Due to their excellent characteristics, ESAB UONI 13 45/55 welding electrodes have become widely used in the domestic industry. Today they are actively used to create heavily loaded metal structures, which are subject to increased requirements in terms of strength and reliability.

UONI welding electrodes are available in several modifications, which differ in their composition and are used to work with various materials. The coating of all these products includes carbonates and fluorine compounds, which provides the seam with good impact strength and ductility, and also minimizes the likelihood of hot cracks.

Moreover, all models of these consumables imply manual arc welding with direct current of reverse polarity. The positioning of the welded joint can be different, with the exception of a vertical seam created from top to bottom.

When using alternating voltage, arc breakage and sticking of the electrode are often observed, while with a straight-polarity welding current, the end of the USI core burns out very quickly, thereby increasing the discharge length.

Purpose and marking of the product

UONI welding electrodes allow you to create metal structures and steel products that:

- consist of thick-walled parts and elements;

- operated at low temperatures;

- designed for constant increased loads.

In other words, welding is used when forming high-strength joints, as well as when it is necessary to correct defects in parts formed during the casting process. For this reason, the consumables in question are designed for highly qualified craftsmen, while novice welders are recommended to use other, simpler analogues.

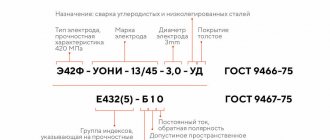

If we talk about marking according to GOST, then the decoding of the designation of the electrode UONI E40A-UONI-13/45 SM-3.5UD GOST9467/60 indicates the following parameters.

- E – welding electrode.

- 40 – connection tensile strength in kgf/sq.mm.

- A – viscosity and plasticity of the seam.

- UONI is a product brand that stands for “universal coating of a scientific institute.”

- 13/45 – modification of the welded electrode.

- SM-3.5 – welding wire with a diameter of 3.5 millimeters.

- D – in the design the coating is made in a thick layer.

- U - used for welding carbon steel parts.

Note that, in addition to the letter “U”, the marking of UONI electrodes may include the letters “V”, “L” and “T” (high-alloy, alloy and heat-resistant steel), as well as “H” (indicates the model for surfacing and repair) . In addition, in place of the letter “D” you can find the letters “C” and “M”, which mean that the coating is of medium thickness or thin.

Application area

The scope of application here is very wide, since UONI-13 55 electrodes have characteristics that are convenient for almost all industries. They can be found both at home and at construction sites. They are best suited for joining steel structures, since the composition of the deposited metal is as similar as possible to ordinary steel. The connection has a long service life, which is suitable for the construction industry. It is used to repair various products, weld sealed containers, tanks and pipes. The process is high-quality and simple, which only increases the demand. At home, use is complicated by the need for calcination, because it is not always possible to reach such a temperature. In other places this problem does not arise.

Electrodes UONI-13 55 for welding steel structures

Popular varieties

Consumables of this type are produced in a wide range of diameters (from 2 to 5 millimeters). The most popular in the model range are UONI 13 55 3mm and 4mm electrodes. At the same time, there are four types of products that have a specialized purpose and their own specific application.

- 13/45 – designed for creating highly demanding metal structures from low/medium carbon steel blanks. They are also used to repair cast and forged products and eliminate defects. The core of these electrodes contains molybdenum and nickel, which provide the weld with the necessary toughness and ductility.

- 13/55 – focused on welding structural elements made of low/high carbon steels. The coating of such models contains phosphorus, sulfur, silicon and manganese, which guarantees excellent quality of the welded joint. Used in production workshops. The products are demanding on the condition of the parts (dirt, rust and moisture on their surface).

- 13/65 - used in the same cases as analogues 13/55. These electrodes are used to produce a seam of improved quality, but the price of such SSSI per kg is noticeably higher. Therefore, such consumables are used only when creating especially critical metal structures and products.

- 13/85 - the most expensive welding electrodes from the UONI model range. They are actively used in the process of forming structures from parts made from alloy steels.

Specifications

Today, there are a lot of different materials on the market for welding accessories. Electrodes of the UONI 13/55 brand have gained the most popularity, the technical characteristics of which allow welding work to be carried out in poor climatic conditions, where work with conventional tools is impossible.

UONI electrodes have been used for a long time in production and home welding work; they have passed the necessary tests and are approved by GOST. When welding, the seam is obtained with the required impact strength and is plastic under load. The technical specifications include a base coating that primarily interacts with the metal. Welding with UONI electrodes creates a high-quality seam on which even microscopic cracks are not detected.

Specifics of SSNI electrodes

In addition to SSNI consumables, their closest analogues, MP-3, are very popular, which have their own advantages, namely:

- can work with direct and alternating current of different polarities;

- suitable for professionals and beginners;

- allow welding at high relative humidity.

Products of the MP-3 brand have rutile coating, and their main disadvantage is the high price.

If we talk about SSSI electrodes, their main technical characteristics are as follows.

- Material - rods made of welding wire Sv-08/08A (13/55).

- Consumption - 1.7 kilograms per 1 kg of molten metal.

- The coating is basic (the composition depends on the model).

- Length – 35-45 centimeters with a diameter of 2-3/4-5 mm.

- The deposition coefficient corresponds on average to the value of 9 g/Ah.

The chemical and mechanical properties of SSNI electrodes are given in the following table.

UONI electrodes equipped with basic coating, unlike rutile analogues, are contraindicated in high-ampere current. The fact is that it causes the release of a large amount of heat, which reduces the quality of the seam being formed. If you ignore this requirement, you can observe:

- warped material;

- increased splashing;

- active evaporation of metal;

- melt leakage;

- making it more difficult to control the weld pool.

Recommended current parameters for products of various diameters are given in the following table

SSNI electrodes are packaged in packs weighing 1 and 5 kilograms. Depending on the diameter of the products, the package can contain from 10 to 100 electrodes.

Electrodes UONI-13/55 DC GOST 9466-75

| Catalog / welding electrodes UONI-13/45, UONI-13/55 |

Electrodes UONI 13/55 GOST 9466-75 are intended for:

- for welding structures made of steel grades 10ХСН2Д, 48КS.

- for welding the listed steel grades with steel grades St3, BSt3, 09G2, 10G2S1D-35, 10G2S1D-40, 10HSND, MS-1, St3s, 10, 15, 20 and forgings made of carbon and dispersion-hardened steels, as well as for welding castings and forgings with each other, when increased demands are placed on the metal of the welded seams in terms of ductility and impact toughness.

Type of current - constant.

Electrodes about 2015

The quality of UONI welding electrodes has been confirmed:

- fill out the simple “Place an order” form at the top of the page;

- call on the phone +7;

- send your application by email;

Buy electrodes. Purpose and length of SSNI electrodes:

| Electrode brand | Electrodes UONI-13/55 | GOST 9466-77, TU1272-175-00187211-97 | |

| Purpose: | For welding particularly critical structures made of carbon and low-alloy steels. Recommended for welding structures operating at low temperatures | ||

| Diameter, mm | 2,0 | Length, mm | 250; 300 |

| Diameter, mm | 2,5 | Length, mm | 300; 350 |

| Diameter, mm | 3,0 | Length, mm | 350 |

| Diameter, mm | 4,0 | Length, mm | 450 |

| Diameter, mm | 5,0 | Length, mm | 450 |

Mechanical properties of UONI electrodes:

| Electrode brand | Mechanical properties, no less | ||||

| weld metal | welded joint | ||||

| tensile strength, MP (kgf/mm2) | relative extension, % | impact strength, J/cm2 (kgf/cm2) | tensile strength, MP (kgf/mm2) | Bend angle, degrees. | |

| 13/45 | 410(42) | 22 | 147(15) | 410(42) | 180 |

| 13/55 | 490(50) | 20 | 127,4(13) | 490(50) | — |

| 13/45(A) | 430-530(44-54) | 26 | 160(16) | 430-530 | 180 |

Chemical composition of electrodes (%):

| Mass fractions of elements, % in deposited metal | ||||||

| carbon, no more | silicon | manganese | nickel | molybdenum | sulfur, no more | phosphorus, no more |

| 0,11 | 0,12-0,25 | 0,35-0,70 | — | — | 0,030 | 0,035 |

Type of current, position of the seam in space during welding:

| Rod current | Seam position in space |

| DC current, reverse polarity |

Welding current, electrode consumption coefficient during welding:

| Diameter, mm | Welding current, A | Electrode consumption coefficient per 1 kg of deposited metal | Surfacing capacity, g/A. hour | ||

| lower | vertical | ceiling | |||

| 2,0 | 40-60 | 35-55 | 35-55 | 1,65 | 9-10 |

| 2,5 | 50-70 | 40-65 | 40-65 | 1,65 | 9-10 |

| 3,0 | 80-100 | 70-90 | 70-90 | 1,65 | 9-10 |

| 4,0 | 130-150 | 130-140 | 130-140 | 1,65 | 9-10 |

| 5,0 | 170-200 | 160-180 | — | 1,65 | 9-10 |

Coverage type: basic.

How to buy UONI-13/55 DC electrodes GOST 9466-75 at low prices:

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

| Steel wire Welding electrodes Steel rope Fasteners | Metal mesh Hex bolts Nut GOST, DIN Steel rivets | Adjustable cotter pins GOST, DIN washers Threaded rods Calibrated rolled products | Slings, rigging Construction nails Steel cable Screws GOST, DIN |

Advantages and disadvantages

In the list of undeniable advantages of UONI welding electrodes, experts highlight such aspects as:

- the ability to create a high-quality seam with high impact strength, reliability and ductility;

- low consumption of electrodes due to iron powder in the coating;

- no need to use protective gas.

If we talk about the disadvantages of SSSI products, then it is necessary to note:

- the need to attract experienced welders;

- thorough preparation of welded parts;

- inability to use alternating voltage.

Based on the above, it can be stated that SSSI products are highly specialized electrodes that require professionalism and a competent approach to welding.

How is the marking of UONI 13 electrodes deciphered?

Electrodes for arc welding UONI-13/55 were created by specialists from the laboratory of the then secret Scientific Research Institute No. 13. Hence the decoding characteristic of UONI-13/55:

- U – universal (electrode);

- O – main type of coating;

- N – research;

- I – institute;

- 13 – institute number.

The institution, founded back in 1922 in Petrograd, still operates successfully today. The current name is FSUE “Central Research Institute of Materials”.

Welding process

Before starting the process of welding a metal structure, the SSSI electrodes must be calcined. This is due to the porous structure of their coating, which actively absorbs atmospheric moisture, reducing the performance characteristics of the consumable.

This process involves placing electrodes in a special oven. Temperature parameters for calcination are indicated on the packaging of products for each specific model. On average, this is a temperature effect of about 250-300 degrees Celsius for 4 hours. It is not recommended to do calcination more than three times to avoid loss of performance characteristics of the electrodes.

The welding itself is carried out in the following sequence.

- Cleaning the surfaces of parts.

- Cutting edges of workpieces according to GOST.

- Placement of structural elements according to the drawing.

- Connecting welding equipment.

- Setting current parameters for a specific electrode.

- Excitation of the arc.

- Creating a herringbone seam.

- Turning the workpiece over and forming a reverse seam.

- Cooling, cleaning and checking connections.

UONI welding electrodes should be stored in a dry, heated place with a humidity of no more than 50%. Direct exposure to sunlight and moisture should also be avoided. Low temperatures (less than +15°C) are also contraindicated.

Electrodes for welding UONI-13/55 – technical characteristics

Consumable material of this brand provides a fairly high deposition rate - it reaches 9.5 g/Ah. Other indicators include:

- surfacing productivity for a rod with a diameter of 4 mm is 1.4 kg/h;

- per 1 kg of deposited metal, an average of 1.7 kg of electrodes is consumed;

- weld metal yield strength – 420 MPa;

- relative elongation rate – 22%.

The impact strength of the metal is: at t +20 °C – 130 J/cm²; at t -40 °C – 80 J/cm²; at -60 °C – 50 J/cm².