One of the main tools for working with various materials for a home craftsman is a hacksaw. It has several varieties, used depending on the type of surface being treated. It is important to know how to use each of them correctly.

What is a hacksaw?

In carpentry, a hacksaw is a special type of hand saw designed for cutting wood, metal, aerated concrete, plastic and other materials. Scientists find mention of the first such instruments in ancient times in the civilizations of Egypt, Greece and Rome. Over the course of its centuries-old history, the hacksaw has undergone significant changes, but has not lost its relevance and is always kept in a set of basic tools for a home craftsman.

Hacksaw device

Like any other carpentry tool, a hacksaw has a certain structure that affects its performance characteristics. It consists of:

- Working, hacksaw or saw blade. It is made of metal of various alloys, which, together with the size, affect the purpose of the tool. Another important parameter of the working blade is the number, shape and size of the teeth. Thanks to them, the surface is divided into parts using the reciprocating movements of the master.

- The working blade is attached and securely fixed to the handle or a special frame. It performs the functions of fixation, protection and ease of use. When selecting a saw, you must take into account its ergonomics.

Electric cutting tool

Reciprocating type electric saw. The ability to use blades of various lengths or widths as cutting devices, as well as various tooth sizes, determines the versatility of using this tool. This makes it possible to successfully work not only with wooden products, but also to effectively cut metal and plastic.

The main parameter of a reciprocating saw (piranha) is its power, which ranges from 400 to 1600 W. The depth of cut completely depends on the power of the unit. For household hacksaws it is up to 90 mm, but a professional tool is capable of cutting parts up to 200 mm.

Disk devices

Structurally, circular-type electric saws are divided into units without a gearbox and geared models. In the first option, the disk is mounted directly on the rotor shaft of the electric motor, which makes it possible to reduce the weight of the entire unit and make it more affordable in terms of price.

In gear units, rotation to the saw blade from an electric motor is transmitted through a gear system, on the shaft of which the disk itself is attached. A feature of the working discs is the angle of inclination of the cutting teeth. In passive elements, the teeth are inclined against the direction of rotation (the sharpening angle is negative), while in active blades they are bent in the direction of rotation.

Active discs are used for processing wood, while passive discs are most often used for sawing metal products. The performance characteristics of circular saws directly depend on the power of the electric motor used (0.65-2.5 kW).

Chain devices

The cutting depth depends on the length of the chain saw bar. A tire is two plates connected to each other, at one end of which there is a driven sprocket, and at the other a tensioning mechanism is installed. Chain saws with an electric motor have a power of 1.5 to 4 kW. For household use, it is enough to choose a tool with a power of up to 2 kW and a bar length of 30-40 cm.

Electric jigsaw

Manufacturers of this jigsaw offer a whole set of special blades that differ in the frequency and inclination of the cutting teeth. Quick installation and change of blades is the main operational advantage of this type of cutting tool.

Technical characteristics of household models are:

Some models use a very useful option - a laser pointer, which helps you clearly see the marking line.

Belt type tool

The cutting process on a band saw is much easier than working with a jigsaw, which tends to escape from your hands and vibrates very strongly. The ability to hold the workpiece with both hands greatly improves the accuracy and quality of cutting any curved elements.

The main performance indicator of band-type equipment is considered to be a fairly large cutting depth, which ranges from 8 to 50 cm. The remaining characteristics depend entirely on the cutting blades used.

The design of a metal table saw has little difference compared to a wood cutting jig. However, it can only make a cross cut of a steel angle, pipe or fittings at the desired angle.

What is a hacksaw for?

Having understood the definition of what a hacksaw is, it is worthwhile to dwell in more detail on the areas of its application:

- This tool is widely used in gardening for pruning trees and shrubs, cutting down knots and rough parts of wood.

- A hacksaw is used to saw wooden parts during construction and household repairs.

- It is used to cut out figures from plywood, make curved cuts or make through holes.

- There are special varieties for sawing metal sheets and pipes, aerated concrete blocks.

- Some modifications include cutting grooves, tenons and recessed holes.

Selection by purpose

In addition to taking into account the main types of saws, the choice of a hacksaw for wood should be made upon request for a specific type of work:

- Swing for longitudinal sawing;

- Transverse copes well with wood across the grain;

- Tenoning for cutting grooves, tenons and technological recesses in products;

- Circular for cutting holes of different shapes;

- Folding hacksaw for wood

These types of wood hacksaws generalize the above tool models. The choice should be made according to the main purpose for which the selected type of tool is purchased. For the household, it is advisable to purchase a saw with replaceable blades or have several hacksaws of different types in your arsenal .

How to decide

This amount of new information is not easy to put into practice, so we will give you some tips on how to consistently choose the right saw.

- The first factor to consider is what sawn material will be used and what is the desired quality of the cut. Carpenters who work with small wood products choose small saws with a short blade. For a carpenter, it is better to use large teeth and a blade - this master does not require high precision work, speed is a priority. A folding garden hacksaw is ideal for summer residents who will only cut through trees and shrubs.

- Frequency of application. Determine how often you will need to use the tool. If the need arises rarely, take a saw with hardened teeth; if the need for sharpening often arises, use ordinary steel.

- The quality of the steel must be high for a tool with any frequency of use. The higher the class of metal, the better the quality of the product. Before purchasing, take the tool in your hands and carefully bend the blade to 450. Good metal is elastic and, when the end of the saw is released, it will restore its shape without displacing the central axis. If you notice a deviation, return the hacksaw to the seller.

- In this case, price is a guarantee of quality. Of course, provided that the seller is honest and does not offer you a fake. A good product cannot be cheap. Choose in the middle price range, if your wallet allows it - don’t skimp on an expensive saw. Select a manufacturer based on its trust rating and give preference to its products in the store. In most cases, this tactic allows you to avoid buying something unknown instead of a good tool.

- Take the hacksaw tool in your hand. You should feel comfortable holding it. The material used can be solid plastic with a rubberized handle.

By following these simple rules, you can easily choose a wood hacksaw that suits your needs.

How is a hacksaw different from a saw?

One of the main and frequently used types of saws is the hacksaw. It differs from other instruments in this group in that:

- This is an exclusively hand tool. The hacksaw saw is driven only by the reciprocating movements of the master’s hands. Whereas other saws can be electric or gasoline.

- When using a hacksaw, only return movements are used, while other saws can be circular.

- In the usual configuration, such a tool has one handle for the master to work alone.

- It has a mostly straight cutting blade, whereas analogues may have a chain, tape or disk.

- A hacksaw has only teeth on the working edge, while other varieties may contain abrasive.

Dimensions and material of the canvas

High-quality canvas is made of steel. It is better to use stainless steel. Hacksaw teeth can be hardened or regular. The difference between hardened and regular ones is that they cannot be restored after wear. Regular saw teeth can be sharpened.

The canvas size can be as follows:

- mini - available in a length of no more than 35 cm, has a large number of small teeth;

- standard - has a length of no more than 55 cm, the teeth are at an average distance from each other;

- wide saw no more than 60 cm long, teeth with increased pitch.

When choosing a size, you should be guided by the purpose for which the tool is intended.

Types of hacksaws

The whole variety of hacksaws can be divided into tools for:

- Works with wooden surfaces

. This includes both a universal saw and a garden hacksaw, and some other special varieties. - Treatment of metal surfaces

. This group also has its own modifications for masters of different classes. - Work with aerated concrete

.

The structure of the instrument is:

- Standard with one handle.

- There are modifications with a solid frame.

- A specialized tool is a folding hacksaw, which is an attribute of a traveler's tool kit.

Hacksaw for metal

Often, professional craftsmen use a special carpentry hacksaw for metal, which has the following varieties:

- Classic model with a special frame

. It is often equipped with a rubberized handle for ease of use. Using this model, you can make cuts in sheet metal at angles of 90º and 55º. - Hand hacksaw

. It consists of a special handle to which the equipment is attached only on one side. The special shape of the bracket allows for working in difficult conditions and creating internal cuts.

Wood hacksaw

The largest number of varieties of hacksaws are designed for working with wood. Among them, the popular ones are:

- A classic saw, also called a standard or regular saw. It is a standard tool with a wide cutting blade for straight longitudinal or cross cutting. The number and size of teeth may vary depending on the modification.

- Circular or narrow tool

. It differs from the classic model in that the hacksaw blade is much narrower. This saw is more maneuverable. It is more convenient to cut sheet material along a given contour. - A bow saw has a thin, curved shackle

. This tool is convenient for cutting tree branches and doing other work in the garden. Some varieties have a special connector for attaching a rod for working with high branches. - Passing saw

. It is also called spike or abutment. It is used by carpenters or joiners to remove protruding mortises or tenons, that is, to obtain an even cut.

Hacksaw for aerated concrete

A special type of tool is a hacksaw for foam blocks, specially designed for separating or removing excess parts of aerated concrete. This fragile material requires special tools with hard-melting tips on the teeth. Thanks to this technology it is possible to:

- Extend tool life. Special soldering prevents abrasion and wear of the teeth, making it possible to cut large quantities of aerated concrete.

- A hacksaw for drywall or wood is much sharper, but it cannot be used for foam blocks, since the materials have different densities and rigidities. Special equipment simplifies and speeds up the process of dividing blocks into parts.

- Eliminate the need to buy expensive electric or gas-powered devices for working with gas silicate.

Varieties

By combining the above factors, manufacturers have developed and are now producing standard products with different blades, handle and tooth shapes. To understand how to choose a hacksaw for wood, you first need to familiarize yourself with the existing types of saws.

Type 1: Classic

The main type of saw that almost every man has, even those far from construction and carpentry. This hacksaw can have a blade of any length with a different number of teeth; the tool is often equipped with replaceable blades, which are included with the purchase.

Type 2: Narrow

Its other name is a circular hacksaw. It takes its name from its main application - it cuts out lines of different shapes, and it does it neatly and clearly. It is also used for cutting through round and square holes. The saw blade is narrow, the teeth are frequent, and can be located either on one working plane or on both.

When working with a saw, you should be careful: if you move uncertainly, the blade will turn in the other direction, so when choosing a hacksaw for wood with a narrow blade, you should choose a product made of high-quality hard steel that will not bend during the cutting process.

Type 3: With pad

A hacksaw with a backing is equipped with a stiffening rib (the same backing), which prevents the blade from bending during operation. Thus, the tool is not able to make a cut lower than the width of the working part of the saw.

The backed hacksaw is always equipped with a comfortable handle at an angle of 450 to the blade for easy work execution.

Type 4: Bow

For plumbing, a bow saw is indispensable: it is used for cutting rough parts of the trunk, knots, cutting out figures from plywood and other wood materials, cutting wood along and across the grain. The use of a bow saw is so widespread that it alone can replace a small woodworking machine.

The wide range of work carried out is slightly obscured by the main disadvantages:

- Bulky. A bow saw is a complex structure; its supporting part is made in the form of a large curved arc, to which a narrow, thread-like blade with teeth is attached.

- Fragility. You need to work with the tool extremely carefully: the blade can fly off the mounts and tear during operation; it requires frequent replacement.

Type 5: Reward

The award saw requires a lot of effort to master. This is a tool that resembles a plane. It is equipped with two handles. Its main application is cutting grooves and tenons; the depth of holes and recesses can be of different sizes, and on rocks of any hardness.

Type 6: Folding tool

A mechanical hacksaw that you can take with you on a hike or on vacation. It is compact, lightweight, and completely safe when folded. A folding hacksaw has fine teeth and a short, pointed blade.

Types of hacksaw teeth

All the models described above differ not only in the shape of the blade for a hacksaw for metal or wood, but also in the size and sharpening angle of the teeth. According to shape and sharpening, all teeth are divided into:

- Equipment for longitudinal sawing along the grain. It is equipped with large teeth sharpened at right angles.

- For cross-cutting layers of workpieces. The edges of the teeth are sharpened at an angle and slightly tilted back.

- The so-called Japanese teeth for cross cutting. They differ from the standard analogue by longer teeth and a double slope of the cutting edge.

- Universal teeth of symmetrical size, sharpened along the edges. Suitable for longitudinal and cross cutting.

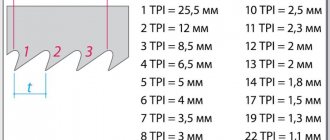

The size of the teeth is:

- Small, about 2-2.5 mm long.

- Medium, the size of which is around 3-3.5 mm.

- Teeth with a length of 4-6 mm are considered large.

Which is better

The best features of a hacksaw are controversial. They depend on the purpose for which the tool will be used.

- It is easier to saw the material if more than ten teeth are involved in the cut.

- The process will happen faster if the hacksaw has large teeth. But at the same time, the edge of the cut comes out uneven. This is due to excessive vibrations arising from too few teeth simultaneously engaged.

- Small teeth are sawed more slowly due to complications in removing sawdust, but the edge of the cut is much smoother and cleaner.

- The handles must be rubberized. They are more convenient to work with, they do not rub and, when used for a long time, do not cause unpleasant sensations when interacting with the skin.

- Hardened teeth are more durable.

How to choose a hacksaw?

Before choosing in a store which hacksaw is best for wood or other materials, you should find out the basic criteria for purchasing a quality tool that will last a long time and function properly:

- Specialization of the model you like. It is worth carefully selecting what material you will work with. Tools for aerated concrete and gardening are significantly different.

- The grade of steel from which the cutting blade is made. High-speed and carbon alloys with a blade strength of 45 HRC and a cutting edge of at least 60 HRC perform best.

- Sharpening the teeth affects the quality of the cut in a certain direction or when working in hard-to-reach places. The universal sharpening is somewhat inferior in cutting quality to more specialized models.

- The length of the blade varies not only among different types of models, but also differs among tools of the same category.

- Comfortable handle. This parameter is especially important if the master will carry out a large amount of work with the tool. The more comfortable the hacksaw fits in the palm of your hand, the less your hand will get tired.

Cordless hacksaw

A special type of tool that has appeared relatively recently is the cordless reciprocating saw, which is also called an electric hacksaw. This device is useful when performing a large number of construction or gardening works. Its compact size allows you to use the electric hacksaw in confined spaces that would be difficult to handle with a conventional saw. Such a hacksaw should be selected based on its following characteristics:

- Battery capacity, which directly affects the operating time without recharging. Professional models can last about 5 hours before changing the battery.

- Voltage that affects the power and number of movements made by the saw per unit time.

- Possibility of connecting additional batteries to increase performance.

Guarantee

You can return or exchange the instrument within 14 days if the following conditions are met:

- there are no signs of use on the hacksaw: chips, scratches and abrasions;

- the box was opened carefully and not damaged;

- if the set included accessories (cases or additional sheets), they are all in place;

- Labels and factory marker are not erased.

Many manufacturers are so confident in the quality of their products that they offer a lifetime guarantee.

This concept means:

- maintenance of the hacksaw throughout its entire service life;

- free repairs are carried out if the breakdown occurred due to the fault of the factory;

- Blades and nuts damaged during operation are not covered by the warranty service - these are consumables.

Hacksaw rating

Before purchasing a carpentry tool, you should pay attention to reviews from professionals and home craftsmen who have already assessed the quality of work with a particular hacksaw. The ranking of the most popular saws with excellent reviews includes:

- Gross Piranha 24101

is one of the best classic professional woodworking models with a comfortable handle from a German company with production in China. Cost – $20. - Vira 800240

is a high-quality domestic saw with three-sided teeth sharpening and additional hardening. High quality at a modest cost of about $7. - Stanley 1-15-122

– frame metal saw with a comfortable handle. Price – $8. - Stayer Max Cut

is a convenient folding type of woodworking tool that many hunters and tourists prefer to take with them. Price – $7. - Irwin 10505549

is a specialized tool for professional masons for working with aerated concrete blocks. Price – $24.

Hand saws for wood: garden tool parameters

There are several types of classification of hand garden saws. To choose a hacksaw, you need to take into account differences in the characteristics of the blade, type of teeth, steel grade, and variations with the handle.

For the manufacture of this tool, mainly alloy steel is used. The silicon and carbon in the composition must correspond to certain grades to produce a durable fabric. Hardness parameters usually do not exceed 45 HRC, but experts recommend paying attention to products with a higher hardness of 15-20 units. They have a darkened shade of resistant teeth and excellent blade flexibility.

The canvas should be without bends. This indicates the quality of the metal used to make the saw.

A hacksaw blade for wood has two main parameters: length and width. Long ones make it easier and faster to cut wood. And short ones are less springy and make the work more neat from an aesthetic point of view. Therefore, models up to 0.35 m are suitable for hard raw materials and one-time, rather than daily, operations. But a garden saw is more relevant at 0.5 m or more.

A wood blade for a hacksaw with a width of 0.1-0.2 m. Wide ones are intended for cutting bulky objects, narrow ones for thin ones.

You might be interested

How to choose a good chainsaw: advice from professionals

How to choose a good garden tool

Garden pruners: recommendations for choosing and caring for a tool

How to use a hacksaw?

The principles of working with basic plumbing tools, which include a hand saw, are simple, but failure to follow them can lead to a broken saw or a poor-quality cut. Main rules for handling the tool:

- The master takes a comfortable standing position with firm emphasis on his legs. Your elbows should bend at an angle of 90º.

- Reliable fixation of the sawn surface. If possible, it is better to secure the material in a vice.

- The hacksaw blade is firmly positioned strictly perpendicular to the surface. It is important to eliminate all vibrations of the instrument to prevent damage.

- Tools for metal are held with two hands, while tools for wood or aerated concrete are held with one.

Problems and difficulties

The disadvantages of hacksaws depend on the manufacturer and the craftsman who uses them. The main ones can be identified:

- quality manufacturers have a narrow range;

- hard wood species can damage the panel;

- the cheapest hacksaws are not re-sharpened;

- when choosing large teeth, the cuts are inaccurate;

- if the handle is not rubberized, it is inconvenient to work;

- may react negatively to humidity, but this depends on the material of the panel;

- The warranty does not apply to consumables.

How to sharpen a hacksaw?

After carrying out a certain amount of work with a hacksaw, the saw teeth simply become dull. The first signs of the need for sharpening include:

- Heavy and uneven cutting.

- Uneven cut.

- The blade often gets stuck.

- It is difficult to maintain a given trajectory.

When the above “symptoms” appear, every master should understand how to sharpen a hacksaw while maintaining the working profile of the teeth:

- Securely fix the tool in a vice or clamp.

- Set the teeth. This procedure involves alternately bending each tooth in different directions by the same amount, approximately 1.5-2 mm, with a special tool.

- A triangular file with a fine notch is selected.

- The sharpening angle of the teeth is determined by eye, which is approximately 15-30º.

- Carry out the same number of file movements in the selected direction on one side. Repeat the process for the other side.

- The teeth are aligned in height.

Device and purpose

The design of a manual hacksaw includes two components: the hacksaw blade itself and the holder, which is a special frame to which the sawing blade is attached. Such a part is more often called a frame or machine. It can be sliding or solid. The former are considered more comfortable, since they make it possible to fix canvases of several sizes. On one side of the holder there is a static head and a tail part with a handle, and on the opposite side there is a moving head and a screw to create tension on the saw blade.

The heads have special slots; they are used to attach the metal part.

The blade is fixed in the frame according to this scheme: its ends are placed in the slots so that the teeth are directed from the direction of the handle, while the holes themselves on the edges of the saw blade and the small holes in its heads must completely coincide.

Then pins are secured in the slots and the fabric is pulled well, not too loosely, but at the same time not too tightly. If the saw blade is overtightened, then during sawing it will break from any distortion, and a weakly tensioned one will begin to bend, which often leads to a deterioration in the cut, and can also cause tool breakage.

Depending on the density of the metal used, the teeth range from 0 to 13 degrees, and the relief angle varies from 30 to 35 degrees.

The pitch of hacksaws made from soft metals is 1 mm, and from hard ones – 1.5 mm. For tools made of steel, the cutter pitch is 2 mm. For carpentry work, a blade with a small pitch of 1.5 mm is mainly used, then with a length of 20–25 cm, the tool includes 17 cutters.

Rules of operation and care

In order for a hacksaw to serve for a long time, you need to take care of it. It is necessary to clean the tool and sharpen it periodically, otherwise it may become completely dull. At the first damage, it is recommended to repair the instrument immediately rather than wait until it falls apart.

Not all saws can be stored for a long time; there are disposable hardened ones. If you need a hacksaw that will last a long time, you need to look at the detailed specifications and determine the best saw for you. One of the most popular is the Japanese hacksaw; it is great for various types of work and can serve for a long time.