Many farmers use walk-behind tractors to work in their fields. The adapter for the walk-behind tractor makes it possible to speed up its execution. This unit is used as a trailer that moves on wheels and is attached to a motor cultivator. You can add attachments to the device and mount a chair. Often gardeners make such a unit themselves.

Walk-behind tractor with steering control

With this method, the power unit will be located behind the driver and rigidly attached to the front adapter.

Consequently, the coefficient of adhesion of the driving wheels to the soil will increase. This, in turn, will increase traction force, which will make it possible to work with any attachments. For such experiments, the light Salyut walk-behind tractor, which weighs about 75 kg and has a power of 6.5 liters, is best suited. With. In this case, you will need a steering column with a gearbox. But this is for this case, if you dare to make a walk-behind tractor with front steering. This procedure is much more complex and painstaking than a simple joint, but the result will please you - you will get a walk-behind tractor with a steering wheel and a seat, and all the necessary levers will be at your fingertips.

During production, you will need not only a steering wheel and gearbox, but also steering rods with coulters. You will definitely need gas, clutch and brake pedals located under your feet. They are connected to standard controls with homemade rods or steel cables.

On the right side of the seat there is a lever for raising or lowering attachments, as well as a parking brake handle. Fenders with headlights are placed on the front wheels. And the mini-equipment finally takes on the finished look of a walk-behind tractor with a front adapter.

It should be noted that the price of such a product with a steering wheel starts from 24 thousand rubles. At the same time, the adapter has good technical characteristics that allow you to fully appreciate the advantages of working on your mini equipment.

The walk-behind tractor is a mechanized gardener's assistant, which reduces labor costs and the user's health. If such a device is supplemented with an adapter with steering control, it increases the comfort of control and further reduces physical strain.

In fact, the adapter allows you to turn a walk-behind tractor into something like a mini-tractor. From the material in this article you will learn the device of the adapter, its purpose, types, installation nuances and subtleties of operation.

Overview of attachments: attachments for Neva walk-behind tractors

The manufacturer supplies extensions for wheel axles complete with Neva walk-behind tractors. The second starting bonus is 8 entry-level cutters. Tools with a diameter of 360 mm allow you to loosen the soil to a depth of no more than 20 cm.

This is clearly not enough. The flimsy metal only copes with cultivated soil. An area overgrown with weeds becomes a problem. Therefore, equipment owners, trained by experience, purchase additional attachments.

Adapters for walk-behind tractors MB-2 series

Adapters are units designed to connect a walk-behind tractor with attachments. Without them, it is impossible to equip a seat for the operator and connect mechanisms such as a hiller.

APM adapter

APM adapter is an intermediate link with an operator station that allows you to combine the Neva walk-behind tractor with additional equipment. The design includes a foot brake for added safety. The universal hitch and soft seat cover will have to be purchased separately.

Snow removal equipment

Snow removal equipment is indispensable in the harsh conditions of the middle zone. It will help clear garden paths and driveways, especially in remote areas that are bypassed by municipal vehicles.

Rotary brush

850 at a time and has an enviable productivity of up to 2200 m²/h. The main advantages are low weight (only 45 kg) and decent maneuverability, which is provided by a rotary joint with a degree of freedom of 24 °.

Auger snow blower

The passage width is 640 mm. The mechanism is capable of clearing sediment up to 25 cm high. The augers throw snow up to a distance of 5 meters. The knives are made of high-quality steel, so the equipment can last 6

and more seasons.

Mounted blade blade

The knife in an oblique position clears 810 mm of the width of the area from snow, and in a straight position - all 900 . In the first case, the productivity is 0.33 ha/hour, in the second - 0.36 ha/hour. The walk-behind tractor can move at speeds up to 4 km/h.

Soil preparation equipment

Loosening and preparing the soil for sowing is the main function of the walk-behind tractor. To implement it, manufacturers of small-sized tractors "Neva" created 3

type of attachment. We mentioned cutters at the beginning of the article, so let’s move straight to heavy artillery.

Mounted plows

Preparing the land for sowing crops begins with plowing. The working width of a single-body plow is 220 mm, and the depth is 200 mm. The mounted PN has different parameters: 180 and 220 mm, respectively.

To prevent the walk-behind tractor from “ emerging ” from the furrow , you can use weights that are installed on the wheel rims and on the pin. The lugs increase the stability of the equipment and prevent slipping.

Harrow BD 850

After pre-treatment of the soil, it needs to be harrowed to loosen it. The harrow model BD 850 . Thanks to the simultaneous operation 8 discs, it is capable of capturing 700 - 960 mm of soil. The angle of attack is 10 - 20 °.

Hillers and weeders

To pile soil onto the lower parts of plants, you can use single-row , double-row or disk hillers with a working width from 210 to 650 mm. Weed rippers will help to cope with weeds .

Planting and harvesting

For planting potatoes, a planter with a hopper is provided, operating with a planting step of 27-31 cm. A mounted potato digger or a more productive model with a conveyor belt is responsible for harvesting the crop.

Transportation of goods

When transporting large-sized cargo, it is difficult to do without a trolley. The first two models - single-axle and two-axle chassis - work only with the APM . The remaining 3 modifications are connected directly. TPMs are capable of taking on board 150 kg of cargo, and VRMZ - all 400 kg.

Mowing grass

For grass harvesting, owners of Neva walk-behind tractors have access to a proprietary mower with a working width of 560 mm and a productivity of up to 0.15 ha/hour. The third-party model has better characteristics: 800 mm and 0.2 ha/hour, respectively.

To attach the Zarya mower to a small-sized tractor, you will need an additional mount for attachments.

Equipment sets

The manufacturer produces 2 types of kits: additional wheels and a set for transportation with cutters. The first consists of 2 wheels, 2 rollers for pairing and 4 stoppers. The second is designed for transporting a walk-behind tractor without removing the cutters. Includes: 2 transport wheels, 2 adapters and 4 stoppers.

: demonstration of attachments

In the video, the author talks about the main attachments that can be useful to the owner of a private house for more efficient use of the Neva walk-behind tractor:

An NMC water pump can be installed on a small-sized tractor . It is capable of supplying water to a height of up to 24 meters with an enviable productivity of 12 m³/h.

Source: https://bydom.ru/news/read/vse-o-navesnom-oborudovanii—luchshie-dopolneniya-dlya-motoblokov-neva-serii-mb-2.html

Design Features

The design of this device is very simple. At its core, the adapter is a trolley that is attached to a walk-behind tractor. It consists of a frame on which the driver's seat or body is mounted. The frame is mounted on a two-wheel chassis. Another indispensable element of this equipment is the drawbar, with which the trolley is attached to the main unit. It pulls the trailer, and this force is transmitted to the wheels of the adapter. You can attach many different devices to this device: a milling cutter, a flat cutter, a harrow, a potato digger and much more.

This ensures the reliability of the device

When making homemade equipment of this kind, it is necessary to pay great attention to the strength of the coupling between the adapter and the walk-behind tractor, since this is the weakest point of the entire unit. The hitch must be made of steel or cast iron. As a rule, it is performed by welding, and special attention should be paid to the weld seams

As a rule, it is performed by welding, and special attention should be paid to the welds. Modern models of this technology also include a control panel conveniently located near the driver’s seat

From this panel you can control the vertical movement of various equipment that is attached to the adapter. You can also change the angular movement of attached devices

Modern models of this technology also include a control panel conveniently located near the driver’s seat. From this panel you can control the vertical movement of various equipment that is attached to the adapter. You can also change the angular movement of attached devices.

For this purpose, the device is equipped with a system of levers or hydraulic units.

In addition to the equipment set that is sold with the adapter, various additional devices can be used to make gardening work easier. Some of them are purchased in the store, others can be made independently if you have the appropriate tools, materials and skills.

Buying a new adapter for a walk-behind tractor is not difficult. There are many different types of this equipment on sale. The more functions this equipment performs and the more convenient it is to use, the higher its price. Even the cheapest adapters have a considerable cost, so many owners of walk-behind tractors decide to make this trailer with their own hands.

In this case, it is necessary to perform a preliminary calculation of the strength and mechanical characteristics of the device.

Need for differential

Many works performed with a walk-behind tractor (for example, cultivation) require its linear movement . In this case, a rigid drive on both wheels works great, significantly reducing the cost and simplifying the walk-behind tractor.

If frequent sharp turns are necessary, a walk-behind tractor of this type will require significant physical effort - one of the wheels will be braked by lugs, and the walk-behind tractor will have to tilt, hanging the outer wheel in the air.

This is especially difficult if the walk-behind tractor has a wide track and is quite heavy.

Adapter for walk-behind tractor preparation and production of basic elements

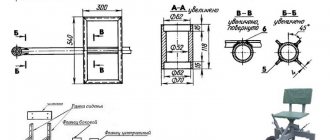

Despite the simplicity of the design, making an adapter is a rather complicated procedure. To make a device, you first need to study the drawings. The more accurate diagrams you have at your disposal, the better the result of your work.

Manufacturing will require certain tools and materials.

Be sure to prepare:

- electric drill;

- hammer;

- file;

- welding machine;

- steel sheet, 5 mm thick;

- several square pipes, 1 inch in diameter;

- electric hacksaw;

- square;

- set of bolts and nuts.

Next we move on to manufacturing the main structural elements. You will need:

- Make a hitch - it is a welded mechanism, which will later be installed in the base of the adapter frame and attached to it with bolts. The coupling mechanism consists of two pieces of square pipe welded to each other and one piece of water pipe, each no more than 1 inch in diameter and 20 cm long. Insert a rod with a welded tee into the water pipe, which is not completely pressed by the bolt. Be sure to lubricate the rod with grease or grease - this will ensure free rotation of the tee along the horizontal axis when the walk-behind tractor with the adapter moves over bumpy terrain;

- Make a unit that secures the wheels - to do this, take 2 pieces of pipe, 1 inch in diameter and 10 cm long, and weld them perpendicular to each other. After this, insert the horizontal section into the mounting pipe and securely secure it with a bolt. The vertical section of the pipe will serve as a place for attaching the axle and bearing with the wheel.

Having prepared the equipment, materials and made the main elements of the adapter to the walk-behind tractor, you can proceed to assembling the equipment. Be sure to follow the instructions in the drawings, as the slightest mistake will lead to incorrect operation of the entire structure.

Wheels for walk-behind tractors: an overview of each type

The cross-country ability and maneuverability of a walk-behind tractor largely depends on the presence of high-quality wheels in its design. Due to regular use of the unit in difficult conditions, even the most reliable and powerful wheels become unusable. However, it is not always necessary to purchase new parts to replace old ones. Let's talk in more detail about how to make wheels for a walk-behind tractor with your own hands.

Types of wheels for walk-behind tractor

Each walk-behind tractor is a multi-tasking agricultural unit. Its design must be as balanced as possible, otherwise the machine will not be able to cope with the work for which it is intended. A special role in the design of a walk-behind tractor is played by the wheels with which it is equipped.

Depending on its characteristics, wheels on a walk-behind tractor can be of the following types:

- Traction;

- Solid rubber;

- Metal, equipped with lugs;

- Supporting;

- Paired.

Each type of wheels for walk-behind tractors is suitable for solving different problems. Using certain elements of the movement of an agricultural unit, its owner has the opportunity to increase the productivity of the machine and make it more stable.

Traction wheels

Pneumatic wheels of this type are distinguished by their versatility and unique tread pattern, which is why they received their second name - “herringbone”. Such movement elements are quite wide; they are equally successfully used for driving both on a flat road and for moving a walk-behind tractor on viscous wet soil.

As a rule, the width of such wheels exceeds 20 cm, and their diameter reaches 40 cm. Large sizes make it possible to actively use such wheels for plowing large areas.

Solid wheels for walk-behind tractor

The wheels for this type of walk-behind tractor have an aggressive tread pattern, which is why they are often installed not only on walk-behind tractors, but also on mini-tractors.

These wheels on the walk-behind tractor are quite large, making them considered the best option for use in difficult areas in wooded and mountainous areas.

Metal wheels with lugs

These wheels from a walk-behind tractor are not large in size, but they have weights that make them quite powerful and durable.

The design of the wheels includes steel teeth designed to push the walk-behind tractor forward, preventing it from slipping even in the softest soil.

Support wheel for walk-behind tractor

As a rule, the walk-behind tractor design includes one support wheel, which takes on the entire load from the engine and other mechanisms located in the front part of the unit.

This element is also responsible for increasing the endurance of the walk-behind tractor and optimizing its operation.

Twin wheels

Each such wheel consists of two elements having the same size and shape. This design allows you to significantly increase the cross-country ability of the walk-behind tractor on uneven surfaces and increase speed on a flat road.

Slipping of a unit equipped with twin wheels is practically eliminated, which is why such elements are often mounted to move the walk-behind tractor over snowy terrain.

Do-it-yourself walk-behind tractor wheels - manufacturing procedure

It is unrealistic to make wheels for a walk-behind tractor without any blanks. To work, you will need a base, which can later be formed to the required size and improved.

Wheels from a motorcycle or car do an excellent job as a base. To make the track width a little larger, special extensions should be used for the wheels of the unit. They will help you make wheels that best suit the specific needs of the walk-behind tractor owner.

Tires for a walk-behind tractor should be selected based on the type of soil on which the unit is used. If the soil is viscous and the terrain has a lot of unevenness, then the tires must be studded and have an aggressive tread pattern.

Homemade wheels must be large. Otherwise, they will not be able to cope with the load created by the units during operation. In addition, small moving parts often slip, and in most cases it is impossible to pull them out of the mud without towing.

A fairly reliable option is to make wheels from car rims. The operating procedure is as follows:

- To make two wheels you will need 4 car rims. Each of them will need to be cleaned of burrs with a file;

- Next, you need to weld 2 disks to each other so that you end up with 4 elements. The discs need to be welded with their convex sides facing each other;

- After this, you need to put rubber tubes on the finished wheels;

- At the end, all that remains is to inflate the wheels with air and install them on the walk-behind tractor. The video will help you get acquainted with the basic intricacies of making wheels for a walk-behind tractor.

To weld disks, it is best to take automotive parts made of steel or elements made by forging. The diameter of the discs must be at least 19 inches. Thanks to this size, the moving elements will freely pass through swampy areas and not slip in viscous soil.

How to make twin wheels for a walk-behind tractor?

If the operation of a walk-behind tractor is most often carried out in very difficult conditions, then in such a situation it is impossible to do without dual wheels. They show the highest cross-country ability, have excellent soil stability in mountainous areas, and do not slip even in the most viscous soil. The production of double elements is carried out in the following order:

- First, find the right wheels and tires;

- Carefully cut small protectors on them;

- Take pieces of steel, weld them into squares measuring 25x25 cm, and install them in the central part of the rim;

- After welding, you need to install the second rim and get a product somewhat similar to a vase;

- Finally, tires need to be installed on the interconnected rims.

Making paired parts is quite simple. The main thing is to find rims of the same size in advance so that both finished wheels are exactly the same.

Manufacturing of wheels with lugs

Elements equipped with lugs are best installed on a walk-behind tractor with a capacity of at least 6 hp. With. A motor with this indicator will not be subject to excessive loads and overheat.

To work on such wheels, you will need to prepare certain materials:

- Car wheels with pre-removed rubber;

- Squares made of thick steel;

- Steel corners;

- Bolts.

With everything you need at hand, you can get to work. First of all, weld the steel plates to the wheels. The edges of the latter must be securely fixed to the rim. Cut the corner into tooth-shaped pieces and weld them to the rim. In this case, the distance between the plates and teeth must be at least 15 cm. Finally, you will need to install rubber tires on the rims and secure the wheels to the axle of the walk-behind tractor.

Varieties

Adapters with steering can be classified according to the type of wheel arrangement. The steering gear is performed in the format of a separate unit. The steering wheels can be located at the front or rear. As for the position of the steering gear, this depends on the design features and spare parts, because during operation it is impossible to avoid repairs and replacement of worn parts.

Models in which the adapter is located at the front are called front-steering varieties. In such modifications, the engine is a kind of tractor for the entire unit. If the adapter is located at the rear, and the walk-behind tractor has to pull it behind it, such a device is called rear-wheel drive. In other words, if the adapter is located in front of the walk-behind tractor, it is a front-type product, and if at the back, it is a rear-type product.

The choice of one or another option is made by the buyer himself, based on his own preferences.

However, you can take a closer look at the option where the adapter is located closer to the drive axis. In this case, the operator’s weight will create additional load, preventing the walk-behind tractor from jumping out of the ground while the equipment is operating.

Based on the variety, adapters can be classified into body and bodyless. The former involve the transportation of goods, the latter are more suitable for cultivating the soil. Depending on the power of the unit, the adapters are connected to the walk-behind tractor using a long or short drawbar. The first modifications are used on heavy equipment, the second are used on light equipment.

Options for power distribution mechanisms

Structurally, the simplest way to solve the problem arising from the rigid connection of the wheels is to use overrunning clutches, which allow the wheel to rotate faster than the axle driving it.

Overrunning clutches

This mechanism is well known in all its variations: both with a ratcheting mechanism (bicycle wheel hub) and with wedging rollers (electric starter bendix).

Overrunning clutches are also used in the power drive of a number of cars with plug-in axles. However, this solution has a characteristic feature: when cornering, the overrunning clutch is disconnected on the wheel running along the outer radius, as it tends to rotate faster than the drive shaft.

Making an adapter for a walk-behind tractor with your own hands

The base of the adapter to the walk-behind tractor is made of a rectangular pipe 170 cm long. Another pipe 50 cm long is welded across it, to which the adapter wheel mounting posts should be attached. The height of these racks from the top point of the rack to the axis of the adapter wheel is 30 cm. You can adapt the wheels from a regular garden cart, and bore their inner bushings on a lathe. Bearings of the required size are put on the bushings.

Then braces should be welded to the adapter wheel bushings and to the central pipe. Their length can be different and is determined by the angle that you will need to maintain. This is followed by calculation and welding of the frame for the attachments. The side tubes of this frame are attached to the wheel stands using bolts. The bolts must be of sufficient diameter to withstand various mechanical loads.

Such an adapter for a walk-behind tractor with your own hands moves quite confidently on the ground when working in virgin lands and arable land. You can make a special blade for it for snow removal. In front of the adapter there is a coupling unit, which you can also make yourself or buy ready-made.

The only thing you need to pay attention to is that the reliability of both the adapter coupling and the walk-behind tractor itself must be quite high. On top, to the central pipe, a metal “leg” is welded to accommodate the seat

That's all, actually.

Wheels for walk-behind tractor - types, extensions, manufacturing

Wheels for a walk-behind tractor are responsible for the maneuverability and maneuverability of the vehicle. When mini-units are constantly used in difficult conditions, even the most reliable and high-quality wheels become unusable.

You don't always need to spend money on new parts. It is quite possible to make wheels for a walk-behind tractor yourself.

Types of wheels for walk-behind tractors

The walk-behind tractor is a multifunctional agricultural machinery. For high performance, all parts and systems must be in good working order. Otherwise, the technology will not cope with the assigned tasks. A special role in this regard is given to equipped wheels.

Depending on the design characteristics, wheels on a walk-behind tractor are divided into the following types:

- traction;

- supporting;

- solid rubber;

- metal type with lugs;

- paired.

Each type of wheel allows you to solve different problems. By using special components, you can significantly increase the performance of a walk-behind tractor and make it as stable as possible.

Solid wheels

The wheels from the walk-behind tractor are solid rubber with an aggressive tread pattern. This feature allows them to be installed also on mini-tractors.

Due to their fairly large size, these wheels are most often used in difficult terrain, wooded and mountainous areas.

Support wheel

Most modern walk-behind tractor models are equipped with one support wheel. It bears the entire load from the engine and other mechanisms that are located in the front part of the motorcycle.

With the help of this support wheel, the endurance of the walk-behind tractor increases and its performance characteristics are optimized.

Wheel extensions for walk-behind tractor

Axle extensions for walk-behind tractors allow you to expand the wheelbase. With the help of such a part, the unit becomes more stable, regardless of the track width.

Extension cords may be needed to implement the following tasks:

- performing heavy types of work and work on difficult soils;

- using equipment on uneven areas;

- preventing the walk-behind tractor from falling over and slipping when using complex attachments;

- provides better cross-country ability and maneuverability of the equipment;

- installation of iron and pneumatic wheels, lugs.

This part is selected for a specific walk-behind tractor. Among the important characteristics of extension cords:

- length of parts within 200-375 mm;

- internal diameter of the mounting hole - it is important that it matches the characteristics of the unit;

- the outer diameter of the mounting hole is responsible for the reliability of fastening the attachments.

How to make extension cords?

- Prepare two pipes with a diameter two millimeters larger than the size of the unit axis;

- Make a thread for screwing extensions onto the axle;

- On the back side of the pipe there should be holes two millimeters thinner than the holes in the wheel rims.

If necessary, the pipes are cut; - The wheels are fixed to the extensions using steel plates and secured with bolts.

Wheel extensions are installed on the output shafts of walk-behind tractors.

During installation, it is checked how reliable the fastening and tightness of fixation is.

Making wheels for a walk-behind tractor with your own hands

It is impossible to make wheels for walk-behind tractors without blanks. It is necessary to prepare a basis that can be further modified and improved.

Simple recommendations for production:

- You can use motorcycle or car wheels as a base. To change the track width, special axle extensions are used. With their help, you can make wheels to implement specific tasks;

- tires for walk-behind tractors are selected for the type of soil. For sticky, uneven ground, studded tires with an aggressive tread pattern are suitable;

- homemade wheels are quite large. Otherwise they will not cope with the work. Small-diameter wheels slip, so they often have to be pulled out of wet soil;

- It is optimal to make wheels from car rims.

Work algorithm:

- Two wheels will require four rims from the car. They are cleared of burrs with a file;

- The discs are welded together with their convex sides;

- Rubber tubes are put on the prepared wheels;

- At the last stage, the wheels are inflated with air and installed on the walk-behind tractor.

To avoid any difficulties during manufacturing, it is worth watching the video.

Making twin wheels with your own hands

When using equipment in difficult conditions, you need to get dual wheels.

Double elements are made according to the following scheme:

- Treads are cut out on suitable wheels;

- Squares of 25*25 cm are welded from steel pieces and installed in the central part of the rim;

- After welding, the second rim is installed. The result should be a product that resembles a vase;

- Tires are mounted on the combined rims.

To make paired parts, you will need rims of the same size.

Adapter design features

In fact, the adapter looks like a trolley, significantly increasing the functionality of the walk-behind tractor and making it easier to use.

The adapter design consists of the following parts:

- A durable frame with all structural elements attached to it;

- Footrest, near which the brake pedal is located;

- A manual brake lever, when lowered, the wheels are finally fixed;

- Wheelbase of two wheels of medium size;

- Seats with lift lever.

The hitch, which allows you to attach the adapter to the walk-behind tractor, is located in front or behind the device. The standard type is a single design that includes two main elements. The first is a connecting link, the second is a regulator.

Separate adapters with a universal double hitch, allowing additional attachment of various awnings.

Wheels for walk-behind tractor - varieties, manufacturing, video

Wheels for a walk-behind tractor are one of its most important components. The cross-country ability, maneuverability and functionality of the walk-behind tractor as a whole will depend on their quality, size and variety.

In order to decide on the optimal choice of wheels for a walk-behind tractor, before purchasing or manufacturing them, you should familiarize yourself with their varieties and features.

Twin wheels

The design of these wheels from a walk-behind tractor involves connecting (pairing) together two identical rims and placing these devices on both sides of the unit.

This type of tires for walk-behind tractors significantly increases the cross-country ability of the walk-behind tractor, eliminates the risk of slipping and overturning of equipment, and increases speed on a flat surface.

Main varieties

With the help of a homemade adapter, you can greatly facilitate the work with the Neva mechanism, because it acts as a kind of transitional link between the unit and the working elements: a plow, attachments for planting potatoes, etc. Physical stress will have a different effect on the body, because while working you can sit and simply direct the process, and the work itself will go faster, because you will be able to increase the working speed almost 2 times - up to 12 km/h.

The adapter for the Neva walk-behind tractor can have a lifting rod, with the help of which movement around the territory is much easier, as well as a body, which, in addition to performing work in the field, also allows you to transport materials and products (see photo). Most often, such designs have steering control. Also, the adapter with steering wheel for the Neva walk-behind tractor can have a short or long drawbar. Units with short drawbars can only work with light mechanisms, while long drawbars are designed for heavier structures.

The homemade adapter is attached to the Neva walk-behind tractor using a single hitch consisting of two parts, one of which plays the role of an adapter between the device and the lifting mechanism, and the second attaches the equipment to the device. In order to be able to simultaneously use several additional tools, a double hitch can be used instead of a single one, as, for example, in the photo.

Simple design

How to make an adapter for a walk-behind tractor? The simplest version of the mechanism is made by hand as follows:

- a frame is made from a metal pipe more than one and a half meters long;

- at one of its ends, a half-meter long pipe is welded perpendicularly, which will act as a basis for attaching the wheel stands;

- the height of the racks is made equal to 30 centimeters;

- The braces are attached by welding;

- the dimensions of the adapter for the walk-behind tractor can be anything - everything will depend on your own preferences;

- in order to attach auxiliary equipment, a metal beam is welded to the frame;

- side metal pipes are fastened with bolts;

- an adjusting rod is welded to the frame, which should have three inputs 20, 30 and 50 centimeters long;

- a coupling assembly of the structure is created, which can also be purchased at a specialized store;

- if necessary, another adjustment rod 75 centimeters long is made;

- a metal seat support is made by welding;

- A soft or wooden seat is installed on the support.

The video shows how to properly make a simple walk-behind tractor adapter with your own hands. But it can only be created if you have certain skills, equipment and strictly adhere to the presented drawings.

Multifunction device

To make a multifunctional adapter with steering for the Neva walk-behind tractor you will need:

- steel sheets;

- steel corners and pipes;

- sitting;

- 2 wheels;

- welding machine;

- other tools that every owner must have.

Such a device can be used both for work in the field and for transporting materials and products even over long distances. The multifunctional design for the Neva walk-behind tractor can be equipped with a plow, a device for planting potatoes, a harrow and other devices. But in the cold season it can be useful for removing snow from the garden area.

So, in order to create a homemade steering adapter for the Neva walk-behind tractor, you need to:

Make a diagram

In order to avoid distortions of the structure, as well as to protect it from excessive loads, it is necessary to draw up a diagram. You can either create it yourself or use ready-made examples.

Make the main parts

The main parts of the structure, of course, include the frame to which everything else is attached (see drawings). In addition, it is necessary to think over a special mechanism that will ensure free turns of the trailer. The body of the device is usually made of steel sheets, and the height of the sides is about 40 centimeters. The coupling of additional elements and the adapter is carried out using a pin with a ring, which is put on the towbar. The only “disadvantage” of such a clutch is the rapid wear of the elements due to the constant turning of the mechanisms.

Install the seat

The seat is usually attached using bolts, after which the device is considered ready for use.

More detailed information on how to properly make an adapter for a Neva walk-behind tractor with your own hands can be obtained from the presented video, as well as by viewing the drawings.

What can you build on your own?

The market for industrial walk-behind tractors offers customers a fairly wide range of products to suit every taste. But not many people can afford the prices for such agricultural machinery. Therefore, in gardens in rural areas, it is quite common to come across a homemade walk-behind tractor, which in terms of performance characteristics is almost inferior to its factory counterpart.

When creating universal designs, craftsmen in most cases use parts of old bikes and scrap metal

Morally outdated bike models often serve as the basis for the production of various homemade products and small-scale mechanization tools needed in the household.

Since homemade walk-behind tractors are often created from scrap old materials, the motor of the Druzhba saw, which is recognizable to many, is often used as the motor of the unit.

On the basis of homemade walk-behind tractors, craftsmen make more important tools in agriculture, for example: plows, as well as hillers for hilling corn or potatoes

One of these masters is the inventor Valentin Arkhipov, who is the creator of the production of a number of necessary devices and the construction of various household equipment.

A professional designer has made a multifunctional device with which you can not only plow and harrow the land, but also plant and hill up tuber crops, also collect and rake tops

Therefore, thinking about how to make a walk-behind tractor with your own hands

, it is better to suspend your choice on this tested and successfully used option. Any person can handle a simple and easy-to-use agricultural implement.

What is good about this particular design?

There are dozens of analogues of a similar model, but in comparison with them, the unique model of the Kaluga master’s walk-behind tractor has a number of irrefutable advantages.

- Swivel joint. Processing tools and tractors of most similar models have a rigid connection, which complicates the maneuvering of the unit and makes it difficult to work with it. The parts of this agricultural unit are connected by means of hinges. This makes it possible to change the direction of movement as needed during work without removing the plow from the furrow.

- Shift of the axis to the direction of movement. Many owners, when cultivating soil using a walk-behind tractor, have encountered such a difficulty that in the process of moving forward under the influence of the resistance of the earth, the unit moves to the side. To level the furrow, a lot of effort must be made. To compensate for this drift, the master positioned the plow axis at a slight angle in the direction of movement. When plowing, the structure is slightly turned to the left. The required position can always be adjusted using 3 rod joints.

- The level of a given plowing depth. If in other models the plowing depth is maintained by lowering or raising the plow, then when working with this walk-behind tractor it is done automatically. The adjustment is carried out by the configuration of the angle of the plow in relation to the furrow. The structure is equipped with a field board, which acts as a lifting force when burying the plow. If, on the contrary, the opener appears above the surface of the earth, then its angle of attack instantly increases, under the influence of which it again plunges into the ground to a given depth.

Design features of the unit

The walk-behind tractor is a self-propelled machine on two wheels, equipped with an engine removed from a VP-150M scooter. The prerequisite for choosing this particular motor was that it has a design solution that allows forced cooling of the cylinder head with air.

Such a motor from a scooter is capable of operating at lower speeds at fairly large loads

To build the walk-behind tractor, the master used control cables, motor suspensions taken from a motor scooter, as well as a double frame arc, handles and chains. Other design details were industrial production

Separately, the designer made a U-shaped frame welded from pipes and a wheel axle turned on a lathe. He also made 3 homemade hinges for the main and control rods. They will be used as connecting parts between the walk-behind tractor itself, its steering wheel and the plow.

An iron pipe is attached to the frame of the unit by welding, ending with an axis, which is needed to implement the tension of the cables going to the motor box. The tension itself is carried out by means of a swinging rocker arm, the gear shift knob of which is a welded piece of metal pipe.

READ How to Make a Boat Motor From a Stihl Trimmer

The pitch of the chains used to create the device is 12.7 mm and 15.9 mm. Number of teeth on sprockets: output shaft – 11, secondary shaft – 20 and 60, drive axle – 40.

How this whole thing works - an example

A nice example of the implementation of a walk-behind tractor:

Step-by-step device assembly technology

The assembly of the structure begins with the arrangement of the drive shaft. To do this, a housing with bearings is attached to it, a sprocket is welded and overrunning clutches are mounted, which during operation will perform the function of a differential. After which the structure is equipped with wheels and a frame. A telescopic rod, a plow and a steering wheel

.

The main elements of the running shaft: 1 – shaft, 2 – sprocket, 3 – cover, 4 – bearing housing, 5 – support platform, 6 – bearing No. 308, 7 – freewheel housing, 8 – pawl axis, 9 – pawl, 10 – ratchet, 11 – bearing No. 307, 12 – washers, 13 – wheel, 14 – pawl spring

The agricultural walk-behind tractor is equipped with special wheels, which, unlike rubber counterparts, are able to provide the best traction with the ground.

Such iron wheels do not become clogged with earth. When they come into contact with the soil, they do not compact it, but rather loosen it.

To connect the frame of the unit with the motor suspension and the frame of the scooter itself, two arched pipes are used. Between them there is a place for placing a fuel tank.

To equip the motor, a bracket is used, ending with a metal axis 150 mm long. The bracket is welded cantilever to the U-shaped frame of the structure. The motor with suspension is suspended on the axle itself. The assembled structure is connected to the arc-shaped arcs of the frame. Only then do they mount the secondary shaft, stretch the control cables and tighten the chains.

The main elements of the control unit: 1 – connecting axis, 2 – bar, 3 – pipe, 4 – handles

Connecting elements of the structure: 1 – main rod, 2 – control rod

How to assemble an adapter for a walk-behind tractor with your own hands

You can make a simpler or more complex design. Both of these options will be given below.

Assembling a simple version of the adapter for a walk-behind tractor with your own hands

To make it you will need:

- rectangular pipes;

- wheels;

- channel No. 10, 40 cm long;

- coupling unit;

- welding machine;

- bearings;

- mounting bolts;

- sitting

Before starting work, you need to create a drawing. You can use ready-made diagrams or make them yourself.

After this, work begins. First, the pipe is cut into sections measuring 1.7 and 0.5 m. The end of the short pipe is welded to the long one, and strictly perpendicular. It will serve as the basis for attaching the wheel stands. Immediately make marks of 30 cm, indicating the height of the racks from the axis.

Wheels that can be used from an old garden cart are then attached to the hubs. Bearings are first attached to the bushings, after which the braces are welded to the central pipe of the bushing by welding.

The frames are made in dimensions of 40x40 cm, but if necessary, these dimensions can be reduced or increased. A channel is attached to the rear end of the frame by welding, and the side pipes are connected to each other with bolts. A lever is also installed on the frame. To increase the adjustment force, install an additional lever 75 cm long.

Quite often, coupling units are purchased in stores. But it should be noted that this element must be of high quality

Therefore, if you plan to make it yourself, then you need to pay special attention to quality

The seat is attached to a metal support, which is welded in advance to the base of the frame, i.e., the central pipe.

Assembling a complicated version of the adapter for a walk-behind tractor with your own hands

To make such an adapter for a walk-behind tractor, you will need:

- steel pipes;

- Sheet steel;

- sitting;

- corners;

- a pair of wheels;

- welding machine.

Such an adapter for a walk-behind tractor will be more functional. The assembled equipment can not only cultivate the land, but also be used for transporting goods. Additionally, a harrow, plows, hillers, etc. are used. And in winter, the walk-behind tractor can be equipped with a scraper for removing snow.

This design consists of the following elements:

- rim;

- sitting;

- wheels;

- coupling devices.

Before starting work, a kinematic diagram is created. This is necessary in order to correctly calculate all loads. You can also use ready-made drawings.

When making the frame, do not forget about installing a fork with a bushing, which are necessary for free rotation of the trailer. Steel sheet is needed for the body. The coupling assembly looks like this: an iron pin measuring 15 cm is inserted into the aperture of a drawbar shaped like the letter “P”. However, it should be noted that this option wears out quickly, since due to the regular rotation of the trailer, the coupling holes very quickly become unusable. In this case, it is necessary to lengthen the U-like chain.

The seat is fastened at a distance of 80 cm from the front end of the frame. This process is carried out using bolts.

Thus, making a homemade adapter for a walk-behind tractor is not so difficult. Therefore, there is no need to buy expensive equipment when you can make it yourself. All elements can be bought in a store or found in a shed at your summer cottage. A properly created design will allow summer residents to significantly ease their hard physical work.

Motoblock Neva MB 2 improvement, operation

Pavel003 thank you very much, my only question is about v=120. This is no mistake, because the proportions in the photo are different.

No. This is not a fundamental size, the main thing is that the wheel hub fits on the thin part, and it will be less work for the turner.

Pavel003 Well, in principle I agree with you. Thanks again.

Alexey MO Thank you for agreeing, they usually send it.

Pavel003 wrote: Thank you for agreeing, they usually send it.

both usually and more often.

Alexey MO wrote: don’t judge strictly, I drew in painte, Russian letters: a=; b= ; in = ; g= ; d = ; e= ; and= ; k= ; m= ; l = ; This is if there is no Russian layout (keyboard).

I bought these sizes for MB Ugra. Dimension e needs to be checked to ensure that the shaft fits in slightly with a gap. In order not to scrape out dust and scale up to a gram. On my turning extension, the minimum is to turn a pipe Dn = 40mm in size and drill holes D = 10.5mm.

MK_Texas-532- 2008 disk hiller, weeder, MB_Ugra - 2010.

Peter_Pen wrote: minimum turning extension - turn a pipe DN = 40mm in size and

What size should I sharpen it to? 38 or 40 is the same. 40 is even better - stronger.

Pavel003 wrote: And what size should I sharpen? It’s 38 or 40, it’s all the same. 40 is even better - it’s stronger.

The outer one is not standardized, sharpen the hole 30.5 mm - along the shaft. I wrote that it is not necessary to grind an extension out of a blank; you can take a 30mm round timber, weld a pipe and machine an internal hole; that’s what they did at the factory.

MK_Texas-532- 2008 disk hiller, weeder, MB_Ugra - 2010.

This is a gorgeous pipe with a wall thickness of more than 5 mm. It was not easy to find such a pipe even during the Soviet Union, and even more so now. And who said that it is necessary to sharpen, my factory ones are also welded.

Alexey MO wrote: I decided to go through virgin soil with a plow on my Neva 2. Everything is there, the only thing missing is the axle extensions. I called the stores, they quoted a price for a pair of more than 1000 rubles, there is an opportunity to have them made by a turner I know for 100 rubles apiece. Dear seine drivers, maybe someone has a drawing of the extension cords, I will be very grateful if you post it, even if you have a drawing, but there is no way to post it, sign up anyway, then I will post the sketch myself, and you will coordinate the dimensions.

To make extensions (tubes), you can use a KAMAZ transverse rod, a very durable metal, there is practically no wear during the season (there is practically no need to process it, the inside is 30 mm, the outside is 40, and you can find 30 round timber, just drill holes and weld it!). And in the factory ones, over the course of a couple of seasons, the holes became badly damaged.

Tell the beekeeper

How are you? Have you finished cleaning?

Working on a walk-behind tractor with steering control

Let's say a few words about the control features of a walk-behind tractor with a steering wheel, and why it is recommended to use this option during assembly. It’s not for nothing that this type of conventional and home-made machines is so popular, because it has a lot of advantages:

- the operator will not have to waste his energy walking behind the mini tractor;

- the traction potential of the equipment is realized one hundred percent;

- such a mini tractor is more maneuverable and functional;

- Now, in order to cultivate a plot far from home, you will not have to additionally transport a walk-behind tractor - you can simply drive it, like a regular car or tractor;

- control is more lightweight and convenient than other types;

- Now you don’t need to hold the entire mass of this heavy and bulky device in your hands,

- it becomes possible to quickly assemble and disassemble the unit;

- control parts are not significantly modified during rework;

- good balance in weight along the axes.

We will not mention here the noise of operation and other characteristic features of, in principle, all tractors. Let's just talk about one characteristic drawback - not very reliable stability, which is associated with a movable coupling. However, the advantages are, of course, more impressive.

Advantages and disadvantages

After the walk-behind tractor has undergone modernization, the designers note the positive properties of the front adapter:

- ease of operation;

- disclosure of traction resource - available opportunities are growing;

- the ability to work is expanded - land cultivation will speed up;

- if necessary, the unit is disassembled and assembled;

- excellent balance in weight and axles;

- You can move around on the device.

The disadvantages include the fact that in the presence of a movable coupling, durability deteriorates.

The adapter for the walk-behind tractor consists of the following structural parts:

Do-it-yourself hitch to a walk-behind tractor

The U-shaped fastening is the basis of the hitch for the walk-behind tractor, therefore, to make it, a channel of suitable thickness and size is perfect. This mount is located under the steering wheel of the walk-behind tractor.

When making a hitch mount with your own hands, you need to drill several holes to secure the bracket and mounting pin in them. Therefore, the holes must be of the required diameter. The pin also needs to be made of high-strength steel.

To attach additional accessories to the walk-behind tractor, you will need a bracket. The long end of the bracket should be positioned either down or up to avoid interference with connected equipment. In this case, the end of the bracket should not touch the surface of the soil that we are cultivating.

When making a homemade coupling unit, we used a standard sample. Often, additional devices are used for the walk-behind tractor, with non-standard types of coupling. To connect them to a walk-behind tractor, you need to either purchase a special adapter or make an adapter yourself. As a rule, these are U-shaped brackets.

Required tools and materials

With your own hands and even without outside help, you can make a manually operated adapter or a dump truck adapter. Therefore, you first need to decide on the type of additional equipment. The next step is drawings. You can use ready-made ones, based on the instructions for walk-behind tractors of the same brand, but sold with adapters, or you can make it yourself. When making drawings with your own hands, careful attention should be paid to the main elements:

- steering control:

- frame;

- sitting;

- frame;

- adapter portal;

- suspension;

- coupling mechanism.

When the circuit is ready, you need to make sure you have the following tools at hand:

- welding machine;

- drill;

- Grinder;

- two wheels with an axle;

- lathe;

- ready-made chair of suitable size;

- metal profile for frame;

- metal corner and beams;

- fasteners;

- bolts, screws;

- screwdriver;

- control levers;

- a circle of steel with special holes - a base for clutch;

- bearings;

- means for lubricating and priming the finished structure.

With steering

This homemade adapter is made even faster than its previous version. But it is worth knowing that this option involves the introduction of a larger number of different angles and pipes. And one more thing - such hanging equipment is made on the basis of a frame with a ready-made fork and bushing. Its presence will allow the walk-behind tractor to rotate freely in the future from the control action. The sequence of actions will be as follows.

- The frame is made of steel of selected length and thickness. Using a grinder, blanks of the required size are cut out of the sheet, and then fastened together with bolts or screws.

- The creation of the chassis should be based on where the motor of the unit itself is located. If it is in front, then the main aspect is the size of the main wheels. In other words, the gauge size should be based specifically on it. The wheels are attached only to the rear. Weld them to the axle. If the engine is located at the rear, then the distance between the wheels should be wider. Here the standard ones are removed from the walk-behind tractor, and the same ones as on the adapter are installed in their place.

- The axle itself is made from a pipe, and bearings with bushings are pressed onto its ends.

The best hubs and extensions for walk-behind tractors made of high-quality steel.

- The steering wheel is either like a car, or like a bike. There is no fundamental difference. Experienced craftsmen advise removing the finished steering wheel from the vehicle and attaching it to the adapter base. It is quite difficult to make a steering wheel without the help of others, especially for a newbie. It should be noted that a motorcycle steering wheel makes it extremely inconvenient when reversing a walk-behind tractor . And this factor must be taken into account.

- If an all-metal frame is used, the steering control will be connected to the front of the unit itself. If you make a special additional support - articulated, then the control will rotate the additional frame completely. In this case, two gears are used: one is installed on the steering column, and the second on the upper half-frame.

- The next step is installing the seat. As in the case of manufacturing the previous type of adapter, it can be either ready-made or made by hand. It must be secured with a welding machine to the rear frame of this attachment.

- If in the future the modernized walk-behind tractor is planned to be used to install replaceable attachments, it is necessary to attach another bracket with a welding machine. An additional hydraulic system should also be created. The easiest way is to remove it from any type of small agricultural equipment and weld it onto your own walk-behind tractor.

- A towbar must be welded to the rear of the main frame. It is necessary in cases where you plan to use the walk-behind tractor to transport some small cargo. If you do not plan to use a trailer or semi-trailer, then this step can be skipped.

- The final stage is the coupling. To do this, small holes are drilled in the steering column into which screws and brackets are inserted. It is with their help that the hitch itself is attached under the steering column.

READ Replacing the Starter Cord of the Neva Motoblock

Perhaps a step-by-step description of making such a device with your own hands may seem complicated. However, with detailed diagrams and drawings, this problem completely disappears. In order for the created adapter to be functional and durable in use, it is necessary to correctly weld all the main elements and pay special attention to the normal operation of the brakes.

ready-made drawings were used to create an improved seat for a walk-behind tractor walk-behind tractor and, if necessary, adjust them.

Arrangement of a multifunctional model

To manufacture a multifunctional device, you need to prepare:

- Steel pipes and angles;

- Sheet steel;

- Two wheels;

- Comfortable seating;

- Welding machine and set of tools.

This adapter is a multifunctional model. It can be used for basic agricultural work and transporting goods over uneven terrain over short distances. The structure can be equipped with agricultural implements such as a plow, harrow, hiller, and potato digger. During the winter months, you can attach a snow scraper to the adapter for clearing snow.

The main elements of the equipment are: frame and coupling devices, as well as wheelset and seats

The process of producing an adapter at home takes place in several stages.

Stage #1 – drawing up a kinematic diagram

To ensure the balance of the structure and prevent additional overloads at the design stage, it is necessary to draw up a kinematic diagram. You can make it yourself or use a ready-made version.

This circuit is designed for the manufacture of an adapter designed to work on the Neva walk-behind tractor.

Stage #2 - production of main parts

When making and assembling a frame, it is important to provide for the arrangement of a fork with a bushing. It is necessary to ensure free rotation of the trailer

The frame of the structure is made of metal pipes and angles

The body of the structure is made of steel sheet. The height of its sides is made no less than 30 cm.

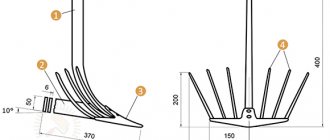

When making stands for the adapter wheels, you can use the diagram below.

The simplest option for manufacturing a coupling assembly is a 15 cm long pin, which is stuck into the hole in the drawbar of a U-shaped walk-behind tractor. The disadvantage of this option is rapid wear: under the influence of a freely rotating trailer, the holes for the hitch quickly break. To reduce wear, it is advisable to lengthen the U-shaped chain.

Stage #3 – seat installation

The seat is secured to the spinal frame of the adapter beam, stepping back 80 cm from the front edge. It is fixed with bolts. The adapter is ready. All that remains is to check the functionality of the multifunctional device.

How can you upgrade a homemade walk-behind tractor?

The Arkhipov walk-behind tractor is multifunctional. It can be used as a plow or a cultivator. To do this, it is enough to replace the removable parts for the plow with parts with removed moldboards for the cultivator. As it moves, the walk-behind tractor will deepen furrows into the ground and place potato tubers in them. To plow the tubers, you just need to put the moldboards in place and walk the unit between the planted rows.

The same principle can be used to hill up sprouted plants. You can learn more about how to independently design a hiller for a walk-behind tractor from the material: https://diz-cafe.com/tech/okuchnik-svoimi-rukami.html

The agricultural unit is also convenient for harvesting. Using different blades you can change the working width. The unit is also good because it is capable of collecting missed potatoes and plant tops remaining after harvesting. For these purposes, it is equipped with a rake or harrow.

The universal design can be used not only for agricultural work. In winter, it is successfully used for snow removal. A faithful assistant will also come in handy for cleaning the paths of the local area. By installing a roller with a round brush and an additional sprocket on the walk-behind tractor, the owner will make it easier for himself to clear the sidewalks.

Sources:

https://piramida-stroi.ru/rukami/adapter-dlya-motobloka-svoimi-rukami-chertezhi-i-razmery-s-rulevym-upravleniem-adapter-dlya-motobloka-svoimi-rukami-perednij-s-rulevym- upravleniem-samodelnyj-s-rulem-chertezhi-kak-sdela.html https://diz-cafe.com/tech/motoblok-svoimi-rukami.html

Making an adapter for a walk-behind tractor with your own hands

At the moment, there are several types of adapters, as a rule, their designs are similar, and are a device attached to the back of the walk-behind tractor with a comfortable seat.

The adapter is made of a square metal profile, 160 to 180 cm long. Across this profile, another one, 50-60 cm in size, is welded, depending on what track you need (wheel stands are attached to it). The height of the racks to the wheel axle from the top to the adapter wheel axle can be from 25 to 40 cm, depending on the design.

Next, braces are welded to the main metal profile and wheel bushings; they also serve as stiffeners. Their length depends on the angle of inclination relative to the entire structure and other parameters. Then, the frame structure to which the attachments will be attached is calculated and welded. The side guides of this design are attached to the wheel stands with bolts.

After this, a control lever with three bends with dimensions of 35, 55, 20 cm is welded to the main frame. To increase the applied force, another lever is attached to the lever, but with dimensions of 80 cm.

The adapter seat is mounted on a support welded to the central metal profile. As you can see, making an adapter for a walk-behind tractor with your own hands is not so difficult.

Purpose of the adapter

Here, I think everything is clear, there is a fairly large amount of work on the ground that is easier, faster and more convenient to do with an adapter. And working with such attachments as a tiller is generally safer.

Design diagram of the adapter for the walk-behind tractor

The adapter for a walk-behind tractor is a kind of towed device made on a frame and having two wheels. Structurally, adapters are divided into several types; in simple terms, they can be simple or more complex. The main types are considered universal, those that are capable of transporting loads and performing soil cultivation, and simple ones, capable of only performing soil cultivation.

For walk-behind tractors of different power, different adapters are used; for a low-power one, an adapter with a short drawbar is installed, for a powerful one, with a long one. Also, universal adapters are equipped with additional functionality, increasing the track, lifting attachments, etc.

https://youtube.com/watch?v=c9649IKGpPI

Motoblock device

In terms of its design, the 4x4 adapter, which is designed for the Neva walk-behind tractor, is a rather simple device. It includes several fundamental parts:

- frame structure on which other components can be installed;

- driver's seat;

- wheelbase, including wheel axle;

- the mechanism for connecting the walk-behind tractor, including.

In other words, the adapter is an ordinary cart with a seat that is connected to a walk-behind tractor.

Motoblocks come in different brands and designs. Russian users know, for example: Cayman, Foreman, Viking, Crosser, Texas, Patriot and others. After coupling the walk-behind tractor and the adapter, the resulting device can be compared in functionality to a mini-tractor, however, such a comparison is somewhat arbitrary, since the power will remain the same, because there is still only one engine, and it comes from the walk-behind tractor.

Moreover, you can attach auxiliary attachments to the adapter, which will further expand the potential range of work. Some types of adapters are equipped with special sections where you can place some loads. There are also models that are equipped with a lifting lever, which greatly simplifies the work with the additional device.

Arrangement of a multifunctional model

To manufacture a multifunctional device, you need to prepare:

- Steel pipes and angles;

- Sheet steel;

- Two wheels;

- Comfortable seating;

- Welding machine and set of tools.

This adapter is a multifunctional model. It can be used for basic agricultural work and transporting goods over uneven terrain over short distances. The structure can be equipped with agricultural implements such as a plow, harrow, hiller, and potato digger. During the winter months, you can attach a snow scraper to the adapter for clearing snow.

The main elements of the equipment are: frame and coupling devices, as well as wheelset and seats

The process of producing an adapter at home takes place in several stages.

Stage #1 – drawing up a kinematic diagram

To ensure the balance of the structure and prevent additional overloads at the design stage, it is necessary to draw up a kinematic diagram. You can make it yourself or use a ready-made version.

This circuit is designed for the manufacture of an adapter designed to work on the Neva walk-behind tractor.

Stage #2 - production of main parts

When making and assembling a frame, it is important to provide for the arrangement of a fork with a bushing. It is necessary to ensure free rotation of the trailer

The frame of the structure is made of metal pipes and angles

The body of the structure is made of steel sheet. The height of its sides is made no less than 30 cm.

When making stands for the adapter wheels, you can use the diagram below.

The simplest option for manufacturing a coupling assembly is a 15 cm long pin, which is stuck into the hole in the drawbar of a U-shaped walk-behind tractor. The disadvantage of this option is rapid wear: under the influence of a freely rotating trailer, the holes for the hitch quickly break. To reduce wear, it is advisable to lengthen the U-shaped chain.

Adapter for motor blocks

Most often, the adapter has two hitches - one is used to attach additional attachments, and the second makes it possible to attach it to the walk-behind tractor. For example, you can connect the following additional elements to the adapter:

- seeder;

- plow;

- hillers;

- harrow and other equipment.

The wheelset and axle in the adapter are quite durable structures that allow the walk-behind tractor to be used even on the most difficult areas of the earth, as well as for transporting quite heavy loads. It is important to understand that transporting goods on public roads on such a unit is prohibited, for this reason they are used only in rural areas. However, despite a certain structural similarity between all adapters, they are also endowed with some significant differences.

For example, rear steering adapters, all-wheel drive adapters and front units are available for sale.

Manufacturing a device with a movable joint

This is the simplest device. The adapter itself will be located behind the walk-behind tractor. It is not difficult to make, but the process requires attention and concentration. The service life of the mechanism depends on the quality of work. This adapter is suitable for heavy walk-behind tractors, for example, “Neva”. It has an engine power of over 7 hp. With. and weight from 105 kg. This allows you to pull not only the adapter, but also agricultural implements without slipping.

For manufacturing you will need the following materials and tools:

- electric drill with the necessary set of drills;

- DC welding machine and electrodes;

- grinder with a set of cutting and grinding discs;

- hammer, file, square, various hardware;

- sheet metal with a thickness of at least 5 mm;

- several profile pipes measuring 40 x 50 and 50 x 50 mm;

- round water pipe with thick walls with a diameter of 30−45 mm;

- steel rods with a diameter suitable for a round pipe;

- channel 40 x 50 mm;

- two wheels from a Zhiguli or Oka with bearings and hubs;

- driver's seat.

You can choose any adapter size, but based on the needs of the mini-equipment. The frame itself can be made slightly higher or lower than the axis of the walk-behind tractor. For wheels, the optimal suspension is portal, providing decent ground clearance. It is not necessary to install shock absorbers on the adapter - this complicates the design. The easiest way is to take a seat with built-in elastic elements.

Step-by-step assembly of the adapter

After the necessary drawings and dimensions of the parts have been thought out, the material has been found and the tool has been prepared, you can proceed directly to assembling the adapter.

- We weld a metal profile about 60 cm long perpendicularly to a section of a square metal profile about 180 cm long. It is this section that will be the mount for the wheels. Wheel stands must be at least 30 centimeters high.

- We weld the braces to the main frame and wheel hubs.

- The dimensions of the main frame will be about 40x40 cm, they can vary depending on the individual wishes of the designer. Channel No. 10 is welded to the rear edge of the frame. The side pipes are fastened with reliable bolts.

- Then the control lever is welded to the frame. To increase the control effort, the lever may have one or more elbows about 70-80 cm long. The elbows are bolted together.

- As a stand for the seat, you can use a pipe about 30–40 cm long, which is securely welded to the main frame.

- We weld the hitch to the walk-behind tractor.

We also invite you to watch the video, which demonstrates various types of adapters and their features for walk-behind tractors of several well-known brands.

Firework:

MTZ:

Agro:

Forza:

Purpose

An adapter for a walk-behind tractor was created for the convenience of gardening. If you attach a hinge to it, you can expand the scope of application of the device:

- remove hay;

- level the soil surface;

- transport goods;

- harrow the ground;

- clear the area of snow.

An adapter is a device that is designed for movement on a motor cultivator. With it, you can control the unit while sitting in a chair, and at the same time cultivate the soil. The trailer for the Neva motor-cultivator is equipped with a steering control. It makes it easier to use the walk-behind tractor.

You can install different attachments for harvesting, a plow, a mower, etc.

This trailer speeds up work in the field. Using this design, you can increase the speed of the cultivator from 5 to 10 km/h. Let's look at the adapter device. The adapter for the motor cultivator consists of:

- frames;

- operator seats;

- two wheels;

- axles;

- coupling mechanism.

After attaching the adapter, the cultivator looks and is used like a mini-tractor. To create an adapter for a cultivator with front steering, you need a frame. The operator's seat is installed on it. The frame is fixed to the chassis.

The seat is fixed to the frame. This will make it easier for the operator to control the cultivator. The wheel system will help move the unit around the site. There are 2 types of wheels: metal (used in the field) and rubber (used for driving on the road).

The hitch for a walk-behind tractor is made of steel or cast iron by welding. She attaches the cart to the cultivator. The U-shaped fastening system is considered the best. With this design the device will be stable.

- The highest travel speed on a walk-behind tractor with a trailer is 12 km/h.

- Maximum load capacity - 100 kg.

- The track diameter is 67 cm.

- Dimensions are 130x70x71 cm.

- The weight of the device is 22 kg.

- The warranty period is 5 years.

Owner reviews

On forums, adapter owners express their opinions on the use of this design, its characteristics and how you can make the device yourself. Here are reviews from some owners of this equipment.

Sergey Petrovich, 53 years old, farmer

For several years, when using a walk-behind tractor, I had to constantly walk behind it and hold it by the handle. Our site is located at a great distance from the house. Therefore, on the advice of friends, we purchased an adapter that comes with a steering wheel and a seat. Now it has become convenient to work. Labor productivity has increased. In addition, with the help of the new device it is possible to transport crops over long distances.

Victor, 42 years old, summer resident

Great difficulties were experienced when clearing snow in winter. For this purpose, we used a walk-behind tractor and a snow blower that is mounted on it. My neighbor helped me make drawings and assemble the design of the adapter for the walk-behind tractor. After the device was manufactured, snow removal work became much easier. The trailer turned out to be durable and reliable.

Commissioning

Before immediately performing any agricultural work using a self-improved walk-behind tractor , it is necessary to perform several final checks:

- make sure the seat is securely installed;

- check the quality of all welds and reliable fastening of bolts and screws;

- start the walk-behind tractor and make sure that the engine is running normally and smoothly;

- install, if necessary, mounted gardening tools and try them in action;

- Be sure to check the operation of the brakes and make sure they are in good condition.

If, after performing all these simple works, no problems were found in the operation of the walk-behind tractor, it is necessary to bring it into proper appearance. To do this, a self-created adapter is primed and painted in any color desired. This stage not only gives the walk-behind tractor a beautiful appearance, but also protects the metal from corrosion.

Creating an adapter with your own hands is a responsible task that requires time, experience and extreme care. Therefore, only those craftsmen who already have similar experience should undertake this work. In other cases, it is better to either purchase a ready-made adapter or seek help from a specialist.

To learn how to make an adapter for a walk-behind tractor with your own hands, see the following video.

Solid wheels

The wheels from the walk-behind tractor are solid rubber with an aggressive tread pattern. This feature allows them to be installed also on mini-tractors.

Due to their fairly large size, these wheels are most often used in difficult terrain, wooded and mountainous areas.