The modern market offers a wide selection of different products for welding - from welding machines of various designs and operating principles to consumables. Such an assortment is justified, first of all, by the desire to make the result of the work of the highest possible quality, regardless of the materials used and the working conditions of the specialist.

Among all this variety, UONI welding electrodes stand out in great demand, as they are used in the most common method of work - manual arc welding.

Electrodes brand UONI-13/45 – features

The main purpose of the material is welding parts made of low- or medium-carbon steel during the installation of particularly critical structures. Thanks to these electrodes, a seam with increased ductility and impact strength is obtained. The created structures can be used for decades at low temperatures. A typical example is pipelines laid in the northern latitudes of Russia.

High ductility and impact strength of the weld metal are ensured due to the main coating of the rod:

- the coating contains calcium fluoride (CaF2);

- During the welding process, hydrogen, which is harmful to the metal, binds with fluorine into a volatile compound and evaporates from the metal surface.

Thus, the amount of hydrogen in the metal is reduced to a minimum. Thanks to this, hot cracks are eliminated, and the risk of cold cracks (due to hydrogen diffusion) is also practically reduced to zero. Thanks to these same properties, the seam does not crack in a hydrogen sulfide environment. This allows the pipes to be used not only in northern climatic zones, but also in areas where there are deposits with a high content of hydrogen sulfide (oil and gas).

UONI-13/45 (NAKS, RRR, RS) 5 mm (6 kg) Current - constant, reverse polarity

172.68 rub. ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 5 mm (1 kg) Current - constant reverse polarity

RUB 190.68 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 4 mm (6 kg) Current - constant reverse polarity

172.68 rub. ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 4 mm (1 kg) Current - constant, reverse polarity

RUB 190.68 ? with VAT per 1 kg.

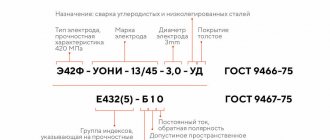

How to read labels

Designation example: E50A-UONI-13/55 SM-4.0-UD GOST 9467-60.

The entry is deciphered as follows:

- E - electrode for arc welding.

- 50 - temporary tensile strength of the seam is 50 kgf/sq. mm.

- A - the joint has plasticity and impact strength.

- UONI is a brand inherited from the name of the UONI-13 coating developed in 1940. The abbreviation means “universal coating of scientific institute No. 13.”

- 13/55 is a type of product.

- SM-4.0 - made of welding wire with a diameter of 4 mm.

- U - designed for joining carbon steel workpieces.

- D - thick layer of coating.

Instead of “U” the following letters may be present in the marking:

- L - alloy steel.

- T - heat resistant.

- B - highly alloyed.

- N - intended for repairs using surfacing method.

Instead of "D" there may be the following letters:

- C - medium thickness coating.

- M - thin.

In GOST 9466-75 this electrode is called “UONII” (universal coating of a research institute). Such an abbreviation must be indicated in design and other documentation.

UONI-13/45 – characteristics

The standard in accordance with which UONI-13/45 electrodes are produced is GOST 9467–75. The material of the rods is steel grades SV08A and SV08.

- The electrodes have a basic (calcium fluoride) coating.

- Temporary tensile strength – 460 MPa.

- Yield strength – 350 MPa.

- Deposition rate – 9.5 g/Ah.

- Surfacing productivity – 1.3 kg/h (for d 3 mm).

- Electrode consumption per 1 kg of deposited metal is 1.6 kg.

- The type of current used in welding is constant, reverse polarity.

- The spatial position of welding is any except for vertical downhill.

- Products are manufactured with a diameter of 2, 2.5, 3, 4, 5 mm.

Typical chemical composition of the deposited metal: C - 0.09%, Mn - 0.57%, Si - 0.25%, S - 0.014%, P - 0.017%.

general information

Welding electrodes of the UONI brand are an excellent choice for those who value high quality seams when manual arc welding. Any professional will tell you that to perform a truly high-quality and aesthetic seam using RDS technology, you need to practice a lot and select the right electrodes. The SSSI brand is perfect for these purposes.

What features does this brand have? Firstly, to work with such electrodes it is necessary to set reverse polarity and use direct current. It doesn’t matter at all what temperatures the welding takes place at, it doesn’t matter.

Secondly, UONI electrodes are still intended for practicing welders. If you are a beginner, you are unlikely to be able to make a high-quality seam the first (or even the fifth) time. This must be taken into account in advance and soberly assess your skills.

SSSI electrodes are available in different diameters. The most popular diameters are 3 mm and 4 mm. With the help of such electrodes you can weld most parts.

Main advantages of UONI-13/45

- Easy initial and re-ignition.

- Stable burning of the electric arc.

- High penetration depth, which allows you to weld thick-walled parts.

- Small amount of spattered metal.

- Easy separation of slag crust.

- Extremely low hydrogen content in the weld metal.

- High resistance of the metal to the appearance of crystallization cracks.

- Relatively low consumption of rods.

UONI-13/45 (NAKS, RRR, RS) 3 mm (4.5 kg) Current - constant reverse polarity

RUB 176.64 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 3 mm (1 kg) Current - constant reverse polarity

RUR 194.64 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 2.5 mm (4.5 kg) Current - constant reverse polarity

RUB 209.64 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 2.5 mm (1 kg) Current - constant reverse polarity

RUR 227.64 ? with VAT per 1 kg.

Decoding what the marking means

The abbreviation “UONI 13” stands for “universal coating of scientific institute number 13” (in Soviet times, many enterprises were assigned names in the form of a digital set for reasons of secrecy).

The variety is indicated by the number after the fraction, for example, UONI 13/55, UONI 13/65, etc. Here “55” and “65” indicate the strength characteristics of the welding seam of a specific UONI electrode.

The packaging with consumables UONI 13/45 has the following inscription:

E42A – UONI – 13/45 – 2.0 – UD/E412(4) – B20.

Explanation of most designations can be found in GOST 9466-75.

Features of use

Before welding, the electrodes must be calcined for an hour at a temperature of 350°C. Other features include:

- Welding is performed outdoors or in well-ventilated areas. This is due to the release of volatile fluoride compounds that are harmful to health.

- The surfaces of the parts to be welded must be cleaned of scale, dirt, traces of rust, and moisture must be removed.

- It is not recommended to lengthen the arc - this disrupts the stability of its combustion and can cause the formation of pores in the metal.

Using alternating current for welding is possible, but is also not recommended due to the risks of unstable arc burning.

What is alternating current in welding

Is it good or bad, which current is better? Variable or constant? No one will give you a definite answer.

Welding classification.

To begin with, it is better to understand the features of processes with alternating current, they are as follows:

- The behavior of the arc leaves much to be desired: with alternating voltage it is the most unstable.

- The welding seam is not of the highest quality due to deviation from the axis of the welding arc.

- If the arc goes out, its combustion can only be resumed when the voltage increases.

- The metal is splattered to a large extent.

Despite all these complexities, the equipment required for AC welding is simple and inexpensive. These are, first of all, transformers - devices that are still very popular among welding masters.

It would seem that electrodes for alternating current should gradually lose their relevance: after all, many rectifiers have appeared on the market - inexpensive and with small dimensions convenient for use. However, these consumables are still in demand in many industries and handicraft workshops.

Most of the brands are universal, which is also extremely suitable for older generation domestic welders.

If you look at it, the best consumables for “change” have and show very serious production advantages. First of all, this concerns the resulting electric arc: its durability and easy ignition. Another feature of such electrodes is the low level of metal spattering during welding.

Welding transformer

Electrode diameter and steel thickness. To carry out welding using a transformer, the following mandatory structural elements are required:

- Windings primary and secondary. The primary is made of a special insulated wire; there is no insulation on the secondary winding.

- Magnetic wire.

- Screw for controlling the position of two windings and changing the distance between them.

- Protective housing for the entire unit.

- Screw handle, running nut.

- Fan and other elements depending on the transformer model.

Despite the fact that many welding professionals regard transformers as equipment of the “outgoing generation,” they are presented on the market in the form of a wide range of models of very different values and for wallets of any thickness.

Transformers differ according to the following criteria:

- dimensions and weight;

- output current strength;

- output voltage level at idle;

- volume of electricity consumed;

Welding generator

Electrode markings. The generator design includes the required structural elements:

- The most important part - the converter consists of an electric generating element with an alternating voltage motor. They provide changes in current indicators.

- Drive internal combustion engine.

- Indicator for monitoring and recording current strength.

- Mode switches.

- Special circuit breaker.

- Regulators for current and arc behavior.

- Terminals for connecting cables and 230V outlets.

These types of generators are available in two versions:

- Collector generators.

- Valve generators.

The main advantages of a gas generator in comparison with other welding machines are:

- Compact and therefore highly mobile.

- Convenience, relative cheapness, noiselessness.

- Wide functionality and high reliability.

- Quite high technical characteristics.

Areas of use

In addition to pipelines used in the oil, gas, and chemical industries, electrodes of this brand are widely used for the production of:

- building structures;

- transport equipment (including for the transportation of dangerous goods);

- lifting equipment;

- equipment for metallurgy enterprises.

They are also used to manufacture boilers and boiler equipment, as well as equipment for the oil industry.

Electrodes UONI-13/45 are presented in the MEZ catalogue. These are the own products of the Magnitogorsk Electrode Plant. The high quality of products is confirmed by several documents, including a certificate from the National Welding Control Agency and a certificate of approval from the Russian River Register. The manufacturer indicates on the packaging all the necessary basic welding parameters. Delivery of goods is carried out to all regions of Russia.

Popular varieties

Consumables of this type are produced in a wide range of diameters (from 2 to 5 millimeters). The most popular in the model range are UONI 13 55 3mm and 4mm electrodes. At the same time, there are four types of products that have a specialized purpose and their own specific application.

- 13/45 – designed for creating highly demanding metal structures from low/medium carbon steel blanks. They are also used to repair cast and forged products and eliminate defects. The core of these electrodes contains molybdenum and nickel, which provide the weld with the necessary toughness and ductility.

- 13/55 – focused on welding structural elements made of low/high carbon steels. The coating of such models contains phosphorus, sulfur, silicon and manganese, which guarantees excellent quality of the welded joint. Used in production workshops. The products are demanding on the condition of the parts (dirt, rust and moisture on their surface).

- 13/65 - used in the same cases as analogues 13/55. These electrodes are used to produce a seam of improved quality, but the price of such SSSI per kg is noticeably higher. Therefore, such consumables are used only when creating especially critical metal structures and products.

- 13/85 - the most expensive welding electrodes from the UONI model range. They are actively used in the process of forming structures from parts made from alloy steels.