Calcium carbide: application and safety precautions

Definition

– chemical compounds that are obtained as a result of alkaline reactions of carbon with metals. In most cases, superhard alloys are obtained, comparable in their hardness characteristics to diamond.

The most widely known and widespread alloy is called calcium carbide - the chemical formula of the compound CaC2

Now a short excursion into the history of the origin of this chemical compound.

Brief history

Thomas Wilson and Ferdinand Moissan, working separately, almost simultaneously developed a method for producing calcium carbide in an electric melting furnace. This discovery was the impetus for the launch of the industry for the production of technical calcium carbide.

Technology

The production of calcium carbide involves two elements: calcium oxide (CaO) also known as quicklime and carbon compounds in the form of coke (anthracite, coal):

CaO + 3C = CaC2 +CO Both components are crushed and then fired and melted using an electric arc method.

The finished solution reaches a solid state in special forms, and is subsequently crushed and sorted.

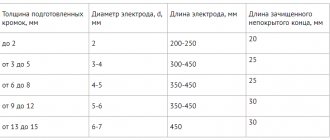

Dependence of the specific gravity of technical calcium carbide on the CaC2 content

| Content of CaC2 in technical carbide, % | 78 | 74 | 69 | 63 | 60 | 56 |

| N/m³(Specific Gravity) of technical carbide | 2,3 | 2,35 | 2,4 | 2,43 | 2,48 | 2.5/td> |

Composition of CaC2 (technical) used for welding work

| Element | Percentage by weight |

| Calcium carbide | 72 |

| Lime | 17 |

| Carbon | 1 |

| Magnesium oxide | 0,3 |

| Sulfur | 0,3 |

| Iron and aluminum | 2,6 |

| Silicon | 2 |

| Other components | 4 |

The minimum temperature threshold for the formation of calcium carbide is 1619°C. As a rule, the production process is carried out at 1900-1950°C. The temperature increase will cause the calcium carbide to decompose into metal and carbon.

If you have a small electric arc furnace and a current source, you can reproduce the process of calcium carbide formation:

- Take a graphite crucible or carbon electrode (before making a depression in it) ⇒ place quicklime and pieces of coke equal in weight

- We bring the electrode to the mixture creating an electric arc. Coal conducts current well in the mixture ⇒ wait about half an hour until the arc burns

- After cooling, the mixture turns into an alloy, which, if the experiment is successful, contains small pieces of carbide. To check this, place the resulting mass in water and collect the resulting gas bubbles in a test tube turned upside down and filled with water.

A number of factors can be identified that influence the speed of formation and quality characteristics of the final product:

- size, density, presence of impurities in the original raw materials

- physical and technical parameters of the furnace

- compliance with the stages of the technological process

Despite the modernization of industrial processes, the production of calcium carbide remains labor-intensive, requiring large areas and financial investments.

Peculiarities

Calcium carbide is a durable element with a crystalline structure. The final tone depends on the quality of the raw materials: it can vary from bluish to violet, black. There may also be an unpleasant odor with hints of garlic. The process of fusion with water, solutions of mineral acids, and alkalis occurs with the release of a large amount of heat and is of industrial importance.

CaC2 + 2H2O => Ca(OH)2 + C2H2 - . This reaction also produces acetylene, an unsaturated hydrocarbon with a triple bond.

With oxygen, the decomposition reaction of calcium carbide occurs only under the influence of elevated temperatures (700 - 900 °C): 2CaC2 + 5O2 → 2CaO + 4CO2 -

Warehousing and transportation

Calcium carbide must be packaged in moisture-proof containers and tanks to prevent the entry of moisture and prevent the decomposition process. The packaging and unpacking procedure should be given special attention

- Be careful and do not use tools that generate sparks during operation.

- It is necessary to provide participants in the process with protective equipment, since the entry of carbide into the human body and skin is dangerous.

- transportation is carried out only by vehicles with a closed body. Air delivery is prohibited.

- it is necessary to provide the production premises with a ventilation system and prevent shared storage with other goods.

Useful aspects

Calcium carbide is the starting element for the production of many compounds.

Aggregation of calcium carbide and nitrogen is used in the preparation of calcium cyanamide .

It belongs to the nitrate stimulants actively used in agronomy. This salt becomes the starting component in the synthesis of urea and guanidine.

In metallurgy it is used for deoxidation of metals and desulfurization (reduction of oxygen and sulfur content, respectively).

And what fun it was for children to steal a carbide pebble from a construction site and throw it into puddles, admiring the hissing and bubbling. And the especially brave ones brought a match to the emanating gas, and a blue flame lit up.

Useful gas

Initially, calcium carbide was used exclusively for the production of acetylene. This organic compound was used to create carbide lamps used for street lighting. Such light sources are still used today in speleology, as camping equipment, and in lighthouses.

Acetylene is a translucent, water-soluble gas used to produce organic compounds such as chloroethane, polyvinyl chloride, and styrene.

There are a number of synthetic products derived from acetylene. For example, combinations with chlorine produce products that excellently dissolve organic compounds, as well as inorganic ones: sulfur, phosphorus. Since such products are non-flammable, they are successfully used in fat extraction. Calcium acetylenides (acetylene salts) with silver, copper and mercury ions are used in the creation of explosives. The compound with gold has a particularly strong destructive explosive force.

A cocktail of acetylene and ammonia is involved in the functioning of jet engines.

Acetylene in combination with H2O forms acetaldehyde, from which synthetic acetic acid, acetone, artificial resins and ethyl or vodka alcohol are made

C2H2 + H2O → СH3-CHO

The well-known PVA glue, gramophone records, and advertising banners are also derivatives of this gas.

Safety precautions

As noted earlier, calcium carbide is an explosive substance and to maintain safety when working with it, several mandatory conditions must be followed:

- create an airtight storage and processing place;

- prevent access to the fire source;

- small particles (carbide dust) cause irritation of the skin and respiratory system, therefore protective clothing and respirators are required;

- acetylene generators must be located in strictly isolated places;

- upon completion of welding work, it is imperative to dispose of unprocessed slag in special places;

- During transportation and storage, it is necessary to exclude the possibility of collision of cylinders and containers, as this carries a mortal danger.

– a source of production of many organic and inorganic compounds that are widely used in various areas of human life. Many of them have no analogues. But, along with the inexhaustible benefits of this substance, we should not forget about the harm that it can cause to humanity and the environment, because it belongs to the first class of danger, has explosive and fire hazards.

Source

CARBIDES

CARBIDES

(from the Latin carbo - coal) - compounds of carbon with metals, as well as with boron and silicon.

These compounds have an amazing variety of physical and chemical properties. Thus, gold carbide Au2C2 explodes even when you try to pour it from a piece of filter paper on which it was dried. On the other hand, carbides of some elements (for example, boron and tantalum) do not decompose even at white heat temperatures and are so chemically inert that aqua regia does not affect them, and their hardness is close to diamond! Also on topic:

CHEMICAL ELEMENTS

For the first time, an unusual compound of metal with carbon (K2C2) was obtained in 1809 by the famous English chemist Humphry Davy. In 1863, the French chemist Marcelin Berthelot studied the properties of another carbide - the very unstable and easily explosive cuprous carbide Cu2C2. In 1878, the German metallurgist F. Müller, having dissolved steel samples in dilute sulfuric acid, isolated iron carbide Fe3C. But only at the end of the 19th century. French chemist Henri Moissan, famous for obtaining fluorine, synthesized many of these unusual compounds and studied their properties. He obtained carbides by heating mixtures of charcoal with various metals, their oxides or carbonates to a very high temperature. To do this, he used the heat of a voltaic arc in an electric furnace of his own design.

Carbides, as it turns out, can be obtained not only in the laboratory. Even before Moissan’s work, the Austrian scientist E. Weinschenk in 1889 discovered the mineral cohenite in meteorites, which is a mixed carbide of iron, cobalt and nickel with the composition (FeNiCo)3C. And Moissan himself in 1904 discovered in a meteorite brought from Diablo Canyon in Arizona a dark green mineral, which is silicon carbide SiC. This mineral was named moissanite in honor of the scientist.

Also on topic:

CARBON

Previously, carbides were classified according to their resistance to water and acids, as well as what gases were released during their decomposition. Modern classification takes into account the type of chemical bond between atoms in carbides - this is what the physical and chemical properties mainly depend on. In accordance with this classification, carbides can be divided into three groups, which differ quite significantly in their properties.

The first group includes the so-called salt-like carbides with ionic bonds. These carbides form alkali and alkaline earth metals, aluminum, rare earth elements, and actinides. Their composition sometimes corresponds to the typical valencies of metals (Al4C3), and sometimes does not (Be2C). Many ionic carbides can be obtained directly from elements (Ca + 2C ® CaC2) or by reduction of oxides with carbon (CaO + 3C ® CaC2 + CO). The ionic nature of the bond results in a high melting point; for example, calcium carbide CaC2 melts at 2300°C, thorium carbide ThC2 - at 2655°C. Ionic carbides are easily decomposed by water or dilute acids - hydrolyzed. In this case, various hydrocarbons and metal hydroxide are formed. The most famous example is the production of acetylene by hydrolysis of calcium carbide: CaC2 + 2H2O ® Ca(OH)2 + C2H2. Acetylene is also released during the hydrolysis of Na2C2, K2C2, etc. Therefore, such carbides can be considered as acetylene derivatives in which hydrogen atoms are replaced by metal atoms. In this case, metal cations and C2–2 anions are located in the corresponding sites of the crystal lattice. The salt-like nature of these carbides is confirmed by the possibility of their electrolysis in the molten state. It is interesting to note that pure calcium carbide is colorless crystals, although they are not easy to see, since the usual technical product is brown to black in color.

The interaction of alkali metal carbides with water is extremely violent. So, if potassium carbide is simply doused with water, a violent reaction will occur, which is accompanied by an explosion of such force that the released acetylene immediately decomposes with the release of coal. To carry out the reaction K2C2 + 2H2O ® 2KOH + C2H2, you must slowly pass water vapor over the carbide.

In some cases, ionic carbides are formed directly by passing acetylene through solutions of metal salts. So carbides of silver, copper(I), gold and mercury, which are more often called acetylenides. Alkali metal acetylenides can be prepared by the action of acetylene on free metals. In dry form, heavy metal acetylenides easily decompose explosively. Hydrolysis of ionic carbides of other metals shows that they “originate” from other hydrocarbons. For example, the hydrolysis of aluminum carbide releases methane: Al4C3 + 12H2O ® 4Al(OH)3 + 3CH4 (beryllium carbide Be2C is also hydrolyzed), and the hydrolysis of magnesium carbide produces methyl acetylene: Mg2C3 + 4H2O ® 2Mg(OH)2+ HC≡C –CH3. Interestingly, magnesium carbide of a different composition, MgC2, produces only acetylene upon hydrolysis. Sometimes, during the hydrolysis of ionic carbides, hydrocarbons are released together with hydrogen, which partially hydrogenates unsaturated hydrocarbons. Manganese carbide decomposes with the release of almost equal amounts of hydrogen and methane: Mn3C + 6H2O ® 3Mn(OH)2 + CH4 + H2. Carbides of rare earth metals and thorium, when decomposed by dilute acids, do not release pure acetylene, but its mixture with methane, ethylene and other hydrocarbons. For example, the hydrolysis of cerium carbide CeC2 produces a mixture of acetylene and methane in a 4:1 ratio, as well as some ethylene and liquid and solid hydrocarbons (the composition of the products depends on the reaction conditions). Uranium carbide produces even more liquid and solid hydrocarbons during hydrolysis.

The release of hydrocarbons during the hydrolysis of carbides allowed D.I. Mendeleev to put forward the so-called carbide theory of the origin of oil in the depths of the Earth from inorganic substances. According to Mendeleev, in the depths of the globe there should be molten metals, mainly iron, which together with carbon produces carbide. During mountain building, cracks form in the earth's crust through which water penetrates into the depths. By acting on iron carbide and carbides of other metals, water (in the form of steam) forms hydrocarbons, for example: 2FeC + 3H2O ® Fe2O3 + C2H4. Gaseous hydrocarbons rise through the same cracks closer to the surface, where they accumulate in porous layers. However, when in the 60s. 20th century The composition of oil hydrocarbons was studied in detail; it turned out that the mixture of “artificial hydrocarbons” formed during the hydrolysis of carbides differs sharply in composition from the natural mixture. In addition, all oils obtained inorganically are optically inactive, while natural oil is optically active. Based on these, as well as a number of other facts, the inorganic theory of the origin of oil has been criticized, and many scientists now believe that oil has a biological origin.

The second group includes carbides, which form transition metals of groups IV–VII, as well as cobalt, iron and nickel. These are metal-like compounds with a different structure. In them, carbon atoms, which are small in size, are not connected to each other and are located in the voids between the metal atoms. Different packings of metal atoms in the crystal lattice result in different compositions of carbides even for the same metal; for example, chromium forms carbides of the composition Cr3C2, Cr4C, Cr7C3, etc. These carbides (they are called interstitial carbides) are often distinguished by high hardness and very high melting temperatures. For example, tantalum and hafnium carbides TaC and HfC are the most refractory of the known substances (melt at 3985 and 3890°C, respectively).

Metal-like carbides have high electrical conductivity and very high chemical resistance to aggressive environments (many of them do not dissolve even in aqua regia). They are used for hardening cast iron and steel (carbides of iron, chromium, tungsten, molybdenum), as well as for the production of very hard alloys that are used for metal cutting (carbides WC, TiC, TaC, VC, Cr3C2). For example, hard tips of cutters and drills are made from pobedit - sintered tungsten carbide powder WC with the addition of metal cobalt. A very important role is played by iron carbide Fe3C (cementite) - solid crystals that are part of the structure of cast iron and steel.

Tungsten carbide WC is also used for the manufacture of drill bits, parts of equipment for the production of synthetic diamonds, and for applying wear-resistant coatings to metal surfaces. Titanium carbide is interesting due to its striking manifestation of nonstoichiometry: the composition of this compound is expressed by the formula TiC x

, where

x

ranges from 0.49 to 1 (

see

STOICHIOMETRY). This substance, like tungsten carbide, is used as a component of heat-resistant, heat-resistant and hard alloys, for the production of wear-resistant coatings, for the manufacture of refractory crucibles in which almost any metal can be melted (the carbide itself melts at 3257°C). Titanium carbide is used to line the inner walls of high-temperature furnaces.

The third group includes covalent carbides. They are formed by silicon and boron - carbon's neighbors on the periodic table, close to it both in atomic size and electronegativity. Silicon carbide SiC (technical name - carborundum) in its pure form is colorless crystals, but impurities often color it in various colors, even black. This compound is similar in structure to diamond; A silicon carbide lattice can be obtained by replacing half of the carbon atoms with silicon atoms in the slightly expanded diamond lattice. This substance has very high hardness; in addition, it has the properties of a semiconductor. It is used to make grinding bars and wheels, refractory materials for furnaces and foundry machines, heating elements for electric furnaces, and semiconductor diodes.

Boron forms two carbides with a precisely known structure - B4C and B13C2. The most important is the first of them - black shiny crystals, which in hardness are second only to diamond and boron nitride BN. This carbide is used for the manufacture of abrasive and grinding materials and as a semiconductor. Carbide enriched with the 10B isotope is used as a neutron absorber in nuclear reactors.

Ilya Leenson

Calcium carbide

The alkaline reaction of carbon with metals can produce various carbides. By combining certain chemical elements, compounds are obtained that are characterized by high strength. A version called calcium carbide has become quite widespread. It began to be used in a wide variety of industries.

Appearance and characteristics of technical calcium carbide

The composition in question was first obtained in 1862. The procedure involved the separation of calcium from lime, resulting in a pale gray composition without the characteristics characteristic of metals. As a result of the experiment, carbide was obtained, which subsequently began to be actively used in the production of various products.

At the beginning of the 20th century, calcium carbide began to be used to produce acetylene in large volumes. That is why active research began to be conducted to identify more productive technology.

The technical characteristics of the material determine its wide distribution. The appearance of the substance is characterized by a light gray color; carbides are produced in the form of stone or powder.

Physical properties

When choosing almost any material, you should pay most attention to physical properties. For the one under consideration they are as follows:

- The compound has a crystalline structure.

- The melting point is 2300 °C. It is worth considering that such a figure is characteristic only of the pure composition. The addition of various impurities to the composition causes the melting point to drop significantly.

Pure Calcium Carbide

It is worth considering that calcium carbide in most cases is in a solid state. In addition, the color can vary from gray to brown. The physical properties of calcium carbide determine its widespread use in a wide variety of industries.

What does carbide look like?

To determine where to find carbide on the street, you need to know its physical properties. Physically, the substance is solid, its color can be dark, having a grayish or brown tint. The color depends on the amount of carbon. There is also a specific odor that characterizes this substance.

It is solid in consistency, but crumbles easily, turning into powder. If you bring a match, combustion will begin, releasing carbon and decomposing calcium. True, this can be achieved at high temperatures, for example with a hunting match.

Chemical properties

Chemical properties are also important. They are also taken into account when using the material. The main characteristics include the following qualities:

- Calcium carbide is characterized by its ability to absorb moisture well. It is worth considering that such a procedure is manifested by a vivid chemical reaction associated with the decomposition of the substance.

- When working with the material in question, it is worth considering that the resulting dust has an irritating effect on the mucous organs. In addition, a similar reaction can occur when crystals or dust come into contact with the surface of the skin. That is why when working with the compound in question, you should use a respirator and some other protective equipment.

- Crystals actively react to the influence of other substances, often only when heated. This may result in the formation of calcium carbonate.

- In some cases, a crystalline substance is combined with nitrogen, resulting in calcium cyanamide.

- When heated, a reaction can occur with arsenic and chlorine, as well as phosphorus.

The most important chemical quality is considered to be susceptibility to decomposition when exposed to water.

Precautionary measures

CaC 2 is an unstable compound that is prone to explosion. The fact is that calcium can even react with air, and as a result of the reaction, volatile gases are formed. The slightest spark can cause an instant fire, releasing a huge amount of heat and methane, which will lead to dire consequences. Therefore, it is necessary to transport the substance in sealed containers.

American Chemical Society National Historic Chemical Landmarks. Calcium carbide is a chemical compound with numerous industrial applications. When combined with water, it produces acetylene gas, which is used in welding and cutting. According to the Hong Kong Trade Development Council, calcium carbide is also a key component of most polyvinyl chlorides produced in China. The Environmental Protection Agency has found that particulate matter and other byproducts are released into the environment from calcium carbide production, but hydrocarbon emissions from calcium carbide production are minimal.

Fans of life hacks and “edgy experiments” with carbide should take care of their own safety. When working with the substance, you should wear special gloves; if you take the carbide with your bare hands, it will be impossible to wash them. The reaction with water causes not only the release of methane and heat, so the skin will burn.

Receipt

As previously noted, calcium carbide is actively used in the production of a wide variety of materials. That is why the process of obtaining calcium carbide has been constantly improved. The features of the technologies used include the following points:

- Quicklime is used as a raw material. In most cases, the substance is obtained from lime, but it is difficult to carry out such a procedure at home.

- Lime is mixed with crushed coke to obtain a homogeneous mass.

- In industry, calcium carbide is produced according to a scheme that involves heating the substance to a high temperature. Electronic ovens are used for this. The recommended melting point is 1900 ⁰C.

- After heating a substance to such a high temperature, it turns into a liquid state. Special forms are prepared for the work.

When considering how to obtain calcium carbide from carbon, we note that according to established standards, the composition must contain at least 80% of the main substance. The share of impurities should be no more than 25%, which also includes carbon. The production of calcium oxide also releases thermal energy, which is worth considering.

Where can you find carbide?

Previously, boys stole calcium carbide from a construction site and made “bombs” that worked according to the reaction: CaC2 + H2O = C2H2 + Ca(OH)2. That is, the guys added calcium carbide to a bottle of water, closed the bottle until it was filled with acetylene, and then set it on fire and, mixing with oxygen in the air, this mixture exploded, but sometimes the bottle could burst, then big troubles with the eyes, face, etc. body parts. But now this source of calcium carbide production is closed, because... acetylene is sold in cylinders, which must be handled with great care, and carbide may be possible to buy in chemical stores (upon presentation of a passport), if they have not ceased to exist. You probably needed carbide for the same purposes? Be careful!

In order to get carbide, you need to have an idea of where it is used. So, carbide is actively used in the welding process, so you can get carbide from welders or in places where extensive welding work is taking place, perhaps where gas pipelines are being laid and pipes are being welded accordingly.

But you can try to buy carbide in construction stores or in stores that sell various types of chemicals. However, a passport is required upon purchase.

Navigation menu

Custom links

User information

Posts 1 page 13 of 13

Share12009-09-22 14:46:49

- Author: ghhjd

- Members

- Registered: 2009-09-22

- Invitations: 0

- Posts: 5

- Respect: [+0/-0]

- Positive: [+0/-0]

- Spent on the forum: Not defined

- Last visit: 2009-10-23 14:51:30

Actually, where can you get calcium carbide? I heard from plumbers, but I don’t know anyone. And I see it everywhere in 125kg barrels... But I need it, just a little.

Share22009-09-22 17:23:19

- Author: MRACOBESS

- Deputy Administrator

- From: Russia-Mother

- Registered: 2009-01-12

- Invitations: 0

- Posts: 3501

- Respect: [+0/-0]

- Positive: [+0/-0]

- Age: 41 [1978-07-02]

- ICQ: 569541908

- Spent on the forum: Not defined

- Last visit: 2014-06-25 09:25:25

I’ve never seen it in barrels, of course there is, but for the average retail buyer only packs of 3-5-10 kg are available. visit welding shops.

Share32009-09-22 17:30:05

- Author: Ox />

- Registered: 2008-05-15

- Invitations: 0

- Posts: 1002

- Respect: [+0/-0]

- Positive: [+0/-0]

- Spent on the forum: Not defined

- Last visit: 2013-09-15 17:50:58

Actually, where can you get calcium carbide? I heard from plumbers, but I don’t know anyone. And I see it everywhere in 125kg barrels... But I need it, just a little.

At the plumbers?! To throw them into toilets. lol*) lol*) lol*) From the welders, you apparently didn’t hear.

Share42009-09-22 20:12:13

- Author: DNK

- Blocked

- Registered: 2009-02-04

- Invitations: 0

- Posts: 2356

- Respect: [+0/-0]

- Positive: [+0/-0]

- Age: 10 [2009-01-31]

- Spent on the forum: Not defined

- Last visit: 2013-03-15 09:58:08

Actually, where can you get calcium carbide? I heard from plumbers, but I don’t know anyone. And I see it everywhere in 125kg barrels... But I need it, just a little.

Come to our village, the curve will give you at least a lot, at least a little for 1 bottle of ts2ash5osh mixed with as2o

Share52009-09-22 20:26:35

- Author: amateur pyrotechnician

- Guest

Of course, I understand that calcium carbide is a weakly sensitive explosive compound, but in what way is it here? do you make mixtures with it? The topic has a better place in chemical reagents.

Share62009-09-22 21:17:55

- Author: DNK

- Blocked

- Registered: 2009-02-04

- Invitations: 0

- Posts: 2356

- Respect: [+0/-0]

- Positive: [+0/-0]

- Age: 10 [2009-01-31]

- Spent on the forum: Not defined

- Last visit: 2013-03-15 09:58:08

Of course, I understand that calcium carbide is a weakly sensitive explosive compound, but in what way is it here?

EEEEE, either my tower was blown away, or yours - when did calcium acetylenide become an explosive compound? acetylene - yes, but carbide. And in general, to the trash topic, such a thing is already in reagents

Transportation and storage

Calcium carbide powder decomposes almost instantly when exposed to moisture. This produces acetylene, which in high concentrations is flammable and explosive. That is why it is necessary to pay quite a lot of attention to the storage of calcium carbide, for which cans and special drums are often used. Other storage features include the following:

- The released acetylene is lighter than air, so it accumulates at the top. It is worth considering that it has narcotic effects and can spontaneously ignite.

- When producing large volumes of a substance, special attention is paid to safety precautions. Special packaging is used for packaging.

- To open the package, use tools that do not cause sparks.

- If the substance gets on the skin or mucous membrane, it must be removed immediately. In this case, the affected surface is treated with a special cream or other protective and healing substance.

- According to established rules, transportation can only be carried out using a covered vehicle. However, delivery by air is prohibited.

Transport container

Regulations also prohibit storing calcium carbide with other chemicals and heat sources. This is because the resulting gases can react chemically with other chemicals and ignite.

Where can I get carbide

Carbide is a chemical substance. There are several types. On this site you will find out what it is, where to get it, and where it can be used. Let's start with the fact that carbide is a smoke bomb, it is usually used by football fans, or to drive rodents out of a hole, etc. Actually, some people are tormented by the question of where to get this so-called carbide; welders use it, but they are unlikely to give it to you! So, it’s unlikely that you noticed when you entered an old commuter train that right above your head there is carbide, it is located at the vestibule doors on the ceiling, but if there is cardboard or a piece of plastic screwed there, then, alas, it is not there. It can also be given in express trains, it is located under the seats in white iron boxes, to unscrew it you will need tools (a wrench, pliers, a flathead screwdriver, and a hammer). In the train, it is there so that in the event of a fire, the carbide smokes and draws out air and the fire goes out. Also on our website you will see photos showing in detail where the carbide is located and how to get it, as well as our friends who conquer different depots in search of carbide (See them in the gallery).

Applications of calcium carbide

As previously noted, calcium carbide is found in a wide variety of industries and is often supplied for industrial synthesis. The properties of calcium carbide and the reaction that occurs when it is combined with various substances determine the use of the substance in the following cases:

- Many synthetic components that make up modern materials are produced on the basis of the component in question.

- Used to produce calcium cyanamide. A similar component is used to produce various chemical fertilizers. That is why raw materials are used to regulate the growth rate of plants.

- Calcium cyanamide is also obtained by combining the substance with nitrogen.

- In some cases, the reduction of alkali group metals is carried out.

- You can use the connection in question in the gas welding process.

When considering calcium carbide and its area of application, it is worth considering that such a substance is most often used to produce acetylene. A similar synthesis of calcium carbide was developed by a German scientist. Among the features of this method of application, we note the following points:

- Acetylene from carbide is obtained by exposing the raw materials used to water.

- As a result of the chemical reaction, the required gas is formed, and slaked lime precipitates.

- It is worth considering that when mixing components, a large amount of heat is generated. Therefore, work must be carried out taking into account safety precautions.

- Depending on the type of raw material processing technology used, about 290 liters of gas come out from 1 kilogram.

- The speed of the procedure depends on the purity of the raw materials used, temperature and amount of water.

Preparation of acetylene from calcium carbide

As practice shows, when using pure carbide, about 20 liters of water per 1 kilogram of raw material are allocated for the chemical reaction. A similar amount of water is required to lower the reaction temperature, thereby ensuring optimal operating conditions.

Qualitative reaction

With little knowledge of where to find carbide, it is necessary to verify the authenticity of the substance. For a high-quality reaction, you only need a little water (on the street you can even use your own saliva). When CaC2 interacts, methane and calcium hydroxide are released. You can observe a characteristic hissing, and if you bring a match at this moment, it will ignite.

Due to a violent reaction with water, carbide decomposes from atmospheric moisture. Therefore, the question of where to find calcium carbide on the street is very controversial. It is known that it does not exist in its pure form; this compound is mostly artificial rather than natural.

Safety precautions

When carrying out various chemical reactions to produce materials, safety precautions must be observed. As previously noted, the released substances can be explosive. Safety precautions when interacting with various chemicals are as follows:

- An airtight place is required for storage and handling. It is not recommended to carry out work in a regular garage.

- Fire should not be allowed to reach the raw material itself, as well as the gases generated.

- Even small particles can damage the skin. That is why work must be carried out in a respirator and protective clothing.

- Acetylene generators are placed exclusively in well-insulated rooms.

- If the raw materials were used during welding work, then the resulting slag should be disposed of in special places.

- When moving metal and other containers, they must be securely fastened; collisions and falls are not allowed. This may result in sparks that could cause the substance to explode.

Calcium carbide combustion

The above information determines that work with the raw materials in question is not recommended to be carried out in a garage or home workshop. Failure to comply with technology, lack of required equipment and many other reasons can lead to sparks and ignition of substances.