For high-quality and confident work with fasteners that have an internal slot, it is important to choose the right tool - a hand screwdriver or a screwdriver bit. The size of the working profile of the tool must exactly correspond to the size of the working profile in the hardware head. The most common self-tapping screws, screws and bolts most often have a straight or Phillips slot, the size of which is directly related to the diameter of the fastener leg.

Below are tables of correspondence between the diameter of the hardware and the size of the screwdriver (bit).

Types of screwdriver tips

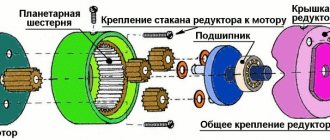

Any simple screwdriver consists of three elements: a handle (plastic, wood or rubber), a metal rod and a working tip. The latter has protrusions corresponding to the slots in the head of the screws or self-tapping screws. The screwdriver is held by the handle and rotated along the axis. It is important that the handle does not slip in your hands.

When screwing in and unscrewing, an increased load is placed on the tip, so the edges on it gradually lick off and stop clinging to the slots in the fastening element. To extend the service life of the screwdriver, the tip is made of durable alloys and hardened.

Chrome vanadium molybdenum steel is usually used. Let's consider the types of fastener slots for which various screwdrivers are produced.

Straight (flat) slot - SL

One of the most ancient types of slots. The slot shape is used in self-tapping screws and screws on products that do not require strong tightening (low-critical designs).

It is inconvenient to work with screwdrivers with self-tapping screws with a straight slot, since the tip constantly moves to the side and slips out, scratching the surrounding surfaces.

Screwdrivers for working with flat slots can be sharpened to a classic or radius shape. In the first case, it will be two faces that meet at a slight angle to a flat flat end. In the second, there is a small protrusion inside that prevents the tip from moving from the center of the screw head.

In terms of twisting, radius sharpening is preferable because it increases productivity. But it’s inconvenient for her to insert a sting into a crack to bend, pry or wedge something.

Cross splines

Screwdrivers got this name because of the shape of the protrusions in the tip, which are based on a cross. Sometimes they may be called simply “cross” or “plus” masters.

Phillips - PH

The slot was almost the only cross-shaped one that was widely used in the USSR. Corresponds to GOST 10653-86 and is designated as type N. According to the ANSI standard, it is designated as Type I Cross Recess.

The spline type was developed by J. Thompson, but the patent was later sold to Henry Phillips. It was his company, Phillips Screw Company, who perfected the spline design and took credit for its advancement.

Thanks to this slot design, the problem of the screwdriver shifting when tightening was solved, and such fasteners could be used with electric and pneumatic tools.

A modern tool for Phillips splines is designated PH and can be numbered 0000, 000, 00, 0, 1, 2, 3, 4. The number indicates the conventional geometric size, written in increasing order.

PH slotted screwdriver.

Pozidriv – PZ

A more complex modification of the launch vehicle is designated Type IA according to the ANSI standard. GOST 10753-86 classifies it as type Z. The patent for this spline shape was filed in 1962 and belongs to GKN Screws and Fasteners.

The design of the slot involves a main cross-shaped intersection of the slots at right angles and additional grooves located at 45º from them. This configuration increases strength and increases contact points with the working part of the screwdriver. There is less ejection with high torque, which is why this shape is more often used on power tools. But the production of additional notches makes the fastener production process more expensive.

Screwdrivers for such slots are designated PZ or Pozidriv. A number from 0 to 5 is indicated next to it, indicating the conditional size in ascending order. An incorrectly selected number leads to a mismatch between the screwdriver and the fastener head, which affects the ease of operation and quality of fastening.

Podriv and Phillips screwdrivers and slotted bits are not interchangeable. In addition to additional risks, the difference exists in the grooves themselves. In Phillips they are sharpened with a small radius, while in PZ they are parallel. Using a PH bit in a head with PZ splines will not allow the tip to fit tightly into the seat, and vice versa - a posidriv bit with its flat edges will break the PH slot.

Screwdriver for PZ slots.

Friason

The name is taken from English Frearson. According to the ANSI standard, it is designated as Type II Cross Recess. May also be called Reed and Prince.

The design is similar to Phillips, but differs in the point of intersection of the edges. If the launch vehicle has a rounded angle of convergence, here it is completely straight. There is no conventional division into sizes - one screwdriver is suitable for all screws with this type of slot.

Due to the clear angle and large blades, it is possible to transmit increased torque. The self-tapping screw does not eject from the head. Due to the reliability of fastening, screws with such slots are used on foreign marine equipment.

Friason slotted bit.

Supadriv

The spline configuration was developed by the same company that developed the PZ standard. Screwdrivers for them are interchangeable and can be used without harm to both the tool and the fasteners. According to the configuration, the main cross-shaped intersection and additional 45-degree risks are also used here. The difference is a wider center, allowing axial movement of the screwdriver tip.

Phillips II

The second generation of launch vehicles is compatible with the first. The difference between PH2 and its predecessor lies in the notches inside the cross-shaped recess. They form a kind of teeth that connect to the mating side in the tip of the tool.

This design increases the adhesion force between the screwdriver and the slots, which reduces the pushing effect. To identify the type of spline, two parallel marks are applied to the head. Screwdrivers and bits are marked with the ACR brand.

Bit for PH2 slot.

French slot

Standardized by the Bureau de normalization de l'aéronautique et de l'espace as BNAE NFL22-070. Structurally, it has a stepped design. A large cross is made from the edge, and closer to the middle it narrows to a small one. Change does not happen gradually, but in steps.

Splined bit BNAE NFL22-070

JIS B 1012

This spline is designed in Japan and used in Japanese equipment. The angle of convergence of intersecting slots is straight, but without a sharp part. Due to the strong bevel, it was possible to minimize the ejection of the screwdriver.

If you insert a PH screwdriver into the head of the JIS B 1012 fastener, the slots will be damaged, so JIS B 1012 is indicated by an additional dot on the head. When working with a Japanese slot, it is better to buy a corresponding JIS screwdriver, which is commercially available.

Slotted screwdriver JIS B 1012.

Mortorq

The development of this slot belongs to Phillips Screw Company. Each of the four sides of the cross has a thickening and is made with a slight cone, as well as a rounding of the top to one side.

This design helped reduce the weight of the fasteners and provide excellent torque transmission. The probability of spline failure is minimal, which is why this type is used in the aviation and automotive industries.

Mortorq slotted bit.

Square splines and square combinations

The square spline configuration provides multiple support points for increased torque transmission. Here are the main types of such slots.

Square (Robertson slot)

The second name of the slot is Scrulox. In the ANSI standards system, it is designated Type III Square Center. It is a square of regular shape with a slight cone. This configuration makes it easier for the screwdriver to fit into the slot and securely fixes it.

This also makes it easier to hold the fastener on the tip of the screwdriver - you can work with one hand. Even hardware with a ground head can be easily unscrewed. Screws with these slots are common in Canada and are most often found in carpentry.

Robertson slotted bit.

LOX-Recess

The invention belongs to Brad Wagner, and in modern production it is produced under license from several large companies Grabber, Dietrick Metal Framing and Hitachi.

The recesses in the fastener head are made in the form of two squares intersecting and offset. This creates 12 points of contact with the screwdriver, reduces wear, and ensures strong contact between the tool and fasteners.

LOX-Recess slotted bits and fasteners.

Double square

Consists of two Robertson squares, which are connected without axis displacement and located at 45 degrees relative to each other. It turns out to be an eight-pointed star.

Triple Square (XZN)

A more complex version with three squares superimposed on a single axis and successively rotated by 30 degrees. Forms a 12-pointed star with a flat top of 180º. The type of XZN slot is structurally similar to a double hexagon, but its apex is brought together at 120º, which does not allow the use of a screwdriver of this type.

But the size of the squares is the same as that of a Robertson slot, which means the fasteners can be unscrewed with a regular square screwdriver, only instead of 12 contact points there will be four.

Triple square slotted screwdrivers are marked M4 to M18, but this designation is not associated with the metric system.

Due to 12 contact points, high torque is possible, which is why XZN is used in the automotive industry on bolts that tighten the cylinder head.

This type of spline can be found in cars:

- Porsche;

- Mercedes;

- Audi;

- Volkswagen.

Triple square slotted bit (XZN).

Internal hexagons

A type of spline built on a recess with six corners. Here are the main options.

Hex Spline (HEX, Allen)

Consists of a groove in the shape of a regular hexagon. Invented and patented in Germany in 1936 by Bauer & Schauerte. In this country it is called "inbus". Screwing requires a screwdriver or a bit with a similar shape. In the USA the tool is called an Allen key.

Due to the widespread use of HEX in the world, there are versions in metric and inch measurement systems. They are visually similar, but slightly different in size. Looseness of a metric screwdriver in the head of a screw made from an inch ruler leads to damage to the edges of the tool and fasteners.

There is a type of hexagonal slot with a pin in the middle. This is anti-vandal design. To unscrew it, you will need a hex screwdriver with a counter recess - a regular one simply won’t fit into the groove.

Hex screwdriver bits.

Outlaw

Hexagonal spline with stepped descent. The larger the diameter of the cap, the greater the number of steps. The main advantage of the slot is that it works with one stepped screwdriver with any size of fastener.

Outlaw fasteners and bit.

Five-point splines

Splines with different designs, based on the mandatory divergence of five slots in different directions. This provides sufficient points to transfer the tightening force and makes it more difficult for unauthorized persons to remove the fastener.

Pentalobe

A proprietary development of Apple. Has five semicircular rays. It is used in the manufacturer's technique to reduce self-disassembly by users, although screwdrivers with Pentalobe slots are commercially available. Such splines were first used in 2009.

There are three main sizes:

- The first one is installed starting from the iPhone 4 model. It can be designated as P2 or 0.8 mm.

- The second has been used in MacBooks since 2010 and in MacBook Pros since 2015. Sometimes referred to as 1.2 mm or P5.

- The third has been found in MacBook Pro batteries since 2009. The second name is P6 or in size - 1.5 mm.

It is worth noting that in this case the TS designation should not be confused with Torq-set splines, which have the same designation.

Pentalobe.

ASTER recess

The credit for the development of this slot belongs to LISI Aerospace, which introduced it instead of the classic hexagon. The result was a pentagon with spherical protrusions at the end. The slot holds securely on the tip of the tool and is used in fastening aircraft panels.

Star splines

They can be pointed or “blunt”, but all have six rays in the form of a star.

Torx

Manufactured in accordance with GOST R ISO 10664-2007. Popularly called simply “star”; in the documentation it is designated Torx. The development belongs to the Camcar Textron company, which created the slot type in 1967. It is a six-rayed star with conical “petals”. The anti-vandal version is similar, but has a recess in the center.

The symmetrical shape ensures an even impact on the entire head when tightening. The hand of the master gets tired less, since he does not need to press hard to hold the screwdriver in the seat.

A type of spline is used in fasteners used in automobiles and electronic equipment. If the equipment comes across screws with hexagonal internal grooves, then the star key may fit the shape, with the same size of the edges.

Torx bit.

Torx Plus

A modification of the previous type of splines, providing a shortened shape of six beams and an enlarged base. This made the structure more durable and increased the tightening torque. The tool for such splines wears out less.

TORX PLUS anti-vandal

Increased protection against twisting of this five-point slot is achieved due to the recess in the center intended for the mating pin on the screwdriver. Bits with this configuration are not sold in standard sets, which increases the reliability of protection of fixed parts.

Anti-vandal fasteners and bits for TORX PLUS slots.

Torx ttap

The head of the fastener has an additional recess, and the screwdriver has a pin of the same size. Thanks to this design, better alignment of the tool and the screw is ensured, eliminating distortions.

Torx ttap slotted bit.

Combination splines

Among the types of screwdriver slots, there are hybrids - combinations of two separate types of slots in one, which either provides increased tightening force, prevents unauthorized unscrewing, or simplifies work with fasteners. Here are the common combination options.

Phillips Phillips and Flat Spline Combination

The hat has two intersecting slits, one of which is longer than the other. This allows you to unscrew the fasteners using either a flat-head or a Phillips-head screwdriver. Of course, here the tightening force is less, but the slots are universal. This option is widely used in furniture screws or electrical equipment (such as a circuit breaker housing).

To make it easier to work with such fasteners, a special combination screwdriver was developed, combining PZ/S and PH/S slots. On sale it is called an electrician's screwdriver, since fasteners for it are often found in electrical equipment.

ACR Phillips II Plus

Universal slot that allows you to use both a Robertson square No. 2 and a standard Phillips PH2 screwdriver. But the use of original ACR Phillips II Plus bits prevents the equipment from falling out of the slots.

Phillips/square

A type of combined slot, where the base is a square, and four more rays emerge from its faces. Thanks to the screwdriver's design with a thick square base, the tool is more durable, and the Phillips cross-shaped design promotes increased torque transmission. In combination, such a slot is much better than each type individually.

Phillips/square slot fasteners.

Clutch

There are two modifications of this slot - type G and type A. The first is made in the shape of a bow tie. The second one has the same shape, only there is a round depression inside the butterfly.

Clutch spline fasteners began being used by GM on 1940-1950 trucks. Now they can be found in campers and mobile homes. If necessary, the fasteners can be unscrewed with a flat-head screwdriver.

External splines

This is the opposite form factor, where the fastener head contains protruding parts rather than recesses.

This design has a number of advantages:

- water does not accumulate in the recesses, causing corrosion;

- the slots are not clogged with dirt and the fasteners are easier to unscrew if necessary;

- when painting the surface, paint will not get into the recesses;

- For unscrewing, the tool is held perpendicular, so the fastener is suitable for narrow spaces.

Square

This form of external slot has been used since the 19th century, since production is relatively simple and cheap. You can work with fasteners with a screwdriver, an adjustable wrench, an open-end wrench, or a socket wrench with 8 or 12 edges (they fit a square inside, but engagement occurs with fewer points).

Nowadays this type is becoming less and less common, as it has been replaced by the more universal hexagonal one.

Hexagon

The most common form of fastener head among external types. Described in GOST 7798-70 and complies with ISO 4033 and 4032. A more convenient option compared to the square. This form is practical for hard-to-reach places where there is not much space for manipulation. You can work with such slots using heads with a wrench or a screwdriver and open-end or ring wrenches.

External hex screwdrivers.

Pentagon

A highly specialized type of external slot, used as an anti-vandal measure in gas equipment, fire hydrants, etc. Since the head does not have parallel edges, it is more difficult to grasp with pliers and ordinary keys do not fit into it.

Classic tool sets also do not have the corresponding devices. To operate, you need a socket head or a screwdriver attachment with five identical edges.

External Torx

The fastener head is made in the form of an external six-pointed star. The tool for such a slot is marked “E”. This helps distinguish it from its counterparts for the classic “asterisk”, marked “T”.

It is worth noting that the sizes of these varieties are not the same. For example, a bit for a T40 slot will easily fit into the head of an E8 screw. External Torx can most often be found on engine blocks and related mounts.

12-point

This type of external spline is obtained by combining two regular hexagons on the same axis with a rotation of 30 degrees. To work on the fasteners, you will need a screwdriver or a 12-point wrench.

Anti-vandal types

Anti-vandal types of splines are designed for several purposes. One of them is to prevent unauthorized disassembly of the equipment body and unauthorized repairs.

Another goal is to prevent the removal of parts and objects in public places. These could be signs, signs, trash cans, ashtrays, chairs in street cafes, etc.

Some equipment manufacturers themselves develop and patent a type of spline that is used only in their products. This makes it possible to protect equipment from being opened by private craftsmen and to prosecute independent sellers of screwdrivers who produce tools for these slots without the manufacturer’s permission.

Anti-vandal design involves the use of slots, grooves and protrusions of complex shapes that common tools do not fit into. As a rule, such equipment is not included in standard kits. The level of anti-vandalism depends on the complexity of the spline form factor. Let's take a closer look at the existing options.

Bristol

This is an internal slot, the shape of which consists of 4 or 6 radial grooves. They are not superficial, but directed deep into the head. The grooves are not square or rectangular, but trapezoidal.

The mirror-shaped counter lugs on the screwdriver provide a strong grip and maximum torque transmission. This is possible due to the perpendicular rather than tangential force transmission vector.

This elongated design allows the use of a Bristol slot in soft metals - the hardware is twisted without deformation. If we compare the Bristol with the internal hex, the former has more torque. It loses only in small Torx values. At the same time, Bristol is anti-vandal and it is difficult to unscrew the fasteners using improvised means.

Some people try to use a flathead screwdriver as an improvisation, but due to the small sides to engage in two places, the working part breaks off easily.

There is an improved version of the Bristol, where an additional pin is provided in the center. Fasteners are used in some types of game consoles to prevent users from disassembling them themselves.

The main type of Bristol is used in:

- telecommunications equipment;

- aircraft manufacturing;

- video cameras;

- foreign-made agricultural and military equipment;

- astronomical equipment.

Line

Japanese type of slot, available in internal and external versions. An option with a pin is possible. Screws with such heads are designated as line head screws. Since such fasteners are often found in game consoles, craftsmen call them “game bat” screws. Line screws were previously found on cartridges for Nintendo Sega consoles and VM computers.

ALR splines. Recesses are classified by size from ALR2 to ALR6. For the external version, with protruding edges, the size chart includes ALH2-ALH6. If the model has increased protection against unauthorized twisting, then when writing it, the postfix “T” is added to it. It looks like this - ALR4T.

DTC splines. In their homeland (Japan), the splines are marked DTC-27, DTC-20 and DTC-45. There was also a DTC-40, but this one is no longer available. Products can also be classified according to the geometric dimensions of the heads: 3.2 mm, 4.6 mm, 7.7 mm, as well as the non-produced 6.4 mm. The most common variants are DTC-20 and DTC-27, used in electronics manufactured in this country.

One-way

As the name suggests, the essence of the spline is to tighten it only once. For this purpose, the head has a slot with a high side, which is caught by the tip of the screwdriver only when rotated clockwise. Turning the tool in the opposite direction causes the tip to be pushed out - the fastener remains in place. A regular flathead screwdriver is suitable for tightening.

One-way fasteners are used for attaching parts and signs that will not need to be dismantled in the near future. It is impossible to remove them without authorization. To unscrew it, you need a special device - an extractor, and you will first need to drill a hole in the head, so you also need a drill.

One-way slotted fastener.

Oval

Jura Elektroapparate produces coffee machines for which it has developed a proprietary type of slot. It has an oval shape and no common types of screwdrivers fit into it.

The development was implemented to prevent disassembly of the case and repairs outside the company’s service department. But official distributors of spare parts for these coffee machines also sell the corresponding screwdrivers.

Polydrive

It has six vertices and semicircular radial slots. Masters call it a type of “star”, and officially it is designated as Polydrive or RIBE. Radial grooves and ribs help increase the tightening torque. The slot is found in cars and motorcycles.

Internal hexagon with pin

The spline is a regular-shaped internal hexagon with a pin protruding in the center. A regular hexagon can be unscrewed with a flat-head screwdriver if the width of the screwdriver is identical to the diameter of the hole. But in this case, the metal pin will not allow such a tool to be inserted. For unscrewing, only a counter hex wrench with a recess in the center is used.

Spanner

The slot is known as Spanner or Snake-Eyes. The head has a round base with a smooth surface and two holes inside. A special fork wrench is required to unscrew it. Such fasteners can now be found in some elevators.

It is used to secure panels with buttons or signs so that they cannot be unscrewed using improvised means. A more complex version with three holes, which can only be removed with a trident wrench, is used by weapons manufacturer Microtech.

Spanner slotted screwdriver.

12-pointed star

Since 2011, the slot has not been used in new products, although it can be found on old ones. It consists of 12 grooves made on a circle. The apex angle was 60 degrees everywhere. This configuration is achieved by superimposing four equilateral triangles on top of each other.

The axis of all figures remains the same, and each rotates 30 degrees relative to the previous one.

The spline is specified by ASTM B18.2.7.1M. Bolts with a diameter of 5, 6.3, 8, 10, 12, 14, 16, 20 mm were produced with such a head. The spline form factor provided a strong grip on the tool and supported twists with added reinforcement.

Torq-set

The Torq-set slot is a Phillips slot, but the screwdrivers used for Pozidriv and Phillips do not fit it. The reason is that all four slots do not intersect at one single point - each slot is offset from the central axis.

The development of the form factor belongs to the Phillips Screw Company, which produces fasteners with this type of spline.

The fasteners are described in detail in the National Aerospace Standard NASM 33781. In addition to the regular version, there is a complicated version, where the ribs have additional notches. The splines are NASM 14191 standard and are designated ARC Torq-set. This type of slot is used in military aviation. It can be found on Bombardier, Embraer, Airbus, as well as E-3, P-3 and F-16 models.

Torq-set slotted bits.

Triangle

“Light” anti-vandal version, the shape of which is an internal isosceles triangle. In the documents, the type is written as “TA”. To unscrew you will need a screwdriver with a triangular bit.

The slot is used in: teapots, travel stoves for cooking, household appliances, children's toys. But its anti-vandal properties are weakly expressed, since the screw can be unscrewed with a slotted screwdriver or a hex key, having correctly selected the width of the working part.

Triangle screwdriver.

Tri-point

The Tri-point spline consists of three grooves converging towards the center. The slots are located 120 degrees relative to each other. Designated as Y-type or Y-shaped, as well as TP.

Actively used in:

- mobile phones iPhone 7 and iPhone X;

- compact Nintendo game consoles;

- Foji digital cameras;

- Sanyo and Kyocera phones;

- MacBook Pro 2010-2011 laptops (battery attached).

Tri-point-3

Another common type of slot. It can be found in Roomba vacuum cleaners (secures battery compartments), electric toothbrushes, toys, video consoles. The type of recess in the head of the fastener is designated tri-lobular or tri-lobe.

This is an equilateral triangle, only its walls are semicircular, not flat. Due to this, the slotted screwdriver rests only on one corner, and the opposite part dangles. You can only unscrew it with a special nozzle.

Tri-groove

An external type spline used on bolt heads and nuts. The form factor consists of a cone and three radial slots. Since the head is truncated, it is impossible to grasp it with pliers. The number of recesses is odd, which makes it difficult to use two screwdrivers from the outside at the same time.

No type of instrument fits it except the “native” one. The nomenclature is written as T-groove or Tri-groove.

Tri-Wing

An internal slot with a triangle, each side of which has a continuation in the form of a slot in the head. Such beams are off-center and do not have a single axis, so the tri-point tool will not fit the slot. The patent for the invention of this anti-vandal type belongs to Phillips Screw Company.

Tri-Wing slotted bits.

Slotted bits

The very first screwdriver to be invented was a slotted screwdriver; it was invented in the 16th century. It was widespread during the Soviet period. Today, there are also types of screwdriver bits made for straight slots, but they are used less frequently. Such bits are designated by the letter S. This marking is placed on one of the edges of the bits. The Latin letter S is an abbreviation for the English word slot, meaning “slit” or “slot.” There is also an alternative designation - slotted. This word when translated into Russian means “slotted”. There is always a number next to the letter indicating the width of the tip. In some cases, its thickness is additionally indicated.

The ratio of the width and thickness of the most common slotted bits:

| Width, mm | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0; 6,5; 7,0 | 8,0 | 9,0 |

| Thickness, mm | 0,3 — 0,4 | 0,4 | 0,5 | 0,5 — 0,6 | 0,6 — 0,8 | 0,6 | 0,8 | 0,8 — 1,0 | 1,0 — 1,2 | 1,2 — 1,6 | 1,4 — 1,6 |

Classic straight bit

Width and thickness are the two main dimensions of a straight spline. In most cases, only the first parameter is specified. It varies from 3.0 to 9.0 mm. The second parameter is often not indicated, but its value can range from 0.5 to 1.6 mm. The peculiarity of this marking is due to the fact that the width and thickness have a standard ratio. The surface of the flat-slotted bits is protected from erosion and has increased hardness.

Bit with straight slot and TIN coating

These bits have a golden color because the surface of the bits is coated with titanium nitride as a result of the CVD chemical process. Thanks to this, the devices have a durable surface. Such nozzles may differ from each other only in width. This value ranges from 4.5 to 6.5 mm. The markings of the devices may also indicate their thickness. This value ranges from 0.6 to 1.2 mm.

Differences in screwdrivers by design and purpose

In addition to the shape of the tip, types of screwdrivers are divided according to the configuration of the rod, handle and functionality. This determines the purpose and ease of use. Let's look at the known species.

Simple screwdriver

It has a handle, a metal rod and a working part. It is important to choose the correct tip width and shape.

Flexible screwdriver

Used to work with fasteners when there is no access to it along a straight axis. A flexible screwdriver comes in one of two designs. The first has a solid rod made of elastic materials. It bends easily in different directions and transmits torque perfectly, but when released it always returns to a flat position.

The second type consists of two rigid rods connected by a universal joint. It maintains the tilt of the working part in all directions and perfectly transmits torque.

Dielectric screwdriver

If the metal fastener is energized, then you cannot touch it with a regular screwdriver. In such cases, the dielectric version is used. Its handle has a thick layer of polycarbonate, additionally coated with polyformaldehyde.

This prevents electric shock when rotating the hardware. To prevent the user from accidentally touching the conductive rod, the latter is coated with dielectric material right up to the tip.

Indicator screwdriver

The design is similar to a dielectric screwdriver, only here the handle is transparent. The conductive rod is connected internally to a resistor and a neon bulb. There is a metal coin at the end of the handle. When an electrician touches it with his finger, it acts as a ground. Holding your finger on the coin, insert the screwdriver into the socket or touch it to the terminal. The light will light up if the voltage in the network is from 100 to 500 V.

To detect lower voltages (for example 50 V), the indicator screwdriver device has been improved. An LED element has been added to it, which is more sensitive to low currents. There is no need to ground the contact with your finger on the penny here.

Screwdrivers for precision work

Designed for unscrewing and screwing in small fasteners used in watches, mobile phones, digital video and photographic equipment, and laptops. The tip of the tool is very thin, but durable because it is hardened.

The handle often has a rotating end part in order to simultaneously press the tool along the axis and rotate it freely. To work accurately with fasteners, the tip must exactly match the size of the slots. To avoid mistakes, it is better to buy a set of such screwdrivers.

Impact screwdriver

A power type of screwdriver, inside of which there is a special mechanism. The coin is made of metal and can withstand hammer blows. The tool is placed on the head of the fastener and a blow is applied with milk. Due to this, a mechanism is activated that rotates the tip a couple of degrees. This type of screwdriver is suitable for unscrewing old fasteners that have become soured in the material.

Ratchet screwdriver

When there is a large amount of work to be done with fasteners, and there is no screwdriver, use a screwdriver with a ratcheting mechanism. With it, it is possible to rotate the tool in one direction, and when rotating in the opposite direction, idle speed is triggered. This means that the tip remains in place and only the handle turns.

Such a device does not require interception, allows convenient operation with one hand and significantly increases productivity with a large number of screws being screwed in.

The ratchet mechanism can be adjusted in three positions: screwing in, unscrewing and locking. The latter turns the screwdriver into a regular one, requiring hand grip when rotating. The ratchet mechanism is controlled by a rotary clutch, slider or lever switch.

Screwdrivers for replaceable tips (bits)

There are screwdrivers that consist of a handle and a rod with a hollow part at the end. You can insert replaceable tips called bits into it. Officially, such replaceable working parts are called screwdriver inserts.

They are used in conjunction with screwdrivers and screwdrivers and are considered consumables. The most common hex seat sizes are 3/4, 1/4 and 1/2 inches. The tool is classified according to GOST 30092-93 or OST 1 52461-01.

The replacement attachment is secured in a hand screwdriver using a spring or magnetic holder or a collet clamp. Most often, screwdrivers are produced with a set of attachments for different types of slots.

Star Bits (Torx)

Star-shaped nozzles are used in the mechanical engineering field and in the production of household appliances for tightening fasteners with the appropriate head shape. They are called Torx and are designated by the letters TX or T. Next to the letter is a number that indicates the size of the nozzle. It corresponds to the distance between the rays of a hexagonal star.

Torx was first used in 1967 by Textron in America. Today, different types of bits are used for this type of screwdriver. So, there is a vandal-proof version equipped with an internal hole. It is designated by the letters TR, which stands for Torx Tamper Resistant. Five-point bits called Torx Brigadier Pentahedron are also used.

Classic bit "Star" (Torx)

In European countries and the USA, the Torx nozzle is the most popular of all existing slot shapes. This is due to its high performance. This bit is distinguished by the presence of six edges, with the help of which contact with a screw or screw occurs.

The design feature of the nozzle improves adhesion to the surface of the fastener. Thanks to this, you do not need to exert much effort to create torque. The likelihood of the device slipping is also reduced, since the load is distributed across 6 edges at once. In turn, this reduces their wear. Consequently, the service life of the bit increases significantly. “Star” nozzles are available in different sizes. The most common models are from T8 to T40. However, there are also smaller bits.

What kind of screwdriver handles can there be?

Screwdrivers differ in the shape and structure of the handle. This affects ease of use, strength and ability to transmit a certain torque.

Handles by design

Structurally, there are three types of screwdriver handles. Let's look at how they differ and where they are applicable.

L-shaped. Due to its pistol shape it gives increased leverage. This allows you to apply increased force when screwing or unscrewing the fastener. Most often it is produced with an asterisk or hexagon spline and is called an L-shaped key.

T-shaped. Has even higher torque. It is convenient to rest your palm on the T-shaped part and requires less frequent interception. If the crossbar is long, then you can hold on to it with both hands, which is important for large hardware with a rod diameter of 8-10 mm.

A turning point. The design consists of a working part, a rod and a handle, where the latter contains a hinge. Thanks to the built-in element, the straight axis can be broken and left at any angle from 1 to 90 degrees. This regulates the length of the lever and the force of action. A screwdriver is useful for hard-to-reach places.

Shaped handles

The comfort of holding and the applied force on the equipment depend on the shape of the handle.

Round handle. It has low torque because it slips in the hand.

Hexagonal handle. The pen type is popular in the USA. Convenient for grasping and tightening with force. The edges do not allow the handle to rotate.

Triangular handle. The most optimal option from an ergonomic point of view. The clenched hand has exactly this shape inside, so good torque is possible and less stress on the user.

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter .

0

Hex bits (Hex)

Another, less popular, but often used is the hexagonal slot. This form of notch first appeared in 1910 and was called Hex socket. This phrase means internal hexagon. It was first used on the factory floors of the Allen Manufacturing Company. The letter H is used to mark these bits. The Hex system features a large amount of torque that can be applied to the head of the fastener as it is tightened. In this case, there is no possibility of damage to the nozzle and the slot breaking off.

The distance between the sides of the hex blade is the main characteristic that distinguishes these bits. If you take a 4 mm nozzle, it is perfect for screwing furniture confirmat. A so-called safe type of slot is also available. It is called Hex-Pin, which stands for protected hexagon. This slot is equipped with a special pin in the center. Its presence helps prevent unauthorized disassembly of the connection.

Classic hexagonal bat

These bits make it very convenient to work with the corresponding self-tapping screws and self-tapping screws, since they have a large area of contact with fasteners. They have been used in the United States for a long time, but their introduction in Russia occurred relatively recently. The sizes of these nozzles can vary from 1.5 to 10 mm.

Hexagonal shaped bit with hole inside

A reliable bit of this type is easy to use. During its use, a person does not need to exert much physical force. Thanks to the presence of the hole, the device does not slip off. The size of the nozzle ranges from 1.5 to 6 mm.

Adaptations

Modern modified models of Phillips screwdrivers are presented in the form of a solid rod with replaceable bits, which are stored in the handle of the tool. Of course, it’s convenient to have a large set with different sizes of screwdrivers, but for home use, a similar option will do.

In addition, each bit has a magnetized tip and, if necessary, can be used in conjunction with a screwdriver, especially during initial installation.

Another undeniable advantage is the high interaction with modern metal anchors.

How is it different from flat?

In the modern world, the most common types of screwdrivers are flat and Phillips models. The difference between them is quite obvious. The tip of a flat-head screwdriver is presented in the form of a straight tip made of a narrow plate. In the recent past, almost all fasteners had a straight tip line, and it was only necessary to select the required tip size. Nowadays, such fasteners are used quite rarely, but if they are installed, then only with a flat-head screwdriver.

Cross models, in turn, are designed for mounting and dismantling figured fasteners. Thanks to the larger number of protrusions on the tip, they have a tighter adhesion to the unscrewed elements.

Unlike flat-head screwdrivers, Phillips-heads can be used not only to work with household items, but also to work on wood and metal.

Requirements for the quality of Phillips screwdrivers

on product quality

Japanese or European products will be much higher quality than Chinese ones. But if you give preference to domestic products, then make sure that they have the GOST or RS markings, which indicate their high quality.

Now let's move on to other quality indicators

For example, pay attention to the strength of the product's core. According to standards, the strength level of the screwdriver shaft must be from 47 to 52 units on the Rockwell scale, which must be marked on the tool itself

If the indicator is below 47, then there is a high probability that the product will bend, and if it is above 52 units, then it may crack. It is also desirable that the rod be made from a chrome vanadium alloy; such a rod is marked on the tool as Cr-V.

Of course, unscrupulous manufacturers can put deliberately false labels, so it is better to purchase products from well-known brands.

The ease of use of the tool also depends on the quality of the handle. It is better to choose products with magnetic coating on the tip; a rubber handle would also be an excellent choice.

Please note that models with rubber handles should not be used in areas in contact with chemicals. Try the product by touch, it should not strain your hand or slip out

Screwdrivers are available for sale at different prices.

If you need high-quality products for occasional and non-intensive use, then pay attention to inexpensive models from the following brands:

- Stayer.

- Fit.

- Matrix.

If you need screwdrivers for production purposes, then it is better to choose professional, more expensive models. Compared to the previous ones, they have a tip with increased strength and their service life is much longer.

Among similar models, one can note products from the Arsenal or Kraftool brands. There are also completely perfect “indestructible” models like Gedoro, but they are very expensive.

We advise you not to buy too expensive tools for household needs, but it’s also better not to buy the cheapest ones. Stop your choice on products where the price-quality ratio has a reasonable balance.

As you can see, screwdrivers differ from each other in types, sizes, areas of application, price and other parameters. You can purchase them in a set or individually. And making the right choice is easier when you know how to choose correctly.

Peculiarities

The Phillips screwdriver is in very wide demand among its counterparts with other types of tips.

It is she who can unscrew and tighten many fasteners of various types. It is simply impossible to disassemble a lot of household appliances, electronics, and other devices without the help of a Phillips screwdriver. The main feature of this tool is the special shape of the tip, made in the form of the “ ” sign. Accordingly, a cross-type assistant will help you remove fasteners with a similar slot.

Lever

This part ensures convenient use.

Depending on where you plan to use the tool, the handle may have a pentagonal, hexagonal, round, square section, etc.

Another important parameter is its size.

For example, there are truly miniature screwdrivers, the handle size of which is so small that it is designed to be used with fingers rather than with the hand.

The materials used to make handles are usually rubber, plastic and wood.

Its shape, in addition to the usual cylindrical one, can be made in the shape of the letter “T” or “G”.

Kernel

Its length and thickness are selected in accordance with the depth and diameter of the hole in which the screw or screw is located.

A tip is a tip, the shape of which corresponds to the shape of the slot of the fastener.

The durability of a tool directly depends on the material from which its tip is made.

Parameters such as strength and hardness influence.

Initially, the shape of the working surface was something like a blade, which corresponded to the shape of the groove of the fastening element.

Over time, hex, Phillips, square and other splines have gained popularity, extending the service life of the tool.

Special screwdrivers allow for reliable installation of non-standard hardware.

An increased coefficient of friction is provided by a special coating that prevents the tip from jumping out of the groove of the fastener.

Subtleties of operation

The ingenuity of a modern person quite often exceeds all expectations. Objects and tools intended for the same purposes are used in a completely opposite profile. For example, with the help of a screwdriver, many people scrape off various types of dirt from different surfaces, separate stuck parts, and even use it along with a chisel.

All these actions contradict the natural operation of the screwdriver; accordingly, the tool quickly becomes unusable. All that remains is to make a choice between buying a new one and tidying up the old instrument.

Everyone can repair the handle of a screwdriver, but not everyone can sharpen a damaged blade. Many people try to carry out rescue work correctly, but the result is not always successful.

Sharpening a screwdriver is not an easy task, much like the principle of sharpening a blade on skates. Only with cross models you should be extremely careful. Initially, the metal is heated until reddened, then it is dipped in a lubricating fluid, then it cools a little and sharpening begins. The complexity of this procedure lies in the small size of the tip rays and the inconvenience of approaching them.

After sharpening, the treated tool should be magnetized. To do this, place a screwdriver next to the magnet and leave it for a while.

How to sharpen a Phillips screwdriver, see the video below.