A homemade metal stove is perfect for heating a greenhouse, garage, work space, and even a living room. To assemble the unit in question, you can use sheets of metal, barrels, pipes and even fire extinguishers of a suitable size. The procedure for making the stove remains the same. Differences are present only in the initial stages of corps preparation.

DIY metal stove

Pros and cons of metal stoves

To begin with, we can look at the main advantages of the design for private use:

- It is easier to get certified - every device in the house must be checked by a special authority, after which its safety is recognized. Devices that are made according to the drawings of metal furnaces without making mistakes are approved without any questions.

- High thermal conductivity - the materials are non-porous, heat up well and quickly. This point is more about efficiency; for heating a small room, like a bathhouse or utility room - such a stove will be enough.

- Cheap - the low cost is regulated by the fact that such a stove can be created with your own hands without special skills. The main thing is to have blanks of material on hand, as well as a welding machine, which can also be rented or free from friends.

Now about the disadvantages of a metal sauna stove:

- Such stoves do not “breathe” - if a brick, when heated, absorbs the air around it, thereby slowly but effectively heating it, then the metal quickly cools down and requires more resources for heating.

- Risk of fire - the walls become so hot that nearby objects can easily ignite.

- Short service life - as practice shows, the service life is a maximum of 20 years. Much depends on the frequency of use and conditions, the material is susceptible to corrosion, even the thickest walls will be destroyed at high temperatures.

If we are talking about equipping a bathhouse or a small room, then which option is quite suitable. The main thing is to build the structure taking into account the operating rules; the dedicated instructions will help with this.

How the stove works

For a steam room, a heater will suffice, under which there will be a firebox that heats the stones to 250 degrees. Thanks to this, you can obtain the necessary steam for the sauna.

The bathhouse has a different microclimate, which is created by small droplets that heat the air to 150 degrees Celsius. Due to this, the steam is called dry. We get dry steam only at temperatures above 500 degrees.

How to choose metal for the stove

Technical characteristics depend on the material from which the stove will be made. Therefore, you need to pay special attention to this nuance. Most often, craftsmen make a device from what is already in the utility room or barn.

However, this is not an entirely correct approach; the following options must be taken into account:

- Structural steel - can withstand temperatures up to 400 degrees, it is better to choose sheets of at least 4 mm. It won’t be possible to use it often, as it can easily burn out in one winter. If it is used for a bathhouse that is heated once a week, it will last a long time.

- Heat-resistant steel - this option can withstand 30 years of operation. The thickness should be at least 1 cm. Many stores sell a ready-made structure that only needs to be assembled; no welding is required, which is very convenient and profitable.

- Cast iron takes a long time to heat up, but retains heat well and heats the room. They have a long service life; such stoves can provide heat every winter for 30-40 years. The material is quite expensive, but fully justifies itself. Self-production is a rather complicated process. Such a device is often used to heat greenhouses and outbuildings. It is advisable to choose thick material, since sheets up to 1 cm will crack at the first temperature change.

Based on these recommendations, you can choose a good material for making a metal stove with your own hands.

Classification of metal furnaces

There are several types of stoves, which also differ from each other in performance characteristics. Briefly about three options for everyday life:

- Chamber ones are popularly known as “potbelly stoves”. The chimney is shortened to 2 meters; when the fuel burns out, the remaining flue gases contribute to combustion. Efficiency is 60%; such a device is cleaned 1-2 times a year. The main advantage is that there is no condensation, because the chimney heats up to 100 degrees and any liquid simply evaporates.

- Duct - inside there is a labyrinth of gas tubes. Operates on the principle of a burner. The efficiency is higher than in the previous version and is 80%. Can be used in several modes - flame and “afterburning”.

- Bell-type - when properly designed, gives an efficiency of 80%. It can run on coal due to the combustion of fuel in the bell. You can even heat a house of 60 square meters.

Each person decides which option to choose for household needs individually. Any type can be built with your own hands.

Making a sauna stove

A good option for heating a bathhouse would be a simple steel stove; the device is lined with bricks for safety. The only negative is that it is not mobile, so it is better to immediately choose dense and high-quality sheets for arrangement. Tools that will be useful:

- Welding equipment;

- Bulgarian;

- 3 mm diodes.

Sheets must be at least 4 mm wide, and reinforcement - 10 mm.

Important! Such a metal stove will ensure safety due to the fact that it will heat up quickly and will not emit carbon monoxide.

How to build a metal stove with bricks:

- First you need to make a foundation. To do this, you can make a wooden formwork of 20 cm, an area of 1 * 1 m.

- Next, install the reinforcing mesh; it must be done in such a way that it does not touch the ground or floor.

- Next, you need to mix the cement and fill everything with mortar. The M400 is suitable for these purposes.

- The foundation takes at least 4 weeks to dry.

- During this time, you can assemble a metal stove according to any drawing.

- Next, they make a brick rim on top of the structure, which is placed on the foundation.

- Everything sets within another 2 weeks. During this time, you can equip the chimney structure, as it plays an important role in safety.

It doesn’t matter here whether the owner of the site will design and assemble the stove himself or purchase a ready-made kit. Since the preparation itself takes most of the time. If all the rules are followed, the stove will last a long time and will delight you with warmth for 20 years.

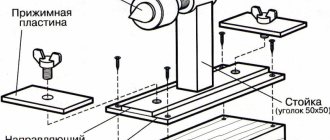

Simple rectangular stove

A simple rectangular do-it-yourself potbelly stove, a drawing that we provided, is a little more complicated to make than a stove made from a cylinder. For this option, as for the manufacture of a sauna stove, sheet material is used. The basis should be metal three millimeters thick. The thickness of the metal will be enough to use the unit for five years.

This homemade model effectively heats a room of up to twenty square meters, the ceiling height of which is three meters. Please note that we will be producing a model that is not equipped with an ash pan. In our case, the stove will have a throttle damper.

How to make this potbelly stove with your own hands for a country house:

- We draw up a drawing of the unit. We indicate in the drawing the dimensions you need for the height and width of the oven. The drawing shows the location on the throttle door.

- Having drawn up the diagram, we proceed to marking the material. We measure the parts of the body according to the dimensions indicated in the drawing. In one of the sides you need to mark a hole for the door, and draw a circle in the door.

- Having carried out such manipulations, we arm ourselves with a grinder and saw the metal into pieces. Using a magnetic square, we expose two parts of the material, and grab them with a few drops. Let's check the evenness of the diagonal and vertical. If all the parts are installed, as required, we weld the joint with a continuous seam.

- Thus, we weld the shape of the furnace. It is advisable to make seams from the outside of the body. We cut out the side walls to the dimensions of the resulting structure.

- We weld one part. In another part we cut out a part for the door; you can choose any door size. Cook the side sides on the cut piece. We weld strips around the perimeter on the body.

- We fix the resulting workpiece on the hinges. We find a piece of rectangular pipe; you can also use a round one. We apply the segment to the door and outline it with a marker. Cut a piece from the door.

- We weld a piece of pipe. We drill two holes in it. We select a round timber of suitable diameter for the holes and cut it into two parts. We insert one round piece of wood on one side and weld it to our cut-out plate on the back side. We put the spring on the outside and secure it with a nut or washer. We do the same with the other side, but when the spring is fixed here, you need to weld the lever. We will use it to regulate the air supply to the firebox.

- Now, fix the hook on the body. We make a latch on the door. Next, we weld the legs to the bottom of the stove. They are made from corners of the height you need. We apply a section of the chimney pipe to the upper part and trace it along the contour. We cut out a piece of metal, attach a pipe and scald it in a circle. If a pipe needs to be bent at a certain angle and you need a pipe bender, then read our article on how to make one.

The rectangular potbelly stove is ready. We don’t have a blower, since the ash will gradually accumulate in the firebox and this will prevent the bottom from quickly burning out.

Simple heater for a summer house

Such a heating metal stove is well suited for quickly providing heat to a small bathhouse or even a sauna.

The main advantages are that it is mobile and easy to manufacture.

Preparing for vaping takes 1.5 hours, the walls heat up quickly. One caveat - you need to attach 2 chimneys to the stove. The first will participate in heating the room itself, the second will remove carbon monoxide.

What does the oven consist of:

- Steel - iron sheets of at least 3 mm.

- It is better to make the firebox from thicker steel -6 mm.

- The kit also includes latches and a metal grill.

This structure can be assembled using a welding machine. Such sets are purchased in a disassembled state, the instructions are already included. Designing a metal stove will not be difficult, as it will fully comply with fire safety rules.

Main design features

A standard metal furnace consists of the following main elements:

- fireboxes;

- ash pan;

- containers for stones (if the stove is created for use in a bathhouse, under other circumstances such a container can be abandoned);

- hot water tank (if necessary);

- grates;

- smoke exhaust pipes;

- firebox doors;

- doors for the ash pan;

- valves for pipes.

Two options for creating horizontal devices

Installation of grates is carried out in the firebox of the structure above the ash pit. If there is a need to install a tank for hot water, the tank, as a rule, is attached directly to the stove or slightly above it. In this case, a smoke exhaust pipe is usually passed through the container to heat the water.

Wood burning heater

The mentioned doors will not allow small coals, wood and sparks to fly into the heated room.

Drawing of a metal furnace

To make the body of a metal furnace, you can use sheet iron, barrels, pipes with a diameter of 50 cm and even large fire extinguishers. The use of ready-made containers is more preferable, because in this case, the amount of welding work is significantly reduced.

Chimney pipes

Before using a pipe to make a stove, carefully examine its condition for rust and other damage. If holes are found, apply patches to them. In areas with the most serious damage, you can make a door for the ash pit or furnace firebox.