Nowadays, almost every family has personal transport. Moreover, some people own several cars. This is not surprising, because the choice between personal transport and public transport is quite obvious. It is important to understand that after purchasing a car you need to take care of it.

The main points of car maintenance include balancing wheels and tires. This is a very common service that can be performed at any auto repair shop. This work is carried out using a balancing machine. Without it, it will not be possible to carry out a technical inspection of the vehicle and repair it. It is noteworthy that if the wheels are poorly balanced, it is dangerous to use the car. At high speed this could lead to an accident.

Today the market is replete with a large number of different models of balancing machines. Therefore, choosing a device may not be so simple. In this article we will tell you about the main characteristics of the devices and point out details that will help you when purchasing.

How does a balancing machine work?

The wheel balancing process is a clear algorithm that must be performed in strict order. Need to do:

- To begin, install the car wheel in a special device and fix it;

- The next step is wheel alignment . It must be installed strictly in the center to ensure reliable fixation. To do this, it must be secured using special elements;

- After this, the wheel is spun . It is important to stick to a certain speed. You can untwist it by hand or with a special device;

- A special device records all information and then sends it to the processor for processing;

- Next, the specialist studies the data obtained. It determines whether the wheel is suitable for further use. If not, then it needs to be replaced or repaired.

Note that there are many different balancing machines. As a rule, models differ in configuration, functionality and appearance. The differences may seem significant at first glance, but the principle of operation of balancing machines is the same. Various manufacturers can equip their models with a number of additional parameters. When choosing, carefully study the technical characteristics of the device, as this is the most important point.

Conditions for equipment calibration

Before setting up the machine, it must first be installed correctly. To do this, the following conditions must be met:

- The equipment is installed on a concrete floor and securely screwed to it to eliminate shocks and vibrations that could disrupt the operation of the device.

- The unit should not be placed on a wooden floor or other flooring that transmits vibrations well, otherwise vibration from the operation of other devices or personnel steps will be transmitted to the body of the device.

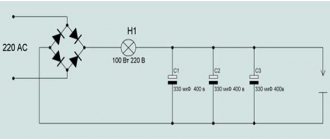

- Voltage drops are also unacceptable, so it is worth installing a stabilizer suitable for power to prevent sudden surges in current in the network.

Before setting up the equipment, be sure to ensure that all conditions are met. Without this, the equipment will not work correctly.

What is a balancing machine used for?

Experts consider wheel balancing to be one of the most important procedures. They note that each machine must conduct it at least twice a year. High-quality wheel balancing guarantees:

- Increasing the service life of bearings and vehicle suspensions;

- Tires and wheels will be protected from wear.

It is customary to balance wheels during the changing seasons. It is at this time that the road surface is most unstable. To preserve the car's wheels when driving on such a surface, balancing should be performed. When done correctly, the load on vehicles from vibration will be significantly reduced. This will protect the wheels and tires from rapid wear.

When to calibrate a balancing machine

There are several cases when equipment necessarily needs adjustment and precise calibration:

- After purchasing a new machine. You must set up your device immediately after you purchase and install it. Even if the equipment was calibrated at the factory, it will have to be done again after transportation.

- After moving the balancing equipment to a new location. If you had to move the unit, even within the premises, you still need to set it up again for proper operation.

- Before the start of the season. Drivers en masse change their shoes to summer or winter tires twice a year: in spring and autumn. You should calibrate before you have a line of customers.

In addition, you definitely need to set up the device if you begin to notice any inaccuracies in its measurements or operation. For example, the device began to incorrectly display the wheel diameter.

What to look for when choosing a balancing machine

If you select a reliable device when purchasing, it will ensure high quality and speed of work on balancing car wheels. When choosing, it is important to pay attention to a number of nuances. Among them:

- Entering data . The machine can have both semi-automatic and automatic data entry methods. The latter is found in more expensive devices. However, this increases productivity several times.

- Balancing speed. Services that have more expensive high-quality balancing machines in their arsenal perform this type of work much faster.

- Equipment power. This criterion also affects the speed of work completion and will help to complete more work in a given time.

- Various tasks. Some machines can be used to perform several types of work at once. The multi-purpose balancing machine allows you to work with wheels of different weights and sizes.

- The speed of wheel installation will also help you complete the job in a shorter time.

Calibration of AE&T balancing machines

The process of setting up equipment differs depending on the type of device (automatic, manual, semi-automatic), as well as the manufacturer and model. The given algorithm of actions will help you set up AE&T equipment, as well as similar ones.

To self-calibrate, perform the following sequence of actions:

- Place the balanced wheel on the axle and secure it.

- Using the buttons, set the distance to the wheel, its width and diameter. If the instrument does not detect this automatically, the values can be measured using a sliding ruler and calipers.

- If the device itself determines the wheel parameters, be sure to double-check the values - you may need additional calibration of the ruler.

Important note: be sure to make sure that the stand correctly determines the width and diameter of the wheel, otherwise all further manipulations are meaningless - the calibration will be inaccurate. In addition, you should also ensure that the weights used weigh 100 grams. To do this, you just need to weigh them on an electronic scale. An error of up to 1 gram is allowed.

We continue setting up the calibration stand:

- On the control panel, press the keyboard shortcut "F" + "C". Keep them pressed until “CAL” lights up on the display, indicating that calibration has begun.

- Be sure to hold down the keys until “CAL” stops flashing, otherwise the setup process will not begin. When the display stops flashing, you need to lower the cover and press “Start”.

- After the wheel has finished rotating, the inscription “ADD 100” will appear on the display on the right. After this, you need to attach a 100 gram weight to the outside of the wheel at the 12 o’clock position. Lower the protective cover and press “Start”.

- The machine will carry out a calibration cycle, after which the message “END CAL” will appear, indicating that everything has been successfully completed. After this, remove the weight from the wheel.

- The data will be automatically saved in the device’s memory, and from that moment on it can be used for work.

It is important to know that AE&T balancers and other equipment of this type are calibrated on one side. The position of the weight on the inside and other data can be corrected by going to the factory settings of the device. If you do this incorrectly, the operation of the equipment will be seriously disrupted, so we do not recommend doing it yourself.

Determining the power of a balancing machine

When purchasing a device, it is important to consider its performance. This parameter depends on several factors that need to be paid close attention to. Let's look at these factors below:

- Speed of information input and processing. To ensure that this process takes as little time as possible, you need to opt for an automatic device.

- Time to install a car wheel. If the installation of a wheel takes less time, then more work can be completed in one working day.

- Duration of measurement and adjustment of loads. Adjusting loads and selecting them is the action on which, as a rule, the greatest amount of time is spent. If all factors are taken into account correctly, the balancing machine can be installed in a short time.

Turning the unit on and off

The balancing machine is equipped with a main switch, which is located at the rear of the equipment. To activate the device, you must enter the program and turn on the system by moving the main toggle switch to the ON position. When performing this operation, do not get close to the rotating elements.

Wait a while for the operating system to load. The first program page will then appear on the display. Several options will be presented on the screen. The remaining functions of the technology in question are controlled by five keys located at the bottom of the monitor.

Where can I buy a balancing machine

If you decide to purchase a balancing machine for your car service center or for use at home, then our best choice will be our repair and construction equipment store “Diam Almaz”.

In the showroom of our store you can find high-quality equipment designed for balancing car wheels. We also offer a wide selection of other tools and equipment for various types of work.

Diam Almaz works exclusively with reliable manufacturers and suppliers. If you choose our store, you will definitely not be disappointed. The store also provides a delivery service to all regions of the Russian Federation. From us you can buy a reliable balancing machine with a guarantee at a competitive price.

Thank you for choosing the Diam Almaz market.

Is it possible to calibrate the equipment yourself?

You won’t be able to calibrate expensive automatic balancing machines yourself. The fact is that this requires special devices, as well as program codes, which only specialists who deal with this have. But such equipment is installed, as a rule, only by large service centers, for which calling a calibrator is not a problem.

Budget segment equipment can be calibrated on your own - detailed instructions on how to do this are in the accompanying documentation. The procedure is carried out using a stamped wheel and a set of calibration weights weighing 50-100 grams.

Design elements

There are automatic and semi-automatic stands

Semi-automatic machine design

The main detail of the stand. It rotates in a horizontal plane thanks to an electric drive. The wheel is placed on it and secured with clamping jaws. The table can rotate in both directions. For large wheels, not a table is used, but a special holder.

Special foot for re-stitching on the mounting stand. It is fixed in horizontal and vertical planes. On automated models, the stand is retracted by pressing a pedal or button.

- Double locking handle.

- Shovel for tearing off the bead.

- Cylinder.

Automatic machine design

Turntable with clamps.

Locking handle with vertical rod.

Bead breakout blade.

Lever mechanism for raising the tire bead.

Additionally, the tire changer can be equipped with a pressure gauge and a device for inflating tires.

Detailed description of parameters

You should start by manually entering parameters. This is very important, as it increases preparation time and also requires special training for the operator. Automatic devices do not have this disadvantage. As for the diameter of the disk, this does not mean the diameter of the wheel in general. The 10-24 range allows you to balance rims on cars, SUVs and small trucks.

Next, it is worth noting the maximum weight. This characteristic often goes unnoticed, and many people believe that weight is not regulated. However, installing an object with a weight exceeding the maximum usually leads to a rapid decrease in the life of the unit, which will lead to its rapid failure. As for the measurement time, as mentioned, the parameter is not too important. But it’s still worth paying attention to, for example, if there is a lot of workload. That is, for large-scale workshops this is an important characteristic.