Electroslag welding (ESW) is used for mass vertical joining of metal parts. The method helps to obtain high-quality seams at a low cost. Flux protects the molten material from oxidation and promotes better heating of the metal. The consumable electrode or filler wire is the alloying component.

ESW is used for welding vertical objects.

Features of electroslag welding

The absence of an arc is the main distinguishing feature of this method. Electricity is transferred to the slag, which is considered a conductor. This helps release the heat needed for melting. Before starting work, a special electrode is placed in a container with by-products. The welding method has the following features:

- large distance between parts located vertically;

- lack of contact of the weld pool with oxygen (the entire area remains under slag);

- low flux consumption, alloying the joint with a consumable electrode;

- the seam remains in a liquid state for a long time, facilitating the evaporation of gases.

The essence of the process

The essence of the technology is to transfer current to the slag, and from it to the electrode and the edges of the parts. The stability of the process is ensured by a constant temperature, which can reach 1900-2000 °C.

Most of the heat enters the weld pool, then the energy flows to the edges of the parts.

Basic schemes

The electroslag method is used not only for joining parts, but also for casting and surfacing. Welding is performed with consumable electrodes or nozzles, filler rods of large diameter. There are 6 main operating patterns that can be seen in the image.

It is worth considering the features of each option:

- The first 2 methods are considered the most common. They are used to connect workpieces with a height of 2-4.5 cm using an additive with a diameter of 3 mm.

- The third scheme can be used for welding more massive structures. The thickness of each part can reach 12 cm.

- The fourth option is characterized by high performance.

- The fifth scheme belongs to the category of narrowly focused methods. It is used when working with low-alloy steels. The leaf height can reach 10 cm.

- The sixth scheme is intended for creating dimensional structures without further heat treatment. The thickness of the welded workpieces can be up to 6 cm. The method helps to obtain a strong, uniform seam.

Welding process diagram.

Types of Welds and Joints

ESW technology allows you to weld parts located in different spatial positions. The most commonly used types of seams are:

- Butt joints. A small distance is left between the parts, which is considered the main feature of electroslag technology. The procedure for cutting edges and forming welds is regulated by GOST 15164. When butt welding parts of different thicknesses, the thicker edge is thinned. It is possible to weld a metal plate to a less massive workpiece.

- T-joints and corner joints. They are used less frequently than butt ones. When using a melting tip, the weld edges are cut in a K- or V-shape.

- Straight connections. Performed in a vertical position. A slight tilt is allowed.

- Circular seams. Used when working with spherical or cylindrical workpieces.

Recommended reading: What is TIG welding

Welding methods

Electroslag welding is not suitable for all metals, but its scope of application cannot be called narrow. It is usually used to join low-carbon and medium-carbon steels, cast iron, non-ferrous metals (up to titanium and aluminum), and less often for alloy steels.

They are used in the production of massive, large-sized parts (thickness about 100-600 mm), and in waste remelting.

In practice, 3 main welding techniques are used. The first involves the continuous supply of a filler electrode directed in a horizontal plane into the melt. The movement of the electrode is reciprocal in nature to ensure maximum contact density.

The second electroslag technique is welding with large plate electrodes, which actually replace copper sliders.

In this case, the additive is used to a lesser extent - the electrodes themselves tightly close the gap and provide an effective melt: the ends of the parts are connected without an additive. But in this case, the electrodes must be adjusted in shape to the parts; this is a highly specialized method.

The third technique is based on combining the first two. It contains both a plate electrode and a special consumable electrode. The first remains stationary during the entire electroslag welding process, the second is fed into the melt zone and is, in essence, an additive.

Please note that the chemical composition of the additive must be similar to that of the base metals.

There are also two different operating principles for electroslag welding installations. Devices that implement the first method work with a solid slag mixture, which they independently melt. Installations operating on the second principle use a liquid mixture pre-melted in an oven.

The first ones require a more powerful starting current to start working, because a lot of energy is spent on bringing the slag to a liquid state. The latter, accordingly, requires a nearby smelting furnace.

Areas of application

The technology is considered highly specialized. It is used in shipbuilding and automotive manufacturing, creating bridges and other massive structures. Using ESW, supporting elements of rolling machines weighing up to 100 tons are welded. The technology can be used in electroslag remelting. In this case, the current flows not to the filler wire, but to the material being melted. EHS is not used for:

- work with thin-walled elements that completely melt under the slag;

- formation of multidirectional connections;

- welding parts that are too massive to be covered by sliders.

Thermal classes

Dugovaya

It is this type of welding technology that most often “works” on construction sites and industrial facilities. The electric discharge heats up to a degree that is completely inaccessible to even the best gas burners. Under the influence of the arc, a weld pool is formed, upon subsequent solidification of which a weld is generated. But behind this apparent simplicity there is very careful work, and a welder’s mistake can lead to very unpleasant consequences

Arc welding can be:

- manual;

- partially automated;

- fully automated (the higher the degree of automation, the greater the requirements for the qualifications of performers and the quality of equipment).

Gas

There are various methods of welding with flammable gas. But all of them, no matter what gas is used, and no matter what problem is solved, are clearly ahead of electric welding in terms of mobility and flexibility. You can carry out work almost anywhere where you can place cylinders and stretch hoses. At the same time, however, even the most massive combination of acetylene and oxygen is more expensive than electricity. Other gases cost even more.

Important - gas welding is much more effective than arc welding in relation to:

- copper;

- lead;

- cast iron;

- brass products and structures

Types of Electroslag Welding

The methods differ in the types of filler materials and the methods of their supply.

With electrode wires

The material is selected taking into account the type of welding machine and the characteristics of the metals being joined. The wire enters the space between the parts slowly. It is fed from top to bottom, following the moving electrodes.

Electroslag welding with electrode wires.

With large cross-section electrodes

The welding process uses round or rectangular elements of increased diameter. They are moved closer to the gap as the melt forms. Unlike wire, electrodes with a larger cross-section quickly form a large volume of suture material.

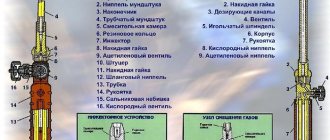

With melting mouthpiece

The technology combines the 2 previous methods. The conductive plates are installed in a position that facilitates rapid heating of the flux. The wire enters the weld pool through the guide nozzle. The method is intended for the formation of curved connections.

Electroslag welding using a nozzle.

Varieties

When connecting 2 parts, between the gap surfaces of which there is a gap, welding is performed. It is divided into types according to the type of current supply element, its shape and design. There are varieties:

- single-electrode,

- multielectrode,

- with wire,

- plates,

- melting mouthpiece

- flat.

Welding with one current-feeding wire is used to join thin sheets using automatic and semi-automatic machines.

Flat electrodes are used for surfacing metal onto the surface of a part. Their current supply edge is flat, wide, located in the slag bath parallel to the plane of the part. A flat electrode covers a wide strip of the part with weld metal in one pass.

With wire

There can be from 1 to 3 wire electrodes. They are fed into the slag bath at a constant speed. When connecting joints of large width, they can perform a zigzag movement perpendicular to the axis of the seam.

The current is applied directly to the wire itself and passes through the flux, heating it and melting the wire-electrode itself.

With plates

Wide gap-sized plates are used for welding large parts. The filler wire is fed from the side or laid along the bottom of the seam. The electrode is lowered into the bath and mixed along the seam, immersed in flux.

With melting mouthpiece

The mouthpiece is a plate immersed in slag, through channels inside which wire is fed into the melting bath. It moves at a constant speed. Depending on the width of the seam, there may be 2 or 3 holes for the wire.

The mouthpiece can be wide only at the bottom and have any shape. The wire is fed along a rod mounted perpendicularly to the base of the melting die. Externally, the part is an inverted letter T with one or more legs. The welding speed does not decrease.

Preparatory work

Welding begins with the selection of filler materials and equipment. After this, the parts are prepared for joining.

Selection of welding materials

The types of wires used for ESW can be studied using the table:

| Type of steel | Filler material grade |

| Structural | SV-08A, SV-08GA |

| Medium carbon cast | SV-10G2S, SV-10G2 |

| Boiler room | SV-10G2S, SV-10G2 |

| Medium Carbon Forged | SV-10G2 |

| Low alloy | SV-10G2S, 18ХМА, SV-08-G2S, SV-08ХН2М |

| Medium alloyed | SV-08Х3Г2СМ, SV-20ХН3МФ |

| High alloy | SV-04Х19Н11М3 |

All materials presented in the table can be cooked using fluxes AN-99, AN-8. When joining steels 08Kh18N10T and 25KhN3MFA, grade 48-OF-6 material is used.

Mode selection

The main indicators are:

- current strength, I;

- reduction in voltage between the slag bath and the electrode, U;

- wire arrival speed, Vе;

- speed of electrode guidance, Vst;

- slag bath depth, h;

- wire extension, L;

- electrode oscillation speed, Vk;

- number of rods, n;

- electrode cross section.

Formula for calculating current strength

To calculate the current strength, use the formula I = (0.22Ve 90)n 1.2(Vst 0.48Vp)ab, where a and b are the height and width of the workpieces. The additive feed rate is: Vе= VсвF/S. Indicators Vk, L, h are constant.

Selecting the number of electrode wires

The parameter depends on the dimensions of the workpieces being welded. If the thickness does not exceed 5 cm, work with 1 wire. 2 electrodes are required when the parameter is 5-12 cm. When welding more massive elements, 3 wires are used.

We recommend reading Description of the thermite welding process

Preparation of products

Before starting work, the ends of the parts are cleaned of rust and oxide film. For this purpose, special grinding machines are used. The edges are given the desired shapes and sizes. It is recommended to install parts with a wedge-shaped gap that increases upward. The opening angle is selected taking into account the method of welding and fixing the workpieces. The indicator is most often 1-2°. The parts are secured with strips or brackets welded along the joint. After welding is completed, the fasteners are cut off using a gas plasma method.

Electroslag welding technology

The process of melting the edges of parts begins after flux is supplied to the weld pool. The treated area is heated to the desired temperature. There are 2 methods for creating a slag bath:

- Solid start. Melting begins due to the burning of an electric arc. The desired characteristics of the bath are maintained by adding slag.

- Liquid start. Molten flux is fed into the working area. The material is preheated in an oven.

Scheme of the ESW process.

When using the first method, increased energy consumption is observed due to the need to increase the current strength. The bottom of the bar must be covered with metal powder required to initiate the arc. During the process, you need to monitor the condition of consumables and add them regularly.

General principles

It is easier to understand the essence of electroslag welding if we consider this process in a simplified form. Everything happens as follows:

- The parts to be joined are installed with a certain gap, the value of which varies depending on the size of the product, the chemical composition of the material and the parameters of the welding current. A chemical called flux is placed in this gap and an electrode is applied to it.

- The current supplied to the electrode passes through flux, the composition of which can be different. As a result of heating, a so-called slag bath is formed, inside which the temperature necessary for melting the metal is maintained. Slag, lighter than metal, is always on top, blocking the flow of atmospheric air to the weld formation zone and increasing the cooling time of the molten metal.

- To keep molten materials from flowing out, the processing area is fenced with water-cooled movable sliders made of copper. In some cases, it is possible to use the enclosing plates remaining on the finished part.

Equipment used

Most often, the A535 machine is used for welding using the electroslag method. It works with alternating current and is suitable for creating longitudinal or circular seams with a width of no more than 30 cm. The device has the following technical characteristics:

- thickness of welded workpieces – up to 45 cm;

- power supply – connection to a 380 V network;

- number of electrodes – 3;

- current frequency – 50 Hz;

- filler wire diameter – 3 mm.

The A550 machine is used less frequently. Welding is carried out in the same way as when working with the previous unit. However, the technical characteristics of the machines are somewhat different. In A550, the stroke height of automatic sliders is set, depending on the thickness of the parts.

Quality control

The appearance of defects deteriorates the quality of the welded joint, making it less durable. Special methods are designed to detect deficiencies.

How is quality control of welded joints carried out?

Characteristic defects

When working using ESW technology, welded joints may acquire the following disadvantages:

- Hot cracks. Occurs when working with any type of steel. However, high-carbon alloys are most susceptible to cracks. High welding speed with rigid fixation of parts also contributes to the appearance of defects.

- Cold cracks. Appear when connecting workpieces made of medium-alloy steels with a ferrite additive. Reducing the depth of the bath and uniform penetration of the joint help prevent the appearance of defects.

- Other defects. These include foreign inclusions, pores, and lack of penetration. Appear when welding rules are not followed.

We recommend reading Features of pulse welding

Methods for controlling welds

Compounds obtained as a result of ESW require comprehensive research. The following control methods are used:

- visual inspection;

- ultrasound scanning;

- magnetic flaw detection;

- X-ray control;

- radiation flaw detection.

Ultrasound scanning of seams.

Advantages and disadvantages

The positive qualities of the technology include:

- Protection of the metal from oxidation. There is no need to use argon or other gas.

- Uniform heating, slow cooling of parts. The temperature rise starts from the flux layer. The slag coating maintains a stable heating level. This has a positive effect on the quality of the seam.

- Minimal influence of current on the connection formation process. Warming up occurs not due to the arc, but due to the slag. Melting does not stop after disconnecting the machine from the power supply.

- Possibility of welding thick parts in 1 pass. There is no need to form multilayer seams. When using 2 electrodes, workpieces thicker than 20 cm can be connected.

- Minimum slag consumption. The volume of the material does not exceed 5% of the mass of the metal. A small amount of energy is expended. There are no losses inherent in other welding technologies.

- High efficiency. With a minimal investment you can perform extensive welding work.

- Automation of most welding processes.

- Reducing the duration of the preparatory stage. It is not necessary to trim the edges. The gap between the parts is filled with melt.

The disadvantages of the method include:

- the impossibility of forming certain types of seams (only vertical or similar connections are made using the ESW method);

- continuity of the process;

- granularity of the root layer, reducing the strength of the seam.

Advantages

Electroslag welding has a number of undoubted advantages that cannot be neglected when organizing production processes.

- The ability to ensure a stable and high-quality seam structure when connecting parts of significant mass and thickness.

- There is no need for preliminary chamfering of the edges and subsequent processing of the finished product to remove slag.

- In the case of simultaneous use of several electrodes, it becomes possible to apply a welding seam along the entire length in one pass, which significantly reduces work time and speeds up production.

Additional Information

Seam parameters (width, depth, appearance) can be changed using one or another mode. The main factors are considered:

- electrode installation locations;

- welding speed;

- number of electrodes;

- electrical parameters.

Additional values must be set in accordance with the main ones. The slightest changes are reflected in the properties of the seam. At a low specific current intensity, electroslag welding proceeds stably. It can be used to connect rods to metal sheets.

What fluxes are used?

Fluxes and slags for electroslag welding are one and the same. This substance is the leading one, and it must meet certain conditions:

- ensuring the start of the reaction in the shortest possible period of time and with any voltage;

- edge penetration at a high level;

- high attributes and strength of the finished seam;

- ease of cleaning up excess upon completion of actions.

Also, for each procedure you need to choose your own type of substance. For example, AN-8 is intended for low-alloy or carbon types of iron. Its calcination modes are 400-500 °C. The chemical composition of the granules includes oxides of silicon, manganese, calcium, magnesium, and aluminum. The weld metal will contain 0.12% phosphorus and 0.1% sulfur.

AN-22 is intended for high-alloy materials. This matter is similar to a glassy structure of yellow color. As for the calcination mode, it should reach 650-800 °C.

Flux for electroslag welding

When processing stainless steel, fluxes AN-45 and its analogues are used. However, when this substance melts, a large release of fluoride gases is observed, which is the main disadvantage. Technological properties are as follows:

- Good seam formation with a smooth transition to the base of the product.

- Low tendency to chip and crack formation.

- The grain size can be 0.25-3.0 mm.

- Satisfactory definition of the slag crust.

There are also less popular varieties. For example, AN-9, ANF-1, ANF-7. Each of the components differs in chemical composition, melting point and appearance, which must also comply with GOST.