Mechanisms for transmitting motion

On the simplest models of serial drilling machines and on equipment that is made by hand, coordinate tables are installed mainly, which are driven mechanically.

If high precision and processing performance are required from a drilling machine, tables driven by electric motors are installed on it. Three types of gears are used in coordinate table drives:

- based on gears and racks;

- based on belt mechanisms;

- ball screw.

Helical rack and pinion transmission ensures positioning accuracy

The choice of transmission type is influenced by a number of parameters:

- the speed at which the table and the workpiece attached to it must move;

- power of the electric motor used;

- requirements for precision processing of parts.

High precision of movement is ensured by a ball screw drive, which also has a number of other advantages:

- very slight play;

- smooth movement;

- quiet operation;

- resistance to significant loads.

Ball screw in high precision coordinate table

The disadvantages of this type of transmission are the inability to ensure high speed of table movement and the significant cost of such a mechanism.

To reduce the cost of a homemade coordinate table for a drilling machine, you can equip it with a drive based on a conventional screw drive. However, in this case, care must be taken to ensure that the transmission screw mechanism is lubricated as often as possible.

Homemade coordinate table with screw gears and cylindrical guides

A budget option is also to use a drive for moving the coordinate table, made on the basis of a belt drive. When installing such a drive on a home-made coordinate table, you should take into account the disadvantages of using it:

- rapid wear of belts;

- stretching of belts during operation;

- increased risk of belt breakage under increased loads;

- low accuracy.

Accuracy and high speed of movement are ensured by coordinate table drives, made on the basis of a rack and pinion transmission. Meanwhile, when using such a drive, you should be prepared for the fact that play will form in the elements of its mechanism after a certain period of active use.

Materials and mechanisms of structural elements

The durability of the structure and cost depend on the material of the product. You should immediately decide what type of table it will be - steel, aluminum or cast iron. The second important step is to decide on the control mechanism. You should also decide whether the drive should be mechanical or electric. The third step is to select guides. This will affect the processing accuracy of the workpieces.

Base

The following materials are used for the base:

- Cast iron. Expensive, heavy material turns out to be very fragile in operation, so it is used extremely rarely in the production of a drilling machine.

- Steel. The material is the most highly durable and durable. Its main drawback is the cost. Not every master will be able to purchase it.

- Aluminum. Light and soft material is easier to work with. It is not as expensive as steel. But it is not suitable for making a large-sized table, since it will not withstand the heavy weight of large workpieces. This is an ideal option for creating mini-equipment.

If the master processes metal workpieces, then it is better to make the table from steel or cast iron. True, you should immediately evaluate your costs: perhaps purchasing a ready-made manipulator will cost less than expensive hardware. An aluminum tabletop is suitable for working with wood or plastic.

Cast iron

Steel

Aluminum

Drive unit

The drive is a control mechanism with which the coordinate table will change its position. It happens:

- Mechanical. The easiest way is to make it yourself. It allows you to significantly reduce the cost of the table. The basis is a conventional screw or belt drive - this is enough to set up small-scale production. Mechanics are not capable of providing 100% accuracy, and this is its clear drawback.

- Electric. It guarantees zero error when performing work operations, but it is very difficult to do it yourself. Often found in factory models of tables. If there is no own power source near the workplace, this option will not work.

Models with CNC (computer numerical control) should be included in a separate category of coordinate tables. This is high-tech equipment that is used by large enterprises for production in huge volumes. Their main advantages: good performance, as well as complete or partial automation of the process. Disadvantages: high cost, such a drive is not suitable for some parts.

Mechanical

Electric

CNC

Guides

The accuracy of the workpiece processing depends on these elements, so they need to be selected correctly. Among those that you can do with your own hands, the following are distinguished:

- Rail. Rectangular guides are considered structurally more advanced. When using them, lower friction losses are observed and serious errors are avoided. It is possible to connect a lubricant supply system.

- Cylindrical. The use of rounded guides is fraught with high heating due to friction. They are suitable for machines of the so-called small category, but you will have to lubricate all the mechanisms manually.

The guides are made with a carriage and bearing units. The use of plain bearings will ensure high precision machining of the part. The use of a rolling shaft support will reduce friction and extend the service life of the manipulator.

The rolling bearing can cause noticeable play, which reduces the accuracy of the workpiece.

The carriage is a block of guides (mechanism assembly) that moves directly along them. It can provide increased flange dimensions, which allows it to be mounted on the underside of the table. If it is not there at all, then the carriage is placed on top (threaded method).

Rail guides and carriage

Cylindrical

Moving device

When choosing a moving device, you should answer a number of questions:

- What should the processing speed be?

- What positioning accuracy is acceptable when performing work operations.

- How productive the equipment will be used.

A belt moving device is most often used in the manufacture of homemade coordinate tables. It is cost-effective, but has a number of disadvantages. The belt wears out quite quickly and can also stretch during use. In addition, due to its slipping, the accuracy of the moving element is reduced.

Ball screw drive is a more durable and reliable option. Despite the small dimensions of the device, it has a good load capacity, and movement is carried out evenly and with great accuracy. Smooth and almost silent running, as well as high quality surface treatment are not all the advantages of ball screws. However, it also has some disadvantages: high cost and limitations in the speed of rotation of the propeller if its length is more than 150 cm.

Rack and pinion devices provide high speed and accuracy of work, withstand heavy loads, are easy to install and are reliable in operation. The error in rack transmission is extremely low. If their size does not fit, then they undergo a fitting operation.

Belting

Ball screw

Rack and pinion

Step-by-step algorithm for manufacturing a household table with a mechanical drive

How to make a vacuum table for CNC with your own hands

To make a coordinate table with the simplest mechanical drive, you need to follow the instructions:

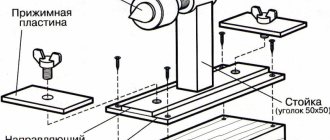

- It is necessary to make the central unit of the table in the form of a cross from metal profiles 20 x 20 cm (2 mm thick). It must ensure the stability of the entire structure, so all parts are welded.

- On the surface of the finished cross, assemble carriages with a stroke of 94 mm.

- File the profiles and then insert M10 nuts into them.

- Using M10 studs, assemble the handles with the bearing assembly.

- Next, you should weld two U-shaped bases from the corner, and then assemble the entire structure using bolts that were screwed into the previously pressed nuts.

- Wipe all components, as well as moving parts, with lubricant.

- The assembled table must be attached to the drilling machine bed.

To protect the lubricated structural elements from chips or other waste when processing the workpiece, it is advisable to lay plywood between the coordinate table and the machine. The dimensions of the finished manipulator will be 35 x 35 cm, and the thickness of the product will be 6.5 cm. It is desirable that the total length of the guides be about 30 cm.

Make the central unit of the table in the form of a cross

Assemble the carriages on the surface of the finished cross

File the profiles, insert the nuts

Assemble the handles with the bearing assembly on the studs

Weld two U-shaped bases from a corner

Assemble the entire structure

Wipe all components and moving parts with lubricant.

Attach to drill press bed

Warping characteristics

Coordinate-type tables, which are equipped with drilling machines, can be made with bases made of various materials:

- cast iron;

- become;

- light alloys based on aluminum.

Tables with a base made of aluminum construction are not designed for heavy loads, so they are used to equip drilling machines that process parts made of soft materials (wood, plastic). The advantages of devices whose frame is made of aluminum profile are:

- light weight;

- ease of installation;

- affordable price.

PROXXON-MICROMOT coordinate table made of high-strength aluminum alloy for benchtop drilling machine

Thanks to the simplicity of its design and the availability of manufacturing materials, such a table is easy to make with your own hands. If you don’t want to use a home-made device when working on a machine, you can purchase a ready-made kit for its assembly, which is produced by many companies.

Industrial coordinate tables for drilling machines, which are used most intensively and experience significant loads during operation, are manufactured with bases made of cast iron.

Cast Iron Cross Table for Industrial Drilling Machine

Both serial and home-made coordinate-type tables can be made on the basis of welded steel frames, which demonstrate high reliability. When making such a frame with your own hands, you should keep in mind that welded joints do not withstand vibration loads well, so in the finished structure it is necessary to get rid of internal stresses as much as possible. This is achieved through appropriate heat treatment (tempering).

Coordinate tables, depending on their purpose, can be made according to two design schemes:

- cross;

- portal

Tables made according to the first scheme are equipped with universal drilling machines, on which parts of complex configurations are processed. The design features of such devices allow access to the workpiece being processed from three sides. Portal-type tables are equipped with machines on which holes are drilled in sheet blanks.

Gantry 3-axis CNC table

Where is it profitable to buy a coordinate table?

How to make a table for a circular saw with your own hands?

We recommend buying a coordinate table at a good price in this Chinese store. Read more about how it can be successfully applied. Video of the youtube channel “Technician” at the end of the publication.

In this video review, there is a coordinate table that will become part of a milling machine. Made of aluminum alloy. Transverse stroke 50 mm, longitudinal 200. Do not pay attention to the play, it can be easily eliminated with a hexagon included. A standard M8 steel pin is used as lead screws. In addition to the dials, the marks on which are ordinary stickers, there is a ruler on the longitudinal movement. But there is no mark on the table by which you can keep a report.

The master disassembled the table to understand what we were dealing with. Where to buy, see at the beginning of the article. As you can see, the backlash is removed by pressing the plate. The lead screw rotates into bushings made of the same material. The table is a profile made of strong aluminum alloy with a wall thickness of 3 millimeters. There is no talk about working on steel, but we’ll try milling duralumin later.

Instead of a standard pin, which was tightened with a screwdriver, it was held in place by a shaft with a handle; now, thanks to the work of a turner, it was held in place by a wing screw. By screwing it all the way, the vertical movement is stopped. What you need for milling. Unscrew it a little more, the position of the shaft changes so that the handle does not interfere. Two bushings for the drill and router were also made. All that remains is to make a mount for the table and test it in operation.

Now drilling a 6 mm steel bar is a pleasure. Even 12 bolts for mounting on a Soviet machine table would be too small. Therefore, I had to screw 8 pins into pieces of steel pin. Now you can definitely fix the coordinate table and move on to the most important thing. To the test.

The first experimental material was a piece of acrylic plate. Its properties are slightly tougher than plexiglass. Not as sticky. To secure the part, there are two clamps included with the table. The minimum speed of the router is at 8000 rpm. No load is felt on the router, about 1 millimeter is removed. Continued in the video from the fifth minute

Production of homemade versions

How to make a carpentry workbench with your own hands?

When manufacturing, you should initially select the material of manufacture:

- Cast iron is an expensive, heavy, brittle material. It is quite rarely used in the production of a drilling machine.

- Steel is a strong, hard, durable metal, which also has a fairly high cost. Steel can be called the most attractive material.

- Aluminum is a light, fusible, but expensive and soft material. It is quite easy to use in the manufacture of any machine parts. As a rule, mini equipment is created using this alloy.

The above materials are selected for a full or mini machine.

Hardware Definition

A coordinate table is a manipulator that is used to secure the workpiece being processed. There are several options for machine tables:

- vacuum fastening method - used quite rarely due to the complexity of the design;

- the mechanical type of fastening is simple to implement, you can do it yourself quickly;

- fastening due to the weight of the workpiece. When using a drilling machine, large workpieces can be processed. Due to its weight, the supported part remains in place even under strong impacts.

There are positioning with one, two, three degrees of freedom. This point determines that the workpiece can be fed along three different coordinates. When drilling a flat product, it is enough to move it along just one horizontal plane.

We can roughly distinguish two main types:

- Large dimensions. A large coordinate table is created taking into account the fact that the equipment itself, as well as the workpiece, will be installed on it.

- A coordinate table of small overall dimensions is mounted on the equipment frame.

There are several control mechanisms by which the coordinate table changes its position:

- Mechanical drive is quite common. You can make it for a drilling machine with your own hands to set up small-scale production.

- An electric drive is installed quite often for a drilling machine. Making it yourself is quite difficult, since you need to maintain high precision during manufacturing. For automatic movement, the coordinate table must have its own power source.

- Another separate group can be called a mechanism that operates using numerical control.

You can make a small coordinate table with a mechanical drive with your own hands.

Design selection

When choosing a design, you need to decide on its dimensions. If equipment that processes a part will be installed on a coordinate table, then its dimensions must be taken into account. If it is needed to fix the workpiece, it is mounted on the frame of the drilling equipment, and its width and length will be about 35 x 35 cm.

Tables are also distinguished by the type of fastening:

- When making a coordinate table with your own hands, the structure is equipped with a mechanical fastener. This is the simplest solution in terms of implementation, but it has a number of disadvantages. For example, it often leads to processing errors, and there is a risk of deformation of the product surface.

- Vacuum fastening is considered the best option. With its help, precise positioning of the workpiece on a horizontal plane is ensured. When an air stream is supplied into the gap between the tabletop and the workpiece, the pressure in this area changes. Thanks to this, it is possible to perform processing more efficiently (without mechanical damage to the product).

- Workpiece weight clamping is suitable when using a drill press to machine heavy parts. Due to its mass, the base product remains in the same place even with strong impact.

The functionality of the table depends on the number of degrees of freedom:

- If there is only one, then the workpiece can only be moved in one direction (this is a good option for processing flat products).

- If there are two degrees, it becomes possible to move the workpiece along X and Y coordinates.

- If there are three of them, then the part can move up, down and along the Z coordinate.

If the table is made for home production and processing of parts, then using two degrees of freedom is more than enough.

When making a coordinate table with your own hands, it is important to decide for what purpose it will be used. The parameters of the manipulator are selected in accordance with the dimensions, weight and shape of future workpieces. To work with various parts from metal and wood, a complex multifunctional mechanism is made. Usually, home craftsmen have enough capabilities of a small-sized table with mechanical fasteners and two degrees of freedom.

Mechanical

Vacuum

Fastening under the weight of the workpiece

Types of gears for table movement

With a small tabletop machine, the table is moved mechanically. But the greater the speed, accuracy and performance required, the more carefully the type of drive is selected. Electric motors are mainly used.

The essence of the unit’s operation is to convert the rotational work of the engine into translational motion of the table plane. There are three types of transmissions:

- rack and pinion;

- belt;

- ball screw.

The choice of node type is made based on:

- workpiece movement speed;

- machine engine power;

- required processing accuracy.

Machining accuracy at various transfer units

| Type of transmission mechanism | Accuracy Rate |

| Ball screw | 6-12 microns |

| Rack and pinion | up to 10 microns |

| Toothed belt | 50 … 100 µm |

Advantages of Ball Screw:

- possibility of high-precision processing;

- small backlash;

- smooth movement of the table;

- quiet operation;

- ability to take heavy loads.

Ball Screw Drawing

A significant disadvantage is the limited feed speed. The decrease in speed is especially noticeable when the propeller length is more than 1500 mm. Approximate speed calculation: for a 1 kW drive, the rotation speed is 3000 rpm. With a screw pitch of 10 mm, the transmission speed is 0.5 m/sec. In this case, 3 m will be covered in 6 seconds.

Another disadvantage is the high cost. You can reduce the cost of the project by using a connection with a screw and nut. In this case, it is necessary to ensure constant lubrication of the unit.

The rack and pinion transmission ensures high speed and sufficient accuracy. The disadvantage is the high degree of play when transmitting forces from the drive.

Installing a belt is the most budget-friendly and common method when creating a table with your own hands. The low cost of belt drive and feed speed up to 1 m/s is compensated by the following disadvantages:

- rapid wear;

- loss of tension due to stretching;

- possibility of breakage during acceleration;

- low accuracy of work.

When purchasing a coordinate table for drilling or do-it-yourself installation, you must take into account the working conditions. The ratio of all mechanisms in terms of parameters: workload, service life, heating and cooling will give a good result during operation

This is especially important when making it yourself from scrap materials.

Materials and tools used

To work you will need a welding machine, a drilling machine, an angle grinder with discs, a hammer, brushes, and a corner. At the preparatory stage, it is necessary to select the material for the base of the device, the control mechanism and guides. The accuracy of the future operation of the device, service life, reliability of the device, and financial costs of manufacturing depend on the correct choice of these components. To create a base, one of three metals is suitable:

- cast iron;

- steel;

- aluminum.

The first material is rarely used in work. The reason lies in its fragility, heavy weight, and fragility. Steel wins by these criteria, which is why it is often used in production. Its only drawback is its high cost. Aluminum is much more affordable. Its advantages are lightness and softness. But it is only suitable for small-sized tables, since the malleable metal cannot withstand large heavy parts.

Step-by-step making of a desk with your own hands, examples of decor

When making a coordinate table with your own hands, you need to think about what type of drive the device will have. According to the control method, manipulators are divided into three types: mechanical, electrical, and program control. The latter drive is not used in self-production. The electrical analogue gives a small error, but in private conditions it is problematic to use. For personal home appliances, a more suitable type of control is mechanical. However, it has a drawback - the lack of perfect accuracy.

For manual production, rail or cylindrical guides are suitable.

Cast iron

Steel

Aluminum

Mechanical drive

Electric

Software controlled

Advantages and disadvantages of self-production

A coordinate table is an additional structure to a milling, drilling metal or woodworking machine. Thanks to it, you can increase equipment productivity by reducing the labor intensity of the parts processing process. The workpiece is simply fixed on the working surface and can move smoothly along a given path.

Homemade coordinate tables have the following advantages:

- small dimensions;

- simple design form;

- controlled mechanically;

- used in handicraft production.

Their main advantage is saving money. Making such a design from scratch will cost much less than buying a factory-made manipulator. Of course, there are a number of difficulties when making it yourself. A suitable drawing is needed, according to which the required trajectory of the workpiece will be set. If there is no someone else’s experience, then you will have to create it yourself, but any error when drawing a diagram will make itself felt during work. In addition, a homemade table is only suitable for small-scale production, since the simplest homemade mechanisms wear out much faster than factory ones.

Simple design form

Small dimensions

Mechanical control

Saving money

Homemade coordinate table, perhaps? — Homemade machines

Absolutely right, transverse and small longitudinal from a lathe, cast iron bed from a Komunaras drill with a screw feed, the working field turned out to be 300x300, mainly for processing small steel parts and is being invented, now everything is still in the process of experimentation and debugging, but there is positive experience with steel, It seems to cope with cutters up to 6 mm normally, but with a larger diameter problems begin (all mainly from using a 1200 W impact drill as a head), you need to come up with a tough, powerful head, when installing an angle grinder instead of a drill, you get a small grinder

Here’s a photo I took (though the quality is not very good) while working with steel, one has an x35 plate on it, the second photo shows the actual part for working with which the device was intended to work with (in the photo, one part is before processing, the second one, clamped in the chock, has already been passed through three times)

Modified on January 25, 2014 by BM_906