reliability of fastening and fixation. Factory sensors are equipped with an arrow drawn on the body - this is the direction of flow, which must match during installation. When installing relays in water supply pipelines with dirt particles, cleaning filters are first installed. It is better to mount them next to the sensor to extend the service life of the device.

Testing of the installed device is carried out with connection to the power supply:

- the free ends of the contacts are connected to the wire core;

- grounding is mounted to the screw;

- the device is connected by connecting the device with a wire (watch the color of the corresponding wires);

- system functionality is checked.

Self-adjustment of the water movement sensor

The factory device is equipped with bolts, by tightening or loosening which you can increase/decrease the spring compression. Bolts will be required if you need to install the sensor at a certain pressure level at which the mechanism is triggered.

Algorithm of actions:

- drain the liquid from the system;

- wait until the pressure mark reaches zero;

- start the pumping unit;

- run the water back in the slowest mode;

- remember the flow pressure indicator when the pump relay is turned off;

- drain the liquid again, recording the indicators when the system starts operating.

Now you need to open the relay, use the bolt to adjust the compression level of the larger spring - this will trigger the device when the pump starts. The adjustment is made taking into account that strong compression will increase the degree of pressure, and weak compression will decrease it. Then the compression force of the smaller spring is adjusted - here the limit of the maximum pressure level is set, upon reaching which the relay will automatically turn off the pump.

As soon as the adjustment is completed, start the system, evaluate the results of the work when filling the pipeline and draining the flow. If adjustment changes are necessary, repeat the procedure. Checking functionality and adjusting operating parameters is an annual procedure that extends the life of the device.

Review of popular models

There are two types of pressure switches: mechanical and electronic, the latter are much more expensive and are rarely used. The market offers a wide range of devices from domestic and foreign manufacturers, making it easier to select the required model.

RDM-5 Gilex (15 USD) is the most popular high-quality model from a domestic manufacturer.

Characteristics

- range: 1.0 - 4.6 atm.;

- minimum difference: 1 atm.;

- operating current: maximum 10 A;

- protection class: IP 44;

- factory settings: 1.4 atm. and 2.8 atm.

Genebre 3781 1/4″ (10 cu) is a budget model made in Spain.

Characteristics

- body material: plastic;

- pressure: upper 10 atm;

- connection: threaded 1.4 inches;

- weight: 0.4 kg.

Italtecnica PM/5-3W (13 cu) is an inexpensive device from an Italian manufacturer with a built-in pressure gauge.

Characteristics

- maximum current: 12A;

- working pressure: maximum 5 atm;

- lower: adjustment range 1 - 2.5 atm.;

- upper: range 1.8 - 4.5 atm.

The pressure switch is the most important element in the water intake system, providing automatic individual water supply to the house. It is located next to the hydraulic accumulator, the operating mode is set using adjusting screws inside the housing.

When organizing an autonomous water supply in a private house, pumping equipment is used to lift water. In order for the water supply to be stable, it is necessary to select it correctly, since each type has its own technical characteristics and features.

For efficient and trouble-free operation of the pump and the entire water supply system, it is necessary to purchase and install an automation kit for the pump, taking into account the characteristics of the well or well, the water level and its expected flow.

A vibration pump is chosen when the amount of water spent per day does not exceed 1 cubic meter. It is inexpensive, does not create problems during operation and maintenance, and its repair is simple. But if water is consumed from 1 to 4 cubic meters or water is located at a distance of 50 m, it is better to purchase a centrifugal model.

Typically the kit includes:

- an operating relay, which is responsible for supplying and blocking voltage to the pump when the system is emptying or filling; The device can be immediately configured at the factory; self-tuning for specific conditions is also allowed:

- a collector that supplies and distributes water to all points of consumption;

- pressure gauge for measuring pressure.

Manufacturers offer ready-made pumping stations adapted to specific requirements, but a self-assembled system will work most efficiently. The system is also equipped with a sensor that blocks its operation during dry running: it disconnects the engine from power.

Sensors for protection against overload and integrity of the main pipeline, as well as a power regulator, ensure safe operation of the equipment.

Review of famous manufacturers and prices

Several models in the $30-40 price category are considered the most famous and reliable:

- Genyo Lowara Genyo 8A. Manufacturer – Poland. The main direction of the company is the production of electronic equipment for control systems. The relay is designed for use in domestic water supply systems and is characterized by high quality and long service life. By monitoring the flow pressure in the pipes, the sensor starts the pumping system at a water flow rate of 1.6 l/minute. The unit requires an electrical connection and consumes 2.4 kW/hour. Operating temperature +5..+60 C.

- Grundfos UPA 120. Manufacturer's plants are located in Romania and China. The device has small dimensions, is convenient to install and is indicated for individual water supply systems. That is, it can be used both in private buildings and apartments. The device starts up at a liquid flow rate of 1.5 l/minute, completely preventing the functionality of the system at idle. The extreme operating temperature is +60 C.

The models have been tested and adapted to domestic operating conditions. Numerous reviews characterize metering sensors as durable and practical units at an affordable price.

Criterias of choice

The choice depends on the purposes for which an individual water supply system is being installed. For a small country house where 1-2 people spend the season, expensive powerful equipment does not make sense.

In a family cottage, reliable and sophisticated automation with an inverter will save expensive plumbing fixtures and eliminate temperature changes while the child is bathing.

When connecting the controller to a high-frequency converter, you need to make sure that the sensor and inverter are compatible.

The price of the sensor depends on the manufacturer and set of functions. The most expensive are imported combined electronic devices that combine pump control, a dry-running sensor, and diagnostics of the entire system.

But no less popular are Russian-made devices with a price of several hundred rubles, which reliably control an autonomous system.

How to set pressure using a flow switch

Briefly - for 5 seconds. – press button “1”:

In this case, the “accident” lamp should blink red. This is where we entered programming mode. Now we turn on the pump, and as it works, it builds up pressure. It is clear that all taps in the house must be closed. We look at the pressure on the pressure gauge. For example, we need the water supply to be 2 atm, so we wait for the pump to build up this pressure. As the arrow on the pressure gauge shows the required pressure, press button “1” again. The pump will turn off.

We press the “2” button, thereby “driving” into the relay’s memory that at this pressure the pump should turn off.

Now we are programming the lower limit. To do this, open any tap so that the pressure begins to drop. When the pressure gauge shows the lower pressure we need, press button “1” again and the pump will turn on. By pressing button “2” we “drive” the relay into the head so that at this pressure the pump must be turned on.

Step-by-step instructions for adjusting the pressure switch

Step 1. Check the compressed air pressure in the accumulator. There is a rubber plug on the back of the tank, you need to remove it and get to the nipple. Check the pressure with an ordinary air pressure gauge; it should be equal to one atmosphere. If there is no pressure, pump up the air, measure the data and check the indicators after a while. If they decrease, there is a problem; we need to look for the cause and eliminate it. The fact is that most equipment manufacturers sell hydraulic accumulators with inflated air. If it is not there when purchasing, then this indicates a defect; it is better not to purchase such a pump.

First you need to measure the pressure in the accumulator

Step 2: Turn off the electrical power and remove the pressure regulator housing protective cover. It is fixed with a screw and removed using an ordinary screwdriver. Under the cover there is a contact group and two springs, compressed by 8 mm nuts.

To adjust the relay, you must remove the housing cover

Big spring. Responsible for the pressure at which the pump turns on. If the spring is fully tightened, the engine switching contacts will be permanently closed, the pump will turn on at zero pressure and run continuously.

Small spring. Responsible for turning off the pump; depending on the degree of compression, the water pressure changes and reaches the maximum value

Please note, not the optimal operating one, but the maximum according to the technical characteristics of the unit.

Factory relay settings need adjustment

For example, you have a delta of 2 atm. If in this case the pump turns on at a pressure of 1 atm, then it will turn off at 3 atm. If it turns on at 1.5 atm, then it turns off, respectively, at 3.5 atm. and so on. The difference between the switch-on and switch-off pressure of the electric motor will always be 2 atm. This parameter can be changed by changing the compression ratio of the small spring. Remember these dependencies, they are needed to understand the pressure regulation algorithm. The factory settings are set to turn on the pump at 1.5 atm. and shutdown at 2.5 atm., delta is 1 atm.

Step 3. Check the actual pump operating parameters. Open the water drain valve and slowly release the pressure, constantly monitoring the movement of the pressure gauge needle. Remember or write down at what indicators the pump turned on.

When the water drains, the arrow indicates a decrease in pressure

Step 4. Continue monitoring until it turns off. Also record the values at which the electric motor shuts down. Find out the delta, subtract the smaller value from the larger value. This parameter is needed so that you can navigate at what pressures the pump will turn off if you adjust the compression force of a large spring.

Now you need to notice the values at which the pump turns off

Step 5: Turn off the pump and loosen the small spring nut about two turns. Turn on the pump, record the moment it turns off. Now the delta should decrease by about 0.5 atm, the pump will turn off when the pressure reaches 2.0 atm.

Use a wrench to loosen the small spring a couple of turns.

Step 6. You need to ensure that the water pressure is in the range of 1.2–1.7 atm. As mentioned above, this is the optimal mode. Delta 0.5 atm. already installed by you, you need to lower the inclusion threshold. To do this, you need to release the large spring. For the first time, turn the nut, check the starting period, and if necessary, fine-tune the compression force of the large spring.

Adjusting the large spring

You will have to start the pump several times until you get it to turn on at 1.2 atm and turn off at a pressure of 1.7 atm. All that remains is to replace the housing cover and turn on the pumping station. If the pressure is correctly adjusted, the filters are always in good condition, then the pump will operate for a long period of time, there is no need to do any special technical maintenance.

Criteria for selecting a relay for a pump

Installation features

Paddle switches are mounted either at the pump inlet or at the valve inlet. Their task is to record the initial entry of liquid into the working chamber, and therefore contact with it must be detected first of all on the relay itself.

Pressure control units are installed only with the help of specialists, as they require adjustment. They are installed in the same way as the petals, by connecting the inlet to the pumping device. However, unlike conventional petals, pressure switches are almost always used in conjunction with pumping stations.

Thermal relays are rarely used separately, since the thing is too expensive. It will most likely be connected at the assembly stage of the pump itself. However, a good master will certainly be able to cope with the installation of this device. The complexity of the installation lies in the need to mount several sensitive thermal sensors, and then bring them together.

Types of water flow switch

The most common water flow switch configuration for a pump is a petal switch. The classic circuit of the device consists of the following elements:

- inlet pipe;

- valve (petal) located on the wall of the inner chamber;

- isolated switch;

- springs of a certain diameter.

The reed switch opens and closes the power supply circuits that activate the compression spring. The principle of operation of the sensor in a water flow: when the chamber is filled with liquid, the flow forcefully displaces the valve from its axis, affecting the magnet, which operates the switch. The contacts close and the pump turns on.

There are several types of sensors with their own operating characteristics and application possibilities.

Mechanical paddles

The device is a device equipped with a blade that is built into the pipeline. The principle of operation is standard: when a flow enters, the blade deflects and acts on a magnet. The contacts close, the switch sensor is activated. The simplicity of the unit explains the wide range of applications. In addition, such sensors are practically not subject to wear and do not require maintenance - there is nothing to break in them.

Mechanical piston

The device operates on the basis of a magnetic piston system. Operating principle: when a flow enters, the piston with a magnet rises, closing the contacts - the relay is triggered to start. Without flow, the piston drops to its original position, preventing dry running. The main advantage of the device is the variety of designs that allow the device to be mounted in any position. Mechanical piston relays are used in high pressure systems.

Thermal

The device is equipped with a meter for the level of thermal energy dissipation from the built-in heating element. Depending on the change in the heating rate of the liquid, the flow itself and its flow rate are recorded. The thermal sensor is used only for safe types of liquid. Due to the use of the hot-wire principle, it is prohibited to use the relay to measure flammable substances, as well as liquids that change composition when heated.

Ultrasonic

The universal pulse water flow sensor operates on the principle of the acoustic effect. The device transmits an ultrasonic pulse through the flow, determining the liquid level. The most common are products whose functionality uses the movement of vibrations of a moving fluid. The devices are suitable for any substances, including flammable ones, and are easy to install and maintain.