Retaining rings are parts of an open structure, made of stainless and carbon steel and special alloys. They are one of the main ways of fastening bodies of rotation in various units. The rings are installed in a groove in the shaft or housing. In this case, the protruding part ensures reliable fastening of adjacent components of the assembly.

The marking of retaining rings is carried out according to the nominal diameter, which, as a rule, corresponds to the diameter of the shaft or hole where the part is mounted. Products that are installed on the shaft are measured by the inner diameter, and in the hole - by the outer diameter.

Advantages of Spiral Retaining Rings

Retaining rings do not have “ears,” which make it much more difficult to assemble mating units. The products are made of flat rolled wire, so the surface of the part has no burrs, and its circumference for multi-turn models is 360 degrees.

Retaining rings are easily installed and removed from their internal and external grooves during operational maintenance of equipment using a standard screwdriver or other available tool.

The products have a homogeneous crystalline metal structure, precisely oriented along the rolled strip.

Standard products are made from carbon and stainless steel. For special products, according to customer specifications, special alloys with high temperature and chemical resistance are available.

Types of retaining rings

- Based on the installation method:

- external - parts are installed on the shaft;

- internal - these locking rings are mounted in the hole.

- Based on the type of construction:

- a) single-turn (light retaining rings and heavy thrust rings, depending on the section of the tape): retaining rings:

- VHM and VSM - light loads, metric;

- VH and VS - small loads, inch. thrust rings:

- FH and FS - heavy loads, DIN, metric;

- FHE and FSE - heavy loads, inch.

- b) multi-turn (from two turns for standard products to the required number of turns for custom products):

- EH and ES - average loads, metric;

- DNH and DNS - heavy loads DIN, metric;

- WH and WS - average loads, inch;

- WHT and WST - medium and heavy loads, inch;

- WHM and WSM - heavy loads, inch.

- c) wave retaining rings:

- WHW and WSW - inch (tension clamping).

- By type of anti-corrosion coating:

- chemical oxidation by oiling;

- galvanizing;

- cadmium plating;

- phosphating

The appropriate coating is selected according to the type of working environment.

Sales Department (St. Petersburg, Russia)

+7 and (Novosibirsk)

Source: www.smalley.ru

External eccentric retaining ring from Ø4 to Ø400, GOST 13942-86, DIN 471

The company returns and exchanges this product in accordance with legal requirements.

Return deadlines

Returns are possible within 14 days after receipt (for goods of good quality).

Return delivery of goods is carried out by agreement.

The company carries out returns and exchanges of finished goods from stock of appropriate quality in accordance with the Law “On the Protection of Consumer Rights”. Returns and exchanges of goods are possible within 14 days after the buyer receives the goods. Goods of proper quality, manufactured or supplied to the buyer’s order, or according to his drawings/sketches, are not subject to exchange or return. Return delivery of goods is carried out by agreement. Return conditions for goods of good quality According to current legislation, you can return the product, as well as exchange it, if the product: 1. Has not been used and has no signs of use: scratches, chips, abrasions, tears in the original packaging, stains, etc. . 2. Fully completed and in original packaging. 3. The presentation and consumer properties are perfectly preserved. 4. All labels and factory markings are preserved without any damage.

Choose from assortment

External retaining rings in accordance with GOST 13942-86 (DIN 471) are available at the warehouse of TANTAL LLC .

We supply rings in sizes from Ø210 to Ø400 upon request.

Types of Flat Retaining Rings

Flat-section retaining rings are widely used in mechanical assemblies for securing bearings on axles and semi-axles, for fixing axles, levers and rods, in the designs of piston pins, differentials, and when securing gears.

Retaining rings according to the method of fastening are divided into: - external - installed on shafts (GOST 13940-86, GOST 13942-86, DIN 471 ) - internal - installed in holes ( GOST 13941-86, GOST 13943-86, DIN 472 ).

According to the shape of the ring, locking rings are divided into: - concentric (the outer and inner circles of the ring are concentric, i.e. they have one single center for these two circles, and, as a result, such rings have the same width throughout the ring) - dimensions are regulated according to GOST 13940 -86 , GOST13941-86 , DIN 5417 ; – eccentric (the outer and inner circles of the ring have two different centers for these two circles, and thus the center of the outer circle is offset with respect to the inner circle - there is an eccentric (displacement). Such rings have an uneven width along the circumference of the ring) - dimensions are regulated according to GOST13942-86, GOST13943-86, DIN 471, DIN 472 .

What are retaining rings made of?

Eccentric retaining rings according to GOST and DIN are made of spring steels, mainly Steel 65G and Steel 60S2A.

The use of retaining rings is described in more detail in the article “Retaining rings, thrust rings and multi-jawed retaining washers. Application for fixing bearings"

Dimensions and parameters of external retaining rings

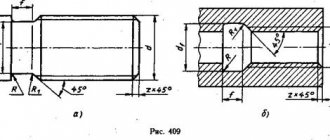

The parameters of external eccentric retaining rings in accordance with GOST 13942-86 are shown in the drawing and table.

The name (designation) of the outer ring is its nominal diameter d , which is the diameter of the shaft (1st column in the table).

The loose size is the ring diameter d2 when you hold it in your hands (2nd and 3rd columns in the table). The name differs from the size of the ring in the free state - the inner diameter of the outer ring in the free state is smaller than the name.

How to determine the name (size) of the outer ring:

- Take the outer ring in your hands and measure its inner diameter - this is the free size d2

- GOST 13942-86 table, find the resulting size d2 in column 2-3, taking into account maximum deviations (±)

- Using the line, determine the value of the name of the outer ring d from the 1st column

The standard sizes of eccentric retaining rings for the shaft according to GOST 13942-86 are given in the table:

What are retaining rings used for?

Today it is difficult to imagine our life without such a simple detail as a bearing. Not a single vehicle can do without them - from a children's bicycle or skateboard to a car. Both passenger cars and the most powerful tractors use bearings. In addition to vehicles, they are used in various mechanisms where there are rotating parts. Some parts must be firmly fixed, others must rotate on their axes.

Another important part associated with bearings is the retaining rings. They are designed to fit securely. With their help, bearings, various levers, shafts, etc. are attached. The correct functioning of the mechanisms depends on the reliability of the fastening, so this part must be made of high-quality materials, in compliance with GOST; and it is best to buy external retaining rings in a specialized store.

External retaining rings are used to secure parts to the shaft. If you need to secure some parts inside the hole, then use inner rings. Both are made, most often, from carbon steel. Stainless steel or beryllium copper are also used for production. For additional protection against corrosion, special compounds are applied to them. In this case, it is necessary to clarify in what environment the ring will operate, because This determines which anti-corrosion composition will be preferable.

Both the inner and outer rings have the appearance of an open circle. They are installed in special grooves, which are sometimes called grooves or grooves, and the part is firmly fixed in the right place.

Depending on the size of the retaining rings, their installation will require either a simple screwdriver (if we are talking about small rings) or special pliers.

High-quality, correctly installed retaining rings ensure long service life of the mechanisms.

Source: sovavto.org

DIY tool for removing circlips

Many people have probably had occasions when they needed to unscrew a screw with a non-standard head, remove/put on a part in a hard-to-reach place, etc. and so on. In general, the review is devoted to just such a specific tool, the need for which arises no more than once a year, but when it is needed, it is better if it is there. For those interested, take a look under the “cut”

Once I needed to replace the mowing reel for the trimmer - the old one “died”. Well, of course, I have a screwdriver and hands. I unscrewed what was unscrewed, took off what was removed... And here’s the ambush.

In the depths of the Siberian shaft there is a retaining ring, the removal of which takes quite a long time without a special tool.

With the help of 2 nails, a flat-head screwdriver, I took off this ring about the 20th time (it’s much easier to put it on), but when I came across “or” this product, I decided to buy it, fortunately the price was not high, and the Welcomeback_User_Coupon_Oct_R1_2_1 coupon for $2 came in handy.

After 3 days, the seller provided me with a tracking number, and after 16 days I received a parcel.

The pliers are packaged in a blister, on the back of which there is an instruction manual.

The kit includes additional attachments at 45° and 90° for various “situations”. The pliers are universal - they work both for expanding (to remove the locking ring from the shaft) and for compressing (if it sits inside the tube).

Simply press the central spring-loaded pin, pull out the “lock”, pull it out, and then put the attachment on the other side of the pliers onto the pins and lock it again. Voila! In this way, the principle “there is no extra tool in the house” is observed, and the next time you replace the coil, when it falls apart again, 20 minutes of time and a lot of nerves will be saved.

Well, of course, I didn’t buy these pliers just to repair the trimmer; there are rings in many tools that sooner or later will have to be disassembled/lubricated/repaired.

Retaining rings are widely used in the designs of a wide variety of mechanisms to secure a shaft, rod, axis of rotation or bearing. They are used in water valves and gearboxes, in ship gearboxes and in space stations. If it is necessary to replace or repair a mechanism assembly, the ring must be removed. For this purpose, special tools are used - ring removers.

What is a snap ring

Due to the similar name and shape of the ring, many people confuse a locking ring with a lock washer. Despite the similarity in name and appearance, they have fundamentally different functions.

A lock washer secures a threaded connection by preventing rotation of the nut or bolt head.

A locking ring prevents axial movement of a bearing, shaft, axis of rotation or other structural element.

On the mechanism parts that need to be secured against axial movement, a narrow shaft is machined or milled, slightly wider than the height of the ring. The ring, in a compressed or stretched state, is inserted into the groove and released. The part is compressed, enveloping the shaft, or expanded, fixing the bearing in the hole.

To remove the fastener, you also need to unclench or close the ears.

Ring locking fasteners are widely used in all branches of mechanical engineering, from watchmaking to mining equipment, from paper machines to bicycles, from household appliances to spacecraft.

Types of retaining rings

There are two main types of locking ring connections:

- Internal. Serve to fix parts inside holes. Used for fastening bearings. The ears protrude inward. To install them, you need to compress them so that the length of the outer circumference decreases, insert the part into the inner groove and release the ears. The part will straighten and partially fall into the groove, and partially protrude from it. This protruding part will not allow the bearing resting against it to move in the axial direction. To remove the mount, the ears need to be spread apart.

- External. Used for fastening parts on shafts, axles, rods. They are put on the shaft from the outside, the ears protrude on the outer side of the product, the cut between them is minimal. For installation, the ears are moved apart, the length of the inner circumference of the product increases, and it can be put on a shaft or axle, placed in a machined groove. After this, the ears are released, the part is compressed under the influence of elastic forces, fits tightly into the groove, leaving an annular rim on the outside. It will not allow the part to move in the axial direction. To remove such a part, the ears are brought together.

Retaining rings

A retaining ring is a closed ring made of carbon steel to secure parts and assemblies to a shaft or hole. Retaining rings are widely used in mechanical assemblies to secure bearings, axles, levers and rods. Retaining rings are mounted in grooves (grooves, grooves) in such a way that the protruding part acts as a shoulder, fixing the part in the mounting location.

According to the method of fastening, locking rings are divided into external ones - for fixing parts on the shaft and internal ones - for mounting mechanisms in the opening. According to the shape of the ring - concentric and eccentric. Dimensions are regulated by:

- GOST 13942-86, DIN 471 - for fixation on the shaft;

- GOST 13943-86, DIN 472 - for fixation in the hole.

The difference between rings produced according to GOST and DIN is in the thickness of the sheet from which they are made; as a rule, DIN ones are thicker; here it is necessary to measure the thickness of the mounting groove.

The metal from which snap rings are made is most often carbon steel, stainless steel or beryllium copper. The opening of these rectangular rings is that they are made from tape or from spring steel. There are rings for the same purpose made of round or oval wire, according to the drawing or standard by which they are made. Rings may also differ in anti-corrosion coating:

- chemical oxidation by oiling;

- zinc

- cadmium plating

- phosphating

Depending on the working environment, the appropriate coating is selected.

For fixing in the hole.

Retaining rings are mounted or removed using a special tool - pliers (puller), this applies to rings that have mounting holes GOST 13942 or an analogue of DIN 471, GOST 13943 or an analogue of DIN 472.

To select a retaining ring, you need to know the following (we are talking about steel rings):

- What cross-section does the ring have: round or rectangular? In other words, made of wire or tape.

- Where the ring is mounted: on the shaft or in the hole. Rings can be external and internal, their differences are in size and the design of mounting holes, slopes, and “ears”. GOST 13942 and DIN 471 are used for the shaft. GOST 13943 and DIN 472 are used for the hole.

- Which DIN do you need? If you know that the ring is mounted in a hole, but do not know which standard to choose, first you need to visually determine the ring with or without “ears”. GOST 13942 (DIN 471) and 13943 (DIN 472) with “ears”. The difference between rings produced according to GOST and DIN is in the thickness of the sheet from which they are made; as a rule, DIN ones are thicker; here it is necessary to measure the thickness of the mounting groove.

- What size? Rings are marked in standards according to their nominal diameter, which, as a rule, corresponds to the diameter of the shaft or hole where the ring is mounted. External retaining rings are measured by the inner diameter, and internal retaining rings are measured by the outer diameter. The actual diameter of the ring is slightly larger or smaller; this size takes into account the mounting groove (groove).

- What grade of steel? GOST standards, according to which rings are made, provide for a number of spring steels. The most common grade of high-carbon steel for the manufacture of such products is 65G. Can also be ordered from steel 60С2А or stainless steel 40Х13.

- What kind of coverage? Typically, chemical oil oxidation is used to coat retaining rings. If necessary, you can order them coated with cadmium or zinc.

Retaining ring pullers for removal and installation

Ring locking fasteners are widely used in the design and manufacture of various mechanisms.

They limit or block the axial movement of shafts, rods and bearings. The ring is made of elastic spring steel. It has a narrow cut, next to which it expands into rounded areas. In the center of these areas there are holes for the jaws of the circlip remover. A narrow groove is machined into the body of the part, the holder, or the shaft itself; the ring is inserted into it in a compressed state, when the pads are brought together by the puller jaws inserted into the holes and there is practically no gap. Due to the elastic deformation of the ring, its circumference decreases, and it fits freely into the groove. After the jaws are unclenched, the fastening, under the action of elastic forces, returns to its original shape and is tightly fixed into the groove, clamping the locking ring. This makes axial movement of the fastened part impossible; when axial forces are applied to it, the ring locking fastening, resting against the groove, stops the movement. Rings can be external, put on the cylindrical part from the outside, and internal, inserted into a groove milled or machined in the inner surface of a cylindrical hole, blind or through. The pullers designed for such rings also differ. External ones have smaller dimensions, and for internal ones, circlip pliers with elongated jaws are used

If the external ring fastening can still be installed and removed using improvised means, then for the internal one, and even located in a certain recess, a puller is the only way to accurately install and dismantle the rings without the risk of injuring your fingers or breaking the part.

In everyday life, retaining ring pullers are often called pincers, round nose pliers or pliers due to their external similarity. Technically this is incorrect, since by type of instrument they are classified as forceps.

Pullers are precision tools and must withstand large short-term loads. Therefore, they are made from high-strength tool steel. Often, to save weight and reduce prices, only jaws that experience maximum loads are made from high-strength alloys. Manufacturers offer a wide selection of pullers for a wide variety of ring sizes. Some include sets of several pullers for the most popular sizes, while others have gone the route of producing universal pullers. The kit of such a device includes several pairs of replaceable jaws, which can be quickly rearranged as needed.

If a tool is purchased for one-time work, there is no point in chasing the brand; cheap Chinese products will remove one or two fasteners no worse than famous ones. But if the equipment is purchased for regular use, for example, in a car service, then, of course, you should choose products from a well-known brand. Such manufacturers use the most advanced technologies and engineering solutions; their products are equipped with additional functions that make work easier and increase safety.

They use screw joints, which ensure exceptionally smooth and even movement of the handles. The special shape of the working surfaces prevents the ring from slipping off. The limit screw allows you to adjust the range of travel of the jaws, preventing excessive stretching or compression of the ring material, which could lead to its breakage. The detachable locking mechanism allows you to fix the locking fastener in an extended state, saves the worker’s energy and allows you to move the ring to the seat more accurately and quickly. Ergonomic handles do not injure hands and reduce worker fatigue, so he can work effectively for an entire shift.

Retaining ring

There are simply a huge number of different options for fastening materials, which are characterized by their specific properties. Retaining rings are used in various operating conditions. They are installed as an intermediate element, for example, responsible for transmitting rotation from an electric motor to an actuator. Let's consider all the features of using retaining rings, their varieties and many other points in more detail.

Internal retaining rings DIN 472, SEG W

In some cases, in addition to serving as a part-holding function, circlips of varying thickness also determine the amount of play.

Retaining rings are easy to install and take up little space. Their use eliminates the need to make shafts with steps, shoulders or threads for nuts. They can withstand significant axial loads.

The disadvantage of fastening with retaining rings is that the parts are weakened by the annular grooves. This disadvantage is especially noticeable in shafts. For rings mounted on shafts, the fit tension is weakened by centrifugal forces. At very high rotation speeds, it is necessary to secure the rings from leaving the grooves. According to the type of installation, lock rings of axial and radial assembly are distinguished. According to the manufacturing method, retaining rings are divided into turned, wire and stamped.

Retaining rings

To ensure reliable fixation of a wide variety of elements, locking rings are used. They are represented by fasteners of a special shape, which can be used to increase the degree of fixation of parts relative to each other. Outer retaining rings can often be found when attaching rolling bearings, which are responsible for reducing the degree of wear of bearing shafts and other elements during operation. When considering, attention is paid to the following:

- The classification is carried out according to the area of application and design characteristics; there is also a table of sizes, which simplifies the selection of the most suitable part for specific operating conditions.

- When choosing, attention is paid to parameters that differ depending on operational properties. If we consider the description of common products, we should pay attention to the fact that there are several different parameters. They are also indicated in the table.

Such a small and inexpensive product is part of various mechanisms and devices. Due to the use of special production technology and special materials, performance characteristics are significantly increased. When choosing, the following are taken into account:

- Nominal hole diameter. Often the part in question is fixed to a shaft, so the internal diameter is considered a decisive quality.

- Attention is also paid to the outer diameter. It should not be much larger than the fasteners and should not extend outside. In addition, the outer diameter is taken into account when choosing rings that are installed inside.

- The thickness of the ring is determined by subtracting the inner diameter from the outer diameter. It is also standardized in GOST. Increasing the thickness significantly increases strength.

- To ensure the required functionality, a groove is created, which is characterized by diameter and width.

Do not forget that all sizes are maintained within a certain range with varying accuracy. Many parameters are selected in accordance with the standards specified in GOST.

Overview of types and sizes

In one of the options, the “pull” method is used. The thread has some positive tolerance. When a part is twisted, intense friction is created between the turns. This is what secures the fastener to the bolt rod; the connection will not lose stability even with strong vibration.

Some versions come with a nylon ring. Typically their size ranges from M4 to M16. Fasteners with an insert can have a durable or particularly durable design. Most often it is intended to be used in conjunction with a bolt (screw). In some cases, additional equipment with a washer is practiced; its role is to reduce the risk of the connection unwinding.

Sometimes a self-locking nut has a flange - this can be easily recognized by its hexagonal shape. There are also versions with a collar, which additionally helps in stopping. As for the sizes, everything is simple and strict:

- M6 - height from 4.7 to 5 mm, grip height for the key - not less than 3.7 mm;

- M8 - with a rifling pitch of 1 or 1.25 mm (the second option is standard, other dimensions are indicated in the order and in the markings);

- M10 - standard height from 0.764 to 0.8 cm, with the lowest key grip level 0.611 cm.

Types of retaining rings

Various types of retaining rings are made, the choice is made taking into account the classification and size. The most common types of retaining rings are:

- Internal. These retaining rings are in Russia in accordance with two standards: GOST 13943 and GOST 13941. With lugs they are much more common, since it is designed for a large axial load. However, a more complex shape increases the cost of the product. The purpose is to eliminate the possibility of displacement of internal parts, the reliability of fixation is significantly increased.

- External. These products are also manufactured in two versions. On the production line, two standards are taken into account: GOST 13940 and GOST 13942. The purpose of the product is to fix various round-shaped parts, the location remains unchanged relative to the axis. Many other fasteners are used to prevent rotation.

This classification is related to where exactly such an element is fixed at the time of operation. An example is that internal ones are installed in the hole of the product, external ones on shafts. In some cases, the product has a special groove designed to fix the retaining ring.

Classification is also carried out according to design characteristics. The use of casting technology allows us to obtain a wide variety of products. To achieve certain properties, mechanical processing is additionally carried out, as well as thermal and chemical treatment to improve the basic characteristics. The following execution options are available:

- Spring thrust flat eccentric for internal and external use.

- Resistant external and internal.

- Retaining rings for external and internal use with special claws.

- Options with special sockets for fastening.

- Rings made from round wire.

A variety of materials can be used in manufacturing. Certain properties that a part must have are established in GOST and DIN,

The most widespread is the spring product, which is obtained by using a special alloy. External and internal GOST 13943 can have different diameters. Also often used is a hardware retaining ring and a spiral axial outer one, it all depends on the specific operating conditions.

Dimensions of external circlips DIN 471 (normal), SEG Z (mm)

d1 - shaft diameter s - ring thickness d3 - inner ring diameter a - eyelet width b - max. ring width d5 - hole diameter m - groove width n - protrusion height d4 - circle diameter

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

| 3 | 0,4 | 2,7 | 1,9 | 0,8 | 1 | 2,8 | 0,5 | 0,3 | 7 |

| 4 | 0,4 | 3,7 | 2,2 | 0,9 | 1 | 3,8 | 0,5 | 0,3 | 8,6 |

| 5 | 0,6 | 4,7 | 2,5 | 1,1 | 1 | 4,8 | 0,7 | 0,3 | 10,3 |

| 6 | 0,7 | 5,6 | 2,7 | 1,3 | 1,2 | 5,7 | 0,8 | 0,5 | 11,7 |

| 7 | 0,8 | 6,5 | 3,1 | 1,4 | 1,2 | 6,7 | 0,9 | 0,5 | 13,5 |

| 8 | 0,8 | 7,4 | 3,2 | 1,5 | 1,2 | 7,6 | 0,9 | 0,6 | 14,7 |

| 9 | 1 | 8,4 | 3,3 | 1,7 | 1,2 | 8,6 | 1,1 | 0,6 | 16 |

| 10 | 1 | 9,3 | 3,3 | 1,8 | 1,5 | 9,6 | 1,1 | 0,6 | 17 |

| 11 | 1 | 10,2 | 3,3 | 1,8 | 1,5 | 10,5 | 1,1 | 0,8 | 18 |

| 12 | 1 | 11 | 3,3 | 1,8 | 1,7 | 11,5 | 1,1 | 0,8 | 19 |

| 13 | 1 | 11,9 | 3,4 | 2 | 1,7 | 12,4 | 1,1 | 0,9 | 20,2 |

| 14 | 1 | 12,9 | 3,5 | 2,1 | 1,7 | 13,4 | 1,1 | 0,9 | 21,4 |

| 15 | 1 | 13,8 | 3,6 | 2,2 | 1,7 | 14,3 | 1,1 | 1,1 | 22,6 |

| 16 | 1 | 14,7 | 3,7 | 2,2 | 1,7 | 15,2 | 1,1 | 1,2 | 23,8 |

| 17 | 1 | 15,7 | 3,8 | 2,3 | 1,7 | 16,2 | 1,1 | 1,2 | 25 |

| 18 | 1,2 | 16,5 | 3,9 | 2,4 | 2 | 17 | 1,3 | 1,5 | 26,2 |

| 19 | 1,2 | 17,5 | 3,9 | 2,5 | 2 | 18 | 1,3 | 1,5 | 27,2 |

| 20 | 1,2 | 18,5 | 4 | 2,6 | 2 | 19 | 1,3 | 1,5 | 28,4 |

| 21 | 1,2 | 19,5 | 4,1 | 2,7 | 2 | 20 | 1,3 | 1,5 | 29,6 |

| 22 | 1,2 | 20,5 | 4,2 | 2,8 | 2 | 21 | 1,3 | 1,5 | 30,8 |

| 24 | 1,2 | 22,2 | 4,4 | 3 | 2 | 22,9 | 1,3 | 1,7 | 33,2 |

| 25 | 1,2 | 23,2 | 4,4 | 3 | 2 | 23,9 | 1,3 | 1,7 | 34,2 |

| 26 | 1,2 | 24,2 | 4,5 | 3,1 | 2 | 24,9 | 1,3 | 1,7 | 35,5 |

| 28 | 1,5 | 25,9 | 4,7 | 3,2 | 2 | 26,6 | 1,6 | 2,1 | 37,9 |

| 29 | 1,5 | 26,9 | 4,8 | 3,4 | 2 | 27,6 | 1,6 | 2,1 | 39,1 |

| 30 | 1,5 | 27,9 | 5 | 3,5 | 2 | 28,6 | 1,6 | 2,1 | 40,5 |

| 32 | 1,5 | 29,6 | 5,2 | 3,6 | 2,5 | 30,3 | 1,6 | 2,6 | 43 |

| 34 | 1,5 | 31,5 | 5,4 | 3,8 | 2,5 | 32,3 | 1,6 | 2,6 | 45,4 |

| 35 | 1,5 | 32,2 | 5,6 | 3,9 | 2,5 | 33 | 1,6 | 3 | 46,8 |

| 36 | 1,75 | 33,2 | 5,6 | 4 | 2,5 | 34 | 1,85 | 3 | 47,8 |

| 38 | 1,75 | 35,2 | 5,8 | 4,2 | 2,5 | 36 | 1,85 | 3 | 50,2 |

| 40 | 1,75 | 36,5 | 6 | 4,4 | 2,5 | 37,5 | 1,85 | 3,8 | 52,6 |

| 42 | 1,75 | 38,5 | 6,5 | 4,5 | 2,5 | 39,5 | 1,85 | 3,8 | 55,7 |

| 45 | 1,75 | 41,5 | 6,7 | 4,7 | 2,5 | 42,5 | 1,85 | 3,8 | 59,1 |

| 48 | 1,75 | 44,5 | 6,9 | 5 | 2,5 | 45,5 | 1,85 | 3,8 | 62,5 |

| 50 | 2 | 45,8 | 6,9 | 5,1 | 2,5 | 47 | 2,15 | 4,5 | 64,5 |

| 52 | 2 | 47,8 | 7 | 5,2 | 2,5 | 49 | 2,15 | 4,5 | 66,7 |

| 55 | 2 | 50,8 | 7,2 | 5,4 | 2,5 | 52 | 2,15 | 4,5 | 70,2 |

| 56 | 2 | 51,8 | 7,3 | 5,5 | 2,5 | 53 | 2,15 | 4,5 | 71,6 |

| 58 | 2 | 53,8 | 7,3 | 5,6 | 2,5 | 55 | 2,15 | 4,5 | 73,6 |

| 60 | 2 | 55,8 | 7,4 | 5,8 | 2,5 | 57 | 2,15 | 4,5 | 75,6 |

| 62 | 2 | 57,8 | 7,5 | 6 | 2,5 | 59 | 2,15 | 4,5 | 77,8 |

| 63 | 2 | 58,8 | 7,6 | 6,2 | 2,5 | 60 | 2,15 | 4,5 | 79 |

| 65 | 2,5 | 60,8 | 7,8 | 6,3 | 3 | 62 | 2,65 | 4,5 | 81,4 |

| 68 | 2,5 | 63,5 | 8 | 6,5 | 3 | 65 | 2,65 | 4,5 | 84,8 |

| 70 | 2,5 | 65,5 | 8,1 | 6,6 | 3 | 67 | 2,65 | 4,5 | 87 |

| 72 | 2,5 | 67,5 | 8,2 | 6,8 | 3 | 69 | 2,65 | 4,5 | 89,2 |

| 75 | 2,5 | 70,5 | 8,4 | 7 | 3 | 72 | 2,65 | 4,5 | 92,7 |

| 78 | 2,5 | 73,5 | 8,6 | 7,3 | 3 | 75 | 2,65 | 4,5 | 96,1 |

| 80 | 2,5 | 74,5 | 8,6 | 7,4 | 3 | 76,5 | 2,65 | 5,3 | 98,1 |

| 82 | 2,5 | 76,5 | 8,7 | 7,6 | 3 | 78,5 | 2,65 | 5,3 | 100,3 |

| 85 | 3 | 79,5 | 8,7 | 7,8 | 3,5 | 81,5 | 3,15 | 5,3 | 103,3 |

| 88 | 3 | 82,5 | 8,8 | 8 | 3,5 | 84,5 | 3,15 | 5,3 | 106,5 |

| 90 | 3 | 84,5 | 8,8 | 8,2 | 3,5 | 86,5 | 3,15 | 5,3 | 108,5 |

| 100 | 3 | 94,5 | 9,6 | 9 | 3,5 | 96,5 | 3,15 | 5,3 | 120,2 |

| 105 | 4 | 98 | 9,9 | 9,3 | 3,5 | 101 | 4,15 | 6 | 125,8 |

| 110 | 4 | 103 | 10,1 | 9,6 | 3,5 | 106 | 4,15 | 6 | 131,2 |

| 115 | 4 | 108 | 10,6 | 9,8 | 3,5 | 111 | 4,15 | 6 | 137,3 |

| 120 | 4 | 113 | 11 | 10,2 | 3,5 | 116 | 4,15 | 6 | 143,1 |

| 125 | 4 | 118 | 11,4 | 10,4 | 4 | 121 | 4,15 | 6 | 149 |

| 130 | 4 | 123 | 11,6 | 10,7 | 4 | 126 | 4,15 | 6 | 154,4 |

| 135 | 4 | 128 | 11,8 | 11 | 4 | 131 | 4,15 | 6 | 159,8 |

| 140 | 4 | 133 | 12 | 11,2 | 4 | 136 | 4,15 | 6 | 165,2 |

| 145 | 4 | 138 | 12,2 | 11,5 | 4 | 141 | 4,15 | 6 | 170,6 |

| 150 | 4 | 142 | 13 | 11,8 | 4 | 145 | 4,15 | 7,5 | 177,3 |

| 155 | 4 | 146 | 13 | 12 | 4 | 150 | 4,15 | 7,5 | 182,3 |

| 160 | 4 | 151 | 13,3 | 12,2 | 4 | 155 | 4,15 | 7,5 | 188 |

| 165 | 4 | 155,5 | 13,5 | 12,5 | 4 | 160 | 4,15 | 7,5 | 193,4 |

| 170 | 4 | 160,5 | 13,5 | 12,9 | 4 | 165 | 4,15 | 7,5 | 198,4 |

| 175 | 4 | 165,5 | 13,5 | 12,9 | 4 | 170 | 4,15 | 7,5 | 203,4 |

| 180 | 4 | 170,5 | 14,2 | 13,5 | 4 | 175 | 4,15 | 7,5 | 210 |

| 185 | 4 | 175,5 | 14,2 | 13,5 | 4 | 180 | 4,15 | 7,5 | 215 |

| 190 | 4 | 180,5 | 14,2 | 14 | 4 | 185 | 4,15 | 7,5 | 220 |

| 195 | 4 | 185,5 | 14,2 | 14 | 4 | 190 | 4,15 | 7,5 | 225 |

| 200 | 4 | 190,5 | 14,2 | 14 | 4 | 195 | 4,15 | 7,5 | 230 |

| 210 | 5 | 198 | 14,2 | 14 | 4 | 204 | 5,15 | 9 | 240 |

| 220 | 5 | 208 | 14,2 | 14 | 4 | 214 | 5,15 | 9 | 250 |

| 230 | 5 | 218 | 14,2 | 14 | 4 | 224 | 5,15 | 9 | 260 |

| 240 | 5 | 228 | 14,2 | 14 | 4 | 234 | 5,15 | 9 | 270 |

| 250 | 5 | 238 | 14,2 | 14 | 4 | 244 | 5,15 | 9 | 280 |

| 260 | 5 | 245 | 16,2 | 16 | 5 | 252 | 5,15 | 12 | 294 |

| 270 | 5 | 255 | 16,2 | 16 | 5 | 262 | 5,15 | 12 | 304 |

| 280 | 5 | 265 | 16,2 | 16 | 5 | 272 | 5,15 | 12 | 314 |

| 290 | 5 | 275 | 16,2 | 16 | 5 | 282 | 5,15 | 12 | 324 |

| 300 | 5 | 285 | 16,2 | 16 | 5 | 292 | 5,15 | 12 | 334 |

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

Installation of retaining rings

As previously noted, the retaining ring is manufactured in accordance with established standards in GOST and DIN. However, improper installation can cause a significant reduction in service life. The part has special grooves, which simplifies the installation and operation process. The installation features include the following:

- It is important to choose the right part of the required dimensions and characteristics.

- During installation, do not place a large load on the ring. This is due to the fact that even a minor defect can reduce performance.

It is precisely the fact that there are no difficulties in installing the product that determines its wide distribution. Installation, as well as replacement, is quite simple, but do not forget that such a product acts as an intermediate element. Therefore, in order to get to it, in some cases it is necessary to disassemble almost the entire mechanism. The flat inner ring is often installed in a special groove, so removal can be very difficult.

Functions of retaining rings

Many technological maps and drawings indicate the need to use such a product. The main functions are:

- Significantly increases the reliability of fastening.

- Eliminating the possibility of displacement of other elements, for example bearings on a shaft.

- Fixation of critical parts.

Often a retaining ring is placed on a shaft that has the required grooves. Due to this, the fixation of individual elements along the axis, for example, bearings and gears, is significantly increased. That is why such a product has become very widespread in the field of mechanical engineering.