Two-handed saw

- a tool with many teeth for cutting (sawing) wood.

It is made in the form of a metal plate, on the working edge of which there are teeth. Handles are usually wooden. The most productive of hand saws.

This saw is convenient for cutting down trees. It is difficult to saw a log lying on the ground, as with any other tool (under its own weight, the log settles and pinches the place where it was cut) [1].

For normal operation, pads or “goats” are required.

It is designed for two people to work with, although with some skill you can cut with a two-handed saw alone.

Proper sharpening and setting of teeth is very important.

Facts[edit | edit code]

When working with a saw or simply running any metal object across its blade, an original howling sound is produced, which is modified by bending the blade. Thanks to this, the saw can also be used as a non-standard musical instrument.

Take saws away from humanity and progress will stop. This statement is not a joke. Without a tool capable of cutting wood and metal, concrete and stone, the functioning of industrial enterprises and other areas of commodity production is impossible.

In the household, too, it is impossible to do without saws. Every man has at least one hacksaw, and a good craftsman can find a whole arsenal of “toothed helpers.”

We will look at the most common types of saws to get an idea of their operating capabilities and application features.

Ode to the handsaw

Top Redevelopment

- Catalog of houses

Where to start renovation About the project Advertising Contacts Facebook Vkontakte Odnoklassniki Instagram Design and decor

- Apartment

- Bedroom

- Kitchen

- Dining room

- Living room

- Bathroom, toilet

- Hallway

- Children's

- Attic

- Small rooms

- Workplace

- Wardrobe

- Library

- Decoration

- Furniture

- Accessories

- Vacation home

- Landscape

- Storage systems

- Corridor

- Cleaning

Construction and repair

- Foundation

- Roof

- Walls

- Window

- Doors and partitions

- Ceiling

- Balconies and loggias

- Internal structures

- Floor

- Water supply and sewerage

- Heating

- Ventilation and air conditioning

- Gas and energy supply

- Lighting

- Plumbing equipment

- Security and home automation

- Baths, saunas, swimming pools

- Construction Materials

- Decoration Materials

- Tools

- Technique

- Laws and finance

- Magazine

- News

www.ivd.ru

It all started with a simple hacksaw

It is this saw that is the ancestor of the family of hand tools designed for wood processing. As soon as the first ingot of iron was smelted, a person had the idea to forge a tool from it for cultivating the earth.

It can be assumed that the ax became second after the hoe. The third was probably a saw with a handle, known to us today as a hacksaw. Over the centuries since its invention, it has acquired numerous “brothers and sisters” performing dozens of different jobs.

The accepted classification divides this type of hand saws into two groups:

- Wood saws;

- Hacksaws for metal.

Depending on the direction of cutting, hand saws for wood are divided into three categories:

- For rip sawing cutting;

- For cross cutting;

- Universal (longitudinal-transverse).

The difference between them is in the shape of the cutting teeth: on a rip saw they are inclined forward, while on a cross saw they are straight.

The universal hacksaw tooth is also inclined forward, but has a special sharpening. It allows you to cut along and across the fibers.

According to their purpose, hand saws are divided into several types:

- Classic hacksaws (transverse or longitudinal cutting);

- Circular saws (for cutting holes);

- Tenon saws (for cutting connecting tenons).

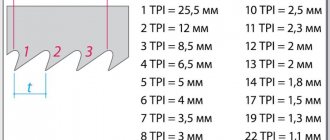

When choosing a hand hacksaw, not only the shape but the size of the teeth plays an important role.

There are three types of incisors:

- Fine tooth – 2.0-2.5 mm (for high-precision sawing and cutting small products);

- Average tooth – 3.0-3.5 mm (for medium-sized parts);

- Large tooth – 4.0-6.0 mm (for rough cutting of timber and logs).

The international classification divides hacksaws not by the height of the teeth, but by their number per 1 inch of cutting blade. This standard has taken root here too, so don’t be surprised if you see the letters PPI or TPI on the instrument label. The number behind them is the number of teeth per inch of length. The larger it is, the finer the tooth (for example, PPI 8 or TPI 14).

Today you can see a modernized type of hacksaws on the market. They are easily distinguished by the gaps cut into the canvas. As a result, the teeth are arranged in groups of 6-7 pieces.

This tool is designed for cutting raw wood. The spaces between the teeth are needed so that wet chips do not clog the cut and can be easily removed during work.

In addition to the usual hand hacksaws, users today are offered an electrified version of the tool. A powerful electric hacksaw can easily cope with a large volume of work on cutting lumber without tiring the owner too much.

Its versatility is achieved by being equipped with saws with different lengths and widths of blades and tooth sizes. This allows you to successfully work not only on wood, but also on plastic and metal. Another name for this tool is a reciprocating saw.

Hand saw - Wikipedia. What is a Hand Saw

Material from Wikipedia - the free encyclopedia

Hand saw

- a carpenter's and joiner's tool designed for sawing wood. There are several types of saws by design.

Depending on the purpose and shape of the teeth, they are divided into transverse, longitudinal, fine-toothed and circular.

Varieties

- The bow saw is used for cross cutting. It consists of a beam and a saw blade stretched in it. The bow consists of two posts, a spacer, two handles, a tension string and a twist. Instead of tightening, a screw with a nut connected by a metal (wire) string can be used. Circular bow saws are designed for sawing along curved lines.

Wood hacksaw

- Wide hacksaw: used for sawing thin lumber, cutting curved parts and making through cuts; for cross cutting of boards, bars, and slab materials. The total length is 750 mm, the width of the canvas is from 60 to 160 mm, the thickness is from 1 to 1.5 mm. The teeth are shaped like an isosceles or right triangle. The cutting and sharpening angles are the same as for bow saws.

A hacksaw for wood with rectangular-triangular teeth (see enlarged). On the left is a leatherette sheath for it. Saw teeth close-up. Large-tooth saw teeth close-up.

- Narrow hacksaw: used for sawing thin lumber, cutting curved parts and making through cuts.

- Boning saw: used for making shallow cuts, cutting and sawing small pieces of wood; can be used when adjusting connections; the teeth are shaped like a right triangle.

- Passing saw: a type of butt saw, usually used for making precise angular (longitudinal, transverse) cuts when making tenon joints, miter joints, etc., often using a miter box. Sometimes, to improve the accuracy and safety of the miter box, it is performed without setting the teeth. The teeth are in the form of almost equilateral triangles without a slope or with a slight slope back.

- Hacksaw: for blind cutting of grooves for dowels, as well as for cutting narrow grooves.

Chain Saw

- A hand chain saw is a saw with handles for sawing wood by hand. Can be used both for two people and alone. For normal operation, the saw must be bent, lowering (raising) the handle below the level of the sawing surface when operating, so that the saw seems to grasp the tree when sawing. A larger contact area of the working surface provides faster results[1].

Two-handed saw

A two-handed saw is a tool with many teeth for cutting (sawing) wood.

It is made in the form of a metal plate, on the working edge of which there are teeth. Handles are usually wooden. The most productive of hand saws.

This saw is convenient for cutting down trees. It is difficult to saw a log lying on the ground, as with any other tool (under its own weight, the log settles and pinches the cut site)[2].

For normal operation, pads or “goats” are required.

It is designed for two people to work with, although with some skill you can cut with a two-handed saw alone.

Proper sharpening and setting of teeth is very important.

Hacksaw for metal

A hacksaw is a type of saw for cutting metal workpieces. Consists of a hacksaw frame[3] and a hacksaw blade[4].

Notes

see also

Literature

- Grigoriev M. A.

Handbook of a young joiner and carpenter: Textbook. allowance for vocational schools. — 2nd ed. - M.: Timber Industry, 1984. - 239 p. — 70,000 copies.

wiki.sc

Circular saws

The idea of replacing the back-and-forth motion of the cutting blade with a circular one can rightfully be called revolutionary. It arose after the advent of the electric motor and significantly increased the speed and productivity of work.

A typical tool that uses this principle is a circular saw. Its main advantages - mobility and high power - have overshadowed the modest capabilities of a hand hacksaw.

By design, circular electric saws are divided into geared and gearless. In the first case, the electric motor rotates a gear reducer, on the shaft of which there is a saw blade. The second option is to mount the disk directly on the rotor shaft of the electric motor. Both designs have a mechanism for adjusting the cutting depth and tilt angle.

The advantage of gear mechanisms is the ability to make deeper cuts. Gearless saws have two advantages: lighter weight and affordable price.

The second category of differences consists in the features of the saw blade. It can be active or passive. Everything here is determined by the shape of the tooth. The active disk has teeth bent in the direction of rotation.

In the passive one, they are tilted against the stroke (negative sharpening angle).

Passive discs are indispensable when sawing metal. Active ones are used for wood processing. The teeth of the disc can be tipped with carbide. They make it possible to cut harder materials, but have a negative effect on the cleanliness of the cut.

The operating capabilities of the tool depend on the power of the electric motor (from 0.65 to 2.5 kW). Manufacturers also indicate the maximum depth of cut that can be made using a circular saw (from 25 to 85 mm).

A variation of this power tool is a circular saw, which is mounted on a stationary frame. This solution allows you to cut long and wide materials with high precision.

Some manufacturers offer an interesting compromise - hand-held circular saws that can be turned over and mounted on a table, turning them into a stationary “circular saw”.

When answering the question of what types of saws there are, one cannot fail to mention cross-cutting devices. In this case, the circular saw is mounted on a pendulum arm. A rotating plate with transporter (angular) markings is used as a bed.

The advantages of a miter saw over a circular saw are obvious: you can make perfectly precise cross cuts at any angle. This operation is especially important when joining various wooden parts (platband, plinth, lining, timber).

Types of saws

Disc, reciprocating, band, chain - and this is not the entire list of saws on the market. How to determine which one you need

On the picture:

Jigsaw

Universal saw.

A jigsaw is perhaps the most popular and most affordable of all types of saws.

They can really cut both straight and curved; you can make both quick rough cuts and neat ones without chipping (depending on the blade installed). A jigsaw can handle wood materials (including chipboard, MFD, plywood), metals, thin steel parts, plastic, and ceramics. Even the simplest jigsaw will cut through workpieces with a thickness of 60-70 mm, and powerful advanced models will cut through arrays up to 150 mm thick. Good performance will be ensured by a pendulum motion. True, a jigsaw does not always provide ideal accuracy, because the file can “lead” to the side.

On the picture:

Circular Saw

Sawing wood: accurately and quickly.

The circular saw has a powerful motor, due to which it provides high performance. The disc provides a stable cutting angle, because such equipment does not bend like a jigsaw blade. The circular saws come with a rip fence, and in addition, they are well suited to work with a guide, which ensures very precise guidance of the tool. In terms of cutting depth, a circular saw is not able to compete with a jigsaw. Even the most powerful models can handle workpieces with a maximum thickness of 80-86 mm, although there are exceptions. For sawing metal, some manufacturers produce a separate type of circular saw.

Varieties.

Chain Saw

Pictured: Makita UC3020A electric chain saw.

Indispensable when preparing firewood.

A tool for a country house in a forest or a huge garden. It cuts roughly, but very quickly and easily, so it is ideal for felling trees, trimming branches and preparing firewood. This type of tool is often used in construction. The chain saw comes in three versions. A chainsaw is a mobile and most popular type, an electric saw requires an outlet, and the few cordless saws are compact, autonomous, but require battery charging.

Reciprocating saw

The “rude one” slept.

We can say that a reciprocating saw is a relative of a jigsaw, because their operating principle is similar. Only the “saber” cuts large blades and is designed for rough work (for example, dismantling wooden structures), where high precision is not required. This tool can cut a lot of things: boards, beams, logs, steel profiles, angles and pipes, plastic parts, slate. Important quality: when sawing metal, a reciprocating saw does not produce sparks. But - alas - reciprocating saws are expensive and vibrate a lot. In Russia they are not in high demand.

Band-saw

Pictured: DeWALT band saw DW738.

For wood or metal.

It cuts the material with a looped blade with teeth, which is put on two pulleys. Such saws are found in the form of machine tools (for wood or metal), or in the form of hand-held machines for cutting metal and plastic. Wood saws can make precise straight or curved cuts. Here it is necessary to add that the cut is thin, that is, a minimal amount of material is converted into sawdust. The band saw cuts metal without sparks.

Table saw

For carpenters.

Such machines cut accurately and are easy to use, and therefore are in demand among carpenters. The workpiece is placed on the table, guided along the stop and cut with a disk. You can cut both lengthwise and crosswise, and for cutting at an angle there is a separate adjustable stop with a scale. The disc can be tilted to the side.

Miter saw

For cross cutting of boards, slats, bars, platbands.

One of the varieties of stationary saws. Designed for precise cross cutting with specified horizontal and vertical angles. These angles are adjusted by rotating the table relative to the stop and tilting the “head” of the saw to the side. There are also combined “crosscuts” with an upper table. They can be used to make straight longitudinal cuts. Another variety is broached miter saws, in which the “head” moves to guide rods, making it possible to cut wide workpieces.

On the picture:

Alligator saw

For carpenters and builders.

Outwardly, such saws resemble chain saws, but the Alligator cutting equipment is not an endless chain, but two narrow blades. They are guided by a tire, which ensures a stable cut without the blades moving to the side. The teeth of the equipment move towards each other, and vibration is not felt during operation.

In the photo: hand-held electric hacksaw KS880EC from Black and Decker.

“Alligators” are intended for solving carpentry and construction tasks, but not carpentry. A long tire makes the work easier if you can’t reach the desired board with your hands (you can saw with the end of the tire). Alligators are less productive than chain saws, but are safer. Available in various designs (for cutting wood, brick or aerated concrete).

Carpenter's chain saw

Precise and deep cuts.

In design, it is very similar to a circular saw, only instead of a disk, a bar and chain are installed. This modification made it possible to significantly increase the capabilities of the tool: now it is not a problem to cut a large beam in one pass, although a circular saw would require a huge disk for this.

Images used in the article: bosch-professional.com, skil.ru, milwaukeetool.ru, blackanddecker.ru, makita.com.ru, dewalt.ru

www.4living.ru

Chainsaws

Often when working with wood, it is not the cleanliness and accuracy of the cut that is important, but its depth. This is exactly the problem that a chain saw solves - a powerful device with an electric or gasoline motor, designed for felling forests and cutting firewood.

It has two main interrelated technical parameters:

A bar is two flat plates connected to each other with a small gap for installing a saw chain. At one end it has a driven sprocket, and at the other there are cutouts for the tensioning mechanism.

The power of electric chain saws ranges from 1.5 to 4 kW. When choosing a device for household work on the site, it is better to choose a power of 1.5 to 2 kW with a saw bar length of 30 to 40 cm. This is quite enough not only for sanitary pruning of the garden, but also for preparing firewood.

If necessary, you can use this tool to dismantle a board, log or beam, although you will not get high quality and precision cutting.

There are two subtypes of electric chain saws:

- With lateral (transverse) engine placement;

- With longitudinal installation of the motor.

The first type is simpler in design and cheaper in price. But the second one is more convenient to use, although it is more expensive due to the introduction of a gearbox into the design.

The main thing that a chainsaw gives its owner is autonomy. With such a tool you can go into the forest and cut wood there. For such a significant advantage you will have to pay a price: chainsaws are more complex in design than electric ones. This difference is especially noticeable when purchasing a cheap “no-hire” device. Problems with starting, carburetor, rings and spark plugs are frequent companions of such a purchase. Therefore, it is better to purchase a more expensive chainsaw than to lose money when using an economy option.

Operating rules

In villages, this tool is still used today for collecting firewood. Visually, the process may seem quite easy. Pull one at a time, that's all. However, it is not. Inexperienced craftsmen often find that the saw jams, it bends and tears the timber, and also gets stuck in the cut. While sawing, you just need to guide the tool, the saw will do the rest itself. It is not recommended to press or push the saw too hard, as this will cause it to jam. For more convenient work, a log or other workpiece must be secured on trestles so that the area to be sawn hangs above the ground.

The ideal option would be a position in which one of the sawyers would be slightly higher than his partner, for example, on a pallet. In this position, due to the bevel, in one stroke the saw will be able to cut through a significant area, as for a hand tool.

A very long time ago, this saw was even used to cut logs into boards, however, their cost was very high due to the high labor intensity of the work.

Band-saw

The logical development of the jigsaw design was the compact band saw. Its working body is a closed steel belt with teeth, which is rotated by an electric motor.

Sawing with it is easier than working with a jigsaw, which vibrates strongly and tends to break out of your hands. The cleanliness and precision of the cut of a band saw is ideal. This not only reduces waste, but also produces a cut surface that does not require sanding.

Here the workpiece can be held with both hands, which increases the accuracy of operations when cutting curved elements.

The main indicator of band saws for wood is the cutting depth, which can range from 8 to 50 cm. A jigsaw and a circular saw are not capable of cutting such thick material.

The remaining characteristics relate to cutting blades.

There are two categories here:

- Carbon saws (manufactured steel C75 and analogues);

- Alloy saws made of D6A steel (have increased wear resistance and resistance to alternating loads).

Depending on the manufacturing technology and hardening of cutting teeth, blades are divided into two types:

- Saw blades with a notched, unhardened tooth;

- Blades with cut hardened teeth.

The advantages of saws of the first type are low cost and the ability to cut wood with foreign inclusions: nails, stones, splinters. This blade is used for small sawing volumes (2-4 m3 per day) and at a minimum feed speed (6-10 meters per minute).

The main advantage of a saw blade with a hardened tooth is its high wear resistance (2 times higher than that of saws with non-hardened cutters). Disadvantages - high cost and sensitivity to foreign inclusions.

The remaining parameters of band saws are summarized in a simple list:

- Web width;

- Number of teeth per inch of length (TPI).

For standard wood sawing jobs, a 1/2″ wide strip is ideal. Narrower blades (3/8") are used for shape cutting.

The number of teeth of the cutting band directly affects the evenness of the cut (the more teeth there are, the smoother the cut). Coarse saw blades (2.3 TPI) are used for cutting wood and logs up to 200 mm thick. For cleaner work, saws with 6 TPI are used, and for precise cutting, a size of 10-14 TPI is used. The optimal size at which high productivity and good cutting quality are achieved is 8 TPI.

A table saw for metal is similar in design to a device for cutting wood. However, its capabilities are more modest. This tool can only perform cross cutting of rolled steel (pipes, angles, fittings, channels) at different angles.

A two-handed saw is used when you need to cut wood. The tool is a metal plate with teeth on one side. Compared to other saws, the two-handed one has the highest productivity.

Saw Wikipedia

Saw

- a tool with many cutters, usually teeth, for cutting (sawing) various materials: wood, metal, plastic, stone and others.

Usually the saw has the form of a metal elongated plate or disk, on the working edge of which there are teeth.

There are also toothless saws, the cutting edge of which is made in the form of a fixed abrasive coating (for example, diamond - for cutting stone) or a saw made of iron or copper (bronze) with a free abrasive (regular sand, corundum, iron balls, iron oxide).

Flexible saws are a cable made of metal or other material with a fixed or free abrasive or blades in the form of a set of elements, like chain saws. Also called saws are tools, machines and devices that use a saw.

, - for example, “chainsaw”.

A curious way to use a two-handed saw is to use it as a musical instrument.

History[ | ]

The saw is one of the oldest tools. Small, often flint, tools were used already in the Neolithic era (7-3 thousand years BC). Stone saws had a solid blade or a blade made up of separate elements. Also in ancient times, flexible rope saws and toothless ones with a free abrasive were used.

Metal saws originated in Ancient Egypt. They made it possible to improve woodworking. The carpenter's saw was known to the Minoan civilization of the Bronze Age. Saws are mentioned in the Old Testament (Is. 10:15). The Etruscans were famous for their bronze saws.

The first iron saws were invented by the Scandinavians. Saws were cast in stone molds. However, due to their low quality, such saws could not compete with axes.

Many centuries later, in Ancient Greece they began to make saws using the forging method, which made it possible to achieve high hardness of the metal and, as a result, improve the quality of products[1].

In ancient Greek myths, the invention of the saw is attributed to Talos, the nephew and student of Daedalus[2]. About iron saws ( serrae

) mentioned by Thomas Aquinas in the Summa Theologica (III, 74, 2)

In 1926, a mechanical chain saw based on an electric motor was patented, and in 1929 the first chainsaw appeared[3].

Types of saws[ | ]

According to the nature of movement, saws are distinguished:

- hacksaw

- a long narrow blade makes reciprocating movements - round (disc)

- a disk with an outer cutting edge rotating on a shaft. - belt

- in the form of a closed flexible tape stretched between two rotating pulleys. - chain saw

- a saw, the working part of which is a chain closed in a ring and moving along a guide bar.

ru-wiki.ru

Varieties

The industry produces two-handed saws of the following design:

- transverse;

- for longitudinal cutting, with a rectangular blade;

- onion, characterized by its large size;

- chain

The most commonly used models are two-handed saws for cross-cutting wood; they are characterized by high productivity. The cross-cut two-handed saw, which is found in many farms, is called “Friendship-2”. It got its name because this tool is often used when working in pairs.

The industry produces several types that differ from each other in the length of the working blade. The line opens with a model with a blade length of 1000 mm. You can purchase a larger tool; there are 1200 and 1250 mm saws. Tools with dimensions of 1500 and 1750 mm are also in demand. Even the smallest tool has a lot of weight, so it is difficult for 1 person to work with it.

Many organizations are engaged in production, but the products differ little from each other. Most often, a two-handed saw has triangular teeth that are sharpened at an angle of 70°. Specialists who use such blades in their work can change the sharpening angle, depending on their needs.

Working alone

Unfortunately, a cutting partner is not always present. And working alone with a two-handed device is very difficult. But skilled craftsmen know that even such a massive tool can be made into a one-handed tool. You can make a bow saw from a two-handed saw.

Most often, the handles on saws are not firmly secured. They must be removed from the two-handed saw, and long sticks installed in their place. A rail of the required size is inserted across them between them so that the sticks do not break from pressure.

The upper ends of the sticks must be connected with a rope, twisted like a tourniquet, to ensure high tension of the canvas. That's all, you have a one-handed tool that you can use alone.

Manufacturing options

When producing two-handed saws, the scope of their use is taken into account. The first 2 models in the line are suitable for everyday use. The rest can be worked by physically strong men; the tool is used in logging and related areas. The two-handed saw “Bison” and other models are in demand.

Canvas size

Models with 1000 and 1250 mm blades have triangular teeth. With the help of such a two-handed saw you can prepare firewood, saw logs, and cut down trees in the garden.

Large saws (1500 and 1750 mm) have complex M-shaped teeth. First there is 1 tooth, then 2 or 3 simple ones, they are replaced by another 1 M-shaped tooth. Such saws are also called “Kremlin” saws.

Fine teeth are designed for sawing wood, and M-shaped teeth are needed to ensure that chip particles come out of the cut.

Manufacturers make the saw so that complex teeth are 1-2 mm higher than simple ones, so when sharpening yourself, you do not need to bring all the teeth into one line. If you make them at the same height, the M-shaped teeth will tear the wood, making the job more difficult.

There is also the opposite pattern. If the difference in height is large, then the teeth designed to remove chips simply will not cope with their task.

Handle shape and position

Most models have wooden handles; they are inserted from above into the designated seats. This position is the most comfortable. When working, the hand is located above the logs, so it is almost impossible to get injured. Since the seats are on top, in case of fatigue you can work with not 1, but 2 hands.

There is another option for the location of the handles. A hole is made in the saw blade, the edges of which are treated with plastic. The advantage of this model is that it is more convenient to transport, because the handles do not protrude. This saw looks beautiful, but it will be more difficult to work: the brush is in line with the blade.

When purchasing a carpentry tool, you need to ensure that the saw, after bending, straightens to its original position. You also need to take into account that the logs are cut by placing them on trestles. If the household does not have them, you need to purchase the product along with the saw.

types and purposes, how to do it yourself with video instructions

With the help of a two-handed saw, made by yourself, you can easily cut the hardest wood in the transverse or longitudinal direction. This tool can handle complexities and tasks that an electric jigsaw or other mechanical tool cannot.

A two-handed wood saw will help you out in a situation where there is no access to electricity, and you need to cut wood with minimal effort. This tool is inexpensive, but has unique advantages that even many automated similar devices do not have.

What are the different types of hand saws?

Handmade saws are divided into several types according to their purpose:

- an ordinary hacksaw with a handle - cuts plastic, wood and even metal, if its layer is not too thick;

- “reward” type hacksaw - similar in appearance to a plane - two handles, compact size; used to create narrow, deep cuts in a straight line; It’s not easy to learn how to saw with this tool, but in the end you will be able to make exactly the intended grooves;

- Passing and butt saw models - the handle has a curved shape, the blade is straight; convenient to saw small parts, make corner and straight cuts; the device is characterized by accuracy and low productivity;

- folding, factory or homemade bow saw for wood - more bulky and brittle than models with a solid blade; With this model, one person will be able to do all the work of cutting wood - cut workpieces along complex contours in any direction, without the help of power tools and partners.

What elements does a bow saw consist of?

The name of the instrument is explained by the similarity of the mechanism of action of a bow saw with the elastic structure of a shooting bow.

The base of the device is a varnished machine consisting of one horizontal (middle) and two side posts.

The level of ease of working with the saw depends on the shape of the working handles of the tool. The steel cutting blade has the shape of a thin strip, jagged at the bottom edge. The narrower it is, the more maneuverable the saw will be during sawing.

The bow saw also has a bowstring, but it serves exclusively for peaceful purposes - it maintains the level of tension between the handles of the device. The bowstring is made from natural threads made from flax or hemp, since synthetic ropes are inferior in strength and elasticity.

Thanks to its well-thought-out design, the wood rip saw easily copes with cuts of different directions, knots and complex cutting lines of wood.

How to make your own two-handed saw?

A bow saw for wood is made with your own hands in several stages. Follow the following sequence and as a result you will get a reliable and convenient tool:

- the steel blade of the bow saw is secured in the slots of the handles using dowels;

- check by eye whether the canvas is parallel to the base;

- if the canvas is fixed unevenly, it is leveled by turning the handles;

- Once the blade is aligned, the arrow is carefully rotated to stretch the base, twist the string, and secure the cutting blade.

A wood hole saw is assembled using a similar method, but with the help of slightly different parts, for example, the necessary ring.

Before you start working with a saw you assembled yourself, check for cracks and other defects on the wooden elements of the device.

To sharpen your saw, use a file with a triangular blade, a vise to secure the saw blade, and a template to set the teeth evenly.

First, the teeth that are higher than the others are cut down with a flat file to a general level. Then the saw is set on the wood - the bases of the teeth are leveled with a triangular file. When all the teeth are aligned, they are bent in opposite directions every 1 mm. This way, the tool will cut through even difficult sections of wood easier and faster.

Video: two-handed saw in action

derevostroika.ru

Working with a two-handed saw

It is most convenient to cut logs together. During the work, the partners take turns pulling the saw towards themselves, and when moving back, slightly pushing it forward, helping the second person move the tool in their direction. The process is not complicated, so the required skill will be developed quickly.

If beginners take on sawing logs, the following difficulties may arise:

- the saw jams;

- the canvas bends;

- wood may rupture.

To avoid difficulties, you need to work by making consistent movements. The pressure force in both directions should be approximately the same. It is most convenient to perform sawing when one participant rises slightly above the other. This creates an angle that allows the saw to penetrate deeper into the wood.

If everything is done correctly, the tool can be used not only for sawing logs into pieces, but also for dissolving them into boards.

How to saw with a two-handed saw - detailed instructions with description

At first glance, the process of sawing with a two-handed saw may seem easy and straightforward. However, as soon as a beginner takes up a hacksaw, it immediately becomes clear that this is a job for real and strong hands. However, you don’t have to have a mountain of muscles to properly cut wood with the Druzhba-2 saw. To do this, you need a little experience and also understand the principle of operation.

This is interesting!

Even if you have experience working with short-stroke hacksaws, a beginner who picks up a two-handed saw for the first time will be unpleasantly surprised.

If an experienced sawyer stands at the other end of the saw, then a beginner will have a hard time until he masters the principle of operation of the device. Instructions on how to cut logs and trees with a two-handed saw are as follows:

- First, the log must be secured by placing it on the “goats”. It must be taken into account that it is most convenient to carry out the work while standing on your feet, so even if the log lies on the ground, then in order to cut it correctly, you should place it on a special stand - sawhorses

- The section of the log that is sawn off from the main part should hang above the ground

- Both sawers take a comfortable position with their feet shoulder-width apart. The main thing here is to firmly support your feet, otherwise the possibility of injury cannot be ruled out.

- Ideally, it is recommended that one of the sawers position himself slightly higher than the other, for example, by placing a tray. This will speed up the cutting, but is not at all mandatory.

- By holding the handles of the tool, you can begin. The main thing when working with a two-handed hacksaw is synchronized work with your hands. The effectiveness of achieving the final result depends on smooth hand work.

- The principle of pair sawing is as follows: it is necessary to apply force only in one direction - to pull the blade towards you. There is no need to push the tool away from you, since this task is assigned to your partner. While the partner is pulling the blade towards himself, the hand of the first sawyer is resting

- In this way, not only work efficiency increases, but also rapid fatigue is eliminated

The speed of achieving results is influenced by many factors, such as the thickness of the log, the length of the blade, the quality of sharpening the teeth, as well as the synchronized work of the sawmills. It is worth noting that with the right approach to sawing, it is possible to achieve fast sawing comparable to the operation of a chainsaw.

This is interesting!

If the blade has signs of corrosion deposits, then before carrying out work it is recommended to clean the surface with fine sandpaper (to speed up the work, you can use a hand brush for metal), and then apply machine oil to reduce resistance when working with the tool.

Top 5 best saws

Buyers will find saws of domestic and foreign production in stores. The product rating is as follows:

- The saw is two-handed, the size of the working part is 1250 mm. The product is produced by Izhevsk. Model with a wooden handle, the tool is designed for working with large massifs. For release, steel grade 65 mn is used. The teeth are straight, step 2.

- MATRIX MASTER 23410, China. The blade size is 1000 mm, the product has a two-component handle. The saw is made of steel grade 65 mn, the coating is colorless.

- SIBRTECH, length 1000 mm. The handle is made of wood, colorless canvas coating. The teeth are straight, 2D, pitch 2.5.

- Two-handed saw, blade length 1000 mm, manufacturer Izhevsk. Straight teeth, step 2. Colorless blade, made of 65 mn steel.

- Inforce 1000 mm 06-08-06. The product is made in Russia and is designed to work with thick logs. The tooth pitch is 10, the handles are made of plastic. High-strength tool steel was used to make the blade; the anti-corrosion coating further increases the service life of the saw.

All two-handed models have a long resource. The tool, made of durable steel, quickly cuts wood. When a metal object is passed along the blade, the saw produces a sound similar to a howl, which is modified by bending the blade.

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

One-handed saw Wikipedia

Saw

- a tool with many cutters, usually teeth, for cutting (sawing) various materials: wood, metal, plastic, stone and others.

Usually the saw has the form of a metal elongated plate or disk, on the working edge of which there are teeth.

There are also toothless saws, the cutting edge of which is made in the form of a fixed abrasive coating (for example, diamond - for cutting stone) or a saw made of iron or copper (bronze) with a free abrasive (regular sand, corundum, iron balls, iron oxide).

Flexible saws are a cable made of metal or other material with a fixed or free abrasive or blades in the form of a set of elements, like chain saws. Also called saws are tools, machines and devices that use a saw.

, - for example, “chainsaw”.

A curious way to use a two-handed saw is to use it as a musical instrument.

Story

The saw is one of the oldest tools. Small, often flint, tools were used already in the Neolithic era (7-3 thousand years BC). Stone saws had a solid blade or a blade made up of separate elements. Also in ancient times, flexible rope saws and toothless ones with a free abrasive were used.

Metal saws originated in Ancient Egypt. They made it possible to improve woodworking. The carpenter's saw was known to the Minoan civilization of the Bronze Age. Saws are mentioned in the Old Testament (Is. 10:15). The Etruscans were famous for their bronze saws.

The first iron saws were invented by the Scandinavians. Saws were cast in stone molds. However, due to their low quality, such saws could not compete with axes.

Many centuries later, in Ancient Greece they began to make saws using the forging method, which made it possible to achieve high hardness of the metal and, as a result, improve the quality of products[1].

In ancient Greek myths, the invention of the saw is attributed to Talos, the nephew and student of Daedalus[2]. About iron saws ( serrae

) mentioned by Thomas Aquinas in the Summa Theologica (III, 74, 2)

In 1926, a mechanical chain saw based on an electric motor was patented, and in 1929 the first chainsaw appeared[3].

Types of saws

According to the nature of movement, saws are distinguished:

- hacksaw

- a long narrow blade makes reciprocating movements - round (disc)

- a disk with an outer cutting edge rotating on a shaft. - belt

- in the form of a closed flexible tape stretched between two rotating pulleys. - chain saw

- a saw, the working part of which is a chain closed in a ring and moving along a guide bar.

| [[File:Small saw teeth.jpg|300px|thumb|Saw teeth close-up]] | [[File:Close-toothed saw teeth.jpg|300px|thumb|Close-up of large-toothed saw teeth]] | Setting tool (tool for setting saw teeth) |

Hand saws come in two-handed and one-handed varieties.

According to the design of the instrument, they are distinguished:

- bow

- a thin fabric is stretched between two holders - hacksaw

- the blade itself has sufficient strength and elasticity to hold its shape.

Saws are classified according to their purpose (what they cut):

- for wood

- the most common type of saw, characterized by a variety of teeth, handles, and structure.

Teeth size: height 1–18 mm, width at the base 1.5–12 mm. Large teeth cut wood more efficiently, but leave a rough cut; medium ones - they cut more slowly, but their cut is cleaner; small - they cut wood cleanly, but very slowly. Sharpening teeth: pulse sharpening - they become dull the fastest, but can be re-sharpened; hardened tooth - remains sharp longer, but cannot be sharpened again, 3D sharpening - very sharp, allows you to cut towards and away from you.

- for metal

- this saw is usually called a hacksaw. It has a relatively narrow replaceable blade stretched between the ends of a U-shaped metal bracket. With small teeth relative to other saws (height 1-1.5 mm, width 1.2-2 mm) - for cellular concrete

- this saw usually has a Teflon coating and carbide tips on every second tooth. - for drywall

- this saw has a pointed steel blade. - for stone

, etc. Usually these are various types of electric saws. Often, several types of diamond saws are used to cut stone, mounting them in a machine, the design of which depends on the size of the stones being cut and the purpose of sawing the stone. A diamond saw is a thin disc with small diamonds on the edge. It is not the disc itself that cuts, but the smallest invisible diamond particles located along the edge of the disc.

Technological features

Depending on the material for which a particular saw is intended, the optimal shape, length and width of the teeth, additional elements (slots in the disks, overlays on the teeth) and the speed of the tool are selected.

To prevent jamming, the saw teeth are set apart (sometimes “triple set” is also used) in different directions, which widens the cut. For the same purpose, shaping the teeth into a trapezoid or riveting them is used [4].