Graphite, copper-graphite and carbon electric contact brushes (hereinafter referred to as “brushes”) are used in a variety of electrical machines, where it is necessary to provide a moving electrical contact. During operation, the brushes wear out, decreasing in length, and sooner or later there comes a time when worn-out brushes need to be replaced with new ones. To correctly select and replace worn brushes, you need to know the following parameters:

In the online store https://aktivenergo.ru, graphite and copper-graphite brushes can be selected by size and parameters and purchased with fast delivery throughout Russia.

- Brush sizes.

For example 10x12.5x32 , the first two numbers are the size of the window into which the brush is inserted, the last number is the length of the brush, it will wear out during operation.

There are two main types of brushes: single and split.

A single brush is a solid bar with or without leads, it looks something like this:

Most electrical contact brushes for generators are single brushes.

A split brush is two bars connected by a common wire, it looks something like this:

Split brushes are two brushes connected by one current-carrying wire. For example, the size is written 2/16x32x40 K1-8 (design type), the same size can be written as 32x32x40 K1-8R (the letter P in the design means that the brush is split.)

Large electrographite brushes are split for better electrical connection and optimal wear during operation.

- Brand of brush material.

This is what the brush is made of. Conventionally, all brushes are divided into two categories: Graphite and Copper-graphite.

Graphite brushes consist of graphite of varying densities and with various additives and binders that give the material the necessary characteristics.

Copper-graphite brushes, in addition to the above, also contain non-ferrous and precious metals such as copper, lead, tin, silver, which makes them harder, wear-resistant and allows higher currents to pass, but at the same time reduces the linear speed of the brush (linear speed is the speed with which the brush rubs against the surface of the current collector). Separately, we note that these metals can be purchased separately, for example, lead in pigs.

When replacing used brushes, it is best to use brushes of the same brand, however, in the vast majority of cases, replacement with other brands with not very different characteristics is allowed. The brand of brush material is usually indicated either by a symbol on the body of the brush, or on the wire terminals, or the full brand is written on the body of the brush. If the marking is indicated by a conventional number, then to decipher the brand you can use the table of conventional and full brush designations.

It is difficult to disclose all the information on product labeling in one article; for example, there are several labeling technologies - droplet inkjet, heat inkjet, laser and thermal transfer.

Explanation of symbols for brush material brands

| Symbol | Full designation | Symbol | Full designation | Full designation | Full designation |

| 9 | MGS5 | 56 | 611ОМ | 83 | M3 |

| 12 | EG2A | 59 | EG4E | 84 | EG84 |

| 14 | EG4 | 61 | EG61 | 85 | EG85 |

| 17 | MG | 62 | EG62 | 86 | M6 |

| 18 | EG8 | 63 | EG63 | 87 | EG51A |

| 19 | MG4 | 65 | EG17 | 88 | 611M |

| 20 | G20 | 66 | EG13P | 89 | MGS9A |

| 21 | MGSO | 67 | EG13 | 91 | MG64 |

| 32 | G22 | 68 | EG2AF | 92 | MGSO1 |

| 34 | G21 | 71 | EG71 | 93 | M20 |

| 41 | EG14 | 72 | MGS20 | 94 | 20 |

| 43 | G3 | 74 | EG74 | 95 | MG4S |

| 44 | G4 | 74K | EG74K | 96 | 96-0 |

| 50 | EG50 | 75 | EG75 | 97 | M1A |

| 51 | EG51 | 77 | MGSOA | 103 | G33 |

| 52 | MGS21 | 79 | EG74AF | 106 | EG86 |

| 53 | MGS51 | 81 | M1 | 108 | EG84-1 |

| 82 | MG2 |

The most common brands of brushes today:

- Electrographite EG-14, EG-4, EG-8, EG2A, EG71, EG-74, EG8, G3

- Copper-graphite M1, MGSO, MG4, MG2, MG, 611OM, MGS7

If the original brand is unknown, then you can select brushes according to the performance characteristics that are given in the following table:

| Brand | Hard | Specific electrical resistance, μ Ohm*m | Friction coefficient, no more | Density current, A/cm2, no more | Nominal pressure on the brush, kPa | Linear speed, m/s, no more | Preferred area of application |

| EG4 | 2 – 6 | 6 – 16 | 0,25 | 12 | 20 | 60 | DC electric machines with pronounced load unevenness; propeller engines; electric drive of fans, universal-purpose machines; Slip rings for excitation circuits of turbogenerators with a power of less than 200 MW and single-armature converters; Low-power DC electric machines for slip rings of synchronous and asynchronous wound-rotor motors |

| EG14 | 8 – 30 | 20 – 38 | 0,25 | 12 | 40 | 45 | Electric drive for various purposes, incl. powerful engines and generators with pronounced uneven loads; propeller engines; welding and traction generators; Crane DC motors; DC electric machines for ferrous and non-ferrous metallurgy and for slip rings |

| EG141 | 10 – 30 | 20 – 60 | 0,3 | 17 | 30 | 50 | Traction and auxiliary electric machines for railway and urban transport, as well as electric machines for general industrial use |

| EG2A | 8 – 21 | 11 – 27 | 0,23 | 12 | 25 | 50 | Auxiliary electric machines of railway rolling stock, diesel locomotives, industrial transport; generators and engines with pronounced uneven load |

| EG50 | 11 – 31 | 19 – 39 | – | 13 | 15 | 60 | DC electric motor ME 272, for fans of the cooling system of transport engines |

| EG2AF1 | 6 – 22 | 10 – 32 | 0,23 | 15 | 20 | 90 | Slip rings for turbogenerators and synchronous compensators |

| EG61A EG61 UMK | 20 – 65 | 36 – 72 | 0,15 | 17 | 40 | 60 | Electric motors with voltage up to 500V for rolling stock and modern mainline electric locomotives |

| EG-71 UMK | 6 -14 | 19 – 35 | 0,30 | 12 | 25 | 45 | DC machines with voltage up to 500 V. with severe switching conditions/td> |

| EG74 | 15 – 55 | 35 – 75 | 0,22 | 20 | 40 | 50 | DC electrical machines with the most severe switching conditions and pronounced unevenness of applied loads; powerful traction motors of some types of modern locomotives |

| EG75 | – | 35 – 65 | 0,17 | 15 | 40 | 50 | Electric traction motors and high-voltage auxiliary machines of modern mainline electric locomotives; traction electric machines with severe switching conditions and elevated heating temperatures |

| EG841 EG84 UMK | – | 40 – 80 | 0,16 | 17 | 40 | 55 | Traction and auxiliary engines of urban transport; traction motors of powerful electrically driven dump trucks |

| MG-4 | 10 – 22 | 1.3 no more | 0,20 | 24 | 25 | 30 | Contact rings for single-armature converters, asynchronous motors and synchronous generators; DC machines with voltage up to 40 V |

| 611ОМ | 6 – 12 | 8 – 28 | 0,30 | 15 | 30 | 90 | Electrical machines with slip rings; low-voltage collector electric machines with facilitated switching conditions |

If you had foreign-made brushes, then in order to help you choose the most suitable ones, you need to contact the employees of our company.

Pros and cons of brushed motor

So we briefly figured out the structure of the brush motor. Now what are its pros and cons?

pros

- The first advantage of tools with brushed motors is their lower cost

compared to brushless ones. This is due to production technologies and more affordable materials. - The second advantage, experts note the simplified design of the engine

, which affects

the cost of repairs

. It is easier to change the brushes than the entire motor as a whole. - Another advantage is the relatively low weight

and

size

of the instruments.

Minuses

- At high speeds, brush friction increases. This leads to the problem of their rapid wear

.

In addition to the wear and tear of the brushes themselves, they are worn out during operation. Erased graphite can clog the collector

and render the instrument completely unusable. - Also, the disadvantages include the lower power

of brushed tools, in contrast to brushless models. This is because brushed motors physically cannot produce power above 3,000 rpm. But this power is quite enough for household use. - Another disadvantage of brushed motors is the presence of sparking

during work. Please note that when starting the tool, the brushes rub against the commutator and create visible sparks. This means that you need to work with brush tools more carefully - remove all possible flammable substances and objects away from you, and also take periodic breaks from working to avoid overheating of the engine. - The last disadvantage is the not very high efficiency

of tools with a commutator motor - only 60%. This means that the tools are slightly less capable of cutting through tougher materials (such as metal) and do less work in the same amount of time as a brushless tool.

The motor brushes of power tools spark: the reason is that they spark strongly at the armature of a drill or grinder

Commutator motors are widely used in household electrical equipment. Small dimensions, lightness, and ease of operation determined their presence in grinders, rotary hammers, circular saws, and screwdrivers. The main disadvantage is increased wear of the brush-collector pair. The failure of this unit is predetermined by the sparking that occurs in it.

Electric motor design and operating principle

The operating principle of an electric motor is based on the interaction of a conductor with a current located in a magnetic field.

The magnetic field is created by the stator.

The main element of its design for a DC motor is a permanent magnet, for alternating current it is an excitation winding. The rotor (armature) has its own winding, to which voltage is supplied using a brush-commutator unit. The interaction of magnetic fields causes the rotor to rotate.

The collector consists of a set of contacts, which are copper plates located directly on the rotor. Micanite or mica cuffs act as insulators for each individual contact. Graphite brushes are sliding contacts pressed against the commutator.

Causes

Transient processes occur in the rotor windings due to intermittent mechanical contact of the brushes with the commutator plates, which causes the formation of small arcs.

Important: a fully serviceable engine does not exclude sparking during operation. There are other reasons that cause severe sparking and create the possibility of motor failure

Brush wear

With prolonged use or poor-quality brush material, they no longer press tightly against the contacts of the commutator. Due to poor contact, the engine does not gain speed or does not start immediately. A worn brush can be easily identified visually.

Sometimes it is not possible to correct the situation by replacing only the worn part. The brush holder and spring should be replaced.

Short circuit in the armature winding

The consequence of such a defect is uneven sparking on the collector. It will be stronger on some plates than others. Due to the presence of an interturn short circuit, the current in certain sections of the rotor winding will be stronger than in others.

Rewinding the rotor or replacing it will eliminate the problem.

Fault in the stator winding

A defect similar to a short circuit in the rotor winding occurs in the stator winding. You can check the presence by measuring the resistance of parts of its windings. If there is a strong difference, it is necessary to rewind the winding or replace it.

Pollution

The product of brush wear is graphite dust, which is an additional source of increased sparking. Dust accumulates between the plates, which creates additional conditions for the formation of sparks. Preventive cleaning of the commutator with sandpaper and removing dirt between the plates will keep it clean.

Brushes not installed correctly

If the brushes are deviated from the norm towards the commutator surface, a significantly larger amount of graphite dust is generated during operation. Misaligned brushes must be corrected.

Poor contact between brushes and commutator

The electric motor spends part of its operating time in overheating mode. Under such conditions, carbon deposits form on the collector. Poor contact leads to increased brush sparking and even more carbon deposits.

You need to use fine-grain sandpaper to clean the surface of the commutator. To increase the stripping effect, use a screwdriver. Clamp the engine rotor into the chuck and remove carbon deposits with sandpaper at low speeds. Afterwards you need to finally polish it on a felt wheel.

Mechanical problems

Mechanical reasons are caused by non-compliance with the requirements of design and technological documentation. Most mechanical causes can be eliminated by turning the manifold on a lathe. Refer this repair operation to a qualified technician. Here are some types of faults that may indicate a breakdown:

- The surface of the collector is uneven;

- The shaft runout exceeds the value specified in the technical documentation;

- Individual collector plates protrude beyond a common level for all;

- Insulation protrusion (mica);

- The brushes in the brush holders move with jamming;

- On the contrary, the brushes are inserted into the brush holders with a large gap, which creates vibration during operation;

- The brush holders are installed far from the commutator;

- Uneven tension of the springs, resulting in a difference in the pressure applied to the brushes.

Brush Contact Selection

The most important thing when selecting electric motor brushes is to know the parameters of the used brushes. In addition to geometric dimensions, the new brush must match the grade of graphite, type and cross-section of wire. It is not necessary to take the same brand as the original, but the hardness of the electric motor brush and operating modes must match. The thickness of the wire should not be less than the original, and the flexibility should be consistent. Main mistakes when selecting a brush contact:

- Installing a harder graphite contact where softer ones were used. The result can be rapid wear of the manifold.

- Installation of “universal” brushes everywhere. This may interfere with the operation of the device.

- When purchasing a brush, focus on the graphite markings on the side of the old electric motor brush. Marking graphite is not marking contact parameters!

Features of selection

How to choose graphite, copper-graphite and carbon brushes for electric motor, generator, converter and other electrical machines

When planning a purchase, you should study in detail how to choose brushes for an electric motor. If the installed brushes are worn out, then it is advisable to determine their main parameters, which will help in the future to correctly replace the devices. Geometric shapes, size, and grade of graphite are also important.

If you choose graphite brushes, keep in mind that they can be hard or soft. At the same time, the copper on the collector also differs in hardness. When you choose mismatched options, one of the elements will fail faster due to high friction and wear.

Brushes also differ in the level of active resistance

This is important to know for calculating winding parameters and PRU characteristics. The brush assembly must work in harmony

Therefore, it is necessary to take into account the features of the clamping block, the characteristics of the guides and contact groups.

Reliability of operation depends on the degree of pressure. If the pressure is excessive, the commutator and brush block may overheat, and if the pressure is insufficient, sparking may occur.

The photo of brushes for electric motors shows their different modifications. However, not all of them can be used in specific conditions. For example, it is not recommended to install generator modifications of copper-graphite products in power tools. Excessive overheating and high currents will lead to problems with the performance of the windings.

First way

First of all, a rough adjustment of the brushes to the commutator is required - this is done using a file and coarse paper. Then:

- The brushes are installed in place, and special glass sanding paper (No. 00) is placed under them. Its working surface should be facing the brushes. A piece of paper is measured so that its length is approximately 1.5 times the circumference of the collector.

- The armature is turned manually until the paper comes into contact with the entire surface of the brushes and grinds it.

- The mechanism is cleaned of coal dust and blown with a strong stream of compressed air.

- The engine is turned on with a load of 25-30% of the rated load for more thorough grinding of the brushes.

Since the presence of dust and brush wear products in the engine can lead to a short-circuit to ground in the brush holder bracket, after grinding it is necessary to blow out the generator with compressed air.

How to change

Maintenance of an angle grinder with replacement of electric motor brushes is not difficult.

Remove the rear housing cover and you will gain access to the brush-collector assembly. We show in the video using the example of the Interskol 115/900 model (also suitable for 125/900).

For some models of angle grinders, it is enough to unscrew the plastic plugs on the sides of the case, and the brushes assembled with springs, current leads and contacts will fall out on their own.

The brush assembly located on the body of the Makita GA9020 angle grinder provides convenient replacement of brushes. Photo

Replace brushes when they are worn to one third of their original height .

When cleaning and flushing the commutator and brush holders, use only gasoline or white spirit .

to blow and dry the insides of the car using a car compressor. You can use a household vacuum cleaner.

Some manufacturers produce brushes with a pre-run-in working surface. These brushes do not require running-in.

Run in (run in) brushes with a flat end on the grinder at idle speed, without load. After running in, it is advisable to blow out the brush units and collector to remove coal dust.

Types of brushes

There are several classes of brushes that satisfy different switching conditions:

- Graphite brushes. They are made on the basis of graphite with the addition of filler in the form of soot and other substances. Brushes are intended for light commutation in generators and engines. The grades EG61A and G20 are produced.

- Carbon-graphite type. Low strength brushes for light mechanical loads. Brands G21, G22.

- Electrographite type. Brushes of increased mechanical strength, saturated with carbon. Perform switching of medium complexity. Withstand high current loads. There are brands EG2A, EG74, EG14, EG4, EG841.

- Metal-graphite type (copper-graphite brushes for electric motors). The main component of the brush is copper, tin and graphite powder. They come with different fillers. The brushes are highly durable and do not allow gas or liquid to pass through. Applicable in high and medium complexity switching conditions. Ensure the functioning of low voltage generators. The brands are MG, MGS, MGS 5, MGS 20, MGS 51, MGSOA, MGSO, MGSO1M, M1A, M1.

The described brush contacts are applicable in industry; brushes of the G33MI, G33, G30, G31 brands are produced for household equipment.

Main characteristics of devices

Brushes can be produced together with conductors. They are made of metal. But there are modifications without conductors. To secure the wire to the brush structure, several different options are used - flaring, pressing, soldering.

At the same time, the current conductors themselves differ by brand. They can be stranded from copper wire (MCW), flexible, distinguished by weaving from a similar wire (PS), universal with a high degree of flexibility (PS).

When considering the description of brushes for motors, it is necessary to note the presence of contact-type tips on the wire. They are necessary for better bolting of the holders located on the brushes. For convenience, such tips vary in shape - fork, flag, double and plate.

Electric brushes must ensure the specified operating mode of the main and auxiliary electrical equipment with minimal costs for repair and maintenance work.

Therefore, certain requirements are imposed on them:

- safety and reliability of the switching contact without sparking and the risk of short circuits on the windings;

- avoidance of contact violations with moving components of the unit;

- elimination of electricity losses in sliding contacts;

- mechanical strength, friction resistance;

- wear resistance of the material.

When to replace motor brushes

Dust particles getting between the carbon brushes and the formation of a spark, combined with the rotation of the engine rotor, leads to their natural wear. This is expressed in a simple change in shape in the form of erased contacts and linear dimensions of the element. As a result of wear, the operation of the electric motor, and as a consequence of the entire washing unit, is disrupted. You can determine brush wear by the following signs:

- noise and crackling noises are emitted from the motor installation location during operation, caused by direct contact of the pressure spring to the rotor commutator;

- insufficient power of the electric motor when the laundry remains wet even at high speeds during spinning;

- sudden stop of washing;

- the appearance of smoke, sparking and a specific burning smell;

- displaying an error code (typical engine malfunction).

Replacement instructions

At home, this operation is carried out according to the following scheme: first you need to clean the collector from dust. For this purpose, experienced users recommend gasoline. As soon as there is no trace of dirt left, you need to try to rub the new element into the collector. Sandpaper will help to cope with unevenness.

Read also: Use of hot injections

Even if the degree of wear is different, all elements need to be replaced. Their average shelf life is determined by the operating hours of the equipment. So, if the tool is used once a month, 90 hours is the minimum, which can be quite realistically increased to 125 hours. With frequent use of equipment in different weather conditions, 85 hours is the ceiling.

Diagnostics of malfunctions in the operation of angle grinders

Signs of an angle grinder malfunctioning for a sensitive ear and a keen eye appear long before the actual failure of the tool. Before it completely breaks down, the grinder usually starts giving distress signals. It could be:

- increased vibration of the housing during operation;

- excessive sparking of commutator brushes;

- uterine humming of the engine when turned on;

- cracking of the gearbox due to broken teeth or dried out gears without lubrication;

- jamming of the rotor shaft rotation bearings or their piercing creaking during acceleration;

- a specific smell or even smoke emanating from the angle grinder body.

To save your angle grinder from major and expensive repairs, you should be attentive to the technical condition of the tool and promptly respond to changes in its operation.

If the first symptoms of improper operation appear in the grinder, it is necessary to urgently diagnose the device and find the cause of the problem. To do this, you need to check two main systems of the device - electrical and mechanical.

How to understand that the generator brushes are worn out

If you don’t know how to understand that the generator brushes are worn out, just take a few simple steps. The negative wire is disconnected from the battery, the voltage regulator is removed and the graphite parts are assessed.

If the height is less than 5 millimeters, they urgently need to be replaced. You can install new parts in a service that repairs generators in Lyubertsy 24 hours, if you suddenly want to do it urgently.

It should be remembered that regular maintenance and diagnosis of possible faults will extend the life of your car. Even such a simple part as a generator brush needs regular maintenance and replacement. Safety on the road and normal operation of the machine depend on this.

Sanding attachments

An electric drill is a universal tool, and a wide range of different attachments allows you to use it for different purposes:

- polish metal, wooden surfaces, glass or paintwork;

- clean metal from scale or rust, old paint or primer;

- polishing wooden and metal surfaces;

- remove beads on concrete when pouring floors.

The list could go on for quite a long time; it is worth noting that cleaning brushes are in demand everywhere in various areas of human production activity. In some cases, the use of an electric drill with various attachments has no alternative.

Drill sanding attachments look the same as special sander blocks, but instead of a threaded connection, they use a pin to secure it into the tool chuck. Their modifications are very diverse: in the form of a cup or plate, end, drum, soft nylon or hard with an abrasive base, shaped like discs or a fan. They are used depending on the power of the tool and the skills that the worker has.

Many home craftsmen invent additional devices to secure the drill in the desired position - this greatly facilitates the process of processing various parts, especially small ones.

Types of products

- graphite - made from graphite with various fillers, such as carbon black. Their purpose is to provide easy switching in motors;

- carbon-graphite - since they are not very strong, they are used in devices with the most minimal mechanical load;

- electrographite – are high-strength products. Such brushes guarantee medium-level contact with increased current loads;

- metal-graphite with graphite powder, copper or tin fillers. The main distinctive properties of such products are work with complex contacts, a high degree of protection against the penetration of various liquids and gases, and increased strength.

Electrographite

| Brand | Hardness, kPa×104 | Electrical resistivity, µOhm×m | Nominal current density, A/cm2 | Maximum permissible linear speed, m/s | Transient voltage drop across a pair of brushes, V |

| EG2A | 7-21 | 2-8 | 11-27 | 50 | 0,9-1,9 |

| EG4 | 2-6 | 13-35 | 15 | 60 | 0,9-1,9 |

| EG8 | 8-34 | 36-50 | 11 | 42 | 1,0-1,8 |

| EG14 | 8-30 | 20-38 | 12 | 45 | 1,1-2,1 |

| EG141 | 1-30 | 20-40 | 11 | 40 | 1,1-2,0 |

| EG61AK | 20-65 | 36-60 | 19,5 | 60 | 1,7-3,2 |

| EG74 | 15-49 | 35-75 | 15 | 50 | 1,2-2,4 |

| EG74AK | 20-40 | 35-75 | 12 | 60 | 1,3-2,5 |

| EG75 | 35-65 | 13 | 60 | 1,5-3,2 | |

| EG841K | 40-80 | 17 | 50 | 1,7-3,7 |

Metal-graphite

| Brand | Hardness, kPa×104 | Electrical resistivity, µOhm×m | Nominal current density, A/cm2 | Maximum permissible linear speed, m/s | Transient voltage drop across a pair of brushes, V |

| 611ОМ | 6-12 | 8-28 | 15 | 40 | 0,7-1,7 |

| M1A | 8-25 | 2-8 | 12 | 60 | 0,8-2,0 |

| MG | 4-14 | no more than 12 | 30 | 30 | no more than 0.4 |

| MG4 | 10-22 | no more than 1.3 | 24 | 30 | no more than 1.6 |

| MGS5 | 6-20 | 2-15 | 45 | 16 | 0,7-1,9 |

| MGS20 | 6-25 | no more than 0.4 | 120 | 15 | 0,3-1,0 |

| MGSO | 6-20 | 2-15 | 30 | 30 | no more than 0.35 |

| MGSO1M | 6-20 | no more than 0.8 | 80 | 15 | 0,1-0,5 |

| MGSOA | 14-45 | no more than 0.3 | 100 | 15 | 0,1-0,45 |

| M1A | 8-25 | 2-8 | 12 | 33 | 0,8-2,0 |

| MGSO51 | 6-20 | 2-13 | 80 | 15 | 1,2-2,5 |

Carbon graphite

| Brand | Hardness, kPa×104 | Electrical resistivity, µOhm×m | Nominal current density, A/cm2 | Maximum permissible linear speed, m/s | Transient voltage drop across a pair of brushes, V |

| G3 | 7-19 | 8-20 | 12 | 60 | 1,9 |

| G20 | 35-100 | 15 | 40 | 2,9 | |

| G21 | 20-60 | 150-450 | 8,5 | 30 | 2,5-5,5 |

| G21A | 20-60 | 150-400 | 10 | 25 | 3,0-6,0 |

| G33 | 18-64 | n/a 900 | 10 | 35 |

Brushes selection criteria

Place text to fit the width of the page

To select the right brushes, you need to know and take into account such parameters as:

- Brand and material from which the contact is directly made

- Dimensions (length, width, depth). In this case, the length may have slight fluctuations in the direction of decreasing or increasing.

- Type or configuration of the part. The design is determined as follows: whether there is a conductor or not, the material from which it is made, the place where it should be attached, a ring or plug as a tip for connection.

How they can be useful

These products supplied by us are used in various industries. The main task of the devices is to transmit electric current from the power source directly to the rotating commutator of the engine, ensuring its stable and non-stop operation.

All presented products are highly reliable due to the high degree of precision in the connection of mechanical parts and the use of wear-resistant materials in brush designs. These models do not lose too much energy in the sliding contact and do not spark, ensuring a reliable switching process. Brush-collector units are considered consumables, but the models purchased here are designed for a long period of operation.

Advantages of purchasing electric brushes from our

- Each original model produced by us is designed for a strictly defined area of application.

- All offered electric brushes for electric motors have a high degree of wear resistance.

- When purchasing products from us, you buy them from the manufacturer, avoiding overpayments in the form of unreasonable trade markups by intermediaries.

- It is possible to produce batches of products according to the client’s individual order, in accordance with his technical needs.

- The high quality of all products produced using modern equipment is guaranteed.

If necessary, managers will assist you in choosing, introducing you to the technical characteristics, features of installation and operation of the equipment. In addition, we provide convenient methods of payment and delivery of orders, and also cooperate with both wholesale and retail customers.

Favorable prices

Flexible discounts

A wide range of

Delivery across Russia

Satisfied clients

Quality products

Abnormal sparking of the electric motor

Sparks appear due to the mechanical action of the brush and commutator. This phenomenon occurs even with a working engine. The brush moves along the commutator, in turn forms and then breaks the connection with the contacts. A small number of sparks that burn is considered an acceptable phenomenon for a working unit, but if it sparks a lot, then it is necessary to diagnose the vacuum cleaner.

The actual cause of the breakdown may be an incorrect angle of inclination. Correct position: two brushes rotate parallel to each other and along the same path. If the device is used for a long time, the brushes in it may move, so it is necessary to control this process so that they do not become bent. If popping noises occur, strong sparking appears, the product body turns black, we may be talking about an interturn short circuit.

It is difficult to fix such a problem on your own; it is better to contact a specialist or replace the motor.

Another cause of malfunction is wear of parts. In this case, the vacuum cleaner is completely disassembled. Brushes create contact between special electrodes; they are components of an electric motor, so you first need to diagnose it, replace old parts and continue to use the equipment. Some experts recommend purchasing additional spare parts for a new product.

Poor contact between equipment elements can occur when new brushes are installed. They must be tightly installed. The malfunction occurs in the presence of dust; in this case, clean the contacts regularly. If the contact is poor, then you can let the device run for 10 minutes at neutral speed.

With excessive tension, which is associated with high friction, dirt is formed. The more carbon deposits appear, the faster the unit breaks down. Contacts must always be clean.

Dirt (carbon deposits) is removed with sandpaper or chalk, then the surface must be degreased.

Washing machine motor sparks

If the washing machine sparks from below, then the problem is most likely in the electric motor that drives the drum. In most cases, brushed motors are used here, which wear out over time and begin to suffer. But don’t be upset - most often a complete replacement is not necessary, and self-repair of the engine will result in a simple replacement of the brushes. Let's try to look at the repair work in more detail.

Brushes for electric motors of washing machines

Brush motors transfer electricity to the windings using graphite brushes that rub against a rotating commutator.

A high rotation speed causes wear to the brushes, as a result of which they become the cause of sparking - contact with the lamellas becomes worse, sparks and even an unpleasant odor appear. And the more wear, the more sparks appear at the point of contact between the rotating rotor and brushes. The solution to this problem is very simple - you just need to change the brushes for the electric motors of the washing machine. After this, the engine can continue to operate. In order to replace the brushes, you need to remove the belts from the motor shaft, disconnect the connecting terminals through which power is supplied, unscrew the motor fasteners and carefully remove it - at this stage we may be hindered by the tank to which the motor being removed is attached. A little skill and patience - and the engine will be removed. Next, the problem will be solved in one of two ways:

- With engine disassembly (relevant for older models);

- No engine disassembly.

Old motors are designed in such a way that the brushes with fastenings are located inside the housing - in this case, the motor needs to be disassembled, the brushes replaced and assembled back, paying attention to the fact that it must be assembled correctly (for this we mark one side with a marker so that we know , how to then combine several parts of a disassembled engine). If the engine is new, then you don’t have to disassemble it to replace the brushes - their holders are visible from the outside. In this case, the brushes are removed using a regular screwdriver, which is used to pry off the fasteners.

As soon as the replacement is made, we install the engine in place and conduct test tests

In this case, the brushes are removed using a regular screwdriver, which is used to pry off the fasteners. As soon as the replacement is made, we install the engine in place and conduct test tests

If the engine is new, then you don’t have to disassemble it to replace the brushes - their holders are visible from the outside. In this case, the brushes are removed using a regular screwdriver, which is used to pry off the fasteners. As soon as the replacement is completed, we install the engine in place and conduct test tests.

The brushes of the electric motor of the washing machine spark even if the machine is completely new - the contact is being ground in. The same thing can happen after replacing brushes that have worn out over time.

Damage to the engine manifold lamellas

Is the washing machine motor sparking? Then the reason may lie in faulty lamellas (contacts on the commutator in contact with the brushes). Such breakdowns occur due to overloads to which some users subject the equipment - excessively frequent washing and overloading the weight of the laundry. If you give the washing machine a rest and do not overload the drum with laundry, then the slats will be able to serve for many years without any breakdowns.

What to do if the cause of sparking is broken lamellas? In this case, it is recommended to replace the engine completely - this will be the best way out of this situation. If the brushes can be easily replaced, then most likely it will not be possible to cope with the lamellas.

Electrical diagram

For practical work, it is convenient to use two types of its representation:

- simplified;

- more detailed.

Simplified display

The method allows you to very simply imagine the connection of all motor windings to the electrical network diagram.

The switch breaks both phase and zero potentials or one of them. Through the brushes with the commutator, a current circuit is created along the rotor windings.

Schematic diagram

Depending on the design features of the stator and rotor windings, they may have additional taps for powering various control and automation devices of the commutator motor or do without them.

Thermal protection prevents overheating of the motor winding insulation. It removes the supply voltage when the sensor is triggered, stopping the rotation of the rotor and actuator.

The tachogenerator allows you to judge the speed of rotation of the rotor. For some engines it is replaced with a Hall sensor. To transmit signals to these devices, collector plate contacts are also used.

We disassemble the washing machine

Operating principle of the electric motor

To replace the brushes of the electric motor of the washing machine, you need to prepare for the upcoming work by studying the instructions and the layout of the main components. All operations must be carried out with the utmost care. When disassembling, try to remember well the location and method of fastening the affected components.

Expert advice! It will be useful for a beginner to take a photograph of the internal structure of the opened machine in order to know exactly what and where should be after assembly.

Required Tools

To get to the motor and replace the brushes, you will need:

- Screwdriver Set;

- spanners;

- pliers;

- sandpaper.

Preliminary disassembly

All repair work on household electrical equipment must be carried out when it is completely disconnected from the network. First, remove the plug from the outlet. In preparation for replacing brushes you will need:

- disconnect the automatic machine from the supply and sewer water pipes;

- unfold the unit in order to achieve convenient access to its rear side;

- remove the back cover, which is usually secured with self-tapping screws;

- dismantle the belt connecting the electric motor to the drum shaft for loading laundry, which will require pulling it towards you while carefully rotating the pulley;

- disconnect the motor from the power circuit by opening the corresponding connector;

- Unscrew the bolts securing the engine to the frame and remove it.

Need to know. Models from different companies may have their own design features. That's why you studied the manufacturer's instructions before starting work.

Collector motor diagram

Replacing brushes on a washing machine

It is better to carry out work with a dismantled engine on a table in conditions of sufficient lighting. The procedure for replacing brushes is as follows:

- place the motor on its side to gain easy access to the brush installation location;

- unscrew the mounting bolts;

- remove the brush from the socket, remembering the direction of sharpening the tip;

- repeat the above operations with another brush;

- inspect the rods (if there are no visible damages and the length of the graphite exceeds 1.5 cm, then the reason for the failure is not them);

- check the condition of the engine manifold by sanding all irregularities;

- install new brushes, securing them in the desired position with standard bolts.

Do not forget! The bevel of the brushes should provide the maximum area of their contact with the commutator. If this is not the case, you need to rotate them 180 degrees.

Shutdown

Reinstalling the engine is done in reverse order. To do this you need:

- place the motor on the frame, securing it with bolts to the mounting holes;

- connect the power cable;

- tighten the belt by slightly turning the motor and drum shafts;

- replace the back cover;

- restore the water supply and sewerage connections and insert the plug into the socket.

Any repairs made must end with startup tests. They will consist of the initial start-up of the washing machine in one of the gentle modes. In this case, you should make sure that it is in good working order and listen to the noise of the motor. The brushes will take some time to grind the surfaces to the shape of the commutator. In such a situation, it is possible to slightly increase the operating volume without particularly sharp sounds or increasing vibration of the unit.

Advice! For the first few washes after replacing the brushes, it is not recommended to load the drum to the limit to avoid triggering the emergency protection.

If you are unsure of your ability to correctly determine the cause of the breakdown and replace the brushes on the electric motor of your washing machine, then use the services of a service department. This kind of work is done fairly quickly and is paid at minimal rates. Most likely, knowing the make of your car, the technician will arrive with the necessary spare parts, and you won’t have to look for them yourself by calling or visiting stores.

Watch a video on how to replace the brushes in your washing machine yourself

With field windings

DC motors with excitation windings have found wider application. This type of engine powers cordless power tools: angle grinders, drills, screwdrivers, etc. The field windings are made of insulated copper wire (in a varnish sheath). The grooves in the pole pieces are used as a basis. Windings are wound on them as a base.

Commutator motor with winding excitation system

If we look at the design of a commutator motor, we see two unrelated devices, the rotor and the field windings. The characteristics and properties of the engine depend on the method of their connection. There are four ways to connect the rotor and field windings. These methods are called excitation methods. Here they are:

- Independent. This is only possible if the voltages on the field winding and the armature are unequal (this happens very rarely). If they are equal, a parallel excitation circuit is used.

- Parallel. Speed is well regulated, stable operation at low speeds, constant characteristics, independent of time. The disadvantages of this type of connection include instability of the motor when the inductor current drops below zero.

- Consistent. With this connection, you cannot turn on the motor with a shaft load below 25% of the nominal one. When there is no load, the rotation speed increases greatly, which can destroy the engine. Therefore, this type of connection is not used with a belt drive; if the belt breaks, the motor is destroyed. The series drive circuit has high torque at low speeds, but does not work very well at high speeds, making it difficult to control the speed.

- Mixed. Considered one of the best. Handles well, has plenty of low-end torque, and rarely gets out of control. Among the disadvantages is the highest price compared to other types.

Methods for connecting field windings

Brushed DC motors can have an efficiency from 8-10% to 85-88%. Depends on the connection type. But high-performance ones are characterized by high speeds (thousands of revolutions per minute, less often hundreds) and low torque, so they are ideal for fans. For any other equipment, low-speed models with low efficiency are used, or a gearbox is added to productive models; no other solution has yet been found.

Explanation of markings

Domestic marking of brushes for electric motors includes complete information about the product, for example:

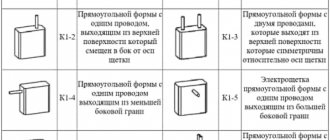

EG-14 20*32*40 K1-3

The brush marking will look like this:

- EG-14 - the material from which the brush is made;

- 20*32*40 - dimensions;

- K1-3 - configuration (determined from the table).

At the same time, there is additional information in the reference books, which indicates the parameters for each type of brush.

According to the information on purpose and dimensions in the reference books, you can select brushes for power tools that use a commutator motor. It should be taken into account that their markings are different.

For a rotary hammer, drill, mixer and grinder there can be either the same or different brands of brushes, since these devices have different loads and speeds. This must be taken into account when replacing, and not selected only by size.

If the engine has special design features, you can specify the required parameters when ordering:

- The number of current-carrying conductors, as well as their length and cross-section.

- Configuration of connection contact and lining.

Often, power tool manufacturers provide a table of brands or catalog numbers, which displays information about which brush is suitable for which device. Below is a compliance table for power tools, which indicates the type of tool and the marking of the installed brushes.

The following two tables will help you select components for Bosch power tool motors. The top column shows the types of brushes marked by numbers (#1, #2, #3 ... #15) and their catalog numbers; vertical columns indicate the models of power tools and also their numbers.

When selecting, you need to have an idea of the difference between carbon brushes and graphite and other types of electric brushes. Incorrectly selected components can lead to failure of the commutator, and the electric motor will quickly become unusable, or simply the newly installed parts will quickly wear out.

Now you know what markings exist for motor brushes and how to choose the right electric brushes for the right tool. We hope the information provided was useful and interesting for you!

Commutator grinding process

The process of grinding the collector must begin with the selection of sanding material. It is recommended to use sanding paper or a file to sand the commutator.

Choose several sizes of sanding paper, starting from #100 and above.

Now start sanding. Applying a wooden block with sandpaper attached to the commutator, rotate the drill and, without pressing the block too hard to the surface of the commutator, grind.

Grinding the commutator in a drill

It is recommended to use the grinding operation on already operating rotors with minor wear on the commutator.

Proper brush sparking

If you have replaced the commutator on the rotor of the Makita 2470 rotary hammer, then after installing it on the shaft, the commutator must be machined. This operation is performed to eliminate radial runout of the surface of the lamellas of the new collector relative to the armature shaft.

It is best to grind the manifold on a lathe using mandrels. But this operation can also be performed at home. True, you can’t do it without an additional device. The video will help you understand the manifold groove.

Read also: What can be cast from lead

As a rule, brush holders on hammer drills are mounted opposite each other. Prolonged operation of the brushes leads to the formation of grooves on the collector, creating waviness on the surface. Such wear can only be eliminated on a lathe by turning the commutator.

To reduce the formation of grooves on the commutator, you should try to arrange the brush holders in a checkerboard pattern.