A chisel is a percussion-cutting tool that is used for chopping metal or chipping stones.

The scope of application of the device is very wide.

You can’t do without this device in construction, plumbing, and on the farm.

With its help, grooves and grooves are made on metal surfaces, and brick or concrete walls are dismantled.

You can also remove old finishes, disassemble pressed hardware, remove nails or unscrew nuts.

Different types of chisels are designed to perform different tasks.

Manufacturing materials

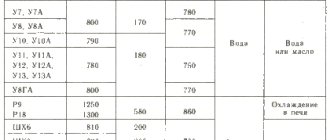

The use of a chisel is associated with high impact loads. The working part is rested against the material and hit with a hammer on the impact end. Therefore, it is important to have high strength of the material used, which will not deform upon impact. Steel meets these requirements. The main types of steels are described in the table.

| Type of steel | Description | Marking |

| Carbon | Makes the tool resistant to shock loads and allows you to work with metal workpieces. Depending on the percentage of carbon in the composition, the quality of the material is determined - the higher the indicator, the stronger the product. In the labeling this is indicated by numbers from 7 to 9 | U7, U8, U9, U7A, U8A |

| Structural | Gives the tool increased strength and wear resistance greater than carbon steel. These chisels are suitable for working with stone. At the end of the working part there are carbide plates. Steels may contain alloying components, for example, chromium (marked X), silicon (marked C), etc. | 45, 50, 40Х, 60С2 |

An important aspect is the hardness of the steel. For example, according to GOST requirements for chisels made of steel grades U7A and U8A, the hardness of the working part should be 54 - 58 HRC, the hardness of the impact end - from 36.5 to 41.5 HRC. The higher this indicator, the stronger the tool and the higher the load it can withstand.

Tools for hot metal forging

Blacksmith hammer-smoother. Photo ForgingPRO

Each master creates a set of necessary equipment independently, depending on the level of skills and assigned tasks. The blacksmith's kit includes a different list of tools: basic and auxiliary:

- hammer, sledgehammer and anvil;

- pliers (tongs);

- nail shop;

- manual and lining forks;

- vice.

Using the listed tools, various operations for processing metal workpieces are performed: chopping, bending, giving the desired shape through deformation.

Hand tools for artistic forging have a simple design, so they are easy to make with your own hands.

What kind of coverage can there be?

In addition to shock loads, chisels are exposed to moisture. To prevent the tool from rusting, it undergoes anti-corrosion treatment. There are galvanized and painted tools. In this case, the cutting part and the striking end must be lightened. Some chisels have a plastic cover with a stop on the striking end, the so-called protector. It promotes gentle impact action and makes work easier - it is easier for the user to hold the tool and avoid getting hit on the fingers with a hammer.

Tool sharpening

The purpose and method of using the tool depends on the sharpening of the working part. The sharper it is, the less impact required during operation. This means that hard materials are cut with a blade with a more blunt sharpening angle. For example, to work with cast iron and bronze, a machinist’s chisel is required with a sharpening angle of 70°, for medium-hard steel – 60°, for copper and brass – 45°, for aluminum alloys – 35°. Forge chisels have slightly different requirements: the sharpening angle of the tool for hot cutting should be 50°, for cold cutting – 60°, since hot metal is softer than cold metal.

What is this chisel? Purpose, characteristics, types and choice

A chisel is a percussion-cutting tool that is used for chopping metal or chipping stones.

The scope of application of the device is very wide.

You can’t do without this device in construction, plumbing, and on the farm.

With its help, grooves and grooves are made on metal surfaces, and brick or concrete walls are dismantled.

You can also remove old finishes, disassemble pressed hardware, remove nails or unscrew nuts.

Different types of chisels are designed to perform different tasks.

Malfunctions

Among the most common breakdowns of a forging chisel are:

- break;

- dullness;

- the appearance of notches;

- deformation, curvature of the striker;

- cold hardening on the striker, which is fraught with chips and flying fragments.

Chisel striker broken

Malfunctions arise in the event of incorrect cutting, during prolonged use of the tool, or in the presence of manufacturing defects. Periodically (at least once a quarter) it is necessary to inspect the chisel for any damage to the striker or handle. Faulty tools that have defects must be removed from service.

Device and characteristics

The chisel is a metal rod, sharpened on both sides, with a flat butt.

Depending on the design features, devices are divided into two types: manual and for power tools.

The rod can have an oval, rectangular, circular cross-section or polyhedron shape.

- type of instrument;

- appointment;

- shank type;

- length and width of the working part;

- diameter;

- material of manufacture;

- design;

- weight.

For comfortable operation, the models are equipped with special “fungi”.

This is a rubber pad that absorbs recoil and ensures an accurate hit with a hammer.

Material

One of the most important criteria that you should pay attention to when choosing is the material of manufacture.

Models designed for processing different types of metals are made of carbon tool steel, and for stone processing - from structural steel.

Dimensions and weight

A flat chisel is most often used in this work.

There are more than 20 species.

The models differ from each other in various parameters.

The length of the working part is 25-60 mm.

There are models used for processing soft, medium, and hard metals.

The weight of the device depends on the size.

Light hand-held ones weigh on average 210-380 g, heavy ones, intended for use with different types of power tools - 590-750 g.

Notes

- [protect.gost.ru/v.aspx?control=7&id=141662 GOST 7211-86] “Chisels for mechanics. Technical specifications"

- [protect.gost.ru/v.aspx?control=7&id=164634 GOST 7212-74 ] “Mechanical cross-sections. Technical specifications"

- [protect.gost.ru/v.aspx?control=7&id=163639 GOST 11418-75] “Forging tools for hand and hammer work. Chisels. Design and dimensions"

- [protect.gost.ru/v.aspx?control=7&id=163539 GOST 11419-75] “Forging tools for hand and hammer work. Shaped chisels. Design and dimensions"

- gramota.ru/slovari/dic/?lop=x&zar=x&word=skarpel

- [tybet.ru/wiki/%D1%EA%E0%F0%EF%E5%EB%FC/Skarpel]

- moyslovar.ru/slovari/big_tolk_slovar/slovo/skarpel

How to use a chisel

Despite the fact that the modern market is full of various power tools, in some cases it is impossible to do without the use of a conventional chisel.

And here the question arises, how to properly use this simple tool.

Basic Rules

The work pattern depends on the type of chisel.

When working with it, you need to be extremely careful so that the task is completed efficiently and you do not get injured.

- Check that the hammer is securely seated on the handle.

- Before starting work, put on glasses and gloves.

- The tool must be dry.

- When working with sheet metal, consider the type of metal and its thickness.

It is better to cut thick sheets in several approaches.

• If you need to cut off part of the wire, do not do it in one fell swoop.

First, make a small cut, then break off the rod; it will remain in your hand and not fly away in an unknown direction.

Modern models are equipped with “fungi”.

This is a special head that performs a protective function, so its presence increases work safety, minimizing the risk of injury.

But in some situations this does not help, so you need to work with the tool very carefully.

Excerpt characterizing Chisel

“Eh bien, retournez a l'armee, [Well, then return to the army.],” he said, straightening up to his full height and turning to Michaud with a gentle and majestic gesture, “et dites a nos braves, dites a tous mes bons sujets partout ou vous passerez, que quand je n'aurais plus aucun soldat, je me mettrai moi meme, a la tete de ma chere noblesse, de mes bons paysans et j'userai ainsi jusqu'a la derniere ressource de mon empire. “Il m’en offre encore plus que mes ennemis ne pensent,” said the sovereign, becoming more and more inspired. “Mais si jamais il fut ecrit dans les decrets de la divine providence,” he said, raising his beautiful, gentle and sparkling eyes to the sky, “que ma dinastie dut cesser de rogner sur le trone de mes ancetres, alors, apres avoir epuise tous les moyens qui sont en mon pouvoir, je me laisserai croitre la barbe jusqu'ici (the sovereign pointed with his hand to half his chest), et j'irai manger des pommes de terre avec le dernier de mes paysans plutot, que de signer la honte de ma patrie et de ma chere nation, dont je sais apprecier les sacrifices!.. [Tell our brave men, tell all my subjects, wherever you go, that when I no longer have a single soldier, I myself will stand in the head of my kind nobles and good men and thus deplete the last funds of my state. They are greater than my enemies think... But if it were destined by divine providence that our dynasty should cease to reign on the throne of my ancestors, then, having exhausted all the means in my hands, I will grow a beard until now and would rather go eat one potato with the last of my peasants, rather than dare to sign the shame of my homeland and my dear people, whose sacrifices I know how to appreciate! the depths of his office. After standing there for a few moments, he returned with long steps to Michaud and with a strong gesture squeezed his hand below the elbow. The sovereign’s beautiful, meek face became flushed, and his eyes burned with a gleam of determination and anger. – Colonel Michaud, n'oubliez pas que je vous dis ici; peut etre qu'un jour nous nous le rappellerons avec plaisir... Napoleon ou moi,” said the sovereign, touching his chest. – Nous ne pouvons plus regner ensemble. J'ai appris a le connaitre, il ne me trompera plus... [Colonel Michaud, do not forget what I told you here; maybe someday we will remember this with pleasure... Napoleon or I... We can no longer reign together. I recognize him now, and he will not deceive me anymore...] - And the sovereign, frowning, fell silent. Hearing these words, seeing the expression of firm determination in the eyes of the sovereign, Michaud - quoique etranger, mais Russe de c?ur et d'ame - felt himself at this solemn moment - entousiasme par tout ce qu'il venait d'entendre [although a foreigner, but Russian at heart... admiring all that he heard] (as he spoke afterwards), and he in the following expressions depicted both his feelings and the feelings of the Russian people, whom he considered himself authorized. - Sire! - he said. – Votre Majeste signe dans ce moment la gloire de la nation et le salut de l'Europe! [Sovereign! Your Majesty is signing at this moment the glory of the people and the salvation of Europe!] The Emperor released Michaud with a bow of his head. While Russia was half conquered, and the inhabitants of Moscow fled to distant provinces, and militia after militia rose to defend the fatherland, it involuntarily seems to us, who did not live at that time, that all Russian people, young and old, were busy only with to sacrifice oneself, save the fatherland or cry over its destruction. Stories and descriptions of that time, without exception, speak only of self-sacrifice, love of the fatherland, despair, grief and heroism of the Russians. In reality this was not the case. It seems to us that this is so only because we see from the past one common historical interest of that time and do not see all those personal, human interests that the people of that time had. Meanwhile, in reality, those personal interests of the present are so much more significant than general interests that because of them the general interest is never felt (not even noticeable at all). Most people of that time did not pay any attention to the general course of affairs, but were guided only by the personal interests of the present. And these people were the most useful figures of that time.

Chisel rating

When making chisels, manufacturers pay attention not only to performance characteristics, but also to shape, size, and appearance.

Choosing a good tool from a wide range is quite difficult. Below is a rating of the best chisels (according to experts and buyers).

- FIT 46755. Tool steel hand chisel with a hex shank that is virtually impossible to bend.

Rubber handle reduces vibration. The buttplate is equipped with a mushroom guard to prevent shock to the hand.

- TOPEX 03A149 is used for making large recesses.

A strong grip and comfortable use are provided by four wavy ribs on the handle.

The hexagonal rod with stiffening ribs does not deform under loads.

- Stanley FatMax 25x305 mm is used for processing various metals; it fits securely in the hand and does not slip thanks to the shaped rubberized handle with an increased diameter.

The tool is equipped with a durable, bend-resistant hexagonal rod and a protective “fungus”.

The width of the working part is 25mm.

- SDS MAX MATRIX 70343 is a model for a rotary hammer with which you can lay communications.

The tool is resistant to deformation and corrosion, easy to use, and has a long service life.

- MATRIX. The oxidized chisel is protected from corrosion.

The model is made of carbon steel 50 CrMo, the tool is successfully used for cutting various materials.

Where to buy or order, manufacturers (manufacturers) and suppliers

Not all craftsmen have the necessary skills to make their own chisels. In such cases, it is recommended that you familiarize yourself with the list of manufacturers and suppliers of this tool, which are collected in a separate section. Companies offer a wide range of tools: pliers, hammers, nails, etc.

Sections: Tools

Tags: Forging - basics

Previous article: Mini forge - how to organize a workplace Next article: Decorating forging