Marking a corner with a piece of paper

Marking with a paper sheet is one of the simplest ways to complete the task. A square sheet is required. It folds exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its cross-section.

Then an angle of 45 degrees is formed on the smaller side. All that remains is to mark the cut line using a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with narrow tape to prevent it from being accidentally erased. This method is excellent for long, large pipes with the cut location approximately in the middle of the product.

How to properly cut pipes from different metals

Accurate cutting and trimming of pipes depends not only on well-executed markings. The material is also of great importance - metal of different thicknesses and hardness is cut with different forces and side effects. To properly cut a cast iron pipe, it should not be sawed all the way through. Cast iron is a brittle metal, so several cuts are usually made, and then a specialist knocks a piece out of them with one precise blow of a chisel.

To work with thin-walled pipes, you will have to very accurately check the position of the grinder. At the same time, the master must choose the right [discs for cutting metal with a grinder]. In industrial settings, special pipe cutters, gas cutting machines and welding machines can be used to perform the same tasks.

IMPORTANT TO KNOW: Sliding support for pipelines

Safety when cutting a gas pipe

When working with gas pipes connected to the mains, it is important to follow safety precautions. First turn off the gas supply valve, then make sure that there is nothing in the pipe. To do this, just open the stove burners and light the gas - when it runs out, the flame goes out.

Method of marking using a container of water instead of a pattern

This marking method is suitable for small-diameter pipes that are planned to be cut at a certain angle close to the edge. First you need to prepare a deep container of water. The planned angle of inclination is marked on it. Now you need to carefully immerse the end of the product in the liquid, tilt it towards the mark, and then pull it out.

As a result of such actions, a clear line of contact with water will appear on it; it needs to be highlighted. The pipe is cut along it at an angle. This method is best suited for jobs that require multiple markings.

Preparation

We will use a cutting wheel mounted in a cantilever on the electric motor shaft or an angle grinder securely mounted on a workbench. Let's install the work table so that its plane is parallel to the axis on which the cutting disc rotates.

Let's move the work table down in height by half the outer diameter of the pipe being processed. This way we will achieve symmetrical processing of the end.

Using the computer program

To implement this method of marking pipes for cutting, you will need a computer with special programs. First, you need to draw up a drawing that shows the transverse dimensions of the product, as well as the planned cut angle. You need to get a virtual template.

Print it on your printer. And here it is worth understanding that the larger the diameter of the pipe, the more sheets will be required to print it. Then you need to carefully cut out the details of the drawing from all the pages and glue them together; it is best to use stationery tape for this. All that remains is to attach the template to the pipe and apply the markings.

This method of solving the problem is highly accurate. All necessary programs can be downloaded on the Internet, they are free to download and use. There you can also find a template for cutting pipes at an angle. All you have to do is print it and cut it out. To mark, the pattern is simply wrapped around the pipe.

Making a template

To construct a scan line, draw a straight line of length πd on a sheet of thick paper and divide it into 6 parts. At the division points, perpendiculars are drawn, on which the values 1–1, 2–2, 3–3, 4–4, 5–5 are laid down. The resulting points are connected by a smooth curve. It is easy to notice that the scan line is symmetrical. The second half is obtained by bending the sheet perpendicularly at point 6. Having made a template, it is transferred to the pipe, marking the cutting line with a scriber or chalk.

Figure 3. Universal compass

- 1 – emphasis;

- 2 – protractor;

- 3 – nut;

- 4 – axial stand;

- 5 – measuring ruler;

- 6 – slider;

- 7 – rod – scriber;

- 8 — tension device.

To mark holes in pipes for tapping, you can use a universal compass (Fig. 3.). The compass is fixed on the pipe and by rotating the scribe rod mounted at a certain division of the measuring ruler 360°, the outline of the hole to be cut is outlined. Cutting holes in pipes and cutting cut-in pipes in small workshops and at the installation site is carried out using the gas-flame method.

“>

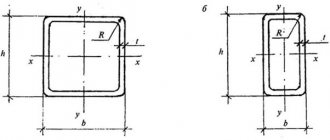

How to cut a profile pipe at an angle

The marking of a profile pipe differs from a round one. Doing it manually can lead to significant errors. The best way to solve the problem is to create a cutting template from the same profile, but with a larger diameter.

You will need a small piece of profile pipe. Using a protractor, mark a 45 degree angle on it. Now, using a grinder, you need to cut off part of the workpiece along the marked line. The edges of the cut need to be sanded and defects eliminated. All that remains is to simply insert the original product into the template for cutting pipes at an angle. Then you need to apply markings along the cut line of the larger profile. And the pipe itself is cut along it.

The text describes ways to cut a pipe at an angle of 45 degrees. When the marking is already completed, it is recommended to use a grinder. With its help you can make an even cut. You can replace it with a hacksaw. You can also cut the product by welding, but you need experience in handling the tool, otherwise there will be unevenness.

Advantages and disadvantages

The saddle is a part consisting of two halves. Thanks to this, it has the ability to tightly compress the pipe on both sides. Pipe saddles are used in different cases based on need. This device allows you to insert into a running communication without turning it off, which is an incredibly convenient function.

There are compression (mechanically mounted) and electric-welded saddles. Compression saddles are usually used for pipelines made of steel. The installation of such a device is not difficult, however, it is more labor-intensive than the installation of electric welded elements.

Helpful information! Their most common use is in the industrial sector and during the installation of sewer lines with a diameter of 110 mm. Less commonly, these devices are used for tapping into gas and heating pipelines.

Saddles for steel pipes have a number of positive qualities that allow them to enjoy such popularity in the modern market.

The advantages of using fittings of this type:

- practicality;

- are characterized by low cost;

- installing the saddle on the pipe will not cause any difficulties and can be done at high speed;

- effectiveness and efficiency;

- reliability.

The design of the saddle is simple, its installation is not difficult and is done very quickly.

Like any other product, the saddle also has its drawbacks. The negative side of operation is this factor: although the device is distinguished by high performance indicators, it still cannot compete with a standard tee for inserting into a pipeline.

Permitting documents

Tapping into a water supply system on your own property does not require obtaining any permits. In this case, it is quite enough to make appropriate changes to the water supply system plan. The situation is completely different if you want to make a connection into a centralized water supply pipe. If you do this on your own initiative without obtaining permission from the competent authorities, this may lead to penalties against you. Such actions must be carried out only legally.

Also, such work requires a certain amount of care, since damage to the water supply system can cause a serious accident, which will lead to the need for restoration work, the cost of which, as well as fines, will have to be paid by the person responsible for the event. Tapping into the main highway for the purpose of organizing a diversion must be consistent with precautions at each stage of the work.

Preparatory work

Before cutting into a pipe under pressure, you need to go through several preparatory steps:

- Make sure that the tie-in is really necessary.

- Examine the material from which the highway is made.

- Make sure that the insertion will not cause damage to the network and premises.

- Choose the most suitable technology.

- Decide whether you are ready to carry out the work yourself.

And these are the hands of professionals - only you can decide whether to seek help from experts or do everything yourself

The need for a tie-in

When do you usually have to roll up your sleeves and change your network design? Get to know the main reasons for tapping pipes.

- Buying a new “device”. Most often these include dishwashers or washing machines. Naturally, you will have to learn how to cut into a sewer pipe, since you will not be scooping used water out of the appliances by hand. Of course, some craftsmen practice simplified schemes for solving the situation. For example, the drain hose from a washing machine is simply placed in the bathroom to release dirty water. However, the pleasure of using modern “devices” with this approach is dubious, isn’t it?!

- Installation of a new plumbing fixture. Nowadays, ordinary people are increasingly adding bidets, showers, and bathtubs with special functions to their bathrooms and toilet rooms. When putting such devices into operation, you will need to know not only how to make an insert into a sewer pipe, but also how to connect to the water supply network.

- Redevelopment in the apartment. This happens when the inhabitants of a house decide, for example, to combine a bathroom and toilet or, vice versa, to share a common bathroom. It happens that there is a need to move the sink in the kitchen, for example, due to the purchase of a new set. In this case, you should also know how to install a tap into a pipe under pressure so as not to turn the kitchen into a lake.

- Connecting a new building to the water supply (for example, a summer kitchen, bathhouse, etc.).

- Wear and tear of main line parts, serious repairs involving the relocation of plumbing units.

Extensive range of pipes offered by pipe manufacturers

Pipe material

To find the right way to cut a pipe into a pipe, you need to know whether it is plastic or metal. The nuances of installation processes and the durability of the network depend on the material. So, pipes are made of plastic and metal (steel, cast iron, copper).

Previously (during the Soviet period), metal products were in favor. It’s not surprising, because this material is reliable – at least even in appearance. The most practical of the metal variations is steel - durable and inexpensive. But it is not without its drawbacks - scale accumulates abundantly on an uneven steel surface, which makes the network non-functional. Cast iron does not have this disadvantage, however, due to its heaviness, this material is rarely chosen as components for communications. Copper is an ideal option, but due to its high cost, it is not widely used.

Either way, plastic is lightweight, practical, inexpensive and literally eternal. The material is suitable for conducting networks with both cold and hot water. This raw material also has subspecies. For example, polybutylene, which is characterized by strength, flexibility and a perfectly smooth surface. The only better material is cross-linked polyethylene, which is highly resistant to temperature changes. Its analogue, polypropylene, is also good, captivating with its affordable price. Ordinary polyethylene is also used, but it can only be used to supply cold water.

Now let's look at how to cut into a heating pipe without welding - under pressure in networks made of metal and plastic.

Let's start practical lessons

Some tips for cutting pipes

Sometimes households need to cut to connect a pipeline at different angles or along an axis. The main tool for performing these works is a universal grinder and metal discs.

Rice. 9 Pipeline slitting

Making a longitudinal cut

To make a high-quality, even longitudinal cut, you can use a simple device in the form of a metal corner. It is securely fixed to a flat wooden surface with screws and the pipe is pressed against it with a heavy weight. Using an angle grinder, make a longitudinal cut in the pipe top, lightly resting the disc on the surface of the angle.

The corner can be attached to the pipe with clamps and a slot can be made along the upper wall of the corner in a similar way.

45 degree cutting

Typically, in order to rotate a pipe by 45 degrees, fittings and bends with a rotation angle of 45 degrees are used, made of the same material as the pipes themselves; if the pipes are steel, then the turns are welded from steel. For HDPE pipes, there are electric-welded or cast bends at 45 degrees (note that it is almost impossible to find compression fittings with this angle of rotation in Russia).

But, if you still need to cut a round pipe made of steel or various types of plastics, then for this you will need a pattern for cutting pipes at an angle, the shape of which is calculated manually or by machine. The task is greatly simplified if it is necessary to cut a square metal profile at an angle of forty-five degrees.

For quick cutting, you can use a regular sheet of paper folded diagonally to mark the surface for future cutting. When using folded paper, proceed as follows:

- carry out on a straight surface of the profile in the place where the cut is made, strictly perpendicular to the line;

- apply a sheet of paper folded diagonally to the side surface with the sharp end to the line so that the upper edge of the paper triangle is flush with the top side of the metal profile.

Precision cutting devices

Among branded devices that could be used in everyday life to make cuts at an angle, you can pay attention to Italian-made equipment.

The Mini Cut band saw is a small-sized device with manual clamping, for working not only with pipes, but also with angles, rods, and profile elements.

The machine supports setting the cutting angle from 0 to 45º. The procedure is carried out using a tape at a speed of 45 reciprocating movements per minute. The device is equipped with a 370 W electric motor, which is powered from a household network. The maximum permissible diameter of a round pipe to be cut is 65 mm.

On an industrial scale, numerous installations with electromechanical and electrical drives have been developed for pipe cutting. Technically sophisticated devices allow high-precision thermal, oxygen and plasma cutting:

Some nuances

You may want to hide the main circuit pipe in the wall or floor. To do this, you will need reliable thermal insulation. For these purposes, it is recommended to use regular gypsum mortar. Firstly, it has good thermal insulation properties, and secondly, it is chemically neutral, so pipe corrosion will be excluded.

The system does not require any specific maintenance. Just regularly check the functionality of the boiler, pump and expansion tank. It would be advisable to monitor possible leaks in the radiator area - this problem can be easily solved by replacing failed elements.

90 degree cutting

To cut a round pipeline or metal profile of rectangular cross-section evenly across, use a sheet of plain paper. They wrap the workpiece so that the edges of the paper sheet coincide, after which it is fixed to the part using tape or glue. Using a grinder, a thin line is drawn near the edge of the paper sheet, after which it is gradually deepened until it is completely cut out.

A metal profile or round pipe can be cut using a template by placing an evenly cut element with a large internal diameter on it.

Collar insert

To obtain branches of metal pipeline lines in the form of tees, a collar insert is used, for which it is necessary to cut the edge of a round pipe adjacent to the walls of another at a right angle. To implement the method proceed as follows:

- cut the edges of the workpiece at right angles using the previously described method.

- On the round end surface, a marker marks four equidistant points located at angles of 90 and 180 degrees to each other.

- The size of the circle is measured, the resulting diameter is divided by 3. The resulting distance is plotted from two diametrically located points, after which these points are connected to two others by a smooth arc, drawing a line with a marker.

Fig.5 Example of a collar section of a pipe

- According to the markings, a cut is made with a grinder and semicircular segments are separated, after which the part is ready for welding. If there are minor inaccuracies in the mating, it can be compacted with a sledgehammer, placing it against the round surface of another element.

The need to deepen the well

The service life of the well largely depends on the quality of construction work. However, the functionality of the source can be influenced by natural phenomena that humans cannot foresee. Often the problem is solved by deepening the shaft.

It is necessary to reanimate a well in a similar way in the following cases:

- The water level varies depending on the season of the year. The reason for fluctuations in debit is due to the fact that the trunk was dug in early spring or autumn, when a large amount of rain or melt water seeps underground. Its level rose temporarily, and the builders accepted it as permanent. After a short period of time, the flow of liquid stops, the water horizon drops, reducing the water level in the well or completely drying it up.

- The appearance in a neighboring area of a deeper mine or an artificial lake, which is fed from the same layer. For this reason, not only your wells, but also your neighbors’ wells dry up.

- Geological changes that cause a layer of water to move far from the surface.

If the decision to repair is made, carry out the work in winter, when the groundwater level is lowest. If the liquid completely disappears, you will have to dig a hole to a depth of at least 5 m. After receiving positive results, you need to check the quality of the liquid and its suitability for drinking. An alternative to reworking a well is to build a new shaft.

Tools used

There are several ways to cut a pipe; for this, construction and industrial tools for metal processing are used. Of all the types, only the grinder allows you to obtain curved surfaces without further processing with the closest arrangement of edges.

For individual use

The following tool is used for cutting steel pipes at home:

Manual pipe cutters. Allows you to cut round parts with an even, right angle of cut due to the cutting edges of the rollers. There are several varieties of products of this type, consisting of single rollers or a series of rollers attached to a chain. In everyday life, such devices are quite rare and are more suitable for professional work.

Bulgarian. It is a universal tool for cutting any metal parts with different angles; special metal discs are used for the work, which are ground down quite quickly during operation. This allows you to accurately cut a curved line with a small diameter disc.

Rice. 7 Customized pipe cutting tool

Gas-burner. A quick and effective method of cutting metal surfaces with a hot jet of flame; the disadvantages include melted edges, which complicate further welding. It is difficult to use a gas torch to cut a product according to a paper template, which will burn, and if a line is drawn, then it will practically not be visible in the stream of flame.

Electric pipe cutters. To work with pipelines of small diameters, you can use compact electric pipe cutters, whose operating principle is similar to a grinder. The device is called a roller machine; during operation, the part is mounted on a bed and rotated on roller guides; its surface is cut from above by an electrical device. The main difference between a pipe cutter is the metal disc, which has a special durable coating for cutting metal.

For industrial use

In industry, large-diameter pipelines are used to transport liquids and gases, so pipe cutting units are heavy and have large dimensions. There are also manual pipe cutters of the rotary and clamp operating principle. In the first case, the cutting rollers rotate along a round surface using an adjustable handle; in the second version, cutting is carried out by arcuate plates, which gradually move during rotation.

Rice. 8 Industrial pipe cutting equipment