Welding is one of the most important crafts for humans. Thanks to discoveries in this area, we can realize any, even the most daring ideas: from making swing gates to designing spaceships. There are many types of welding, including industrial, but among them it is manual arc welding that is most widespread. This is a simple and understandable technology that you can learn on your own.

The modern market offers different types of electrodes for manual arc welding, which are difficult for novice welders to understand. In this article we will tell you what types of electrodes there are for manual arc welding and how to choose them based on your tasks.

The essence of manual arc welding

Before we talk about electrodes, let's understand what manual arc welding is. An arc is a flow of particles formed during the ionization of the anode and cathode. The ionization process itself is formed by the interaction of current and short circuit. At the same time, the welding process is also influenced by the composition of the electrode coating and oxygen obtained from the atmosphere. Together, these processes lead to heating of the arc and the release of a large amount of heat, sufficient to melt the edges of the parts being welded. The edges then cool, forming a strong and reliable seam.

The key element in this process is the electrode. Without it, it is impossible to ignite the arc and keep it burning. Welding can be done using one or more arc welding electrodes. There is no single classification of rods, since the types of electrodes for manual welding can be divided into many small categories: from purpose to materials of manufacture. By the way, the electrodes themselves for electric arc welding can be made not only from metal, and we will talk about this later.

What is this method

Electrodes for electric arc welding have a great influence on the release of a sufficient amount of heat necessary to melt the metal of the welded products, so their correct selection and proper use play a big role.

An electrode is a metal rod coated on the outside with a coating that is a special composition. During the welding process, the electrode core begins to melt. The metals of the rod and the product, being in a molten state, together form a joint. When burned, the coating releases a gas necessary to protect the welding zone from the negative influence of surrounding oxygen and nitrogen. Electrodes for arc welding solve a number of important problems.

The substances included in the coating have a low ionization potential. The consequence of this is that the arc, after its ignition, is saturated with ions that are in a free state. This stabilizes the arc burning process.

The coating takes part in the formation of slag on top of the weld, which reduces the rate at which the molten metal cools. This creates good conditions for removing impurities and non-metallic inclusions from the seam, which impair the quality of the joint.

Electrode coatings contain deoxidizers whose job is to react with oxygen, causing it to bind. With the help of electrodes, the metal forming the weld is alloyed, which improves its properties. This is ensured by substances included in the coating, such as silicon, chromium, manganese, and titanium.

Brief classification of electrodes

As we wrote above, it is difficult to classify electrodes according to only one parameter. But basically, all rods are primarily divided by the type of material from which they are made, as well as by coating (or coating). Here is a brief classification of electrodes:

- Melting electrodes. They are made from metal, such as cast iron, aluminum, steel or copper. The material from which the electrode is made is selected in accordance with the metal that needs to be welded. Consumable electrodes are both anode and cathode. This is the most common type of rod at the moment.

- Non-consumable electrodes. Made from coal, graphite or tungsten. They are used in conjunction with welding wire, because such rods are not capable of forming a welding seam. When using carbon rods, use straight polarity instead of reverse polarity. Tungsten rods are indispensable for argon arc welding due to their high melting point, but are rarely used in manual arc welding.

- Electrodes without coating or coating. They are used in conjunction with flux, which is continuously supplied throughout the welding process. For manual arc welding, such rods are not used.

- Coated or coated electrodes. The most common electrodes on the market. The coating of electrodes for manual arc welding performs several functions at once: protects the metal from the negative effects of oxygen, ensures stable arc burning, and improves the quality of the welded joint. Such electrodes are used not only for manual arc welding, but also for semi-automatic and automatic ones.

What is required from an electrode?

When welding, the first thing required of any electrode is:

-stable burning of a voltaic arc,

-uniform melting of the metal and its stable transfer into the weld pool;

-protection of welded metals from exposure to air;

-obtaining a durable seam with the desired chemical composition and mechanical properties;

-minimal metal loss during welding due to waste and splashes; -so that slag can be easily removed from the surface of the seam;

-minimal toxicity of gases released during welding.

These requirements are met through the selection of electrode coating components.

Types of electrodes by purpose

Depending on the metal being welded, the operating mode of the welding machine and electrodes are selected. Different metals require different electrodes, this is called purpose. The purpose is indicated by one letter on the packaging and on the rod itself.

Electrodes marked “U” are used for welding low-alloy and carbon steels. The letter “L” denotes rods used for welding alloyed structural steels, and for high-alloy steels the designation “B” is used. The letter “T” denotes rods for heat-resistant metals, and the letter “H” denotes rods for surfacing.

Types of electrodes, their purpose

| Electrode type | For welding | Seam position |

| E42 | Critical structures made of low-carbon and some low-alloy steels (for example, grade 09G2) | Lower inclined |

| Critical metal structures and machine parts made of low-carbon steels operating under static and dynamic alternating loads | Any | |

| E42A | Particularly critical metal structures made of low-alloy, low-carbon steels operating under dynamic loads; vessels operating under pressure, as well as welding defects in castings Critical metal structures made of low-carbon, medium-carbon and low-alloy steels, as well as welding defects in cast iron castings Critical metal structures and machine parts made of low-carbon steels operating under static and dynamic loads | Any |

| E46A | Critical metal structures made of low-alloy steels operating under static and dynamic loads Critical metal structures made of low-carbon steels | Any |

| E50A | Critical metal structures made of low-carbon, medium-carbon and low-alloy steels, welding casting defects, repair and installation welding Critical metal structures made of low-alloy steels, installation and repair welding, as well as welding of defects in castings | Any |

| E60 | Critical metal structures made of medium-carbon and low-alloy chromium, chromium-molybdenum and chromium-silicon-manganese steels operating under heavy and dynamic loads | Any |

| E70 | Highly loaded critical metal structures made of structural and low-alloy steels of increased strength, operating under dynamic loads | Lower |

| E85 | Critical metal structures made of high-strength low-alloy steels Critical structures made of steels 40Х and 30ХГСА, subjected to heat treatment to a high tensile strength | Any |

| E100 | Critical structures made of medium-alloy high-strength steels | Lower |

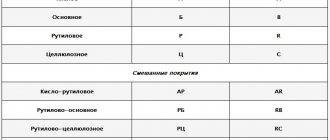

Types of coatings for electrodes

Along with the material of manufacture and purpose, the type of electrode coating is also selected. The choice of coating also depends on the metal being welded. The coating (or coating) performs a protective function. When the electrode melts, the coating releases protective substances and slag, which improves the quality of the seam and produces reliable and durable welded joints. Manufacturers use the following types of electrode coatings:

- Acid coating. Marked with the letter “A” on the packaging and the electrode itself. Used for highly targeted applications, such as bottom welds. Can be used with both AC and DC current.

- Rutile coating. Marked with the letter "P". One of the most popular coatings among both beginners and professionals. Compared to other coatings, it is almost non-toxic and provides good quality seams. When burned, it forms slag with protective properties. The composition can be varied, but the base is always titanium dioxide or simply rutile. Hence the name.

- Cellulose coating. Marked with the letter "C". Suitable for making any welded joints, ensures good quality of the seam, but at the same time contributes to strong metal spattering. We recommend using cellulose-coated electrodes when welding pipelines, since the disadvantages are not critical in such work.

- Basic coating. Denoted by the letter "B". The most popular type of coating along with rutile. Simulates gas welding due to the release of carbon dioxide when the arc burns. We recommend using base coated rods only in combination with direct current and reverse polarity. If you use alternating current, the weld will be of poor quality and additional measures will be required to improve the strength of the seam.

- Other types of coatings. Marked with the letter "P". The composition contains alloying substances. Thanks to this, the quality of the seam improves. In general, other types of coatings are used the least often.

- Special types of coatings. They are designated by the letter “C” or the inscription “special” on the packaging. They are used for complex welding under water, since they contain liquid glass and resin-containing substances.

As you can see, electrodes are selected based on specific tasks. For manual arc welding, rutile-coated rods are most often used because they are universal.

Popular brands

For a number of reasons, some electrodes have become popular among professionals and amateurs.

Causes:

- Special quality of materials.

- Low cost per kilogram.

- Availability in most regions.

Expert opinion

Levin Dmitry Konstantinovich

But to obtain high-quality seams, it is recommended to choose electrodes that can be used to ensure a reliable connection of the starting materials.

Uoni-13/55

Electrodes are produced by a number of factories in Russia and CIS countries. Designed to work with low-carbon, low-alloy steels, and some grades of cast iron.

The result should be a seam with the following characteristics:

- Tensile strength - up to 530 MPa.

- Relative elongation - up to 24%.

- Yield strength - 420 MPa.

Recommended current for welding:

| Diameter, mm | 2 | 3 | 4 | 5 |

| Current value, A | 35-55 | 90-130 | 130-190 | 190-210 |

Expert opinion

Levin Dmitry Konstantinovich

Welding with direct current of reverse polarity is allowed.

MR-3S

Universal rutile electrodes are distinguished by the fact that they transfer metal well even to rusty, damp and dirty surfaces. Often used to work with pipelines and critical building structures.

The regulatory standard is GOST-9466. Features of the finished seam:

- Very viscous.

- Resistant to cracking.

- A thick layer of slag reliably covers the welding area.

Design parameters of seams after welding:

- Tensile strength - up to 480 MPa.

- Relative elongation - up to 25%.

- Yield strength - 410 MPa.

Recommended current for welding with different diameters:

| Diameter, mm | 2 | 2,5 | 3 | 4 | 5 |

| Current value, A | 30-70 | 50-90 | 70-130 | 140-200 | 160-260 |

Expert opinion

Levin Dmitry Konstantinovich

The MP-3S can operate on both alternating and direct current.

Lb-52U

Universal electrodes made in Japan by Kobelco. They differ in that they have passed international certification and certification by NAKS. Complies with GOST 9467-75.

Consumer Features:

- The slag reliably protects the welding zone and is easily removed.

- The arc burns well even with voltage fluctuations in the network.

- The likelihood of cracks forming inside the seams is minimal.

- During welding, minimal metal spatter is observed.

The seam is viscous and plastic.

Characteristics:

- Tensile strength - 530-546 MPa.

- Relative elongation - up to 31-35%.

- Yield strength - 441-455 MPa.

Recommended welding current:

| Diameter, mm | 2,6 | 3,2 | 4 |

| Current value, A | 60-90 | 90-130 | 130-180 |

It is allowed to work on direct and alternating current in all ways, except for welding in a vertical position from top to bottom.

It is required to calcinate the electrodes before welding - 140 degrees - for 60 minutes.

ANO-4

Universal electrodes with rutile coating for operation from AC or DC sources. GOSTs: 9466-75, 9467-75.

Steels can be welded together, provided that the carbon content in them is no more than 0.25%. Surfacing is also allowed. Welding positions are any except from top to bottom.

Characteristics of the resulting seams:

- Tensile strength - up to 430 MPa.

- Relative elongation - up to 20%.

- Yield strength - 390 MPa.

Recommended current:

| Diameter, mm | 3 | 4 | 5 |

| Current value, A | 80-150 | 120-180 | 150-230 |

Electrodes are packaged either in small tubes weighing up to 1.5 kg, or in packs of 5 kg.

ESAB OK 94.25

The electrodes are suitable for working with a number of materials:

- Burnt cast iron.

- Tin bronze.

- Brass.

- Copper.

Can be used for surfacing on steel surfaces to obtain corrosion-resistant layers.

Characteristics of the resulting seams:

- Tensile strength - up to 330-390 MPa.

- Relative elongation - up to 25%.

- The yield strength is 235 MPa.

Recommended current:

| Diameter, mm | 2,5 | 3,2 | 4 |

| Current value, A | 60-90 | 90-125 | 125-170 |

Technologists recommend heating parts before welding to 300 degrees. To control the temperature, you can use a portable pyrometer or thermal pencils.

ESAB OK AlMn1 (OK 96.20)

Electrodes for welding aluminum alloys without the use of inert gases. The composition of the rod is special: Mn (manganese) - 1.00%, Si (silicon) - up to 0.5%, Fe (iron) - up to 0.7%, Al (aluminum base) - everything else.

Information about the quality of the resulting joint: if the technology is followed, it is possible to obtain a seam that is not inferior in strength to the base metal.

Recommended current parameters:

| Diameter, mm | 2,5 | 3,2 | 4 |

| Current value, A | 50-90 | 70-110 | 90-130 |

Expert opinion

Levin Dmitry Konstantinovich

Because aluminum is soft, you need to press it lightly into the weld pool when welding.

The common electrode diameter is 2.4 mm. Length - 350 mm. Packed in sealed packs of 1-2 kg. Often sold individually.

Before welding, it is recommended to calcinate the electrodes at a temperature of 110-140 degrees for about 60 minutes. And the workpieces themselves - up to 150-300 degrees. You can only operate on direct current of reverse polarity.

ESAB OK 61.30

Electrodes for working with stainless steels, including those that operate under temperature loads.

Features of materials:

- The arc starts easily. Small amount of splashes during operation.

- You can cook in any position. Exception: top to bottom.

- The slag crust is easily separated.

Electrodes can be used on both alternating current and direct current.

Seam characteristics:

- Tensile strength - up to 560 MPa.

- Relative elongation - up to 43%.

- Yield strength - 430 MPa.

It is recommended to set the welding current:

| Diameter, mm | 1,6 | 2 | 2,5 | 3,2 | 4 | 5 |

| Current value, A | 35-50 | 45-65 | 60-90 | 80-120 | 120-170 | 150-240 |

Pre-calcination is not necessary.

Analogues of ESAB OK 61.30: KISWEL KST-308L (KISWEL, South Korea), AG E308L-16 (SUPERON, India), OZL-8 (Russia).

Selecting the electrode diameter

Most novice welders classify welding rods by diameter, which is correct. After all, the diameter of the electrode directly depends on the thickness of the part. And even if you choose a rod with the right coating and from the right material, but the size is wrong, you will not get a quality seam.

The diameter of the electrode is indicated in millimeters on the packaging or on the rod itself. In this case, the length of the electrode also depends on the diameter. For welding at home, arc welding electrodes with a diameter of 2 to 4 mm are usually used. This is a universal size suitable for most welding jobs. Thicker electrodes are used in factories or private workshops.

Welding Features

To ensure decent quality of seams, you need to know some of the nuances of welding steels. Of course, we can't list them all, but you'll learn the basics that will make your job easier.

When welding high-carbon steel, it is recommended to preheat the metal to a temperature of no more than 650 degrees. For welding, use contact, gas or arc technology. It is advisable to use fluxes and filler wire. The composition of the wire must be identical to the composition of steel.

To weld austenitic steels, use resistance welding technology using a reduced welding current density.

Dissimilar steels

As for welding dissimilar steels, this too has its own characteristics. Those metals that belong to different classes are considered dissimilar. For example, austenitic steel and pearlitic steel are dissimilar. High-alloy and low-alloy steels are also considered dissimilar. For such work during RDS welding, it is necessary to use special electrodes for welding dissimilar steels. But RDS welding is still not recommended. It is advisable to weld such metals not by electric arc welding, but by laser or plasma. Such technologies require a shallow melting depth of the metal. Therefore, the quality of the seams is much better than with arc welding.

A separate technology was invented specifically for welding pearlitic and austenitic steel. The essence of this technology is simple. A small layer of austenitic steel is fused onto the pearlitic steel part. Then the edges are heated and both parts are welded together. In this case, you need to choose the welding mode that is suitable for the austenitic part.

Use low hydrogen electrodes when welding dissimilar steels. Indeed, with an excess amount of hydrogen, parts begin to form cracks in their initial stages. Also, with an excess of hydrogen, the likelihood of pore formation increases.

Selection of electrodes depending on the type of seam

It is also advisable to select electrodes for manual arc welding according to the type of seam with which you are going to weld metal. In addition to the standard horizontal, vertical, inclined and angled seams, there are also oblique, butt, beveled and many others. This is more useful for experienced welders, but novice welders should also know this information. Now let's talk about what types of electrodes there are for manual arc welding.

Types and purpose of welding electrodes

With welding you can:

- connect metal parts;

- manufacture metal structures of any size;

- cut metal;

- eliminate cracks;

- cut round and shaped holes;

- weld metal to restore wear areas;

- carry out repairs and other types of work.

The industry produces many types of electrodes, about two hundred of them. Each of them is most effective within the limited characteristics of these works, so the choice of electrodes for welding is a very important step. It should be done after thoroughly studying the topic or with the help of specialists.

The criteria for selecting electrodes are the design parameters, characteristics and purpose specified by the product manufacturer. The main ones are:

- electrode brand;

- appointment;

- core diameter;

- type of electrode coating;

- electrode length;

- the magnitude of the working current;

- type of current and polarity of connection;

- composition of the central rod;

- welding position;

- special technological characteristics of the welding process.

Electrode grades suitable for manual arc welding

There are also types of electrodes for manual arc welding, divided by brand. The brand of electrode you use also depends on the metal you need to weld.

The following grades are used for welding low-alloy carbon steels:

- E42: grades ANO-6, ANO-17, VSC-4M.

- E42: UONI-13/45, UONI-13/45A.

- E46: ANO-4, ANO-34, OZS-6.

- E46A: UONI-13/55K, ANO-8.

- E50: VSC-4A, 550-U.

- E50A: ANO-27, ANO-TM, ITS-4S.

- E55: UONI-13/55U.

- E60: ANO-TM60, UONI-13/65.

For welding alloy steels (including high-strength):

- E70: ANP-1, ANP-2.

- E85: UONI-13/85, UONI-13/85U.

- E100: AN-KhN7, OZSh-1.

- E125: NII-3M, E150: NIAT-3.

For metal surfacing: OZN-400M/15G4S, EN-60M/E-70Kh3SMT, OZN-6/90Kh4G2S3R, UONI-13/N1-BK/E-09Kh31N8AM2, TsN-6L/E-08Kh17N8S6G, OZSh-8/11Kh31N11GSM3YuF.

For welding cast iron: OZCh-2/Cu, OZCh-3/Ni, OZCh-4/Ni.

For welding aluminum and its alloys: OZA-1/Al, OZANA-1/Al.

For welding copper and its alloys: ANTs/OZM-2/Cu, OZB-2M/CuSn.

For welding nickel and its alloys: OZL-32.

Welding wire

Solid welding wire is used as an additive in manual argon-arc welding with a W-electrode and gas-oxygen-acetylene welding. The surface of the wire must be clean, free of scale, rust, oil and dirt.

Wires Sv-08MH, Sv-08KhM and Sv-09KhMFA are used for argon arc welding only of alloy steels with a silicon content of no more than 0.25%.

Wires Sv-08MH, Sv-08KhM and Sv-09KhMFA are used for welding pipelines with ambient temperatures up to 510°C inclusive, as well as for root weld welding, regardless of the parameters of the working environment.

For manual argon arc welding of the root seam of pipelines with a wall thickness of more than 10 mm made of chrome-molybdenum and chrome-molybdenum-vanadium steels, Sv-08G2S or Sv-08GS wire is used.

Application area

| Type and grade of steel | Wire grade | ||

| Manual argon arc welding with W-electrode | Manual gas welding with oxy-acetylene flame | ||

| Carbon St2; St3; St4; St3G; 08; 10; 20; 15L; 20L; 25L | Sv-08GA-2; Sv-08G2S; Sv-08GS | Sv-08; Sv-08A; Sv-08GA; Sv-08GS; Sv-08G2S; Sv-08MH | |

| Low alloy structural 15GS; 16GS; 17GS; 14GN; 16GN; 09G2S; 10G2S1; 14HGS; 20GSL; 17G1S; 17G1SU | Sv-08GS; Sv-08G2S | Sv-08GS; Sv-08G2S | |

| Alloy heat resistant | 12MX; 15ХМ; 20HML; 12Х2М1 | Sv-08MH; Sv-08KhMA-2; Sv-08ХМ; Sv-08HGSMA | Sv-08MH; Sv-08ХМ; Sv-08HMFA |

| 12Х1МФ | Sv-08KhGSMFA; Sv-08ХМ; Sv-08HMFA; Sv-08MH; Sv-08KhMA-2 | Sv-08MH; Sv-08ХМ; Sv-08HMFA | |

| 15Х1М1Ф; 20ХМФЛ; 15Х1М1ФЛ; 12X2MFSR; 15Х1М1Ф-ЦЛ; 12Х2МФБ | Sv-08HMFA; Sv-08KhGSMFA; Sv-08KhGSMFA2; Sv-08HMFA2 | — | |

| High alloy corrosion resistant, heat resistant and heat resistant | 08X18H10T; 12X18H12T; 12X18H10T; | Sv-04Х19Н11МЗ; Sv-08Х19Н10Г2Б; Sv-04Х20Н10Г2Б; Sv-01Х19Н9; Sv-04Х19Н9; Sv-06Х19Н9Т | — |

| 12Х11В2МФ | Sv-10Х11НВМФ; Sv-12Х11НМФ | ||

How to choose quality electrodes

Like any welding equipment, electrodes are subject to GOST standards, which regulate their quality. Thus, according to regulations, rods must be made of high-quality materials purchased from certified suppliers.

The coating of electrodes for manual arc welding should not have significant defects; small cracks and dents are allowed due to poor transportation. When melting, the electrode coating should not crumble or melt unevenly, and should also splash within the normal range for each specific type of coating.

The rods must be strong and resistant to mechanical stress. The seam should be of high quality, without cracks or pores. Knowing these features, you can easily choose high-quality electrodes and be confident in the result.

Electrodes with basic coating (symbol B)

The electrodes with the main type of coating include magnesium and calcium carbonates (dolomite, marble, magnesite) and fluorspar (CaF2). The latter reduces work efficiency when using alternating current, so welding with such electrodes can only be performed with direct current. Mixed types containing less CaF2 allow work to be performed on alternating current.

The metal deposited with electrodes with a basic coating corresponds in chemical composition to mild steel. According to the mechanical properties of the weld metal, electrodes with a basic coating are of types E42A, E46A, E50A, E55 and E60 according to GOST 9467-75. The most common and popular type E50A has a tensile strength of up to 490 MPa . Index “A” indicates that the deposited metal has increased plastic properties .

Electrodes with this type of coating are characterized by high ductility and impact strength at normal and low temperatures, and also have increased resistance to the formation of hot cracks. This is achieved due to the low content of gases, non-metallic inclusions and harmful impurities. Also, the gas-protective environment of mineral origin, consisting mainly of CO and CO2, is devoid of hydrogen, which leads to the formation of cold cracks in the deposited metal. The transfer of metal into the weld pool occurs in medium and large drops, the molten metal becomes viscous.

However, in terms of technological characteristics, electrodes with a basic coating have their drawbacks. They are quite sensitive to the formation of pores in the presence of scale, rust and oil on the edges of the parts being welded, as well as when the coating is moistened and the arc is extended. They also require compliance with storage conditions (in a dry, ventilated area) and mandatory calcination at high temperatures before use. Welding is usually carried out with direct current of reverse polarity.

Advantages of electrodes with basic coating

- The seam has good toughness and ductility

- The metal contains small amounts of gases and impurities

- The joint is resistant to hot cracking

- Possibility of welding in all spatial positions

Disadvantages of electrodes with basic coating

- Sensitive to moisture - electrodes should be stored in a dry place

- When operating on alternating current, the arc may be unstable

- Lengthening the arc leads to the appearance of pores

- When working on wet surfaces, the connection may deteriorate

- Electrodes must be calcined before use.

- Before welding, it is necessary to prepare the surface

- Difficult for beginner welders

Areas of use

Electrodes with a basic coating are used when welding critical structures, when high demands are placed on the weld metal. Widely used for welding oil and gas pipelines, bridges and other critical structures.

Diameter

The choice of electrode (core) diameter is determined by the thickness of the parts being welded and the maximum current of the welding machine used. The higher they are, the thicker the connected elements can be.

All three parameters are dependent on each other. Their values are indicated in special tables, which are convenient to use before work and purchasing electrodes. So, for parts with a thickness of 3-4 mm, you need to use electrodes with a diameter of 3 mm with adjustable operating current within the range of 80-160 A.

Welding position

The spatial position of the electrode is also included in its marking. The number 1 denotes electrodes that are used for welding only in the lower position of the part (electrode on top).

The number 2 marks products used with a horizontal or vertical seam (ceiling is excluded).

Number 3 is used for ceiling electrodes (the electrode rests on the part from below). The welder must take these markings into account to avoid a poor-quality weld or injury.

How to determine the quality of electrodes when purchasing?

The best option would be to test several electrodes from the purchased batch in the welding workflow. If this is not possible, you need to pay attention to the following factors:

- shelf life of products;

- name of the manufacturing company (for experienced welders this is important information);

- quality of coating in terms of uniform thickness of application around the rod, absence of crumbling.

If during testing there are signs of excessive moisture, the electrodes should be dried and the test repeated.

In order for the welding of parts to be carried out in accordance with all the rules of the regulations, and the quality of the seam not to be criticized, it is extremely important to study welding technologies well. The choice of electrode type is an integral part of this knowledge, which needs to be constantly replenished and improved.

Calcination of electrodes

Coating of electrodes requires tightness during storage, but this condition is not met everywhere. The sharp edges of the rods, as a rule, break the tightness of the plastic packaging already during the first transfer of packs. Thus, by the time of purchase, the electrodes are saturated with excess atmospheric moisture.

In this condition, due to the danger of obtaining a poor-quality seam and the possibility of too much metal spattering, welding cannot be performed with them. The electrodes need to be dried. The manufacturer gives clear recommendations regarding process parameters, setting drying time and maximum temperature. It usually does not exceed 260 ºС.