Increasingly, electrical wiring installation is not complete without a carbon electrode for welding copper wires. This method is an alternative to soldering copper strands, which requires the use of flux and solder. Like soldering, the task of welding is to ensure reliable contact between the wires, which cannot be achieved by ordinary twisting, because an oxidation film will certainly appear on the copper surface over time. True, after welding, a permanent connection of the twist is not obtained over its entire surface, as with soldering, but only at the tip, which melts within 1-2 seconds, however, such contact prevents overheating of the cables when the load increases.

Due to their technical characteristics, graphite electrodes are consumed more slowly, are easy to cut, and do not crack during welding.

As a rule, welding of wires is carried out in junction boxes. They are located quite high, so for work you need to use portable welding equipment. There are industrial devices for this purpose, the use of which is advisable at a professional level. You can make a homemade welding transformer, but inverter machines, which many people have today, are excellent for welding. They are mobile and also have the ability to adjust the desired welding current.

Types of electrodes for welding copper wires

Classification of electrodes for welding.

Welding of copper must be carried out with specialized electrodes. Coal has already been mentioned. In addition to it, there are graphite electrodes. It must be said that carbon brushes of commutator motors, battery rods and similar products can act in this capacity. They fully replace electrodes from the store, except that they do not have copper plating, but for these devices you will have to design more convenient holders. Homemade alligator clips for both the electrode and ground connection will not be as cumbersome as standard ones, so they are much easier to use when working in junction boxes. Of course, it is necessary to take care of the reliable insulation of their handles.

Carbon and graphite electrodes are similar in the main thing: both have a melting point more than 3 times higher than the melting point of copper. Due to this circumstance, their consumption during installation of electrical wiring is extremely low. At the same time, the electrodes heat up to high temperatures almost instantly, so there is a danger of overheating of the material being welded, which can lead to damage to the insulation in the cables. All these factors must be taken into account by the welder in order to be efficient enough when performing the work, because a few moments will be enough both to reliably fasten the twist and to render part of the wiring unusable.

Inverter welding machine

The inverter device has clear advantages over other devices:

- Small-sized parameters;

- Light weight;

- Adjustment of current parameters;

- The presence of a portable belt (it is convenient to carry out work on a stepladder, in a junction box);

- A stable arc that ignites at low currents;

- Quality of welded joints;

- Less energy consumption without changing the voltage of the household electrical network.

In addition, welding is carried out using transformer devices, devices, stations, devices made independently (if you have certain skills).

The ease of operation of the do-it-yourself electric arc spot welding machine has made it the most widespread. Main parameters of this equipment:

- Electric arc current;

- The mains voltage that forms an arc;

- Type of electric current (alternating, direct).

Differences between carbon and graphite electrodes

Welding with a carbon electrode with the supply of filler metal into the arc: a - “left” method; b - “right” method.

Despite the similarity of carbon and graphite rods in the field of application, their characteristics are somewhat different:

- The first difference is the price. Graphite products are more affordable.

- If carbon rods are completely black, then graphite electrodes have a dark gray color with a metallic tint.

- Welding with a carbon electrode requires some experience from the welder, since this rod creates a very high temperature arc, which can cause the strand to break. At the same time, high temperature values are achieved with minimal current, so carbon electrodes are useful for owners of weak transformer devices.

- Owners of inverter devices equipped with current regulators are better off using graphite rods. They are less demanding on the qualifications of the master. In addition, the welded joint after their use is of better quality, greater strength, and increased resistance to oxidation than after welding with coal.

Assembly instructions

Assembling the device with your own hands will require minimal skills in working with hand tools. For convenience, the manufacturing process should be divided into 5 stages:

- Preparing the body. It is selected based on the dimensions of the transformer.

- Search and installation of a transformer. Checking its performance.

- Selection of power cable. Protection of the device from overload.

- Installation of output terminals. Other connection methods.

- Selection and installation of holder and electrode. DIY alternatives.

Welder body

The easiest way is to use a ready-made housing from any electrical device. For example, from a car charger or a suitable uninterruptible power supply from a computer. It is desirable that the housing be made of dielectric material (plastic, carbolite). This will be a plus in favor of the security of the future device. If none of the above options is suitable, then the easiest way is to make a body from thin sheet iron 1-3 mm thick.

Transformer selection

The required transformer can sometimes be found in stores. Another option is to look for it from friends or wind it yourself.

The primary winding of the transformer is designed for 220 V. The iron is selected based on the overall power of 200-1000 W. Low-power transformers are suitable for welding thin wires, and high-power transformers are suitable for thick ones.

The secondary winding of the transformer is wound with wire from 35 kW. mm, because she will have to experience short circuit currents. It is better to use copper as the material for the output winding. This will reduce heating losses.

Power cables

The 220 V power supply cable is selected based on the power of the transformer. For devices with a consumption of 1 kW, its cross-section is taken to be at least 4 square meters. mm. A thick cable is also better because it is more difficult to break or break during repairs and wiring.

To protect the device, it would be useful to install a fuse or circuit breaker in the primary winding circuit. This way the transformer will be protected from overcurrent.

Terminal Applications

If possible, the use of terminals should be avoided. They tend to become loose and burn over time, especially at high currents in the secondary winding of the transformer. The most reliable connections are made by welding, soldering or crimping.

In some cases, terminals are convenient. For example, at the output of a welding transformer. Using terminals, you can move the device separately from its wires. The main thing is to ensure that during operation the terminals do not oxidize, dangle or overheat. It is permissible to periodically remove dirt using a file.

Electrode holder

Welding is carried out with a graphite electrode coated with a thin layer of copper. This combination provides the good conductivity of copper combined with the heat resistance of graphite. Similar electrodes are commercially available. If you couldn’t find them, you can make them yourself from a graphite brush of an electric motor. It should be taken larger and cut with a hacksaw to the desired size.

Homemade holders for welding. The holder is made of a pair of copper bars and bolts for tightening. The device must securely clamp the graphite electrode.

Welding current regulation

As for adjusting the current, wire welding is carried out in the range from 30 to 120 A (almost all inverter welding machines operate within these limits). In any case, the exact welding current will have to be selected experimentally, since:

Technology of welding copper strands with a carbon electrode.

- Each inverter has its own characteristics.

- The mains voltage may differ from 220 V.

- The chemical composition of copper wires from different manufacturers may vary.

In addition, it doesn’t hurt for the welder to practice so that the work is done as quickly and efficiently as possible.

However, you should be aware of the current values at which wires of different sections are connected:

- When welding 2 wires with a diameter of 1.5 mm2, the inverter is set to 70 A.

- 3 wires of the same cross-section are welded at a current of 80 to 90 A.

- The current for welding 3 wires with a diameter of 2.5 squares is 80-100 A.

- 4 wires of 2.5 mm2 are welded with a current set on the device from 100 to 120 A.

Process Features

Welding copper wires has its own characteristics. This is due to the fact that at a temperature of 300 °C copper becomes brittle, and at 1080 °C it melts.

The electrodes can withstand temperatures three times higher. Therefore, it is important not to overexpose the arc, so as not to damage the insulation and the wires themselves.

To protect them, you need to connect a powerful radiator in the twisting area, preferably made of copper with a large heat transfer surface and tight pressure to the twist, and then only weld.

When welding copper wires, it is advisable to place the twist vertically. In this case, the molten drop will take on a spherical shape, which will cover all the wires being welded.

Sometimes it is necessary to weld not single-core, but multi-core copper wires. In this case, you must first place the twist in the sleeve, crimp it, cut off the protruding end and then weld it.

How to weld twists?

To prevent possible melting of the cable insulation, a metal radiator must be attached to the base of the twist. A clamp with a large surface that improves heat transfer will help remove excess heat from the twist. It is advisable that the radiator be made of copper, as it has high thermal conductivity.

Safety rules for welding work.

The twist welding process is preceded by a preparatory stage, during which the wires are freed from their sheaths and insulation. The length of the exposed cores must be at least 10 cm, then the twist will be no shorter than 5 cm.

When twisting the wires, you need to ensure that they fit as closely as possible to each other. You also need to ensure that their ends end up at the same level, otherwise some of the wires will end up outside the welded joint. If necessary, the end of the twist is cut off with side cutters.

Near the radiator, a ground clamp is attached to the twist, after which an electrode is brought to the tip of the wires. The contact time should not exceed 2 seconds. After it is interrupted during twisting, a small influx of spherical shape is obtained. The remaining twists are welded in the same way.

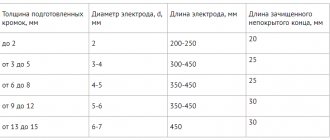

Rod material

The rods that are installed in electrodes and intended for copper alloys are made from rods and wire. Their composition complies with GOST. These are mainly bronze and copper. Metal alloys are often used in manufacturing. Copper rods are made in diameter from 2 to 6 mm. They can be wrapped in 0.3 mm thick sheet metal. They have different coatings applied to them. It can be rutile or basic.

For Komsomolets-100 electrodes, the rod is made of M1 copper. Bronze products are made from a special metal and coated with a mixture of various substances. Sometimes they are made from tin-phosphorus bronze. The bronze rod gives excellent quality to the seams. They oxidize metals less than copper ones. Bronze rods reduce mechanical strength under certain conditions.