Uoni 13 55 electrodes are ideal for the arc welding process and important parts made of carbon-containing and low-alloy metals, in particular those used in low-temperature areas. This type of product has proven itself to be excellent when connecting serious metal structures, where it is necessary for the weld to have a high level of ductility and impact toughness.

Decoding the abbreviation Uoni

First, let's look at the name and find out where the name comes from. The decryption looks like this:

- U – Universal;

- O - Coating;

- N – Scientific;

- And - Institute.

- 13- №13

Those. this is a domestic development of a welding research institute, the name and number of which are fixed in the designation. The designation UONII is also found - the presence of an additional letter “I” indicates the Research Institute.

By the way! In the technical documentation, the correct designation is UONII; the requirements for this rule are specified in GOST 9466-75, but the name on the pack of electrodes may be UONI 13/55.

Why SSSI electrodes are most in demand

A distinctive feature of electrodes of this brand is that they can be used at low temperatures. The main problems arise when the seam cools, and when it cools quickly, cracks, shrinkage cavities and other defects may appear. Subsequently, they will lead to the fact that the welded parts will simply separate from each other.

High quality, as well as the absence of defects during hardening, is due to the fact that the chemical composition of the resulting seam assumes sufficiently high ductility and impact strength. This will extend the life of this connection in the future, especially if the welded parts are intended to be used in harsh and frosty climates.

It is precisely on the basis of these useful properties and qualities that SSNI electrodes have gained such high popularity among users.

It is worth noting that this connecting material is considered more professional than, for example, ANO. Therefore, it will be quite difficult for an ordinary person to work using this brand.

Specifications

Important parameters characterizing Uoni 13/55 welding rods can be reflected in the form of a table:

| Coverage type | Basics |

| Deposition factor | 9.5 g/Ah |

| Productivity (for electrode ∅4 mm) | 1.4 kg/h |

| Consumption (per 1 kg of deposited metal) | 1.7 kg |

An important point in familiarization is information on the mechanical strength of the weld and the chemical composition of the deposited metal, by which one can judge the possibility of use in a particular structure.

Well, the picture would not be complete without indicating the welding modes recommended by the manufacturer depending on the diameter of the electrodes and their spatial position.

Brands and usage

All UONI electrodes are used for manual arc welding, but are divided into several brands, differing in marking and purpose:

- UONI 13/45 electrodes are used for welding forgings and cast parts, as they provide good toughness and ductility of the weld. The coating contains nickel and molybdenum.

- 13/55 contain phosphorus, silicon, carbon, sulfur and manganese and are mainly used for assembling rolled products and parts made of low-alloy and high-carbon steels. The weld they form is characterized by high strength and resistance to cracking. A distinctive feature is that they do not work upside down.

- 13/65 are the most universal grade, allowing a wide range of work on welding steel structures, ensuring a fairly high quality of the seam. They work in all spatial positions.

- 13/85 are used for work involving parts made of high-strength alloy steel. They work perfectly in all positions and provide an extremely strong connection, which is why they are used when installing critical structures.

Features of application

The main technical characteristics of welding electrodes Uoni 1355 consist of the following items:

- for welding with these products you need to use reverse polarity current;

- a special coating of carbonates and fluoride formations, through which the weld practically does not contain gases and other unnecessary impurities;

- Low-carbon steel is used for the rod, which contributes to the long durability of the seam;

- the coating does not contain various organic compounds, due to which such electrodes have a low level of exposure to moisture;

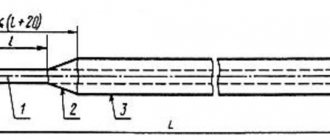

- During the manufacturing process of electrodes, the formation of various irregularities, cracks or swellings is completely eliminated.

We recommend! Technical characteristics of welding electrodes ANO-4

The above factors contribute to the creation of a seam that is not subject to aging and loss of its properties under different temperature conditions.

When welding with electrodes, it is necessary to control the cleanliness of the parts being joined, because the presence of traces of rust or various oils will cause the appearance of pores, and the connection itself will not be reliable. In addition, “stretching” the arc also negatively affects the quality of the weld.

The key competitive advantage of such products over analogues is that the weld is produced with a low hydrogen concentration and is more resistant to the appearance of microcracks during the crystallization process. The most effective result when carrying out actions with Uoni 1355 electrodes can be obtained when welding with a small arc using the supported method.

According to GOST 9466-75, the weight of products in a pack should not exceed:

- 3 kg – for product diameters up to 2.5 mm;

- 5 kg – for a diameter of 3.0 – 4.0 mm;

- 8 kg – for diameters over 4.0 mm.

What is the purpose of calcining electrodes?

Calcination is a fundamentally different technological aspect of preparing rods for work. It is performed at temperatures that are significantly higher than those needed for drying. This heat treatment:

- sets the required technical characteristics of the coating;

- reduces the moisture level in the coating to almost zero (0.2–0.5% versus 8–12% when drying);

- prevents electrode sticking;

- ensures good first and re-ignition and stable arc burning;

- allows you to significantly reduce electrode consumption (by 10–15%);

- sets an even, high-quality seam formation.

The electrodes undergo primary calcination in the factory at the final stage of production. And if they are used almost immediately after manufacture, there is no need for re-calcination. But such situations are rare; finished products can be stored for months in the warehouses of the manufacturer or consumer.

At high ambient humidity (85–90%), the coating tends to reabsorb moisture, and in just two weeks it gains it. Example:

- Electrodes of type E50A calcined at t 400˚C pick up 1.5% moisture;

- Products of the same type, calcined at 200˚C, absorb up to 2.2%.

And this is only for 14 days, but they can be stored much longer. If the coating is damp, it needs to be dried and re-calcined.

Calcination procedure for welding electrodes Uoni 13/55

The main task of calcining electrodes is to reduce the moisture concentration in the coating.

Absolutely every package of electrodes must be sold together with a quality certificate and instructions, which describe the calcination procedure in some detail. Failure to comply with the recommendations given may deteriorate the quality of the products themselves, and as a result, the quality characteristics of the weld.

In a situation where there are no instructions for a variety of reasons, you must follow the recommendations described below:

- To ensure a stable burning process of the welding arc, and, accordingly, a decent level of the seam, the calcination procedure must be carried out only before use.

- If the welding electrodes have not been used within 8 hours after calcination, this process must be repeated.

- It is allowed to calcinate the same electrode no more than 3 times, and the total amount of calcination time should not exceed 4 hours.

- To carry out the correct calcination process, the electrodes are first placed in special boxes, and only then placed in the oven. The temperature range in the oven should be 250 – 300C.

Attention! If at least one condition is violated, the product becomes unsuitable for use.

How to dry electrodes

It is recommended to dry the products, as well as calcining them, no more than twice - otherwise the structure of the coating material begins to gradually deteriorate. For this procedure, thermal cases, thermos cases and electric ovens with an additional drying function are used.

Thermal cases

The devices are quite compact, which allows them to be placed directly at the welder’s workplace. The devices heat up already calcined rods, and then maintain the required temperature for a long time, maintaining the necessary technical properties of the coating.

- The temperature range for drying is from 0 to 120... 130 °C.

- During storage, the humidity level in the external environment should not exceed 80%.

- Temperature range when storing the device is -45…+40 °C.

Thermal cases can hold up to 10 kg of consumables. They operate from a 220 V network, as well as from a transformer.

Electric ovens with drying option

If, in addition to calcination (more on this below), the electric oven also has an additional drying function (i.e., heating), you can also use this device. Warming is provided by thermal electric heaters, heating elements are controlled and temperatures are adjusted automatically.

- Equipment power – 1…3 kW.

- Maximum load – 50 kg.

- Mains voltage – 220 V.

As in the case of thermal cases, warming up should be carried out at ambient humidity of no more than 80%.

Thermos cases

Unlike thermal cases, the electrodes are not heated as such. But they maintain their desired temperature after drying or/calcination of the products, which is very convenient during the welder’s work.

Drying in other ways

Is it possible, and if so, how can I dry the electrodes in other ways? In the absence of the mentioned equipment, it is also possible to dehydrate the coating by placing the rods on a heating radiator for several hours or using a hair dryer. But these are the so-called “home”, “folk” remedies for household welding. In the second case, there is a risk of simply ruining the coating, since the hair dryer can be heated to 150 °C, but it is impossible to set the desired temperature and hold it for the required time. When it comes to industrial work and critical structures, it is recommended to use professional equipment - it will give the desired result in terms of the moisture level of the coating.

Important! Even during drying, the temperature of which is usually much lower than during calcination, it is necessary to know the thermal conditions for a particular type of coating. For example, cellulose-coated rods can be dried at a temperature not exceeding 70 °C, otherwise the coating will be damaged and crumble.

Manufacturers

Manufacturing technology and chemical composition may vary slightly, depending on the manufacturer, among which are the following large companies that guarantee high-quality materials:

- ESAB;

- LEZ;

- Monolit;

- SZSM;

- Special electrode;

- Inforce.

Attention! When purchasing, be sure to request a certificate of compliance of electrodes with regulatory requirements, in particular GOST 9466-75, or a certificate of certification of welding materials in accordance with RD 03-613-03. They are issued by the Federal Agency for Technical Regulation, or certified by the National Welding Control Agency.

Equipment for calcination of electrodes

We have already talked about the electric oven - the equipment copes well with both drying (if this function is available) and calcination thanks to the heating elements and automatic control mode.

An alternative to the oven - a heating cabinet - is intended for professional, industrial use. Modern models are equipped with a thermostat, thermometer, and electronic control unit for full automated control of the process. Like a thermal pencil case, the cabinet also stores products at a given temperature.

SSSI marking and explanation of the main parameters

To distinguish electrodes of even the same brand from each other, they came up with additional markings that determine their purpose. For example, what could the marking e50a or simply e55 mean? Having a special table at hand, you can easily determine what is what and how these names differ.

So, the letter “e” means that this is an electrode designed for manual arc welding. The number 50 is the limit of strength of the connection obtained when used correctly. The letter "A" is used to represent a seam. She says that the seam will be plastic and can easily withstand high impact loads.

This is followed by the name of the SSNI electrodes themselves, after which additional markings are placed, for example, 13-55 or 13-85. After this, the diameter of the steel core is indicated. It is worth noting that it is indicated with an accuracy of tenths of a millimeter. That is, if it’s a 5, then it’s 5.0, if it’s a 4, it’s 4.0, and so on.

At the very end there is a letter “U”, which indicates that this type of electrode is used for welding carbon steels.