Where are they used?

Welding electrodes MP-3S are designed for joining parts made of low-alloy steels with low carbon content using manual arc welding. They are used for welding such critical structures as pipelines, tanks, pipe fittings, and handling equipment.

When installing pipelines, it is possible to form non-rotating joints. Tanks that operate under high pressure can be serviced and repaired. Application areas include the oil and gas industry, shipbuilding and engineering industries. They also find application in everyday life.

MP-3S electrodes can be used regardless of the climatic conditions in which the welding process takes place.

Application of MP-3 electrodes

Electrodes make it possible to weld parts of mechanisms and structures of a wide range of equipment.

- Mills of various types (sheet rolling, section rolling, crimping, etc.).

- Cranes, elevators, conveyors, escalators, winches and other lifting and transport equipment.

- Gas, oil pipelines, oil storage tanks.

- Containers, tanks for transportation of dangerous goods.

- Steam boilers and other boiler equipment.

Electrodes are also used to weld metal building structures, including reinforcement and other embedded elements for reinforced concrete products.

Characteristics

In construction stores you can easily find LEZ MR-3S electrodes, manufactured by the well-established Losinoostrovsky Electrode Plant. They comply with the requirements of GOST 9466.

LEZ MR-ZS electrodes have a rutile coating, which consists mainly of titanium dioxide, which is the mineral rutile. In addition, the coating may contain other elements that increase the toughness of the deposited metal. This reduces the likelihood of defects such as pores and cracks appearing in the weld. Rutile coating ensures rapid ignition of the arc, both primary and secondary.

In this case, the weld pool is reliably protected from the harmful effects of oxygen and nitrogen. LEZ electrodes MR-ZS have technical characteristics:

- An electrode with a rutile coating is classified as a consumable element.

- The internal rods are made of Sv-08 wire.

- The main alloying elements included in the rod are carbon and silicon. It contains small amounts of manganese, sulfur and phosphorus.

- Welding can be carried out in all positions, with the exception of moving the electrode from top to bottom.

- Possibility of working with different types of current.

- Long arc welding is acceptable.

- The spray coefficient is in the range of 9-13 percent.

- Good meltability of the edges of the metal being welded.

- Electrodes can weld parts with a thickness of 3 to 20 millimeters.

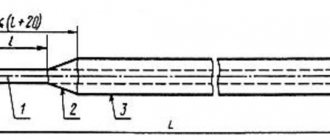

The diameters of the electrodes are in the range of 3-6 millimeters. As the cross-sectional size increases, the length of the electrodes increases.

The welding current is set depending on the diameters of the electrodes used and the spatial position during the welding process. So, for example, if MR-ZS 3mm electrodes are used, then in a vertical position a current of 90-110 Amperes is set. In lower and ceiling positions, these values can be increased.

Welding electrodes MR-ZS 3mm have different packaging. For example, if you need to use a large number of consumables, it makes sense to purchase welding electrodes MR-ZS 3mm 5kg. The number of electrodes that fits in one package depends on the weight. The weight of one electrode with a diameter of 3 millimeters is 30 grams. If you purchase a pack whose weight is two and a half kilograms, then it will contain 86 electrodes with a cross section of three millimeters. A five-kilogram package will hold 54 electrodes with a diameter of 5 millimeters.

Design and material of manufacture

In the center of the product there is a rod made of welding wire Sv-08, it is coated with a rutile-based coating.

Aluminosilicate or carbonate is added to it as additives. Additives increase the viscosity of the surfacing metal and protect against the appearance of cracks and pores in the weld material. Such electrodes have 3 modifications: MP 3 itself, MP 3s and MP 3m. Ilmenite was added to the coating of the MP-3m brand rods, and additives were added to the coating of the MP-3s electrodes to increase the degree of ionization . What is the difference between them: in terms of basic physical and mechanical characteristics, there is practically no difference between all three models. The differences appear during operation: MP-3s, thanks to ionizing additives in the coating, allows easy ignition of the arc on low-power household welding inverters.

They also reduce the amount of harmful substances released into the atmosphere, primarily manganese. With this composition it is easier to obtain a uniform seam on low-power welding machines.

The diameter of the wire is in the range of 2-6 mm, and the length is from 30 to 45 cm. The diameter of the electrode indicated in the marking is also determined from it.

If the rods were stored in a dry warehouse in their original packaging, there is no need for additional calcination . However, if for any reason the moisture content of the coating exceeds 1.5%, calcination will be required for 40 to 60 minutes at a temperature of about 170°C. It is unacceptable to work with wet electrodes: the coating loses its properties, and it is unlikely that a strong and durable seam will be obtained.

The coating is made on the basis of rutile, or titanium dioxide in powder form. It is mixed with a binder, and the rods are dipped into the resulting mass. The ends of the 20 mm rod are not covered with coating: one of them will be clamped in the holder, and the other will be used to ignite the electric arc. Next, the coated electrodes are dried at high temperature.

After drying, finished products are painted blue and markings are applied to the coating. Decoding MP-3 means:

- M – rutile coating;

- P – high quality seam;

- 3 - model number in the manufacturer’s lineup

The rod material, in addition to iron, contains additives in the following percentages:

- Manganese 0.66;

- Silicon 0.1;

- Carbon 0.1;

- Phosphorus 0.03;

- Sulfur 0.019.

Finished products are packaged in boxes sealed with polymer film to maintain low humidity levels . Shipment in cardboard boxes and packs of technical paper is allowed.

Designation

The letter “E” indicates that we are talking about electrodes intended for manual arc welding. The numbers “46” provide information about the value of tensile strength, which is measured in kgf/mm2. MP-3 is the brand of designated electrodes. “LUX” is a trade name assigned to its products by the manufacturer.

Next comes the cross-sectional diameter of the electrode. The letter “U” indicates that low-alloy steels with a low carbon content can be welded with these electrodes. The next letter “D” means that the electrode has a thick coating. The letter "E" refers to the designation of coated consumable electrodes, according to the international classification.

The number “43” is the value of tensile strength after the welding process is completed. “0” means that the elongation does not exceed 18 percent. (3) refers to the impact strength value of the deposited metal.

The letters “RC” stand for rutile-cellulose coating. One letter “P” will mean that the coating is purely rutile. The last two digits “11” indicate that welding with these electrodes can be carried out in all positions, excluding the movement of the electrode from top to bottom. The designation is applied to a tag glued to the packaging. This allows you to find out what characteristics the MP-3C electrode has and make the right choice.

Electrodes E46a

For welding steel products, when increased demands are placed on the weld metal regarding impact strength and relative elongation, electrodes of the E46a grade are used. They are consumables of this type, with improved properties. They can be used when welding structures made of thick sheets, in positions that are inconvenient for the welder, and when installing on construction sites.

This type includes a number of different brands. Electrode grade E46a is used for welding steel products with high ductility requirements. Example notation:

The number 3.0 indicates the diameter of the electrode of this brand. The difference from E46 lies in the plasticity indicators, which are higher. They are preferred when welding structures are to be operated at low temperatures and mechanical loads of variable significance. An example is refrigeration units.

Advantages

LEZ MR-3S electrodes have characteristics due to which they have undoubted advantages:

- The resulting connection is highly durable.

- Ignition of the arc is easy, as is its re-ignition.

- The arc can be short or medium length.

- The seam formed is smooth and has a good appearance.

- There are no clearly defined transition zones between the surfacing and the base metal.

- The rutile coating protects the seam from slag getting into it and the formation of oxidation on the surface.

- Spattering of metal during welding is insignificant.

- Easy separation of slag crust.

- It is possible to connect parts of considerable thickness.

- Connecting wet surfaces and those with traces of corrosion.

- No release of harmful substances during combustion of the coating.

- The seam is resistant to corrosion.

- The welding process is highly productive.

- Electrodes can be used to make not only long seams, but also short tacks.

These advantages are the reason for the widespread use of electrodes of this brand.

Features of use

When working with MP 3, it is permissible to use both alternating and direct current . The welding source must provide an open circuit voltage of 50 volts. When operating with direct current, the connection polarity is reversed. In this case, the positive contact is connected to the holder, and the negative contact to the workpiece.

Electrodes have the following advantages:

- easy ignition and stable combustion of the electric arc;

- making a durable, well-welded seam with specified geometric parameters;

- Spattering of melt droplets is minimized;

- the fragile slag crust that forms above the suture material is easily and quickly removed during stripping;

- facilitated re-ignition of the electric arc after a break in the conduction of the electrode;

- high welding productivity.

Despite the fact that the product is optimized for difficult working conditions, in no case should you neglect the preparation of the seam area for connection. The better the workpiece is cleaned and degreased, the stronger and more durable the seam will be .

The suture material has an impact strength of 80 J/cm2, allows bending up to 150°, and the relative elongation is 18%.

The weld material has physical and mechanical parameters close to the characteristics of the metal of the part itself. Therefore, the seam does not create additional mechanical stresses that weaken the entire structure and reduce its strength and reliability.

Varieties

There are several types of electrodes of this brand. This sometimes leads to a dead end when faced with a choice. Therefore, it is necessary, for example, to understand how the MP-3 electrodes differ from the MP-ZS. These species have a lot in common with each other. Their composition and main characteristics are identical. However, there is one feature that answers the difference between the MP-3 and MP-ZS electrodes.

Consumables of the MP 3C brand contain additives, due to the presence of which the arc is ignited more easily and the stability of its combustion increases. They can be used when using a low-power welding inverter. During the welding process, less manganese is released, the seams are more uniform, and their formation is easier.

The MP 3C brand has proven itself well in household use. But MP 3 electrodes can be called more universal. They are used both in everyday life and in industrial work.

general information

What are they for? MP3 electrodes are used for welding parts made of alloys with a carbon content of up to 0.25% . They can work in the most difficult conditions, with high humidity of workpieces and even in the presence of rust. This property is especially useful when performing repair work on pipelines.

Cooking is allowed in all welding positions except vertical. Welding can be done both with close contact of parts and with some gap between them. In this case, the value of the welding current should be reduced to avoid the appearance of cracks.

What makes them different: easy ignition of the electric arc and high stability of its combustion. The splashing of melt droplets from the weld pool is minimized. The composition of the coating is selected in such a way that during welding it releases few toxic substances. The resulting slag crust can be easily separated from the weld material during cleaning.

inverters can be used as a source of operating current . They must provide a voltage of 50 volts or higher. Electrodes for welding carbon alloys MP 3 are suitable for operation with both alternating and direct current. They allow you to weld workpieces of various thicknesses.

When the edges are cut correctly, they provide high-quality deep penetration. Particular attention should be paid to the correct selection of the operating welding current. It depends both on the diameter of the electrode and on the welding position. Excessive current will not allow you to take full advantage of the product's benefits.

To obtain a strong and durable seam, the electrodes themselves must be properly dried and calcined.

Technical process

Welding can be carried out with both types of currents. If direct current is used, then reverse polarity must be installed on the equipment. The current strength is selected depending on the cross-sectional value of the consumable and its position in space.

It is advisable to pre-clean the surface to be welded, but welding surfaces with traces of contamination and oxides is allowed. During the welding process, the electrode should be held at an angle of approximately 45 degrees. This will reduce the formation of slag and its entry into the weld pool.

Movements with the electrode should be made quickly, moving from the edge of one edge to the edge of the second. When welding large-sized products, it is advisable to fix them with tacks using the same electrodes.

Storage

The quality of the weld, as well as the shelf life of the electrodes themselves, depends on compliance with the rules of their storage. The main condition is storage in a room where there is no dampness and the required temperature is maintained. A thermometer and a device for determining humidity will help fulfill these requirements.

If the electrodes are stored in cardboard packaging, then they must be installed on a rack at some distance from the floor. It is also permissible to store them in special plastic tubes.