The products of the Swedish company ESAB are in demand for various types of repair and installation work. OK-46 welding electrodes are specially designed for welding structures made of low-alloy and carbon steel, the yield strength of which does not exceed 380 MPa. They also performed excellently when joining different grades of ship steel. The scope of use of OK 46 electrodes is not limited to industrial production. They are popular in small repair shops and for performing welding work around the house.

GOST-9467-75, E6013 and other standards, quality certificates, passport

All ESAB welding materials undergo strict quality control. This is confirmed not only by certificates of the National Welding Control Agency, Maritime and River Registers, but also by reviews of the welders themselves.

Certificates:

- NAKS (National Agency for Control and Welding)

- ABS - American Bureau of Shipbuilding Standards

- BV – French Bureau of Standardization in the field of shipbuilding Bureau Veritas SA, Paris

- DnV – Norwegian shipbuilding standardization company Det Norske Veritas, Oslo

- DS – Danish Standard Certificering A/S, Denmark

- GL – German Marine Insurance Association Lloyd's Register, Hamburg

- PRS – Polish Register of Shipping, Gdansk

- PPP – Russian River Register

- RS – Russian Maritime Register of Shipping

- Sepros – Certificate in the Ukr SEPRO system, Ukraine

- SS – Singapore Standard, Singapore

- UDT – Office of Technical Inspection, Warsaw, Poland

- U – German building requirements

- VdTUV – Association of Technical Inspection Agencies, Berlin, Germany

Welding electrodes ESAB OK 46.00. Photo by ESAB

Approvals:

- ABS 2

- BV 2

- DB 10.039.05

- DNV 2

- DS EN 499 E 38 0 RC 11

- GL 2

- LR 2

- PRS 2

- RS 2

- Sepros UNA 485154

- SS EN 499 E 38 0 RC 11

- UDT EN 499

- Ü 10.039/1

- VdTÜV 00623

Standards:

- SFA/AWS – E6013

- EN – E 38 0 RC 11

- ISO – E 38 0 RC 11 / E 43 3 R 11

Specifications:

- TU 1272-024-55224353-2006

- TU 1272-137-53304740-2007

- TU 1272-137-53304720-2009

Compliance

The original OK-46s comply with GOST 9467, E6013, AWS A5.1, DNV2, EN ISO 2560-A, GOST R ISO 2560-A and other standards required in the Russian Federation. They also have all the certificates and approvals for sale and use in most countries of the world.

To order OK-46 electrodes, you need to go through the website menu to the appropriate product page and add the selected electrodes to your cart in one click. For each product there is a description, a list of standard sizes and a table with all the necessary parameters and characteristics.

In addition to the main product, the company's catalog includes welding equipment, masks, tools, fluxes, wire and other consumables. As well as cutting wheels, torches, gas equipment, ropes, hardware, etc.

Explanation of markings, designations of welding rods

ESAB OK 46 electrodes have fairly simple markings. First of all, these are products of an internationally renowned company. The ESAB industrial plant has over 110 years of experience in the manufacture and development of welding consumables. The abbreviation OK used in international markings is nothing more than the initials of the founder of the manufacturing company, Oscar Kjellberg. 46, or 46 00 - the maximum load that a seam resulting from the use of these electrodes can experience.

Who produces

Manufacturer of rods - Swedish). It is a world leader in the production of welding equipment, tools and consumables. The electrodes have many positive reviews: they are easy to use and of high quality, giving an even and durable seam. Experienced craftsmen recommend consumables for beginners.

These products have disadvantages: fakes and high prices. They may have slightly different names and weights. For example, AK46. Many enterprises in our country and abroad produce analogues of Swedish products, which also differ in names: ESAB-SVEL OK 46 D3, ESAB OK 74.46 d4.0 or 5 OK 46.

They are produced in Penza and Novosibirsk, St. Petersburg and Yekaterinburg, Nizhny Novgorod and Simferopol, Krasnoyarsk, Vladivostok, as well as in the cities of Germany and Japan.

To avoid counterfeits, you need to purchase materials from representatives who have certificates. OK 46 is a guarantee of welding results even for a novice master. An electrode with a dense coating protects the bath well from external factors, even with a melted end.

Description of consumables for welding, photo

Electrode packages OK 46.00

A unique electrode in its class, with excellent welding and technological characteristics, designed for welding structures made of low-carbon and low-alloy steels with a yield strength of up to 380 MPa in all spatial positions on direct current of any polarity and alternating current.

The electrode is characterized by relatively low sensitivity to rust, primer, zinc coatings, etc. contamination of the surface of products, ease of slag separation and the formation of a smooth surface of the weld bead with a smooth transition to the base metal.

Due to the ease of both first and repeated ignitions, the electrode is indispensable for welding with short seams, tack welding and welding with periodic arc breaks. Unlike most rutile electrodes, thanks to the ability to weld in the “vertical downhill” position, combined with significantly lower threshold values of the minimum current at which the arc burns stably, OK 46.00 allows you to weld thin-walled products. Low open circuit voltage and stable arcing at extremely low currents allow the use of these electrodes for welding from household sources.

Advantages and disadvantages

Advantages:

- ability to work on contaminated and rusty surfaces;

- easy ignition;

- stable arc burning;

- making vertical, horizontal and ceiling seams;

- minimal splashing of molten metal;

- welding at voltage 50 V;

- low consumption;

- high quality connection;

- electrodes have a quality guarantee and certificates of conformity.

Flaws:

- when welding, it is necessary to maintain an angle of about 35°;

- Apply seams in small sections;

- impact strength is low.

Before work, you need to keep the products in a thermal case for at least an hour.

Welding is possible on rust and contaminated metal.

What are they intended for, what can be cooked, what metals and steels, areas of application

Welding electrodes OK 46.00 are recommended for MMA welding of carbon marine and structural steels . They are ideal for both tack welding and root and short welds. Considering the reduced heat input, these welding electrodes are widely used when welding wide gaps, including during installation . In addition, ESAB OK 46.00 electrodes are widely used when welding galvanized sheets.

Description: with black coating and more

ESAB is the pioneer of manual welding technology using a covered electrode. Extensive experience in the development of various types of coatings for consumables allows us to create coatings to solve specific problems of welding technology. OK electrodes are used for tacking, surfacing, and creating basic welds.

Internet users often look for electrodes from this manufacturer “with black coating.” The composition of the coating has a decisive influence on the welding characteristics of the electrodes, but identifying welding characteristics using, for example, the color of the coating will be incorrect. The same brand of electrode is produced by several enterprises. Technological features of the manufacturing process and equipment may vary quite a lot. The composition of the coating will also differ. Therefore, when choosing, you should not pay attention to the color characteristics of the electrode coating. This quality depends on the pigment that the manufacturer’s engineer incorporated into the technical process.

OK electrodes are characterized by high arc stability, minimal spattering, and easy separation of the slag film. Some brands of consumables do not require preparation of welding surfaces; traces of rust and remnants of galvanic coating may remain on them.

Peculiarities

A distinctive positive feature of OK 46 electrodes is the ability to easily ignite, including when re-igniting. They can be used for welding galvanized (galvanized) products. The low heat input of the electrodes allows them to be used for welding wide gaps, and their insensitivity to surfaces with rust and dirt ensures their high manufacturability.

Due to their high quality indicators, electrodes have found wide application in various branches of industrial production, where the use of effective welding materials is necessary . Minimal spattering and ease of slag removal give the seam a good aesthetic appearance. Despite the universal use of electrodes, they provide good seam properties and are ideal for short and root seams, as well as for tack welds. The ability to use electrodes in all positions in space makes them indispensable when working in confined spaces.

Applications of Lincoln electrodes

These products can be used to work with pipelines and edges. They are also often used for electric welding of metal structures. The maximum voltage of the brand with reverse polarity is 22 V. The tensile strength of the product does not exceed 360 MPa. In this case, the smallest permissible tilt angle is 23 degrees .

The model is used quite often for metal surfacing. The seam after using it turns out to be quite neat. According to comments from welding users, the brand’s consumption is significant. The susceptibility to rust in this case is low. Also, the presented model is not afraid of slag leakage. You can purchase models at market prices starting from 780 rubles .

Advantages and disadvantages

Welding electrodes OK 46.00 are universal electrodes and have a number of advantages that facilitate their use in different welding modes:

- provide good formation of the welding seam and easy initial and re-ignition of the welding arc;

- create a reduced heat input compared to other welding electrodes;

- insensitive to contamination of the welded surface and rust on it;

- it is possible to apply a seam in a vertical position in the direction of descent;

- excellent quality of both consumables and the resulting connection;

- ease of use;

- low splashing;

- low slag formation;

- suitable for beginners.

OK 46 has only two disadvantages: high price and frequent counterfeits. But we do not consider these disadvantages significant. After all, the price is not much higher than analogues, and the final quality of the seams is much better. Well, to avoid counterfeits, you need to buy electrodes from certified representatives or in large stores.

Available operating and welding modes

The correct operating conditions are created by observing the selection of rods depending on the direction of the seam in space. A wide range of parameters helps in this search along with tables and graphs. The device does not require much voltage and connects to your home network.

We recommend reading: The main features and nuances of using electrodes of the E50A type

Users note the disadvantages of consumables:

- high prices;

- workpieces with thick walls are poorly cooked;

- The coating quickly absorbs moisture.

These shortcomings do not spoil the overall impression of the universal electrodes.

Technical characteristics: type, which group they belong to, constant or variable, and others

- OK 46.00 welding electrodes allow welding on alternating (with an open circuit voltage on the transformer of at least 50 V) and direct (any polarity) current in any spatial position.

- electrode coating: rutile-cellulose;

- welding steel wire Sv08 and Sv08A is used as the rod material;

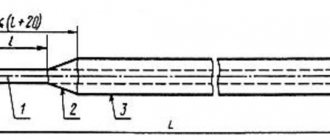

- welding wire diameter 2; 2.5; 3; 4 and 5 mm;

- type – E46;

- consumption coefficient of electrodes with a diameter of 3 mm. g/Ah – 8.5;

- consumption of electrodes per 1 kg of deposited metal, kg – 1.7;

- surfacing productivity (for diameter 4.0 mm), kg/h. – 1.4;

- flow coefficient group – 4.

Characteristics of electrodes of different diameters

To know what type of OK electrodes you need, it is worth considering not only the type of base metal and equipment. We bring to your attention a description of the qualities of the electrodes based on user reviews.

- OK with a diameter of 2 mm cannot be used for pipeline repairs. Resistant to high temperatures.

- 2.5 mm. Such electrodes are best used when welding stainless and carbon steel, and with alternating current. Before starting welding, the working surface should be thoroughly cleaned of dirt and dust.

- 3 mm. They perform well when working on a pipeline. Viscous.

- 4 mm. Before welding, all rust must be removed from metal surfaces. The voltage must be constant.

- 5 mm. Cannot be used for short arc welding. They deposit metal very well and are used economically.

Diameter, length, weight of rod and pack, quantity, how many pieces in a package, tables

Information from the manufacturer's website:

| Amps | IN | Melting time per electrode at 90%, sec. | Electrode diameter x length, mm. | kg deposited metal/kg electrodes | Number of electrodes per kilogram of deposited metal | Coeff. surfacing, kg/hour |

| 30-60 | 26 | 36 | 1.6 x 300 | 0.63 | 263 | 0.38 |

| 50-70 | 25 | 38 | 2.0 x 300 | 0.60 | 172 | 0.55 |

| 60-100 | 22 | 50 | 2.5 x 350 | 0.65 | 86 | 0.80 |

| 70-140 | 32 | 46 | 3.0 x 350 | 0.51 | 77 | 1.0 |

| 80-150 | 22 | 57 | 3.2 x 350 | 0.65 | 53 | 1.30 |

| 80-150 | 22 | 63 | 3.2 x 450 | 0.64 | 43 | 1.33 |

| 100-200 | 26 | 64 | 4.0 x 400 | 0.60 | 33 | 1.69 |

| 100-200 | 23 | 76 | 4.0 x 450 | 0.58 | 33 | 1.94 |

| 150-290 | 24 | 87 | 5.0 x 350 | 0.60 | 24 | 2.30 |

| 150-290 | 30 | 71 | 5.0 x 400 | 0.56 | 22 | 2.2 |

| 150-290 | 24 | 114 | 5.0 x 450 | 0.60 | 31 | 2.30 |

Welding parameters, information from suppliers' websites:

1)

| Diameter, mm | Length, mm | Welding current, A | Arc voltage, V | Weight (kg) of deposited metal / weight (kg) of electrodes | Number of electrodes / mass of deposited metal ( pcs/1 kg) | Weight (kg) of deposited metal / arc operating time (hour) | Combustion time, sec/electrode |

| 1.6 | 300 | 30-60 | 20 | 0.63 | 263 | 0.38 | 36 |

| 2.0 | 300 | 50-70 | 21 | 0.60 | 172 | 0.55 | 38 |

| 2.5 | 350 | 60-100 | 22 | 0.65 | 86.0 | 0.8 | 50 |

| 3.2 | 350 | 80-150 | 22 | 0.65 | 53.0 | 1.3 | 57 |

| 4.0 | 450 | 100-200 | 22 | 0.60 | 39.0 | 1.6 | 65 |

| 5.0 | 450 | 150-290 | 24 | 0.60 | 24.0 | 2.3 | 87 |

| 5.0 | 450 | 170-220 | 24 | 0.60 | 31.0 | 2.3 | 114 |

2)

| Diameter, mm/Current, A | Lower | Vertical | Ceiling | Length, mm | Number of electrodes in 1 kg, pcs. |

| 2,0 | 40…80 | 40…60 | 50…70 | 300 | 50 |

| 2,5 | 60…110 | 60…90 | 60…110 | 350 | 45 |

| 3,0 | 80…160 | 80…140 | 80…180 | 350 | 39 |

| 4,0 | 110…210 | 110…200 | 90…220 | 450 | 19 |

| 5,0 | 150…300 | 150…280 | 150…270 | 350 | 13 |

Chemical composition of the deposited metal

Packaging of electrodes ESAB-SVEL OK 46.00

For reliable storage, OK 46.00 electrodes are packaged in a pack of micro-corrugated cardboard, sealed in plastic film. The pack is yellow in accordance with ESAB standards. The number of ESAB electrodes in packages and packs is given in the following table:

| Diameter of electrodes, mm | Electrode length, mm | Weight of a pack of electrodes, kg | Pallet weight, kg | Number of packs on a pallet, pcs. |

| 1.6 | 300 | 24,0 | 1848 | 77 |

| 2.0 | 300 | 2,0 | 640 | 320 |

| 2.5 | 300 | 5,3 | 954 | 180 |

| 3.2 | 350 | 5,3 | 954 | 180 |

| 3.2 | 350 | 2,5 | 900 | 360 |

| 4.0 | 450 | 6,6 | 950,4 | 144 |

| 5.0 | 450 | 6,6 | 950,4 | 144 |

How to choose by diameter: 1.6; 2; 2.5; 3; 4 and 5 mm.

| 1.6-2 mm. | Suitable for working with carbon steel. In case of cracks in the seams, they can be easily cleaned. They are not afraid of large overheating. Not suitable for pipeline work. |

| 2.5 mm | Suitable for working with carbon steel and stainless steel. Used for surfacing metal, with low consumption. Moderate sensitivity to rust and severe sensitivity to dirt. It is better not to use it for DC welding. |

| 3 mm | They are distinguished by increased viscosity. Suitable for working on pipelines and various metal structures. |

| 4 mm | This diameter allows you to perform work of increased complexity. Consumption when surfacing metal is within normal limits. Often used for work on pipelines. Not for use with AC voltage. Sensitive to rust. Impact strength approximately 77 J. |

| 5 mm | Excellent for metal surfacing. Not suitable for short arc welding. Maximum tilt angle 75 degrees. Moderate consumption. |

Brand Abicor Binzel

These elements, used for metal surfacing, are in great demand by modern users. This is explained by the following advantages:

- Ideally suited for arc welding.

- They have low sensitivity to rust.

- The degree of temporary resistance does not exceed 33 MPa.

- The smallest permitted tilt angle is approximately 35 degrees.

If we note the disadvantages of these products, then welders, as a rule, observe an impressive level of expenditure on deposited metal.

Also, the brand is not suitable for ceiling seams. The maximum voltage with reverse polarity does not exceed 9 V. The deposition rate of such products is no more than 8 g. You can purchase Abicor Binzel products in a specialized store for 570-600 rubles.

How to cook cast iron, instructions

Cast iron. Welding should begin with deposition of the first cladding layers in the groove. Further, it is possible to continue welding with OK 46.00 electrodes.

The cladding layers are fused with special electrodes of the TsCh-4 brand. In order to reduce material costs, it is possible to use a homemade copper-iron electrode. It is made from a cheap steel electrode (for example: UONI 13/45, ANO-4, etc.). To do this, a spiral of copper wire (note: you cannot use brass wire - when heated, toxic zinc and its oxide will be actively released into the air) with a diameter of 1.5...2 mm. The amount of copper wire should be calculated in such a way that the mass of copper is 4...5 times greater than the mass of the steel rod. It is allowed not to wind copper wire, but to use it as a filler rod. The resulting seam will be of acceptable quality.

Explanation of the abbreviation/labeling/name, what OK means and other information

A distinctive feature of the ESAB electrode marking is the presence of the letter “OK” in it. Thus, the company immortalized its founding father Oskar Kjellberg by adding the first letters of his first and last names to the markings. Over time, the designations of many brands of electrodes changed, but the letter combination OK remained unchanged.

So, for example, instead of the old name OK 92.05 (electrode for welding nickel alloys), a new, more convenient to understand, OK Ni-1 appeared. A large number of changes of this kind have been made; all names (old and new) are available on the official website of ESAB.

Manufacturers/brands: ESAB, LEZ, Penzaelectrod (PE), Goodel and others, where they are produced

The production of electrodes of the OK 46.00 brand is carried out by the Swedish concern ESAB. Many companies produce analogues of Swedish products, for example:

- GOODEL-OK 46 – for welding critical structures made of carbon and low-alloy steels with a tensile strength of at least 490 MPa. Used for tack welds, short and root seams, and when welding wide gaps. Manufacturer: GOODEL plant, Shadrinsk.

- LEZ 46.00 are intended for manual arc welding of ordinary critical structures made of carbon steel, when increased demands are placed on the formation of seams in various spatial positions. Manufacturer: Losinoostrovsky Electrode Plant, Moscow.

- PE OK 46.00 – rutile electrodes are intended for manual arc welding of structures made of carbon steel (with carbon content up to 0.22%) in all spatial positions. Manufacturer: Penzaelectrod, Penza.

- SZSM-46.00 are intended for welding carbon and low-alloy structural steels of the pearlitic class with a minimum yield strength of no more than 360 MPa. Manufacturer: Sudislavsky Welding Materials Plant, Kostroma Region.

Characteristics of seam OK 46

The welding site consists of molten metal, which contains in percentage:

- carbon – 0.08;

- manganese – 0.4;

- silicon – 0.3;

- phosphorus – 0.03;

- sulfur – 0.025.

It hardens when cooled and forms an even seam with a smooth transition into the surface of the parts.

Smooth weld seam.

Index group

Sometimes the marking contains an additional designation written under the horizontal line.

E42A-UONI-13/45-3.0-UD ———————————— E432(5)

-B 1 0

Digit 4

indicates the resistance of the weld to corrosion. There are five levels in total (0/2/3/4/5) - the higher the number, the better. In our example, the number is 4, which indicates high protection of the seam from rust during subsequent use.

Digit 3

refers to the maximum temperature at which the heat resistance of a joint is maintained. There are 9 options in total, where 1 is 500 degrees, and 9 is over 850 degrees. In our case 3 - the seam will withstand heating up to 560-600? With no loss of properties.

Digit 2

— limit of working temperature of the seam. It also has 9 levels with an indicator from 600 to 1100 degrees. In our example, 2 indicates a limit of 650? C, after which changes will begin in the metal.

The value taken in brackets (5) is the amount of ferrite phase in the weld. The index is divided into 8 levels with percentages from 0.5-4.0% to 10-20%. With our indicator 5, the content of the ferrite phase ranges from 2.0 to 8.0%.

Such a group of indices does not indicate several characteristics at once. Usually, it is written on the packaging of electrodes intended for working with low-alloy and alloyed metals.

Reasons for popularity

When using these electrodes, experts note the ease of ignition of the primary arc. A repeated arc also occurs without unnecessary difficulties. Working with them, you can easily weld tacks, as well as create root and short welds .

Many specialists also choose products from this brand because they provide comfort when performing work, especially when it becomes necessary to weld wide gaps. This task often arises when performing work on the installation of metal structures. During welding work with these electrodes, slag appears. However, it can be removed from the seam surface without any difficulty.

Where to find the markings

Marking is necessary to indicate the properties and characteristics of the metal rod and its coating, which affect the arc burning process and the formation of the welding joint. The electrodes themselves are produced in accordance with GOST 9466-75 and GOST 9467-75 and are necessarily marked so that the user can look at the designation and understand how best to use welding materials.

Labeling must be applied to the packaging. The inscription is placed on a white or blue field, free from the decorative design of the pack. Markings are also applied to the melting coating, closer to the end of the electrode inserted into the holder. Some manufacturers additionally indicate data on the side of the pack, but this is not a requirement.

Why Esab brand?

A company from Sweden, whose profile is the development and creation of advanced welding equipment, has an impeccable reputation. Its products are distinguished by the highest level of quality and reliability, affordable and reasonable prices, as well as a focus on professionals.

Esab electrodes in Russia can be purchased at any company store. They are distinguished by the bright yellow color of the packaging, the brand logo and the presence of the necessary information on the insert, where the diameter and purpose of the product must be indicated.