Marking devices

One of the different types of devices for marking parts is scribers. These are pointed rods used for applying marks. This bench marking tool is used with guide tools. There are several types of scribers, among which the following three are the most common. Round options are represented by rods with one hardened and pointed end and the other bent into a ring. Tools with a bent end are sharpened on both sides, and one of the ends is bent perpendicular to the rod. In addition, the middle part is thickened. These scribers are designed for marking hard-to-reach areas. Models with an insert needle are similar in design to watch screwdrivers.

Marking materials

The type of materials used is standardized by the state standard and indicated in the project. The regulations allow for the use of several types of markings: paints (solvent-based/water-based), marking tapes, plastic (hot/cold).

Road

Concrete and asphalt concrete pavements are often treated with special road paints. The advantage of this solution lies in rapid drying, which allows marking to be applied in the shortest possible time. The finished coating is obtained after 15-20 minutes. In addition, markings based on road paint are easy to apply and equally easy to remove . In addition to the above equipment, the material can be applied manually - with brushes and rollers.

Markings based on road paints are applied in one layer. The optimal thickness is 100-150 microns. The composition is diluted with xylene and toluene to working viscosity. Average consumption 300-500 g/m2. A protective layer is required to extend service life.

Acrylic/water-based

Based on such paints, glossy, smooth markings are obtained.

The layer is easily washed off from dirt and stains and demonstrates stable resistance to various types of chemicals. That is why such markings work especially well in chemical industry workshops and in warehouses for storing chemical products. The finished marking has a long service life - operation is at least three years . But the application has one limitation. The application temperature should be above +5 degrees. However, this is successfully offset by the ability to work on wet surfaces and in damp conditions. Marking with acrylic and water-based paints is started only after the base has been completely cleaned; thorough cleaning and demarcation must be carried out.

Epoxy

This is expensive, but the most common marking material. The cost of purchasing epoxy paint will be successfully recouped by its service life, which reaches 10 years. First of all, this is due to the high degree of adhesion to the base surface.

The material is recommended for use in production, warehouses, parking lots - wherever there is heavy traffic of equipment, carts, and forklifts. However, protection should be provided with a layer of special varnish. Additionally, quartz sand can be used to provide anti-slip properties.

As in the previous case, marking work is carried out at temperatures above 0 degrees. The floor requires preliminary mechanical preparation. Under favorable conditions, the marking will be ready for full use after 2-2.5 hours. Consumption varies within 0.8 kg/m2.

Adhesive tapes

The popularity of using adhesive marking tapes is due to the simplicity and mobility of their application. The material is presented at an affordable price, which is also a plus. The disadvantage of this solution is insufficient wear resistance. With a high degree of probability, the finished markings will quickly be damaged in areas of heavy vehicle traffic .

It is advisable to use adhesive tape in places where the operation of vehicles is limited or as temporary marking

The market offers a huge range of similar materials, but when choosing, it is recommended to pay attention to the type of adhesive base.

She may be:

- based on natural rubber - due to insufficient resistance to high temperatures, chemicals, moisture, aging, this is not the best solution for extreme and specific operating conditions. But, such material is affordable and characterized by high initial adhesion;

- based on synthetic rubber - a more acceptable option compared to the previous one, due to high strength and good initial adhesion, and affordable cost. But such tapes do not withstand moisture, chemicals well, and do not tolerate heating above 40 degrees. When applied, a specific unpleasant odor is released;

- based on acrylic glue - such tapes demonstrate a high degree of adhesion, are resistant to aging, high temperatures, and negative environmental influences. The disadvantages include a higher price, low initial adhesion, good working adhesion is achieved only 72 hours after sticking the markings on the floor;

- based on silicone adhesive - perhaps the most optimal solution for production facilities, warehouses, and parking lots. Tapes with such an adhesive layer are resistant to ultraviolet radiation, all kinds of chemicals, and the highest temperatures - up to 200 degrees. However, all the benefits come at a high price.

Cold and hot plastics

These are quite popular materials for applying road markings.

A comparison of the two types of materials is presented in the table.

| Options | Hot plastic | Cold plastic |

| Resistance to abrasion by car tires | High | High |

| Adhesion to concrete, asphalt | Physical adhesion is impaired by temperature differences between the thermoplastic and the coating. Pre-heating and priming required | The monomer is able to penetrate into the base, providing high adhesion. Priming required |

| Cost of repair work | High price due to the use of a boiler for heating | Low. Material can be applied manually |

| Adhesion to glass beads | Free dispersion of material. The balls may be pressed into the markings as they soften. | High adhesion. When the plastic softens, the balls do not change position |

| Average layer thickness | 1.5-3.0 mm | |

| Cohesion of particles in a mass | good | |

| Binder | Mineral oils, carbonic acid salts | Hardeners, acrylates |

| Fillers | Quartz, calcite | |

| Dyes | Titanium dioxide | |

| Solvents | Solvent free | |

| Working temperature | +170-200 degrees | 0+40 degrees |

| Product form | Solid blocks, powder | Liquid form or paste ready to use |

| Polymerization | Physical | Chemical |

| Resistance to external environment | Average | High |

Marking technology

Any marking work begins after the project has been developed

The project is necessary to ensure that the coating complies with current standards and requirements. The document should be developed in special organizations after a full audit of the premises, when the areas for marking placement have been determined, taking into account hazardous areas. A typical project contains three parts: an explanatory note, a graphic part and a specification with all explanations .

Based on the technical solutions presented, the recommendations begin to apply markings. In addition to standard horizontal symbols, numbering, text, arrows, and symbols are used.

Additional markings include:

- installation of signs and signs - such signs carry an additional information load, which helps to navigate in spacious production and warehouse premises, parking lots and lots;

- painting columns is a very popular solution in gray, monochromatic industrial premises and works to minimize the risk of collisions and accidents.

If there is old marking in the room, it should be removed using special equipment. It is permissible to use mechanical, thermal and chemical treatment.

Features of installation of marking tapes

To mark the floor, use a tape with a thickness of 150-180 microns. Application can be carried out by one worker without interrupting the production process . The surface is cleaned with construction vacuum cleaners, degreased, and dried. Primer is applied to uneven surfaces. If work is carried out at low temperatures, the surface is heated with a technical hair dryer, as is the finished layer.

Installation procedure:

- the floor is dust-free and degreased with any suitable preparation. As a rule, acetone, gasoline or any universal solvent is used. For interior work, you can use scrubber dryers with a degreasing detergent;

- the base is thoroughly dried with compressed air from compressors. Porous surfaces are primed using rollers and brushes in 1-2 working approaches;

- The tape application begins by cutting a sheet of the required length from the total roll. Gradually freeing it from the protective film, firmly fix it on the surface. The finished marking is rolled with a rubber roller;

- When using a mechanized application method, special devices are used (dispensers for marking tapes).

Features of installation of marking paints

Marking paints can only work on dry, dirt-free substrates. In most cases, a positive air temperature is required - from +5 to +30 degrees. Some manufacturers require that the relative humidity not exceed 85% and that there is no strong wind when working outdoors. The presence of open sources of fire is unacceptable.

The paints are brought to a homogeneous consistency with a construction mixer for several minutes . When mixing, you can use special reflective materials, which makes the marking visible both in dim and bright light, and in the dark. Balls are added to the paint in a volume of 20% of the total amount. It is permissible to apply the material to freshly applied markings using the sprinkling method.

Depending on the volume of work, special equipment or brushes, rollers, or spray guns are used.

Features of applying cold and hot plastics

Cold plastic should be applied to a clean and thoroughly dried coating. The choice of technology is made taking into account the method of adding the hardener or the method of mixing the components.

Some brands of plastic can work on wet surfaces

If self-propelled marking machines are used, extruder, gravity or spray application is used. Symbolic markings are applied manually using stencils . In this case, mixing the cold plastic and introducing the hardener is carried out manually, in portions, in a clean container.

When drawing a line or marking symbol, key points are pre-fixed on the base. The contour is glued along them using masking tape. When the mixture is ready, it is poured onto the floor within the stencil. The plastic is leveled with a spatula, making sure there is a slight overlap with the masking tape. Next, sprinkle the layer with glass beads and carefully remove the tape.

Hot plastics are more expensive and are used mainly in areas with a high degree of wear . Here only a mechanized application method is possible. When working, you should concentrate on the operation of thermometers that control heating in the marking equipment boilers.

Equipment and tools used

This list depends on the method of work. Manual cutting is carried out using:

- cutting tools (chisels, crosspieces, etc.);

- a plumber's hammer (chosen by weight and handle length);

- vice;

- metal substrate;

- marking tool.

A metalworking chisel structurally consists of three main parts: impact, middle (holder) and cutting (working). The shape of the cutting part is different for each and depends on the task being solved. A chisel is used to perform a standard chopping operation. Kreuzmeisel has a narrower cutting edge. The groover is designed for cutting grooves, so its cutting part is made in the shape of a semicircle. The beard is made from a round metal rod, and has a working part in the shape of a circle sharpened around the perimeter. It is used to cut holes in sheet metal. All percussion instruments are made from durable tool steel.

The main parameters of these tools are geometric dimensions and sharpening angles of the cutting part. A plumber's hammer is used to strike the upper (impact) part of the chisel. They differ in the shape of the striker (round or square), the method of attaching the handle, and the total weight.

Cutting out small parts, holes, and individual parts is done using fastening equipment or on steel substrates. To ensure secure fastening, this operation is performed in a vice.

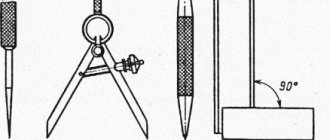

Various metalwork rulers, squares, marking calipers, and small markers are used as marking tools. To make marks, the following are used: cores (of various modifications), scribers with different tip shapes, and pencils. The tools used are manufactured according to developed standards

In industrial enterprises, the tools for cutting metal are special machines. These include:

- guillotines;

- presses (hydraulic and mechanical);

- press shears;

- angle cutting machines.

They have high productivity and allow you to cut even very thick metal.

The hydraulic guillotine is controlled by an electronic unit. With its help, the parameters of the future operation are set. Set the type of metal, the cutting angle, the amount of pressure on the knife, and the cutting speed. In addition to the guillotine, so-called combined units are used to solve these problems. These include cutting machines (press shears) and highly specialized ones (angle notching machines, presses and dies). Press shears are used for cutting sheets and strips of metal, shaped and long products. They work well with profile metal, for example, channel, I-roll, square. With their help, smooth holes and grooves of various shapes are obtained.

Angle notching machines allow angular cutting of metal products of almost any thickness. High precision cutting is achieved thanks to the presence of a scale that allows you to accurately lower the tool to the required place and a correctly sharpened set of chisels.

Presses and stamps solve similar problems. They use mechanical, hydraulic, pneumatic and electric drives.

How to mark a parking lot

In open and closed parking lots, there must be strict designation of parking spaces, pedestrian crossings, and navigation arrows. Additionally, columns are painted and parking spaces are numbered. All marking principles are standardized by GOST 52289-2004, especially places for people with disabilities.

Standard parameters of a parking space: length - 5 m, width - 2.5 m, 3.6 m - for disabled people . The width of the passage is taken into account - 6 m, the width of the marking lines - 10 cm.

For such work, it is recommended to use road paints, cold or hot plastic, epoxy, and polyurethane paints. Preliminary preparation, measurements and calculation of parking spaces are carried out, taking into account the total area, number of parking spaces, fences and the capabilities of the territory. The coating must be thoroughly cleaned of debris and dirt.

The selected material is applied using special equipment, in rare cases manually . A mandatory condition is to fence the locations of fire extinguishers, exits, and fire hydrants with reflective paints and tapes.